The Proposed Lionel Road Station On the West London Orbital Railway

Starting with Lionel Road station may seem a strange place to start, but this important station for supporters of Brentford FC, may in the end define how the new line is designed and built.

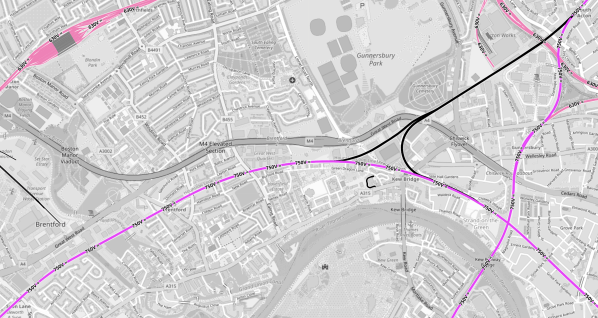

This OpenRailwayMap shows the tracks around the stadium, that has been built for the Premier League football club, which is now called the Gtech Community Stadium.

Note.

- In the North-West corner of the map is the Piccadilly Line branch to Heathrow Airport.

- Northfields Depot is prominent, with the station of the same name to its East.

- South Acton station is in the North-East corner of the map.

- Syon Lane station is in the South-West corner of the map.

- The West London Orbital Railway runs between these two stations.

- Lilac sections are electrified and black sections have none.

- South Acton station is also on the North London Line, which runs North-South to Richmond station off the bottom of the map.

- Syon Lane Station is also on the Hounslow Loop Line, which curves across the bottom half of the map to the South-East corner.

- Click the map to show it to a larger scale.

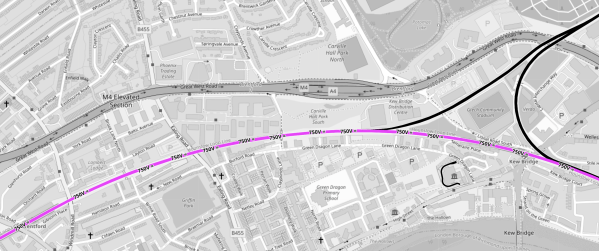

This second OpenRailwayMap shows triangular junction in the middle of the first map to a larger scale.

Note.

- The Gtech Community Stadium sits in the middle of the triangular junction.

- Provision has been made in the layout of the stadium for the station to be on the North-West leg of the triangular junction.

- Kew East Junction is in the North-East corner of the map.

- Old Kew Junction is in the South-West corner of the triangular junction.

- New Kew Junction is in the South-East corner of the triangular junction.

- The lilac track crossing the map is the electrified Hounslow Loop Line.

- The M4/A4 runs across the map

- Only the Southern leg of the triangular junction is electrified.

- Click the map to show it to a larger scale.

These are some of my thoughts.

Lionel Road Station Will Be Unlikely To Be Electrified

Consider

- It will be extremely unlikely that between South Acton station and Old Kew junction will be electrified with third-rail electrification because of safety issues.

- There is a very long chance, that it might be decided to create a 25 KVAC overhead electrified route across London, by means of the North London Line.

- I believe hydrogen trains will be developed for freight services.

- The station will have large numbers of passengers on match-days, so safety may determine an electrification-free station.

- The electrification gap is only 1.4 miles, which is well within range of a battery-electric train.

I think it is more likely that hybrid trains will use what is available.

Will Lionel Road Station Be Step-Free?

Sixty years ago, I used Manchester United station to see a match.

This Google Map shows the station.

Note.

- The station is a single platform tucked in behind the South stand.

- The station entrance is indicated by a red arrow.

- When I went in the 1960s, the train was a steam-hauled shuttle from the city centre.

- This Wikipedia entry gives more details.

I suspect a similar space-saving design could be used at Lionel Road station.

There will be a need for a bridge if the station is used on more than match days.

Will Lionel Road And Kew Bridge Stations Be An Out Of Station Interchange?

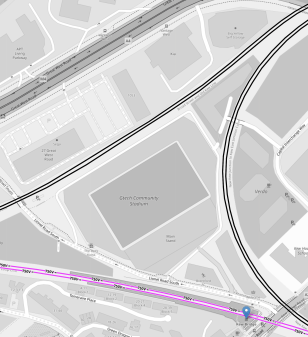

This OpenRailwayMap shows the triangular junction, with the GTech Community Stadium in the middle.

Note.

- Lionel Road station will be on the North-West side of the station.

- Kew Bridge station is marked by a blue arrow.

- There appear to be walking routes all over the plot on which the stadium sits.

- All sides of the junction are double track.

I think an Out-Of-Station Interchange would be useful, especially for those who don’t know the area.

How Easy Will It Be To Get To Lionel Road Station From Major London Stations?

These are my best estimates at a degree of difficulty.

- Bank – 1 Change – Take Central Line with a change at Old Oak Common Lane to Lionel Road.

- Blackfriars – 1 Change – Take Thameslink with a change at Brent Cross West to Lionel Road.

- Bond Street- 1 Change – Take Elizabeth Line with a change at Old Oak Common Lane to Lionel Road.

- Cannon Street – 2 Changes – Get out at London Bridge – Take Thameslink with a change at Brent Cross West to Lionel Road.

- Charing Cross – 1 Change – Take Bakerloo Line with a change at Harlesden to Lionel Road.

- City Thameslink – 1 Change – Take Thameslink with a change at Brent Cross West to Lionel Road.

- Euston – 1 Change – Take Watford DC Line with a change at Harlesden to Lionel Road.

- Farringdon – 1 Change – Take Thameslink with a change at Brent Cross West to Lionel Road.

- King’s Cross – 1 Change – Take Thameslink with a change at Brent Cross West to Lionel Road.

- Liverpool Street – 2 Changes – Get out at Stratford – Take the Overground with a change at South Acton to Lionel Road.

- Liverpool Street – 1 Change – Take Elizabeth Line with a change at Old Oak Common Lane to Lionel Road.

- London Bridge – 1 Change – Take Thameslink with a change at Brent Cross West to Lionel Road.

- Marylebone – 1 Change – Take Bakerloo Line with a change at Harlesden to Lionel Road.

- Moorgate – 1 Change – Take Elizabeth Line with a change at Old Oak Common Lane to Lionel Road.

- Old Street – 2 Changes – Go to Moorgate – Take Elizabeth Line with a change at Old Oak Common Lane to Lionel Road.

- Oxford Circus – 1 Change – Take Bakerloo Line with a change at Harlesden to Lionel Road.

- Paddington – 1 Change – Take Elizabeth Line with a change at Old Oak Common Lane to Lionel Road.

- Piccadilly Circus – 1 Change – Take Bakerloo Line with a change at Harlesden to Lionel Road.

- St. Pancras – 1 Change – Take Thameslink with a change at Brent Cross West to Lionel Road.

- St. Paul’s – 1 Change – Take Central Line with a change at Old Oak Common Lane to Lionel Road.

- Tottenham Court Road – 1 Change – Take Elizabeth Line with a change at Old Oak Common Lane to Lionel Road.

- Vauxhall – 2 Changes – Go to Oxford Circus – Take Bakerloo Line with a change at Harlesden to Lionel Road.

- Victoria – 2 Changes – Go to Oxford Circus – Take Bakerloo Line with a change at Harlesden to Lionel Road.

- Waterloo – Direct – Direct train to Kew Bridge.

- Waterloo – 1 Change – Take Bakerloo Line with a change at Harlesden to Lionel Road

Note.

- It does appear that the connections in stations like Brent Cross West, Harlesden and Old Oak Common Lane, will make a lot of difficult cross-London journeys easier.

- But not many journeys to the GTech Community Stadium, finish at Kew Bridge station.

- Most journeys pick up the West London Orbital at Brent Cross West, Harlesden or Old Oak Common Lane, which probably means these three stations should be step-free.

- As I’ve been writing this, I do wonder if now is the time to create a pedestrian connection between City Thameslink and St. Paul’s stations, that I wrote about in A Pedestrian Connection Between City Thameslink Station And St. Paul’s Tube Station.

I do believe though that there are places on the Central Line, where small projects can give a high return on expenditure.

Conclusion

Surprisingly, this is a lot more than just a station for a Premier League football club.

How Do B12 Levels Affect Pain In Knee Joints?

I asked Google AI, the title of this post and received this answer.

Low Vitamin B12 levels can cause or worsen knee joint pain primarily through nerve damage (peripheral neuropathy), which causes sensations of pain, tingling, or numbness in the legs. Deficiency also increases homocysteine, a pro-inflammatory amino acid linked to joint inflammation and, in some cases, accelerated cartilage deterioration.

Key Connections Between B12 and Knee Pain:

Neuropathic Pain: A lack of B12 damages the myelin sheath protecting nerves, leading to pain, pins and needles, or burning sensations often felt in the extremities, including the knees.

Inflammation and Joint Damage: Low B12 levels are associated with higher homocysteine levels, which can cause inflammation, swelling, and increased friction in the joints.

Deficiency Symptoms: Along with joint pain, B12 deficiency commonly causes fatigue, muscle weakness, and numbness.

Improvement with Supplementation: Studies suggest that maintaining adequate B12 levels, or using supplements, can reduce joint pain and improve mobility.

If you are experiencing persistent joint pain or numbness, it is advisable to have your B12 levels checked.

From my own experience, I would also get tested for coeliac disease.

Does Being Widowed Lower Your B12?

I asked Google AI, the title of this post and received this answer.

Widowhood does not directly cause a biological decrease in B12, but it is often associated with lifestyle changes and stressors—such as depression, loss of appetite, and reduced nutritional intake—that can lead to a lower intake of Vitamin B12.

Key points regarding the connection:

Nutritional Risk: Research suggests that older adults who are widowed or depressed may have lower intakes of various nutrients, including Vitamin B12.

Depression Link: Depression, which is common in bereavement, is significantly associated with lower plasma levels of vitamin B12.

“Undernourishment” Factor: Studies indicate that widowed individuals are frequently represented in groups at high risk for undernutrition, which can contribute to nutrient deficiencies.

Lifestyle Changes: The transition to widowhood often involves a loss of partner support, leading to poorer nutritional habits and neglect of self-care.

While being widowed is not a direct metabolic cause, it is a significant risk factor for conditions that lead to B12 deficiency in older adults.

I certainly, eat less Vitamin B12, than before my wife died, as when we had a meal in a certain pub in Suffolk or Carluccio’s, I always had calves liver or fegato.

Ocean Winds Enters Lease Agreement With Crown Estate For 1.5 GW Celtic Sea Floating Wind Project

The title of this post, is the same as that of this article on offshoreWIND.biz.

This is the sub-heading.

Ocean Winds has entered into an agreement for lease with the Crown Estate for a 1.5 GW floating offshore wind project, for which the developer secured a site in the Round 5 seabed auction last year.

These two paragraphs add detail to the story.

Offshore Wind Leasing Round 5, the UK’s first dedicated floating wind seabed leasing round, was launched in February 2024, offering three areas. In June 2025, the Crown Estate announced Equinor and Gwynt Glas, a joint venture between EDF and ESB, as preferred developers for two project sites and said it was working to ensure the delivery of the full potential capacity of Round 5, which is up to 4.5 GW.

Equinor and Gwynt Glas entered into lease agreements for their floating wind projects in October 2025 and, the following month, the Crown Estate said Ocean Winds had secured the third floating offshore wind site in the Celtic Sea.

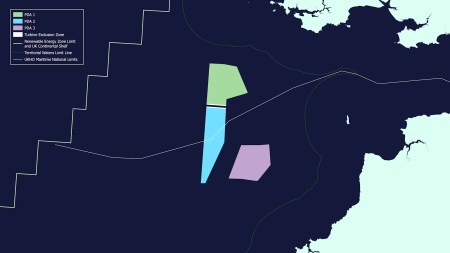

This map shows the three wind farms, that make up the Glynt Glas wind farm.

Note.

- It is expected to be built from and connect to the grid at Port Talbot in South Wales.

- The three sites are expected to be commissioned by the early-to-mid 2030s.

- The elongated white dot to the East of the wind farms would appear to be Lundy Island.

- The large bay to the North of Lundy is Carmarthen Bay with Caldey Island at its West end and Llanelli on its East.

- The Gower separates Swansea Bay from Carmarthen Bay.

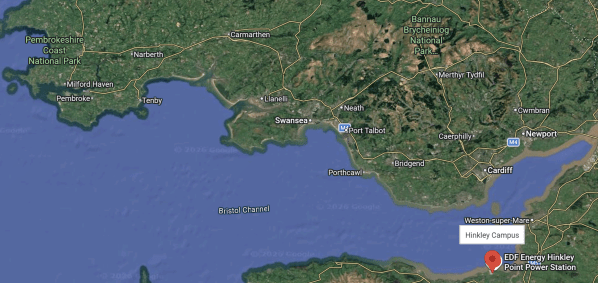

This Google Map shows the Bristol Channel from the wind farms in the West to Cardiff and Hinkley Point.

Note.

- Along the North coast of the Bristol Channel, working from West to East, my 78-year-old eyes can pick out Milford Haven, Pembroke, Caldey Island, Tenby, Llanelli, Swansea, Port Talbot, Porthcawl, BridgendCaerphilly, Cardiff and Newport.

- Coming back along the South Coast, I can see Weston-super-Mare, Hinkley Point C and the tip of Lundy Island in line with Tenby.

- The three sections of Glynt Glas will each generate 1.5 GW, making a total of 4.5 GW.

- Hinkley Point C when completed, will be a 3.26 GW nuclear power station.

- There is also a 2.2 GW gas-fired power station at Pembroke.

Nearly 8 GW of renewable electricity should be enough to convert Port Talbot steelworks to the manufacture of green steel.

How Much Wind Power Is Planned For The Western Approaches?

I asked Google AI, the title of this section and received this answer.

The UK has a target of 50 GW of offshore wind by 2030, with significant projects planned for the Celtic Sea (part of the Western Approaches), which is a key area for 5 GW of floating wind. Total UK offshore wind pipeline capacity exceeds 93 GW, with major developments in this region focusing on floating technology.

Key details regarding wind power in the Western Approaches (specifically the Celtic Sea) include:

Celtic Sea Developments: The area is a primary focus for floating wind projects, designed to capitalize on deep-water potential, with 5 GW of floating wind expected to be deployed across the UK by 2030.

Pipeline and Capacity: The total UK pipeline for offshore wind, which includes the Western Approaches, is 93 GW, and the government is aiming for 43-50 GW of installed offshore capacity by 2030.

Project Status: The region is expected to benefit from the Crown Estate’s leasing rounds aimed at accelerating floating wind, with 15.4 GW of new projects submitted across the UK in 2024.

Wales/South West England Context: Wales has 1.4 GW of projects in the pre-application stage, with some potential for developments off the South West coast.

For more detailed information on specific projects and their development status, you can visit the RenewableUK website and RenewableUK website.

It looks like about 20 GW of offshore wind could be installed in the Western Approaches.

If You Lack Vitamin B12 Is It Sensible To Limit Alcohol?

I asked Google AI, the title of this post and received this answer.

Damages Absorption: Alcohol irritates the lining of the stomach and intestines, which hinders the digestive system’s ability to absorb Vitamin B12 from food or supplements.

Reduces Storage: B12 is stored in the liver. Chronic alcohol use can cause liver damage and inflammation, reducing the liver’s ability to store and release B12 when needed.

Impairs Function: Even moderate amounts of alcohol (one or two drinks a day) can interfere with B vitamin levels.

Increases Deficiency Risk: Research indicates that B12 deficiency is common in individuals who consume high amounts of alcohol.

Severe Symptoms: Increased fatigue, neurological issues (numbness, tingling), and cognitive problems.

Irreversible Damage: Long-term, unaddressed deficiency can lead to permanent nerve damage or severe anemia.

Recommended Steps:

Limit or Stop Alcohol: Drastically reducing alcohol intake allows the digestive system to recover and improves absorption.

Supplementation: If you are treating a deficiency, your doctor may recommend B12 supplements (pills, nasal sprays, or injections).

Dietary Changes: Increase consumption of B12-rich foods like red meat, fish, poultry, eggs, and dairy, or eat fortified foods.

Centrica Energy And Whitecap Enter Long-Term Natural Gas Supply Agreement

The title of this post, is the same as that of this news item from Centrica.

This is the sub-heading.

Centrica Energy is pleased to announce signing of a long-term natural gas purchase agreement with Whitecap Resources Inc., a leading Canadian producer dedicated to the responsible development of oil and gas resources across the Western Canadian Sedimentary Basin.

These first three paragraphs add more detail to the story.

Starting in April 2028, Whitecap will deliver 50,000 MMBtu of natural gas per day to Centrica Energy for a period of ten years – equivalent to roughly five LNG cargoes each year. The supply will be priced against the Title Transfer Facility (TTF), the benchmark for European gas markets.

This agreement advances Centrica’s strategy of managing market price exposure across its LNG portfolio by linking feed gas costs to European price signals. For Whitecap, the agreement provides access to international LNG-linked pricing, supporting the company’s natural gas price diversification strategy.

“Entering into this innovative agreement with Whitecap underlines our focus on building a balanced LNG portfolio through strategic partnerships across the globe allowing us to deliver reliable energy solutions to global markets” said Chris O’Shea, Group Chief Executive at Centrica.

I have some thoughts.

This Is The Seventh Deal Of This Type By Centrica In A Few Months

Note.

- All are marked with a tag of Natural Gas Trading.

- None of the deals appear to be in the Middle East.

- All appear to be fairly long term deals, with three stretching until 2037.

Hopefully, with luck we’ll have enough gas for the next few years.

Grain LNG Terminal Is Very Flexible

Consider.

- It is Europe’s largest LNG Terminal

- It can import, export and store gas.

- It has plenty of space for expansion, which could include new technologies.

- Centrica have said bunkering facilities will be added, which will be able to handle the latest low-carbon fuels.

I can certainly see, why Centrica acquired the terminal.

Cornish Plant Produces Geothermal Power

The title of this post, is the same as that of this article on Ground Engineering.

This is the sub-heading.

Hot water from a granite fault zone in Cornwall is being used to create electricity after a pioneering plant was switched on last week.

These two paragraphs add a few more details.

Geothermal Energy Lithium (GEL) started generating power from its United Downs facility near Redruth in late February.

The company drilled down more than 5km to reach hot water sitting in natural fractures in the rock deep below Cornwall.

This excellent video, shows the wide significance of what is happening in Cornwall.

How Much Electricity Do You Need To Charge A Garage Full Of Electric Buses?

Consider.

- A couple of years ago, I had a long discussion and a few beers with three managers of bus garages.

- In First Bus To Launch 1MW BESS Unit In Hampshire, Aberdeen To Follow, I talk about a specialist battery to charge buses.

- In Is Sumitomo Heavy Industries Highview Power Energy Storage System On line At Hiroshima?, I talk about an efficient, renewable power supply for an LNG Terminal.

I asked Google AI the question in the title of this post and received this comprehensive answer.

Charging a full garage of electric buses requires massive amounts of electricity, with typical, non-optimized charging for a 100-bus depot capable of drawing nearly 10 megawatts (MW) of power. To put this into perspective, a 100-bus depot might require roughly 150 Megawatt-hours (MWh) of energy to recharge over an eight-hour night.

Key Factors and Energy Requirements

Energy Consumption per Bus: A typical electric bus has a battery capacity between 300-500 kWh. Energy consumption averages around 1.11 to 1.35 kWh/km, with higher consumption in winter or with heavy A/C use.

Total Depot Power: For a 100-bus depot, power requirements can reach 10 MW, equivalent to the power output of a small hydroelectric dam.

Optimal Charging: Using smart charging, a 100-bus depot can reduce its peak demand to around 4 MW.

Daily Usage: A single, large electric bus can consume up to 500 kWh per day, with daily demand ranging from 189 to 231 kWh for typical operations.

Infrastructure and Grid Considerations

Charging Infrastructure: Depots often use 40 kW to 250 kW chargers, with 100 kW common for overnight charging.

Grid Capacity: A 34-bus depot might require a new 1000kVA transformer to handle the load.

Voltage: 11,000 volts may be required to power new substations, which are then stepped down to 400 volts for charging.

Operational Factors Affecting Energy Need

Heating and Cooling: Cold weather can increase energy consumption by up to 45% (due to electric heating).

Driving Style: Inefficient driving can increase energy consumption by 0.24 kWh/km above average.

Regenerative Braking: This can recover 37–40% of energy for 40-60 ft buses.

Cost Implications

Energy Bills: A 100-bus depot can incur monthly energy bills between $112,000 and $515,000 without optimization.

Cost Savings: Electric buses are generally cheaper to fuel, costing ~£0.21/mile compared to £0.49/mile for diesel.

Could A System Based On The Sumitomo/Highview Power System At Hiroshima Charge Electric Buses?

The optimal charging figure for a 100-bus garage would appear to be in the region of 4-5 MW.

In Is Sumitomo Heavy Industries Highview Power Energy Storage System On line At Hiroshima?, I state, that it looks like Highview Power’s CRYOBattery™ at the heart of the system has a capacity of 5 MW/20 MWh.

I also state in the post, that the Hiroshima facility is designed to support grid stability and enhance renewable energy integration.

Does this all mean that if you can install enough solar panels on the roof of the garage or perhaps a wind turbine nearby, that you can have buses substantially powered by the sun and wind.

Chicago would just love wind-powered buses!

Is Sumitomo Heavy Industries Highview Power Energy Storage System On Line At Hiroshima?

From some work I did at ICI in the 1970s on a PACE231R analog computer, I believe that Highview Power may have an extremely promising way of storing energy.

The Highview Power web site talks of Sumitomo Heavy Industries, who are building one of Highview’s batteries at Hiroshima in Japan.

So I asked Google AI the question in the title of this post and received this comprehensive answer.

Yes, the Sumitomo Heavy Industries (SHI) Highview Power liquid air energy storage (LAES) commercial demonstration plant in Hatsukaichi, Hiroshima, is operational, having commenced operations on December 1, 2025.

Key details about the plant:Location: Within the Hiroshima Gas Hatsukaichi LNG Terminal.Capacity: 5 MW output with 4-hour storage (4 MW charging).Technology: Uses Highview Power’s CRYOBattery™ technology, specifically utilizing waste cold from the adjacent LNG terminal to improve efficiency.Role: The facility is designed to support grid stability and enhance renewable energy integration.A completion ceremony for the project was held on December 9, 2025. This news item from Sumitomo Heavy Industries gives more details.This paragraph describes Liquid Air Energy Storage or (LAES).

- It looks like the battery has a capacity of 5 MW/20 MWh.

- As it talks about using waste cold, this looks to be a very professionally-designed specialist application.

- But surely, that would be expected from a company like Sumitomo Heavy Industries.

There are hundreds of LNG terminals globally, with significant growth driven by over 300 projects (roughly 177 import/regasification and 124 export/liquefaction) expected between 2025 and 2030. In 2023, there were 22 countries with active liquefaction (export) capacity, while Europe alone operates roughly 28 large-scale terminals, supplemented by a rapidly expanding fleet of FSRUs.Export Capacity: In 2023, global liquefaction capacity was 472 million tonnes per annum (mtpa), with top exporters being Australia, the U.S., and Qatar.Expansion: By 2027, 52 new liquefaction terminals are expected to commence operations.Import Growth: European regasification capacity is expanding, with major terminals in Spain, France, Italy, and new additions in Germany and other nations.U.S. Infrastructure: The U.S. alone has more than 170 LNG facilities performing various services.

- They are listed in this Wikipedia entry.

- There are around thirty in Japan alone.

- Will Centrica add a 5 MW /20 MWh Highview Power battery to their Grain LNG Terminal?

- Each facility installed is claimed to be designed to support grid stability and enhance renewable energy integration, so the last part must cut carbon emissions.

Yes, several major chemical engineering and industrial processes generate significant amounts of “waste cold” (low-grade thermal energy or cryogenic energy) that is often discarded. While the chemical industry conventionally focuses on recovering waste heat, recovering waste cold is becoming increasingly popular for improving energy efficiency, particularly in cryogenic processes.

- Liquefied Natural Gas (LNG) Regasification

- Cryogenic Air Separation Units (ASUs)

- Dry Ice and CO2 Liquefaction

-

Liquid Nitrogen Vaporization

-

Emerging: Cryogenic Carbon Capture

- Creation of this page was not difficult, but you have to get the tricks right.

- I used Google Chrome and Google AI.

- My blog is hosted in WordPress.

- All pages on this blog, where I have had help in their creation from Google AI are tagged as such.

I would be happy to help anybody, who wanted to use Artificial Intelligence to create blog pages.

Polanski And Farage Don’t Agree. But They Have More In Common Than You Might Think

The title of this post, is the same as that of this article on the BBC, by Laura Kuenssberg.

It is very much a must read article comparing two of the most controversial party leaders in the UK.

This is the sub-heading.

One is a former stockbroker from the south who, by his own proud admission, loves smoking, drinking and women. The other’s a proud vegan, gay, northern former actor, who told me he’d never drunk a drop.

These first three paragraphs add detail to the story.

But the jubilant Zack Polanski and Nigel Farage have rather a lot in common.

Before you scream, burst out laughing, or think I have lost my marbles, of course, there are very big differences between them.

The Greens talk about a climate emergency. Reform UK calls the government green plans, “net stupid zero”.

This is Laura’s summing up of the Terrible Twins.

Their views on the cause of Britain’s pain vary wildly.

The Greens might point the finger at the super-rich, the “donor billionaires” they often cite. Reform often blames immigration, which they controversially characterise as an “invasion” of people arriving in the UK without permission.

But both parties feed off and stir up sentiment that’s felt by lots of the public: that Britain doesn’t work any more.

Whether it’s the new Green MP saying “working hard used to get you something” in her victory speech, or Nigel Farage repeatedly telling us “Britain is broken”, the same argument flows from both: that the country is in such a dreadful state that only new political saviours can fix it.

And both Reform and the Greens are willing to push the conventions of what traditional UK politicians would find acceptable – or what they believe would make them electable.

That’s not just about their image or the unstuffy ways they court publicity – Nigel Farage willingly going into the I’m A Celebrity jungle, or Zack Polanski being seen on a dance floor in campaign videos – but how they choose to focus on sensitive issues, where others might not choose to tread.

I would disagree that Britain is broken, but that it needs someone with sensible policies that everybody can get behind.

The Greens policies on the super-rich would drive anybody with ambition and money from this country and already countries like Canada are advertising for migrants.

With two immigrant lines, Farage is everything my father thought was bad about Oswald Mosley and his fascists in the 1930s. If a Reform UK Government started rounding up illegal immigrants on the streets, the violence would probable be enormous.

How Much Renewable Energy Will The UK Be Generating By 2030?

I have to admit, that whether you like the Tories or not, they have developed an energy generation policy and an energy relationship with Germany, that appears to be working and is allowing the current Government to do a bit of spending on defence and other needs.

I asked Google AI, the question in the title of this section and received this reply.

The UK government has set an ambitious target to reach 95% low-carbon electricity generation by 2030, aiming for a system driven by 43-50 GW of offshore wind, 27-29 GW of onshore wind, and 45-47 GW of solar power. This plan aims to dramatically reduce fossil fuel reliance, supported by 23-27 GW of battery capacity.

Key 2030 Renewable Energy Projections & Targets:

Total Clean Power Goal: The goal is 95% of electricity from low-carbon sources (renewables and nuclear) by 2030, up from roughly 74% in 2024.

Offshore Wind: Target of 43-50 GW, deemed crucial to powering the grid.

Onshore Wind: Target of 27-29 GW, with recent policy changes lifting bans to accelerate development.

Solar Power: Target of 45-47 GW, aiming to triple current capacity.

Flexibility: 23-27 GW of battery capacity and 4-6 GW of long-duration storage are needed to manage intermittency.

Challenges and Forecasts:

Shortfall Risks: While the government target is high, some projections suggest wind and solar may only account for 44% of generation by 2030, requiring significant acceleration to reach the 95% clean goal.

Investment Needs: Achieving these goals requires an estimated £48 billion in additional investment, on top of planned projects.

Progress: In 2024, renewable sources already hit a record of over 50% in certain quarters, with low-carbon sources overall (including nuclear) providing nearly 70% of generation.

My Thoughts

I will add some of my thoughts.

Electricity Demand: As I write, according to National Grid: Live it is 33.3 GW, which is met by with Production of 27.1 GW and Transfers of 6.2 GW.

Electricity Production: In 2030, I believe that if the UK has long-term battery capacity of something like 4 GW/40 GWh, that total UK electricity production could be upwards of 125 GW.

Hinckley Point C Power Station: This should add 1.6 GW in 2030 and 2031 to further boost UK electricity production.

Pumped Storage Hydro: In How Much Pumped Storage Hydro Will Be Operational In The UK By 2030?, I estimate that the Bank of England standard of energy storage, will add 5 GW of electricity production.

Highview Power: Highview Power are developing long duration liquid-air energy storage and have identified locations for sixteen 300 MW/3.2 GWh monsters.

Excess Electricity Production: This will be exported, either as electricity or after conversion to hydrogen. It will be a Magic Money Forest for the victor of the General Election in 2029.

If Hinckley Point C, the pumped storage hydro and Highview Power’s batteries work as their engineers hope, then the result of the next General Election will be predictable.

It is certainly, Kier Starmer’s to win, by getting the energy right!

Highview Power And The 2029 General Election

Every extra GWh added to energy storage has the following affect.

It will mean that more wind farms will not have to be switched in times of high wind and over production, as the electricity can be stored.

At the present time, there are four ways of storing energy.

- Turn it into hydrogen. But the Hindenberg did a good PR job for not using hydrogen.

- Store it in a pumped storage hydro system, but these have problems with their large land use.

- Store it in a large lithium battery, but these have problems with fire risks and need a large amount of expensive lithium.

- Store it in one of Highview Power’s liquid air batteries.

I believe that Highview Power’s liquid-air long duration batteries, have several advantages.

- They are built from readily available components.

- They can be scaled to the need at the location, where they are installed.

- A small one is 50 MW/300 MWh and a large one is 300 MW/3.2 GWh.

- The batteries come with grid stabilisation and other features.

- The batteries have a lifespan of greater than 50 years

- The energy storage fluid, is captured from the air.

- They are a product, that would be easy to finance in quantity.

- Goldman Sachs is an investor.

- A village with a power problem could fund a Highview Power battery and have a nice little earner, with perhaps a wind turbine on a nearby hill.

- Centrica is an investor.

If a politician were to understand it, it could wind them the next General Election.