MoU Signed To Develop Scottish Highlands As Offshore Wind And Renewables Hub

The title of this post, is the same as that of this article on offshoreWIND.biz.

This is the sub-heading.

The Inverness and Cromarty Firth Green Freeport (ICFGF) has signed a Memorandum of Understanding (MoU) with the UK and Scottish governments and The Highland Council, creating a formal framework for cooperation in developing the Highlands as a major international hub for the offshore wind and renewable energy sector

This is the first paragraph.

The agreement is said to unlock GBP 25 million (approximately EUR 29 million) in funding from the UK government, which ICFGF plans to use to support the delivery of significant infrastructure projects and its partner ports.

These are some points from the rest of the article.

- Inverness and Cromarty Firth Green Freeport aims to bring up to 11,300 jobs to the Highlands.

- Significant investments we’ve already include the Sumitomo subsea cable plant at Nigg and the Haventus energy transition facility at Ardersier.

- Over the next 25 years, ICFGF is expected to attract over GBP 6.5 billion of investment.

- The Green Freeport includes three tax sites: Cromarty Firth, which includes Port of Nigg, Port of Cromarty Firth, and Highland Deephaven.

- Ardersier Energy Transition Facility has secured a GBP 100 million joint credit facility to create nationally significant infrastructure for industrial-scale deployment of fixed and floating offshore wind.

- It has placed contracts with more than 110 local firms as part of the development.

These investments will setup the long-term future of Inverness and the Highlands of Scotland.

The Inverness and Cromarty Firth Green Freeport (ICFGF) has this web site, with these messages on the home page.

Europe’s strategic hub for renewable energy

Transforming the Highland economy and delivering national energy security

Conclusion

This area will become one of the most vibrant places in Europe.

Haventus, Sarens PSG Unveil ‘On-Land to Launch’ Floating Wind Solution

The title of this post, is the same as that of this article on offshoreWIND.biz.

This is the sub-heading.

UK companies Haventus and Sarens PSG have developed a low-cost solution for the integration and launch of floating offshore wind turbines.

These two introductory paragraphs add more details.

Haventus said that it is working to enable offshore wind project developers to acquire fully assembled floating bases and turbines at Ardersier, Scotland, as well as providing dry storage which does not require complex licensing.

A heavy-lift solution will enable safe on-land integration and launch to the harbour of fully integrated floating offshore wind turbines.

Note.

- Haventus introduce themselves on their web site, as an energy transition facilities provider, offering pivotal infrastructure for the offshore wind industry. The first facility, they are developing is the Port of Ardesier in the North of Scotland, to the North-East of Inverness.

- Sarens PSG introduce themselves on their web site, as specialists in turnkey heavy lifting and transportation solutions for offshore wind component load-in, marshalling, assembly, deployment, and integration.

It looks to me that the two companies are ideal partners to put together flotillas of large floating wind turbines.

These two paragraphs seem to describe the objectives of the partnership.

This should shorten supply chains through single-site sourcing of key components and remove the operational, safety, logistical, and engineering complexity that comes with storage and integration activities in the marine environment.

The companies also said that the solution can also drive down the costs and accelerate floating offshore wind deployment by simplifying transport and installation requirements and remove the obstacles of weather and design life variables that must be considered with ‘wet’ storage and integration.

I was always told as a young engineer to define your objectives first, as you might find this helps with the design and costs of the project.

I do wonder sometimes, if the objectives of High Speed Two smelt too much of a project designed by lots of parties, who all had different objectives.

The Location Of The Port Of Ardesier

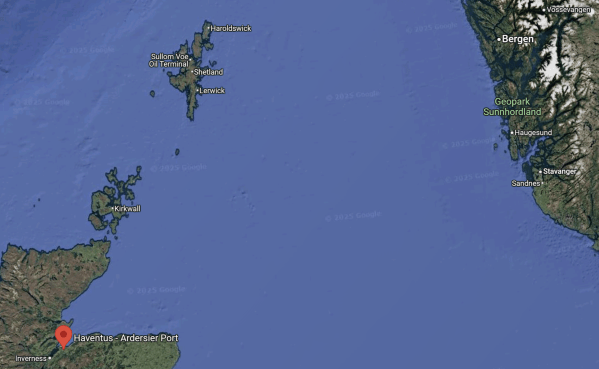

This Google Map shows the location of the Port of Ardesier in relation to Inverness, the Orkneys and Shetlands, and Norway.

The Port of Ardesier would appear to be ideally placed to bring in business for the partnership.

Haventus Chosen To Accelerate Opportunities For Floating Offshore Wind In Scotland

The title of this post, is the same as that of this press release from Cerulean Winds.

These three bullet points, act as sub-headings.

- The under-construction Ardersier Energy Transition Facility owned by Haventus, is selected by Cerulean, the floating wind company with 3GW under development in the Central North Sea

- Announcement marks major boost to future of offshore floating wind in Scotland, as UK floating offshore wind supply chain takes shape

- Cerulean Winds to leverage its unique experience in floating infrastructure from oil and gas sector, in particular, Alliance Contracting

These four paragraphs add detail to the post.

Haventus, owner of the under-construction Ardersier Energy Transition Facility, located near Inverness, Scotland, has been selected by Cerulean Winds, the lead developer of 3GW+ UK floating offshore wind, as its chosen deployment port.

Ardersier Energy Transition Facility, which has secured £400 million of funding, including a £100 million credit facility from the UK National Wealth Fund & Scottish National Investment Bank, will be Scotland’s largest offshore wind facility on the North Sea coast. Cerulean’s commitment to using the facility marks a major step toward realising the UK and Scottish governments’ vision of creating a world-leading floating offshore wind (FLOW) industrial base.

By 2050, FLOW could contribute more than £47 billion to the UK economy and employ 100,000 people. Ardersier will support achieving these targets by deploying and servicing offshore wind installations, providing green jobs and establishing a UK supply chain to rival international competitors.

The Cerulean alliance’s first project will be the Aspen development, a 1 GW wind farm in the Central North Sea approximately 100km from shore, that is targeting first power between 2028-29. The project is designed to enable Scotland’s supply chain and direct more than £1 billion of investment in FLOW manufacturing and service support in the country, with the Ardersier Energy Transition Facility acting as a strategic hub. This early investment will help establish the industrial foundation needed to maximise domestic economic benefits from ScotWind’s planned buildout from 2030.

The numbers are huge and hopefully the initial returns will provide the capital to develop the later wind farms.

In some ways, I’m disappointed, as this is the sort of project, I’d love to be writing the software for.

I also these days have no family responsibilities and only need to look after myself.

UK Breakthrough Could Slash Emissions From Cement

The title of this post. is the same as that of this article on the BBC.

This is the sub-heading.

Scientists say they’ve found a way to recycle cement from demolished concrete buildings.

These five paragraphs outline, why cement is such an environmental problem.

Cement is the modern world’s most common construction material, but it is also a huge source of planet-warming gas emissions.

That is because of the chemical reactions when you heat limestone to high temperatures by burning fossil fuels.

Recycling cement would massively reduce its carbon footprint. Researchers say that if they switched to electric-powered furnaces, and used renewable energy like wind and solar rather than fossil fuels, that could mean no greenhouse gases would be released at all.

And that would be a big deal. Cement forms the foundation of the modern economy, both literally and metaphorically.

It is what binds the sand and aggregate in concrete together, and concrete is the most widely used material on the planet after water.

If cement was a country, it would be the third biggest source of emissions after China and the US, responsible for 7.5% of human-made CO2.

This article shows how by applying chemical magic to two effectively unrelated processes; the recycling of steel and the recycling of concrete to make new cement, very high rewards are possible.

Cambridge University are calling their new product electric cement.

As large amounts of electricity are used in an arc furnace, to produce the two products

These paragraphs outline the innovative Cambridge process.

Cement is made by heating limestone to up 1600 Celsius in giant kilns powered by fossil fuels.

Those emissions are just the start. The heat is used to drive carbon dioxide from the limestone, leaving a residue of cement.

Add both these sources of pollution together and it is estimated that about a tonne of carbon dioxide is produced for every tonne of cement.

The team of scientists,, has found a neat way to sidestep those emissions.

It exploits the fact that you can reactivate used cement by exposing it to high temperatures again.

The chemistry is well-established, and it has been done at scale in cement kilns.

The breakthrough is to prove it can be done by piggybacking on the heat generated by another heavy industry – steel recycling.

When you recycle steel, you add chemicals that float on the surface of the molten metal to prevent it reacting with the air and creating impurities. This is known as slag.

The Cambridge team spotted the composition of used cement is almost exactly the same as the slag used in electric arc furnaces.

They have been trialling the process at a small-scale electric arc furnace at the Materials Processing Institute in Middlesbrough.

These are my thoughts.

The Only Inputs Are Steel Scrap, Green Electricity And Used Cement

Consider.

- We probably need to increase the percentage of steel scrap we collect.

- Gigawatts of green electricity in a few years, will be available in those places like Port of Ardersier, Port Talbot, Scunthorpe and Teesside, where large amounts of steel will be needed.

- I can envisage large steel users having their own hybrid electric cement/electric arc furnace plants.

- Used cement would be collected and brought to the plants.

- Years ago, I used to live next door to an old World War II airfield. The farmer who owned the airfield, told me, that the concrete was his pension, as when he needed money, he called a company, who crushed it up for aggregate.

I can see a whole new integrated industry being created.

Conclusion

This could be one of the best inventions since sliced bread.

Redevelopment Of Scottish Port Begins As Owner Secures GBP 400 Million For Offshore Wind Upgrade

The title of this post, is the same as that of this article on offshoreWIND.biz.

This is the sub-heading.

Haventus, the owner of the Ardersier Port in the Moray Firth, Scotland, has taken a final investment decision and kicked off construction work on redeveloping the port to serve both fixed-bottom and floating offshore wind projects. The revamped port is expected to open in the second half of 2025.

These are the first two paragraphs.

This month, Haventus was granted a GBP 100 million (approximately 117 million) joint credit facility from the Scottish National Investment Bank and UK Infrastructure Bank with GBP 50 million (approx. EUR 58.5 million) investment from each.

This follows a GBP 300 million (approx. 351 million) investment commitment by the energy investment firm Quantum Capital Group in 2023 when Haventus began the redevelopment of Ardersier Port.

This page on the Haventus web site, gives more details of the Port of Ardersier.

Included are.

- Access channel width – 160 m.

- Access channel depth – 12.4 m.

- Landside area – 350 acres.

- 420m main quay.

- 80 m Ro/Ro capable berth.

- People-friendly midges

- Green Freeport tax site designation

- More space is available if required.

There is also an informative video.

Haventus say they are delivering a world-leading energy transition facility. I can go along with that!

These are my thoughts.

The Location Of The Port of Ardersier

This Google Map shows the location of the Port of Ardersier.

Note.

- The large expanse of water in the middle of the map is Moray Firth.

- The blue arrow at the bottom of the map indicates Inverness Airport.

- Inverness Airport, has a railway station on the Aberdeen and Inverness Line.

- The village of Ardersier is on the the Eastern bank of the Moray Firth

- The Port of Ardersier is in the North-East corner of the map.

The city of Inverness, with a population of around 48,000, is a few miles South-West of the South-West corner of the map.

Which Windfarms Will Be Built And Serviced From The Port Of Ardersier?

This map shows the various ScotWind leases, around the North of Scotland.

The numbers are Scotwind’s lease number in their documents.

These are the Scotwind wind farms to the North-East of Scotland, that could reasonably be assumed to be built and served from the Port of Ardersier.

- 7 – DEME Concessions Wind – 200 km² – 1.0 GW – Floating

- 8 – Falck Renewables Wind – 256 km² – 1.0 GW – Floating

- 9 – Ocean Winds – 429 km² – 1.0 GW – Fixed

- 10 – Falck Renewables Wind – 134 km² – 0.5 GW – Floating

- 11 – Scottish Power Renewables – 684 km² – 3.0 GW – Floating

- 12 – BayWa r.e. UK – 330 km² – 1.0 GW – Floating

These are the Scotwind wind farms to the North-West of Scotland, that could reasonably be assumed to be built and served from the Port of Ardersier.

- 13 – Offshore Wind Power – 657 km² – 2.0 GW – Fixed or Floating

- 14 – Northland Power – 390 km² – 1.5 GW – Floating

- 15 – Magnora – 103 km² – 0.5 GW – Floating

- 16 – Northland Power – 161 km² – 0.8 GW – Floating

These ten wind farms add up to 12.3 GW.

Transport

Consider.

- Obviously, heavy components will be brought in by sea, using the Ro/Ro capable berth or using a crane to unload a barge.

- Personnel will be able to fly in for the day.

- Will some visitors rom London use the Caledonian Sleeper to and from Inverness station to get a full day on site and a good night’s sleep, whilst travelling.

But I do see a problem with local traffic to and from the site.

Hydrogen Buses

This page on the Sizewell C web site, discusses how they will use hydrogen buses.

I could see the Port of Ardersier taking a leaf out of Sizewell C’s book and run hydrogen buses to Inverness, Inverness Airport and other nearby towns.

The North of Scotland certainly won’t be short of green hydrogen to power the buses.

Hydrogen

Conclusion

If you thought that the only useful wind-driven thing to come out of Scotland was bagpipes, you had better think again.

The Port of Ardersier will be the factory and operation and maintenance port for one of the largest offshore wind industries in the world.

BW Ideol Unveils Mass Production-Ready Floating Wind Foundation

The title of this post, is the same as that of this article on offshoreWIND.biz.

This is the sub-heading.

France-based BW Ideol has unveiled its standardised floating foundation product and a blueprint for mass production that could drive costs down across projects.

This is the first paragraph.

With over 22 GW already awarded in Scotland, around 8 GW in the US, and several GW currently being awarded or in the tendering phase elsewhere in the world, the floating wind is now entering an industrialization phase, said BW Ideol.

It looks like the French have come up with a solution that’s needed.

These are previous posts about BW Ideol.

- BW Ideol And Holcim To Explore Use of Low-Carbon Concrete In Floating Offshore Wind

- BW Ideol, ABP To Explore Serial Production Of Floating Wind Foundations At Port Talbot

There is also this video of proposed serial production of BW Ideol floaters at the Port of Ardersier.

This Google Map show the area of Scotland to the North-East of Inverness Airport.

Note.

- Inverness Airport indicated by the red arrow.

- Ardersier village in the middle of the map on the bay.

- Fort George is at the North end of the bay.

The Port of Ardersier is the large slab of concrete in the North-East corner of the map, the Carse of Ardersier marked below it.

BW Ideol are claimining they can build one floater a week or one GW a year.

BW Ideol And Holcim To Explore Use of Low-Carbon Concrete In Floating Offshore Wind

The title of this post, is the same as that of this article on offshoreWIND.biz.

This is the sub-heading.

BW Ideol and Holcim have signed a Memorandum of Understanding (MoU) for a feasibility study on supplying beneficial low-carbon concrete for the floating offshore wind industry, with particular reference to Scotland.

These are the first three paragraphs.

BW Ideol and Holcim aim to collaborate on optimising the supply of the innovative concrete needed for the intended mass production of BW Ideol’s floaters in the Port of Ardersier.

Low-carbon concrete’s advantages as a building material for offshore wind farms include its durability in marine environments, its local availability and its comparatively lower carbon emissions, the companies said.

The collaboration includes developing specific durable maritime low-carbon concrete mixes with enhanced mechanical performance perfectly suited to slipform application.

This is surely a good development.