Airbus, Rolls-Royce, EasyJet Headline Formation Of UK Hydrogen Alliance

The title of this post, is the same as that of this article from Future Flight.

These two paragraphs outline the story.

A group of leading companies in the UK aviation and renewable energy sectors including EasyJet, Rolls-Royce, and Airbus has established the Hydrogen in Aviation (HIA) alliance to accelerate the delivery of zero-carbon aviation, the companies said Tuesday. HIA, whose partners also include Ørsted, GKN Aerospace, and Bristol Airport, said decarbonization efforts involving hydrogen should assume more urgency at a time when sustainable aviation fuel and batteries have drawn so much of the sector’s attention.

Working with government, local authorities, and the aviation and hydrogen sectors, the group plans to draw on members’ expertise to propose “a clear and deliverable pathway” to achieving hydrogen-powered aviation. Efforts center on clearing a pathway for preparing the needed infrastructure as well as policy, regulatory, and safety frameworks.

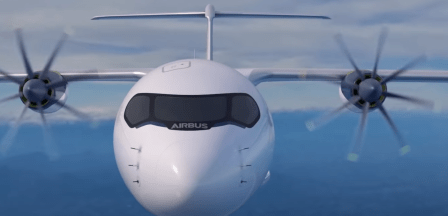

This Airbus infographic describes the aircraft in Airbus’s ZEROe project.

Discover the three zero-emission concept aircraft known as ZEROe in this infographic. These turbofan, turboprop, and blended-wing-body configurations are all hydrogen hybrid aircraft.

These are my thoughts.

Do The ZEROe Turboprop And The ZEROe Turbofan Have Similar Hydrogen Systems?

This is Airbus’s summary of the design of the ZEROe Turboprop

Two hybrid-hydrogen turboprop engines, which drive eight-bladed propellers, provide thrust. The liquid hydrogen storage and distribution system is located behind the rear pressure bulkhead

This screen capture taken from an Airbus video, shows a rear view of the plane.

Note the sizeable cone-shaped rear end to the fuselage with no windows.

This is Airbus’s summary of the design of the ZEROe Turbofan

Two hybrid hydrogen turbofan engines provide thrust. The liquid hydrogen storage and distribution system is located behind the rear pressure bulkhead.

This screen capture taken from an Airbus video, shows the plane.

Note how there are no windows at the back of the fuselage, as the hydrogen tank doesn’t need them.

It looks to me, that similar cone-shaped tanks for hydrogen, customised for each aircraft could be placed behind the rear bulkhead.

There would probably be space for any pumps needed to distribute the hydrogen to the engines.

All the stored hydrogen and its gubbins could be safely sealed behind the rear bulkhead.

I am fairly certain that the ZEROe Turboprop and the ZEROe Turbofan will have similar hydrogen systems.

Do The ZEROe Turboprop And The ZEROe Turbofan Have Auxiliary Power Units?

The auxiliary power unit or APU in an aircraft that provides energy for functions other than propulsion.

In Airbus To Trial In-flight Auxiliary Power Entirely Generated By Hydrogen, I wrote about Airbus’s development of APU’s based on fuel cells and running on hydrogen.

This surely could be a way to go.

- A battery could store power.

- Fuel cells are proving to be reliable.

- The plane would have two independent electrical systems.

Power would always be available for the cockpit, flying controls and to restart the engines, just as it is in any airliner today.

Do The ZEROe Turboprop And The ZEROe Turbofan Have The Same Cockpit?

The cockpits of the A 320 neo and the A 320 ceo seem to have a similar profile, but the cockpit of the ZEROe Turbofan seems to have been reprofiled.

In ZEROe – Towards The World’s First Zero-Emission Commercial Aircraft, I showed these front on views of the cockpits of the ZEROe Turboprop and ZEROe Turbofan.

I questioned if the two cockpits were related.

- A single cockpit for both aircraft would surely ease manufacture, maintenance and pilot training.

- I’m no aerodynamicist, but it certainly looks that the new cockpit will reduce drag and fuel consumption.

This common cockpit concept was used for the Boeing 757 and the Boeing 767 in the 1980s, so it is not a new concept.

Although the cockpit, appears to be being used in the ZEROe for the first time, I would expect it is already under development and might feature in any later version of the A 320 neo.

Do Airbus Have A Preferred Development Order?

Consider.

- My product development experience indicates that the development of the ZEROe Blended-Wing Body will involve more flight testing and aerodynamic checks than the other two aircraft, so I would make it the last aircraft to enter service.

- The ZEROe Turboprop appears to be a development of the ATR 72.

- The ZEROe Turbofan appears to be a development of an A 320 neo.

- The ZEROe Turboprop and ZEROe Turbofan would appear to have similar designs of cockpit, hydrogen systems and auxiliary power units.

- It looks to me that either of the ZEROe Turboprop or ZEROe Turbofan could be developed first.

I would develop the ZEROe Turboprop first, as it is the smaller aircraft.

Why Bristol Airport?

This page on the Airbus web site is entitled Airbus In The United Kingdom, where this is the first paragraph.

Building on a proud 100-year British aviation heritage, Airbus is part of the very fabric of the UK – which is one of the company’s four home markets, alongside France, Germany and Spain. Its 11,000-strong UK workforce is part of a global family of 125,000 employees.

This is said under Commercial Aircraft.

The sites at Filton and Broughton design, test and manufacture the wings for all Airbus’ A320 family, A330 and A350 commercial aircraft, directly sustaining more than 8,000 full-time jobs and hundreds of apprenticeships.

A220 family wings are designed and built by Spirit AeroSystems in Belfast, Northern Ireland.

Broughton has a proud tradition of aerospace manufacturing dating back 80 years, having supplied the RAF with vital aircraft during the Second World War. Employing almost 5,000 people, Broughton is a global centre of excellence for manufacturing and delivers over 500 wing sets per year for the A320 family, A330 and A350. Airbus has invested more than £2 billion in the Broughton plant over the past 10 years.

Core activities at Filton, where an additional 3,000 people work, are the design, engineering and support for Airbus wings, fuel systems and landing gear systems. Teams also work on aerodynamics research, development and test facilities, including our future zero-emissions programme, ZEROe, while wings for the A400M transporter are assembled on site.

It would appear that Filton in Bristol, is a very important part of Airbus’s operations in the UK.

- It appears to have major responsibility for all Airbus wings except the smallest.

- It has a large responsibility with respect to the ZEROe family of aircraft.

- Filton Airfield is now closed.

- Filton can do substantial assembly if required.

So was it just a logical decision to phone up Bristol Airport and ask, if they’d like to join the project?

In addition.

- Bristol Airport has a 2000 metre East West asphalt runway.

- The airport can handle a Boeing 787 Dreamliner and Airbus A330.

- It is the eighth busiest airport in the UK.

- It is a busy general aviation airfield.

- There is plenty of electricity in the area and Hinckley Point C will open down the road in a couple of years.

Bristol Airport is probably typical of many provincial airports around the world.

Why EasyJet?

These paragraphs from the Future Flight article help to explain.

“There is no doubt that the UK has the potential to become a world leader in hydrogen aviation, which could bring with it a £34 billion per annum boost to the country’s economy by 2050, but in order to capture this opportunity, rapid change is needed and the time to act is now,” said Johan Lundgren, CEO of EasyJet and HIA’s first chairman.

“We must work together to deliver the radical solutions required for a hard-to-abate industry like aviation so we can protect and maximize the benefits that it brings to the UK economy and society and that we know British consumers want to be preserved.”

Under its Zero-E program, Airbus aims to bring to market the first hydrogen-powered narrowbody commercial airplane by 2035. Separately, a partnership between Rolls-Royce and EasyJet signed last year saw the companies test hydrogen fuel in gaseous form in an adapted AE2100-A turbine, the engine that powers the Saab 2000 regional airliner. The November 2022 test, which used hydrogen produced in the Orkney Islands by the European Marine Energy Centre using renewable energy, marked the first run of a modern engine using hydrogen.

EasyJet seems to be enthusiastic about hydrogen and their CEO will be the HIA’s first chairman.

EasyJet also has a series of routes from Bristol Airport.

- Alicante – 907 miles

- Amsterdam – 326 miles

- Athens – 1592 miles

- Antalya – 1981 miles

- Barcelona – 733 miles

- Basel/Mulhouse – 530 miles

- Belfast–City – 259 miles

- Belfast–International – 269 miles

- Berlin – 694 miles

- Bilbao – 559 miles

- Bodrum – 1772 miles

- Bordeaux – 462 miles

- Catania – 1295 miles

- Chania – 1719 miles

- Copenhagen – 694 miles

- Corfu – 1356 miles

- Dalaman – 1981 miles

- Dubrovnik – 1155 miles

- Edinburgh – 316 miles

- Enfidha – 1241 miles

- Faro – 1026 miles

- Fuerteventura – 1687 miles

- Funchal – 1473 miles

- Geneva – 536 miles

- Gibraltar – 1060 miles

- Glasgow – 317 miles

- Gran Canaria – 1749 miles

- Grenoble – 556 miles

- Heraklion – 1768 miles

- Hurghada – 2526 miles

- Ibiza – 887 miles

- Innsbruck – 693 miles

- Inverness – 429 miles

- Isle of Man – 203 miles

- Kefalonia – 1451 miles

- Kos – 1770 miles

- Kraków – 991 miles

- La Rochelle – 366 miles

- Lanzarote – 1649 miles

- Larnaca – 2126 miles

- Lisbon – 925 miles

- Lyon – 529 miles

- Madrid – 755 miles

- Málaga – 1020 miles

- Marrakesh – 1393 miles

- Marseille – 662 miles

- Menorca – 863 miles

- Milan–Malpensa – 682 miles

- Murcia – 945 miles

- Mykonos – 1670 miles

- Nantes – 251 miles

- Naples – 1085 miles

- Newcastle upon Tyne – 256 miles

- Nice – 704 miles

- Olbia – 929 miles

- Palma de Mallorca – 859 miles

- Paphos – 2087 miles

- Paris–Charles de Gaulle – 285 miles

- Paris–Orly – 290 miles

- Pisa – 808 miles

- Porto – 755 miles

- Prague – 746 miles

- Preveza/Lefkada – 1421 miles

- Pula – 885 miles

- Reykjavík–Keflavík – 1121 miles

- Rome–Fiumicino – 968 miles

- Rovaniemi – 1436 miles

- Salzburg – 745 miles

- Santorini – 1726 miles

- Sharm El Sheikh – 2507 miles

- Sofia – 1359 miles

- Split – 927 miles

- Tenerife–South – 1766 miles

- Toulouse – 569 miles

- Turin – 645 miles

- Venice – 798 miles

- Zakynthos – 1484 miles

Note.

- There are nine routes under 400 miles, which might enable a round trip without refuelling in a ZEROe Turboprop.

- There are nine routes under 800 miles, which might enable a round trip without refuelling in a ZEROe Turbofan.

- There are only four routes over 2000 miles, which might make a single trip difficult in a ZEROe Turbofan.

- Bristol and Toulouse is a convenient 569 miles for Airbus and its employees, customers and contractors.

It does appear that, EasyJet’s routes fit the 1000 mile range of a ZEROe Turboprop and the 2000 mile range of a ZEROe Turbofan exceedingly well.

Conclusion

Bristol will be important in the development of Airbus’s three ZEROe aircraft.

Could An A320 neo Be Rebuilt As A ZEROe Turbofan?

This post is a follow-up to ZEROe – Towards The World’s First Zero-Emission Commercial Aircraft.

I spent a lot of time yesterday, looking at YouTube videos of the following.

- Airbus A320 aircraft

- Airbus A 320 neo aircraft

- Airbus’s proposed ZEROe Turbofan aircraft

I also captured these profiles from the Airbus web site, of three members of the new Airbus A 320 neo family and the current Airbus A 320 ceo.

A 319 neo – Length – 33.84 metres – Max Passengers – 160

A 320 neo – Length 37.57 metres – Max Passengers – 194

A 321 neo – Length 44.51 metres – Max Passengers – 244

A 320 ceo – Length 37.57 – Max Passengers – 180

Note.

- The links on each variant lead to Airbus’s on-line specification.

- All three variants have a wing-span of 35.8 metres and a height of 11.76 metres.

- All variants have sharklets or blended winglets to improve awrodynamic efficiency.

- There are different door, cargo door and window layouts on all three variants.

- The cockpits, tail and wings look similar.

This capture from an Airbus video, shows the profile of the proposed ZEROe Turbofan.

Note, that the ZEROe Turbofan looks more streamlined than the A 320 neo family, with a redesigned nose and more swept-back tailfin and sharklets.

These are my thoughts on the current A 320 neo family and their relationship with the ZEROe Turbofan.

Focus On Commonality

For each variant on the Airbus web site, there is a section with this title. This is the first sentence for the A 320 neo.

Due to its 95 per cent airframe commonality with the A320ceo (current engine option) version, Airbus’ A320neo jetliner fits seamlessly into existing A320 Family fleets worldwide – which is a key factor for the company’s customers and operators.

Will Airbus follow this philosophy with the ZEROe Turbofan?

If it worked between the changeover between the existing A 320 fleets and the A 320 neo fleets, why change the policy?

The Cockpits

The cockpits of the A 320 neo and the A 320 ceo seem to have a similar profile, but the cockpit of the ZEROe Turbofan seems to have been reprofiled.

In ZEROe – Towards The World’s First Zero-Emission Commercial Aircraft, I showed these front on views of the cockpits of the ZEROe Turboprop and ZEROe Turbofan.

I questioned if the two cockpits were related.

- A single cockpit for both aircraft would surely ease manufacture, maintenance and pilot training.

- I’m no aerodynamicist, but it certainly looks that the new cockpit will reduce drag and fuel consumption.

Although the cockpit, appears to be being used in the ZEROe for the first time, I would expect it is already under development and might feature in any later version of the A 320 neo.

The Fuselages

The fuselage width for both the A 320 neo family and the A 320 ceo are all 3.95 metres, with a maximum cabin width of 3.70 metres.

I would expect that the ZEROe Turboprop and the ZEROe Turbofan will also use this width.

Airbus use a design called Cabin-Flex to get the most out of the interior space in the A 320 neo. This paragraph is from the Wikipedia section, that is entitled Cabin-Flex.

By permanently replacing the second door pair in front of the wing (R2/L2) with a new second pair of overwing exits, the capacity of the A321neo is increased from 220 seats to 240 seats and fuel efficiency per seat is increased by 6%, exceeding 20% together with the new engines and the sharklets. The modifications should weigh 100 kg more.[82] Initial A321neos have the A321ceo exit door configuration with four exit door pairs until the Airbus Cabin-Flex (ACF) layout can be selected.

After reading the whole section, it looks to me, that the A 320 neo fuselage is designed, to be all things to all airlines and doors and seats can be arranged to fit any requirements.

In the ZEROe Turbofan, there is a large liquid hydrogen tank behind the rear pressure bulkhead, which could be brought forward a bit to give more space and hydrogen capacity.

I suspect there will be a lot of commonality between the fuselage of the A 320 neo family and that of a ZEROe Turbofan.

I spent a lot of time, as a child building Airfix models of aircraft and it may be too much of a simplification to think of these carbon-composite airliners, as giant Airfix models.

But I wouldn’t be surprised that just like the previous generation of aluminium airliners, they can be remanufactured into something different, just like British Airways Tristars, ended up as tanker-aircraft for the RAF.

I wouldn’t be surprised to find, that later A 320 neo fuselages will be able to be remanufactured into fuselages for ZEROe Turbofans.

Comparing The Fuselages Of The A 320 ceo, A 320 neo And ZEROe Turbofan

These are the three fuselage profiles.

A 320 ceo

A 320 neo

ZEROe Turbofan

Aircraft balance on the wings, which if I remember what little I know about aircraft aerodynamics and design, apply their lift forces to the centre of gravity of the aircraft.

I know that the profile of the ZEROe is to a different scale, but three things are apparent.

- The windows at the rear don’t go as far back, as they do in the two existing designs. But then there is no need for windows around the hydrogen tank.

- The hydrogen tank could be as long as a quarter of the length of the fuselage.

- The front section of the aircraft appears longer.

The longer front section would balance the weight of the hydrogen tank.

The passengers would also help to balance the weight of the tank, by being placed further forward.

There must be the possibility of creating a larger capacity and longer range variant of the ZEROe design, by adding a larger hydrogen tank and further stretching the nose.

Airbus have been stretching these designs for years, so I suspect that they have plans for a large number of possible variants of the ZEROe Turbofan.

According to the Wikipedia entry for the A 320 neo family, there are already five civil versions of the A 320 neo; A 319 neo, A 320 neo, A 321 neo, A 321LR and A 321XLR, plus corporate and military versions.

Add in the Cabin-Flex interior and the various A320s and the ZEROe to come, must be one of the most flexible transport systems in history.

The Tailplanes

As they are of the same height and look similar, the tail sections of the A 320 neo and A 320 ceo families could be almost identical, but the tail section of the ZEROe Turbofan appears to be slightly more swept-back and perhaps more aerodynamic.

As the ZEROe Turbofan, also appears to have had a nose-job, I would suspect that Airbus have a redesigned fuselage in the works to squeeze more fuel-efficiency out of this family of already very frugal aircraft. Could this feature the more aerodynamic tailplane?

Could this advanced fuselage feature in a later version of the A 320 neo?

I also feel, that the functionality of the tailplane on the ZEROe Turbofan will need to be little different to that on the earlier planes.

- The plane is still powered by two turbofan engines on the wings.

- Rudder forces, with an engine failure on one side, will still be the same.

The big difference will be that the fuel is at the back of the fuselage rather than in the wings, which will affect the balance.

Will this effect the design of the tailplane? I don’t think it will in a large way, as Airbus seem to have lengthened the nose to compensate.

The Wings

All the wings with sharklets for the A 320 neo family and the A 320 ceo have the same wingspan of 35.8 metres, so I would expect they are all substantially similar.

But there is one big difference in that the wings of the conventionally-powered aircraft are full of fuel.

This would probably mean that much of the wing stresses in the ZEROe Turbofan would be like an A 320 neo flying with little fuel in the wing tanks. As some aircraft in the A320 neo family have fuselage tanks, Airbus can even test the wing forces and handling in a real aircraft.

But it does look that Airbus will have little trouble designing, building and certifying the wing of a ZEROe Turbofan.

There is a minor difference in that the sharklets for the ZEROe Turbofan are more extreme.

But then as I said earlier, is there a new more aerodynamic airframe for the A 320 neo in the works?

Conclusion

I very much feel that there will be a route to convert some or all of the A 320 neo aircraft to hydrogen power.