RWE And the Norfolk Wind Farms

In March 2024, I wrote RWE And Vattenfall Complete Multi-Gigawatt Offshore Wind Transaction In UK, which described how Vattenfall had sold 4.2 GW of offshore wind farms, situated off North-East Norfolk to RWE.

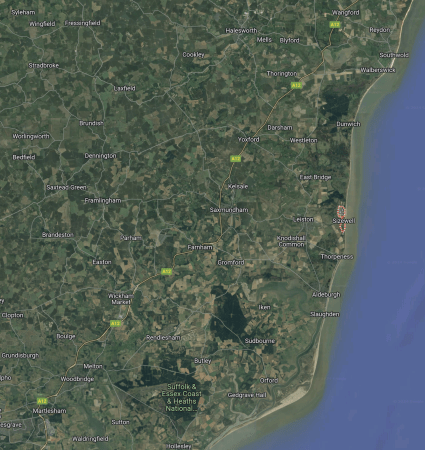

This map from RWE shows the wind farms.

Note.

- The Norfolk Zone consists of three wind farms; Norfolk Vanguard West, Norfolk Boreas and Norfolk Vanguard East.

- The three wind farms are 1.4 GW fixed-foundation wind farms.

- In Vattenfall Selects Norfolk Offshore Wind Zone O&M Base, I describe how the Port of Great Yarmouth had been selected as the O & M base.

- Great Yarmouth and nearby Lowestoft are both ports, with a long history of supporting shipbuilding and offshore engineering.

The wind farms and the operational port are all close together, which probably makes things convenient.

So why did Vattenfall sell the development rights of the three wind farms to RWE?

Too Much Wind?

East Anglia is fringed with wind farms all the way between the Wash and the Thames Estuary.

- Lincs – 270 MW

- Lynn and Inner Dowsing – 194 MW

- Race Bank – 580 MW

- Triton Knoll – 857 MW

- Sheringham Shoal – 317 MW

- Dudgeon – 402 MW

- Hornsea 3 – 2852 MW *

- Scroby Sands – 60 MW

- East Anglia One North – 800 MW *

- East Anglia Two – 900 MW *

- East Anglia Three – 1372 MW *

- Greater Gabbard – 504 MW

- Galloper – 353 MW

- Five Estuaries – 353 MW *

- North Falls – 504 MW *

- Gunfleet Sands – 172 MW

- London Array – 630 MW

Note.

- Wind farms marked with an * are under development or under construction.

- There is 4339 MW of operational wind farms between the Wash and the Thames Estuary.

- An extra 6781 MW is also under development.

If all goes well, East Anglia will have over 11 GW of operational wind farms or over 15 GW, if the three Norfolk wind farms are built.

East Anglia is noted more for its agriculture and not for its heavy industries consuming large amounts of electricity, so did Vattenfall decide, that there would be difficulties selling the electricity?

East Anglia’s Nimbies

East Anglia’s Nimbies seem to have started a campaign against new overground cables and all these new wind farms will need a large capacity increase between the main substations of the National Grid and the coast.

So did the extra costs of burying the cable make Vattenfall think twice about developing these wind farms?

East Anglia and Kent’s Interconnectors

East Anglia and Kent already has several interconnectors to Europe

- Viking Link – Bicker Fen and Jutland – 1.4 GW

- LionLink – Suffolk and the Netherlands – 1.8 GW – In Planning

- Nautilus – Suffolk or Isle of Grain and Belgium – 1.4 GW – In Planning

- BritNed – Isle of Grain and Maasvlakte – 1.0 GW

- NeuConnect – Isle of Grain and Wilhelmshaven – 1.4 GW – Under Construction

- GridLink Interconnector – Kingsnorth and Warande – 1.4 GW – Proposed

- HVDC Cross-Channel – Sellinge and Bonningues-lès-Calais – 2.0 GW

- ElecLink – Folkestone and Peuplingues – 1.0 GW

- Nemo Link – Richborough and Zeebrugge – 1.0 GW

Note.

- Five interconnectors with a capacity of 6.4 GW.

- A further four interconnectors with a capacity of 6 GW are on their way.

At 12.4 GW, the future capacity of the interconnectors between South-East England and Europe, is nor far short of South-East English wind power.

There are also two gas pipelines from the Bacton gas terminal between Cromer and Great Yarmouth to Europe.

The Wikipedia entry for the Bacton gas terminal gives these descriptions of the two gas pipelines.

Interconnector UK – This can import gas from, or export gas to, Zeebrugge, Belgium via a 235 km pipeline operating at up to 147 bar. There is a 30-inch direct access line from the SEAL pipeline. The Interconnector was commissioned in 1998.

BBL (Bacton–Balgzand line) – This receives gas from the compressor station in Anna Paulowna in the Netherlands. The BBL Pipeline is 235 km long and was commissioned in December 2006.

It would appear that East Anglia and Kent are well connected to the Benelux countries, with both electricity and gas links, but with the exception of the Viking Link, there is no connection to the Scandinavian countries.

Did this lack of connection to Sweden make convincing the Swedish government, reluctant to support Vattenfall in their plans?

Bringing The Energy From The Norfolk Wind Farms To Market

It looks to me, that distributing up to 4.2 GW from the Norfolk wind farms will not be a simple exercise.

- Other wind farms like the 2852 MW Hornsea 3 wind farm, may need a grid connection on the North Norfolk coast.

- The Nimbies will not like a South-Western route to the National Grid at the West of Norwich.

- An interconnector to Denmark or Germany from North Norfolk would probably help.

But at least there are two gas pipelines to Belgium and the Netherlands.

RWE, who now own the rights to the Norfolk wind farms, have a large amount of interests in the UK.

- RWE are the largest power producer in the UK.

- They supply 15 % of UK electricity.

- They have interest in twelve offshore wind farms in the UK. When fully-developed, they will have a capacity of almost 12 GW.

- RWE are developing the Pembroke Net Zero Centre, which includes a hydrogen electrolyser.

RWE expects to invest up to £15 billion in the UK by 2030 in new and existing green technologies and infrastructure as part of this.

Could this be RWE’s plan?

As the Norfolk wind farms are badly placed to provide electricity to the UK grid could RWE have decided to use the three Norfolk wind farms to produce hydrogen instead.

- The electrolyser could be placed onshore or offshore.

- If placed onshore, it could be placed near to the Bacton gas terminal.

- There are even depleted gas fields, where hydrogen could be stored.

How will the hydrogen be distributed and/or used?

It could be delivered by tanker ship or tanker truck to anyone who needs it.

In Developing A Rural Hydrogen Network, I describe how a rural hydrogen network could be developed, that decarbonises the countryside.

There are three major gas pipelines leading away from the Bacton gas terminal.

- The connection to the UK gas network.

- Interconnector UK to Belgium.

- BBL to The Netherlands.

These pipelines could be used to distribute hydrogen as a hydrogen blend with natural gas.

In UK – Hydrogen To Be Added To Britain’s Gas Supply By 2025, I describe the effects of adding hydrogen to the UK’s natural gas network.

Are Scotrail Going To Replace The Inter7City Trains With Hydrogen-Powered Trains?

This article in The Times is entitled The Caley Is Ready To Roll With New Venture Building Trains.

I feel that this is one of the most significant paragraphs in the article.

ScotRail has indicated that it wants to replace nearly two thirds of its fleet with new, low-carbon rolling stock between 2027 and 2035, comprising about 675 carriages in total, with an initial core order of 64 four and five-car units. A spokesman confirmed: “We are working on a business case that will go to the Scottish government for the procurement of a new suburban train fleet.”

The current Scotrail fleet includes.

- 25 Inter7City trains which comprise 52 Class 43 power cars and 120 Mark 3 carriages – Diesel – 120 cars – 1975

- 5 Class 153 trains – Diesel – 5 cars – 1987

- 42 Class 156 trains – Diesel – 84 cars – 1987

- 40 Class 158 trains – Diesel – 80 cars – 1987

- 30 Class 170 trains – Diesel – 90 cars – 1998

- 21 Class 318 trains – Electric – 63 cars – 1985

- 34 Class 320 trains – Electric – 66 cars – 1990

- 40 Class 334 trains – Electric – 120 cars – 1999

- 38 Class 380 trains – Electric – 140 cars – 2009

- 70 Class 385 trains – Electric – 234 cars – 2015

Note the last three fields are the traction type, total number of cars and the build year of the first train.

I will split these trains into four groups.

- Inter7City – Diesel – 25 trains – 120 cars

- BR Diesel – Diesel – 117 trains – 259 cars

- BR Electric – Electric – 55 trains – 129 cars

- Modern Electric – Electric – 148 trains – 494 cars

Note.

- This is a grand total of 345 trains and 1002 cars.

- Ignoring the modern electric trains and the total is 197 trains and 508 cars.

- The total for diesel trains is 142 trains and 359 cars.

- As Great Western Railway have withdrawn their similar GWR Castles, there must be reasons for Scotrail to do the same.

I will now look at replacement strategies, based on this statement from Scotrail.

ScotRail has indicated that it wants to replace nearly two thirds of its fleet with new, low-carbon rolling stock between 2027 and 2035, comprising about 675 carriages in total, with an initial core order of 64 four and five-car units.

I would expect 675 carriages would be about 232 trains, if the current average train length of just under three cars is carried over.

The Effect Of 675 New Carriages

Assuming that no modern electric trains were replaced, this would create a fleet size of at least 1169 carriages.

This would be a sixteen percent increase in carriages, which would be welcome news for some rail users.

The Initial Core Order Of 64 Four And Five-Car Units

All we know of this order, is the number of trains and that they will be new and low-carbon, according to indications from Scotrail.

Low-carbon would mean one of these traction options.

- Electric trains with full electrification.

- Battery-electric trains with partial-electrification.

- Hydrogen-powered trains.

Note.

- The heritage Taliban would object violently to full electrification of some historic routes.

- UNESCO would probably remove the World Heritable Site status to the Forth Bridge if it were to be electrified.

- Scotland is developing a hydrogen infrastructure.

- Hydrogen-powered trains have long ranges in the order of a thousand kilometres.

- Hydrogen-powered trains are essentially electric trains with a hydrogen fuel-cell to provide electricity as needed.

- Hydrogen-powered trains would need very little new infrastructure, except for a network of refuelling points across Scotland.

- Well-designed battery-electric and hydrogen-electric trains, should be very quiet and comfortable for passengers.

As an engineer, I would choose hydrogen-power for the initial core order.

Where would the initial core order be deployed?

Twenty-five would be used to replace the carbon-emitting elderly Inter7City trains.

These routes could probably handle the other forty.

- Aberdeen and Inverness

- Edinburgh/Glasgow and Aberdeen.

- Edinburgh/Glasgow and Inverness.

- Glasgow and South Western Line

- West Highland Line.

Note.

- A lot of diesel trains would be retired.

- Trains could be designed, for tourists with proper cycle spaces.

- The West Highland Line would get the five-car trains it needs.

This would be a good start.

Conclusion

It looks to me, that the Inter7City trains will be going and will be replaced by new trains.

But will Scotland take the great leap forward and power the new trains by Scottish hydrogen?

Feadship Ushers In The Fuel-Cell Era With The Launch Of118.80-metre Project 821

The title of this post, is the same as this press release from Feadship.

This picture from Feadship shows project 821.

These are the first two paragraphs of the press release.

When the drydock doors slid open on 4 May at Feadship’s Amsterdam shipyard, the yachting

world was forever changed. Say hello to Project 821, the world’s first hydrogen fuel-cell

superyacht. Five years in the making, innovation-packed Feadship Project 821 is the answer to

a fundamental question: “How far can we push green technology on superyachts?”Designed by RWD and with owners representation by Edmiston, Feadship’s bold response was

a multi-faceted, zero-diesel approach designed to cruise between harbours or anchorages and

to operate the yacht’s hotel load and amenities with emission-free power from green hydrogen.

“The aim has been to develop a new, clean technology not just for this project, but for the

world,” said Jan-Bart Verkuyl, Feadship Director / CEO Royal Van Lent Shipyard. The size of

the proposed yacht – 100-metres-plus – made it a good candidate to explore pure green

hydrogen as the fuel-cell source. For those captivated by cutting-edge innovations, this yacht

presents an opportunity for potential acquisition as it showcases the pinnacle of modern

technological advancements.

As the superyacht is 118.8 metres long, I can see a lot of ships of this size being powered by hydrogen.

ITM Power Seals PEM Electrolyser Deal With Hygen

The title of this post, is the same as that of this article on gasworld.

These three paragraphs give details of the deal.

ITM Power has struck a partnership with Hygen Energy to become the preferred supplier for Proton Exchange Membrane (PEM) electrolysers for major hydrogen projects within the UK and across Europe.

Hygen, a leading developer, producer and asset owner of low-carbon hydrogen production on the continent, focusing on the decarbonisation of mobility, construction and hard-to-electrify industries and power, is targeting 200 Megawatt (MW) of electrolyser projects across the continent.

The two-phase collaboration will see 50 MW of Neptune Plug and Play electrolysers across several projects, many of which will be based on UK government HAR2 or similar funding programmes, followed by 150 MW of larger-scale modular electrolysers. Each project will be subject to a Final Investment Decision (FID).

Note.

- This page on the iTM Power web site gives details of the Neptune electrolyser.

- Neptune appears to be a 2 MW electrolyser, so the first phase could be around 25 electrolysers.

- This news item on the iTM Power web site is entitled iTM Power And Sumitomo Complete Installation Of First If Its Kind Demonstration Electrolyser Un Japan.

Things seem to be looking up for iTM Power.

Conclusion

I can see a time in the not to distant future, where a large number of small-to-medium size electrolysers will be mopping up surplus electricity to create hydrogen.

How Hydrogen Will Power The Green Construction Eevolution

The title of this post, is the same as that of this news item from Ryze Hydrogen.

These two paragraphs introduce the news item.

According to the International Energy Agency buildings operations and construction emissions account for more than one-third of global energy-related emissions, significantly contributing to environmental degradation, with heavy machinery and standby power solutions relying heavily on fossil fuels.

Yet here at Ryze we know the industry stands on the brink of a green revolution, as clean energy solutions lead the charge towards decarbonisation.

The news item, is a must-read for anybody involved in construction.

Recently, a gas leak killed the roadside tree outside my house. I wrote about the incident in It Looks Like The Gas Leak Has Killed The Tree Outside My House.

What I didn’t say, was that when they cleaned up the mess, I had an eight-wheeled diesel truck with a grab, working outside my house for a couple of hours, spewing fumes everywhere.

Hopefully, green construction is friendlier to the neighbours and the workers on site.

High Speed Two is using green construction for this reason in sensitive locations.

Wrightbus Secures Further German Order For 46 Hydrogen Buses

The title of this post, is the same as that of this press release from Wrightbus.

These paragraphs outline the deal.

World-beating zero-emission bus manufacturer Wrightbus today announced a milestone deal to provide 46 hydrogen buses to Germany – taking a demo bus from Belfast to showcase its reliability and range.

The buses ordered by Cottbusverkehr GmbH will serve the city of Cottbus, the second largest city in the state of Brandenburg, and and in the western part of the district of Spree-Neiße.

It follows a landmark announcement by the German government to implement a €350 million scheme to support the production of renewable hydrogen.

Wrightbus is Europe’s fastest-growing bus manufacturer and follows the company’s rapid rise since it was bought out of administration in 2019. It was named Northern Ireland’s fastest-growing company by Growth Index this week – employing 1,650 people and producing 22 buses a week.

The Cottbus order for the Kite Hydroliner buses follow deals in Germany with West Verkehr, Regionalverkehr Köln GmbH (RVK), and Saarbahn GmbH, with more European orders in the pipeline.

If Northern Irish hydrogen buses are selling well to the Germans, why are there so few in the UK.

These pictures show the UK version of the German buses in Crawley.

They are excellent buses.

This Hydrogen Engine From Kia And Hyundai Heralds A New Dawn In Automotive – Everything Will Change – Lagrada

The title of this post, is the same as that of this article on Hydrogen Central.

These are the first two paragraphs.

Hyundai and Kia recently unveiled in Korea a zero-emission hydrogen engine that could disrupt the EV market. Both automakers are at the forefront of the development of hydrogen technology, focusing on both fuel cell systems and investigating the possibilities of sophisticated hydrogen engines.

The future of sustainable mobility is being shaped by Hyundai and Kia’s continuous research and dedication to hydrogen as a clean transportation solution. An increasing number of manufacturers are developing hydrogen engines as an alternative to electric cars and vehicles that use polluting combustion engines.

These three paragraphs outline more details of the engine.

What’s more remarkable about this new hydrogen engine presented in Korea is that it solves all the problems of durability and large-scale viability that hydrogen engines have presented until now.

The project team successfully ensured that the Hyundai-Kia hydrogen engine, designed to burn hydrogen, could sustain high thermal efficiency throughout its operation by infusing hydrogen into the combustion chamber at a pressure of 30 bar.

Although the device’s performance was enhanced by the use of a turbocharger, it was found that the enhanced performance and lower pollution emissions of this kind of “direct injection” eliminated the problems that most automakers have with hydrogen engines. As the emissions of carbon dioxide and fine particles were reduced by 99% and 90%, the Hyundai-Kia hydrogen engine would be considered to have zero emissions.

Thirty years ago, I was involved with a company called DMW.

- The company’s first product was an aerosol valve, that instead of using CFCs or HCFCs as a propellent used nitrogen. The patent was sold to Johnson and Johnson, after being shown during the discussions, that led to the Montreal Protocol and the phase out of CFCs.

- This led to a deal with Glaxo to investigate if DMW’s technology could be used in a metred-dose-inhaler for asthma drugs.

- The successful idea was eventual sold to Boehringer Ingelheim and is now marketed as Respimat.

I can compare the Hyundai-Kia hydrogen injector and the Respimat inhaler

- Hyundai-Kia appear to be using a high pressure of 30 bar to sustain high-thermal efficiency.

- I know that the Respimat inhaler uses high pressure to obtain a fine mist of the drug.

It sounds to me, that both companies are using the same properties of applying high pressure to a small hole, to disperse one fluid in another.

Developing A Rural Hydrogen Network

On my last stud farm, we had three regular fuel deliveries.

- Propane to heat the house.

- Red diesel to power the tractor and farm machinery.

- Road diesel to power the horse box and a couple of diesel cars, that went on the roads.

Note.

- Like most farms in the UK, we didn’t have mains gas.

- The local low-life of whom you never speak their name, used to regularly steal the diesel.

- The police did nothing to stop the thefts as the culprits are untouchable.

- We had two boilers, that both ran on the propane.

- Modern boilers can be converted to use hydrogen.

- All cars, trucks, farm vehicles and machinery could in the future use hydrogen.

Propane and diesel would be replaced by clean hydrogen.

Delivering The Fuel

Consider.

- Propane and diesel are currently delivered in rural areas by truck.

- Hydrogen will be delivered the same way and stored in a tank designed for hydrogen, which could be similar to current propane tanks.

- Boilers would be directly piped to the hydrogen tank.

- The technology exists to fill hydrogen-powered vehicles and equipment from hydrogen tanks.

- I believe that a theft-proof hydrogen tank would be possible.

- The hydrogen will be delivered as needed in a hydrogen-powered truck.

I believe companies like Centrica, will develop the technology so that farms and businesses could have their own hydrogen system.

Collateral Benefits

These would be collateral benefits.

- One set of tankers would be replaced by a single zero-carbon hydrogen tanker, thus reducing road traffic.

- I believe there would be less fuel theft.

- Rural businesses, that needed gas like blacksmiths could be supplied.

- A lot of buildings with a propane-fuelled boiler could be converted to hydrogen.

It would be a path to decarbonisation of the rural economy.

Supplying The Hydrogen

Electrolysers would be needed around the country.

Some could be based on nuclear sites, where others could be powered by offshore wind.

Hydrogen Safety

Hydrogen safety has its own Wikipedia entry.

The entry starts with a description of the Hindenberg Disaster, which has a detailed Wikipedia entry of its own.

I’ve spoken to someone, who was there; Dory Previn, who later wrote a song about it.

The Hydrogen safety Wikipedia entry has this paragraph.

There are many codes and standards regarding hydrogen safety in storage, transport, and use. These range from federal regulations, ANSI/AIAA, NFPA, and ISO standards. The Canadian Hydrogen Safety Program concluded that hydrogen fueling is as safe as, or safer than, compressed natural gas (CNG) fueling,

I’ve also talked to German schoolchildren about their hydrogen trains and as you are educated about hydrogen, the fear decreases and the safety increases.

Sizewell C And Hydrogen

The Sizewell C web site has a page with a title of Hydrogen and SZC.

The page asks this question.

Why Does Sizewell C Want To Produce Hydrogen?

It gives this answer.

Nuclear is a great way of producing hydrogen as it generates huge amounts of reliable, low-carbon energy. Nuclear and hydrogen are also two clean technologies that can help us make big reductions in carbon emissions. While both technologies are vital on their own, at Sizewell C we have an exciting vision to bring them together.

The page is worth a read about how they will use the hydrogen, which will include.

- Providing Wrightbus hydrogen-powered buses to link the main construction site with Park-and-Ride sites on the A 12 at Darsham and Wickham Market.

- Powering vehicles and machinery on the main construction site.

- Supplying hydrogen to Freeport East.

- Refuelling hydrogen vehicles.

I have a few thoughts.

Supplying Hydrogen To Users

On my last stud farm, we had three fuel deliveries.

- Propane to heat the house.

- Red diesel to power the farm machinery.

- Road diesel to power the horse box and a couple of diesel cars, that went on the roads.

Note.

- Like most farms in East Anglia, we didn’t have mains gas.

- The local low-life of whom you never speak their name, used to regularly steal the diesel.

- We had two boilers, that ran on the propane.

- All farm vehicles and machinery will in the future use hydrogen.

- Propane and diesel would be replaced by clean hydrogen.

I believe companies like Centrica, will develop the technology so that farms and businesses could have their own hydrogen system, that would be topped-up accordingly, by road tankers, which themselves would be fuelled by hydrogen.

One set of tankers would be replaced by another zero-carbon set.

Sizewell sits on the Suffolk Coast and it appears, there will be a new road link to the A 12, which connects to Suffolk’s main road system.

This map shows Sizewell C and East Suffolk.

Note.

- The Sizewell site is outlined in pink on the coast, about halfway up the map.

- The A 12 road and the East Suffolk Line run almost parallel to the coast between Ipswich in the South and Lowestoft and Yarmouth in the North.

Energy use in East Suffolk would be transformed and all because there will be a plentiful supply of zero-carbon hydrogen.

Hydrogen And The Arts

Suffolk has been an artistic county for hundreds of years and some works of art, like casting bronzes, firing pottery or working with glass or wrought iron need a lot of energy. Local hydrogen networks supplied by tanker, as propane is now could help to decarbonise one of the most difficult of professions.

Pink Hydrogen

This page on the National Grid web site explains the various hydrogen colours.

It describes pink hydrogen like this.

Pink hydrogen is generated through electrolysis powered by nuclear energy. Nuclear-produced hydrogen can also be referred to as purple hydrogen or red hydrogen.

In addition, the very high temperatures from nuclear reactors could be used in other hydrogen productions by producing steam for more efficient electrolysis or fossil gas-based steam methane reforming.

I also call it Barbie hydrogen.

Sizewell C would be an ideal place to create pink hydrogen.

Before Sizewell C is up and running, the electrolyser at Sizewell could be powered by Sizewell B or even offshore wind.

MAN Expands Its Zero-Emission Portfolio

The title of this post, is the same as that of this press release from MAN.

This is the first paragraph.

Commercial vehicle manufacturer MAN Truck & Bus will be the first European truck producer to launch a small series with a hydrogen combustion engine. The initially planned small series of around 200 units is to be delivered to customers in Germany, the Netherlands, Norway, Iceland and selected non-European countries as early as 2025. The “MAN hTGX”, as the vehicle will be called, offers an alternative zero-emission drive variant for special applications, for example for transporting heavy goods – such as construction work, tank transport or timber transport. The hTGX can also be an environmentally friendly alternative to battery-electric trucks for use in areas without sufficient charging infrastructure or for markets where sufficient hydrogen is already available. MAN will hand over its battery-electric truck to customers for the first time in 2024 and scale it up from 2025. MAN has been the market leader for electric city buses in Europe since 2023.

Note.

- The hydrogen truck is based on the proven TG vehicles.

- The engine is a hydrogen version of one of their current diesel engines.

- The vehicle will satisfy the forthcoming EU regulations on carbon dioxide emissions.

- The maximum range is up to 600 kilometres, which would allow London and Edinburgh, provided there was a hydrogen supply at both ends.

- With hydrogen compressed to 700 bar (CG H2) and a tank capacity of 56 kg, the vehicle can be refuelled in less than 15 minutes.

This could be a very useful truck for the UK.