Replacement Of South Western Railway’s Class 158/159 Trains

South Western Railway use Class 158 and Class 159 trains on the following routes.

- London Waterloo and Salisbury (and Yeovil Pen Mill)

- London Waterloo and Exeter St Davids

- Romsey and Salisbury

- Salisbury and Bristol Temple Meads

The two types of train are very similar, with the Class 159 trains being converted from Class 158 trains.

- There are ten two-car Class 158 trains in service with South Western Railway. which have a capacity of around 140 seats

- There are thirty three-car Class 159 trains in service with South Western Railway, which have a capacity of 196 seats

- Each car has a diesel engine driving two axles through a hydraulic transmission.

- Both trains have an operating speed of 90 mph.

- The trains are all around thirty years old.

I took these pictures on my trip to Basingstoke station on Friday, when I rode in nine-car formation of three Class 159 trains both ways.

Note.

- For much of the route between Clapham Junction and Basingstoke, the trains were doing just a few mph short of ninety on the 100 mph route.

- The interiors are fairly spacious and I got a table seat both ways.

As diesel multiple units go, there are worse ones in service in the UK. And I don’t mean Pacers.

Replacement Possibilities

Ideally, these trains should be replaced with zero-carbon trains.

As most of the routes, on which the trains run are not-electrified, there must either be a lot of new third-rail electrification or battery electric trains must be used.

These are my thoughts for the various trains.

Two-Car Class 158 Train

These trains have the following specification.

- Length – 46 metres

- Seats – 140

- Operating Speed – 90 mph

In Converting Class 456 Trains Into Two-Car Battery Electric Trains, I stated that these Class 456 battery electric trains would have the following specification.

- Seats – 113

- Range on Battery Power – 30-40 miles

- Operating Speed – 75 mph

I also felt that as the trains would receive a new AC traction system, that the operating speed could be increased to perhaps 90 mph.

I wouldn’t be surprised to find, that a professional conversion capitalising on Alstom’s work to create the Class 600 hydrogen train, could turn a Class 456 train into a battery electric replacement for a two-car Class 158 train.

Three-Car Class 159 Train

These trains have the following specification.

- Length – 69 metres

- Seats – 196

- Operating Speed – 90 mph

Could these be replaced with a three-car Class 456 battery electric train, lengthened by the addition of a Trailer Car from a Class 321 train, that has been converted to a Class 600 hydrogen train?

As most Class 159 trains probably work in longer formations, this could be a possibility, to replace units working alone.

Two Three-Car Class 159 Trains Working As A Six-Car Formation

These trains have the following specification.

- Length – 138 metres

- Seats – 392

- Operating Speed – 90 mph

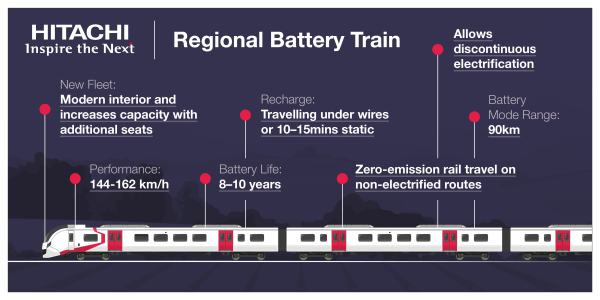

This formation would be impossible for Class 456 battery electric trains, so it must be a case for calling up the heavy brigade, in the shape of Hitachi’s Regional Battery Train, which is described in this Hitachi infographic.

A five-car version of this train could have the following specification.

- Length – 130 metres

- Seats – 326

- Range on battery power – 56 miles

- Operating Speed – 100 mph

- It would probably be able to work with both 25 KVAC overhead and 750 VDC third-rail electrification.

Note.

- More seats could probably be fitted if needed.

- Platforms where the trains would work can already accept nine-car Class 159 trains, which are 207 metres long.

- The trains would charge the batteries using the electrification between London Waterloo and Basingstoke.

- Fast Charge facilities would also be needed at some intermediate and terminal stations like Bristol Temple Meads, Exeter St. Davids, Salisbury, Westbury and Yeovil Junction.

- These trains would be ten mph faster than the Class 159 trains and this may enable the saving of a few minutes between London Waterloo and Basingstoke stations.

A six-car version would be possible, if more capacity is needed.

Three Three-Car Class 159 Trains Working As A Nine-Car Formation

These trains have the following specification.

- Length – 207 metres

- Seats – 588

- Operating Speed – 90 mph

An eight-car version of Hitachi’s Regional Battery Train could have the following specification.

- Length – 208 metres

- Seats – 522

- Range on battery power – 56 miles

- Operating Speed – 100 mph

- It would probably be able to work with both 25 KVAC overhead and 750 VDC third-rail electrification.

Note.

- More seats could probably be fitted if needed.

- Platforms where the trains would work can already accept nine-car Class 159 trains, which are 207 metres long.

- The trains would charge the batteries using the electrification between London Waterloo and Basingstoke.

- Fast Charge facilities would also be needed at some intermediate and terminal stations like Bristol Temple Meads, Exeter St. Davids, Salisbury, Westbury and Yeovil Junction.

- These trains would be ten mph faster than the Class 159 trains and this may enable the saving of a few minutes between London Waterloo and Basingstoke stations.

A nine-car version would be possible, if more capacity is needed.

More Capacity Between London Waterloo And Basingstoke

London Waterloo and Basingstoke was very busy before COVID-19 and it needed more capacity.

- All the express passenger trains are capable of 100 mph, with the exception of the diesel Class 158 and Class 159 trains, which can only do 90 mph.

- If these diesel trains were to be replaced by Hitachi’s Regional Battery Trains, these trains will be able to do 100 mph on battery power.

This speed increase will enable faster journey times and increase capacity.

- But between London Waterloo and Basingstoke, they will be using the third-rail electrification.

- Class 800 and Class 801 trains, which are cousins of the Regional Battery Train are currently able to do 125 mph between London Paddington and Swindon and London Kings Cross and Doncaster.

- London and Doncaster is being upgraded to 140 mph running.

So will we see 125 mph running between London Waterloo and Basingstoke? I will be very surprised if we didn’t, before 2030.

Charging The Batteries

Much of the charging of batteries will be performed whilst running on electrified lines.

But as I indicated there will need to be Fast Charge facilities at intermediate and terminal stations.

The Need For A Universal Fast Charge Facility For All Battery Electric Trains

If you look at Salisbury for example, the facility would need to be able handle all types of battery electric trains. So the Government, Network Rail and the Office of Road and Rail must come up with a universal design of charging facility that can be used by all battery electric trains.

Standard UK electrification, which can be either 25 KVAC overhead or 750 VDC third-rail, can obviously be used, as all battery electric trains will be designed to be able to charge the batteries, whilst running on electrified lines.

But a Universal Fast Charge system is surely needed, that can charge every battery electric train running on the UK rail network.

Splash-and-Dash At Yeovil Junction Station

But I believe that trains like Hitachi’s Regional Battery Train, when working long routes like Salisbury and Exeter will need the equivalent of Formula One’s Splash-and-Dash, where a fast pit-stop enabled cars to complete the race in the most economic manner.

If you look at timings between Salisbury and Exeter on Real Time Trains, you find the following.

- Salisbury and Exeter is 88.5 miles

- Salisbury and Yeovil Junction is 39 miles

- Yeovil Junction and Exeter St. Davids is 50 miles

- Trains seem to be timed to wait between 8-14 minutes at Yeovil Junction station.

- At several times during the day the Westbound and Eastbound services pass at Yeovil Junction station.

I would assume the wait and the passing, are so that trains can safely navigate the sections of single-track line, that are a legacy of British Rail’s policy of saving money, that affectively ruined the efficiency of sections of the network.

It would appear that a well-designed Universal Fast Charge facility at Yeovil Junction station could enable battery electric trains to run between Salisbury and Exeter St Davids stations, without any adjustment to the existing timetable.

This Google Map shows Yeovil Junction station.

Note.

- Yeovil Junction station is in the South West corner of the map.

- The West of England Main Line passes East-West through the station.

- The station has two platforms.

- The two lines running North to Yeovil Pen Mill and Westbury stations.

- The line running between the North side and the South-East corner of the map is the Heart of Wessex Line, between Yeovil Pen Mill in the North and Weymouth in the South.

- Most links between the West of England Main Line and the Heart of Wessex Line have been removed.

The station doesn’t appear short of space.

Great Western Railway’s Gloucester And Weymouth Service

If a link between Yeovil Junction station and the Heart of Wessex Line towards Weymouth, this would enable Great Western Railway’s Gloucester and Weymouth service to call at both Yeovil stations, with a reverse at Yeovil Junction.

It would surely, improve the train service for the town of Yeovil.

If in the future, it was desired to run the Gloucester and Weymouth service using a battery electric train, Yeovil Junction station could be used to charge the train’s batteries.

Vivarail’s Fast Charge System

Vivarail’s Fast Charge system has been patented and demonstrated and this could be used with both the battery electric Class 456 train and Hitachi’s Regional Battery Train.

So it could be used as an initial design for a Universal Fast Charge system.

Conclusion

A mix of these battery electric trains could probably replace the Class 158 and 159 trains.

- Two-car Class 456 train

- Three-car Class 456 train

- Five-car Hitachi Regional Battery Train

- Eight-car Hitachi Regional Battery Train

Note.

- Universal Fast Charge facilities would also be needed at some intermediate and terminal stations like Bristol Temple Meads, Exeter St. Davids, Romsey, Salisbury, Westbury and Yeovil Junction.

- Services between London Waterloo and Basingstoke could be faster.

These rebuilt and new trains would fully decarbonise South Western Railway.

transpennine is getting rid of a load of 185’s due to its new stock. They are officially capable of 100mph but they were built to be more powerful than a typical 100mph dmu due to the hills on their routes, which leads me to believe they are capable of 110mph. The 444’s are also part of the same family and have the same carriage lengths. I don’t think there is much of a capacity requirement west of basingstoke, I would imagine 6x23m cars would be sufficient.

This leads me to believe that with sufficient platform extensions, a pair of 444’s and a pair of 185’s could run out of waterloo and split at basingstoke. This would probably remove at least 2 trains per hour from the southwest mainline, and would prevent massive convoys running in the southwest where that capacity isn’t required. On top of this, the scheme would be very cheap to implement and our country doesn’t have much money at the moment.

If we wanted to spend a bit more money though, we could replace the 185’s cabs with 444/450/350 cabs to allow people to access other units whilst onboard the train, and if we really wanted to splash out we could electrify the swml to 25kV OHLE. I think this is necessary due to the capacity requirement on the suburban lines, and 3rd rail can’t meet this. If we went up to 25kV, I reckon we could get 444’s to go at 110mph, thus meaning we could see 444+185 combinations doing 110mph through to basingstoke. This would also improve services to the west.

Comment by Kermit_O12 | September 13, 2020 |

No such thing as ‘decarbonise’. The energy has to come from somewhere which, with the arguable exception of hydroelectric power, involves the production of CO2 at some point. Even hydroelectric power causes CO2 as the power stations have to be built using concrete and steel, the generators have copper wire inside…the mining and smelting of the raw materials required produces vast amounts of CO2.

It’s only the seriously flawed specifications that are used to decide on the CO2 loading which makes something appear to be carbon neutral; the CO2 produced during manufacture of a product is ignored, the only figure we see is the CO2 produced when the product is used. As an example, 40% of the total CO2 load of a car is due to its manufacture but nobody mentions this, all you hear about is the miles per gallon and CO2 produced per kilometre.

How many tonnes of CO2 were caused by the manufacture of Greta’s yacht, constructed of non-recyclable materials derived from oil, crewed by people who then had to fly home?

Comment by paul harris | April 18, 2021 |

An intriguing and stimulating article. I was taken by the reference to the Vivarail fast charger. Thankfully the patent explains it as a conductive and not inductive device, think of all the EMC and Signalling problems the latter would create in a railway environment.

I am however inclined to wonder about the capital cost of installing a system that may have to provide sufficient charge in a 10 minutes period – to take any longer raises operational issues. On that basis one will need a MV electrical supply (11- 33kV) which suggests a significant capital outlay, especially if efforts were made to incorporate power from a dedicated renewable source.

I’ll now go away and think the rest of the issues. It’s funny but in 1987/88 we actually thought about a bimodal DC/dmu solution for the Waterloo – Exeter route.

Comment by Alan Morris | June 23, 2021 |

I understand Vivarail use high-conductivity carbon shoes. They also have a shipping container full of lead acid batteries, which are trickle charged between trains. As we all know battery-to-battery is the fastest way to charge a battery and that’s what they do.

Remember too, that the Hitachi trains have regenerative braking.

There’s more good ideas in engineering that have been forgotten, than have yet to be invented.

Comment by AnonW | June 23, 2021 |

They might be 2 and 3 car trains but run as 6 and 8.

456 is for the birds really (and they have gone anyway).

Battery tech isnt going to lift 8 coaches 80 miles over the west country hills at speed sensibly, and affordably anytime soon.

More Class 800’s is the favourite, keeps jobs going in the North, fits a nationwide design. But the cheaper option is hand the route over to GWR with their existing 800’s.

Comment by John | April 13, 2022 |

Interesting article, but in my humble opinion a little far fetched in places. But, I tend to be conservative in such matters, though not a Tory lol.

In my view the following is most likely.

SWR won’t replace the Class 158/159’s until another operator places a larger order for a Bi-mode type for example Scotrail for their intercity routes. I consider an a Bi-mode AT-200 to be the more likely/sensible option. Initially with diesel engines, but convertible to Hydrogen/Battery as the technology truly matures. SWR will tag on an order. Neither Scotrail or SWR need stock which can run at over 100mph. Scotrail’s intercity routes are too twisty, and SWT is third rail which is limited to 100mph. Plus the start/stop nature negated the benefit of increased speed, and 100mph gearing ill increase acceleration rate, which is ore important on these services. None of the third rail network will ever be converted to OHLE. The best we can hope is that the power supply is renewed to modern efficiency standards, and that the steel conductor rails are replaced with Aluminium/Stainless Steel capped co-extruded replacements to markedly reduce resistive losses and increase efficiency. Hitachi is more than capable of filling these requirements with their AT-200 platform. Ultra-rapid charging will only come to fruition at terminal stations. If you charge a battery train in dribs and drabs on route, then each one of those dribs and drabs is a battery charge cycle which would reduce the life span of incredibly expensive batteries. It’s best to do one large, more stead charge as a terminal.

There is something to be said for SWR ordering a Bi-mode Aventra to match their Class 701 fleet if indeed the 701’s are ever service worthy. From what I hear, there is a small chance that the 701’s production is to be halted, and the completed ones head to scrap as constructive total losses due to he sheer number of defects. I hope I am wrong on that. Fingers crossed. Given the problems with the Aventra’s I don’t think SWR will risk yet another Aventra fleet, even if Northern Rail do on their Middlesborough area trains now that the Class 600 project has been scrapped.

Comment by Duncan Wilson | March 26, 2023 |