Network Rail’s Test Track Take Centre Stage As Hydrogen Is Delivered By Rail For The First Time

The title of this post, is the same as that of this press release from GeoPura.

These three paragraphs introduce the story.

Network Rail, working with rail and energy partners Freightliner and GeoPura, has transported hydrogen for the first time on Britain’s rail network, marking a major step forward for both the rail and energy sectors.

The milestone was achieved yesterday (Wednesday 3 December) at Network Rail’s Test Tracks* site in Tuxford, where freight operator Freightliner hauled a train of gas containers from Doncaster to High Marnham – marking Britain’s first shipment of hydrogen by rail.

It was part of a rail and energy industry innovation event showcasing several hydrogen initiatives. This included the first re-engineered hydrogen-powered shunting locomotive – seen as a step towards replacing diesel – another milestone towards the rail industry’s goal of becoming net zero. The event also demonstrated HPU hydrogen-powered generators, lighting towers and support vehicles.

These two paragraphs describe Network Rail’s test track at Tuxford and GeoPura’s hydrogen production facility at High Marnham.

Network Rail’s site at Tuxford runs all the way to High Marnham, where it sits adjacent to HyMarnham Power, the UK’s largest green hydrogen production facility operated by GeoPura and JG Pears. Built on the site of a former coal-fired power station, HyMarnham Power is one of the world’s first rail-connected hydrogen production facilities, and Network Rail’s Tuxford site will be the world’s first net-zero railway testing facility.

Currently, hydrogen is transported by road. This breakthrough marks a major step towards the rail network becoming a ready-made hydrogen distribution system, a rolling pipeline, with connections to all major industrial and urban centres across Britain – proving the practical capability of rail to transport hydrogen at scale. Hydrogen will also be utilised to decarbonise wider rail operations, from construction to ongoing maintenance and off-grid operations.

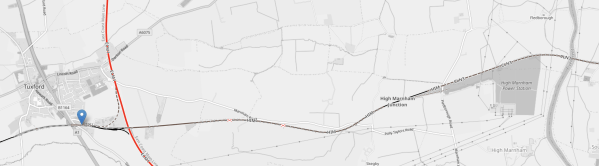

This OpenRailwayMap shows Tuxford and High Marnham.

Note.

- The blue arrow is Tuxford West junction.

- The North-South red track is the East Coast Main Line. East-West track indicated by the blue arrow is Network Rail’s Test Track

- The grey area, to the South of the Test Track in the East is the former site of High Marnham power station, where GeoPura have their hydrogen facility.

- If you continue East on the Test Track it connects to the Sheffield and Lincoln Line at Pye Wipe junction.

Sheffield could be the sort of city, that would need a lot of hydrogen to decarbonise.

Has Hydrogen Been Transported From ICI’s Former Site At Runcorn By Rail

I ask this question, as I used to work at Runcorn in the 1960s, and I don’t remember seeing any hydrogen railway wagons.

I asked Google AI, the question in the title of this section and received this answer.

Hydrogen is typically transported from the INEOS (formerly ICI) site in Runcorn via pipeline or by road in cryogenic liquid tanker trucks or gaseous tube trailers, but it has not been historically transported by rail from that specific site.

The first ever trial shipment of hydrogen by rail on Britain’s network took place only very recently, in December 2025, as part of an industry innovation event. This trial involved transporting hydrogen containers from Doncaster to High Marnham, adjacent to the HyMarnham Power green hydrogen production facility.

It looks like my memory and Google AI agree.

GeoPura’s Construction World First

On the GeoPura web site there is a case study, which is entitled Construction World First.

These two paragraphs outline what was done.

Working in partnership with Siemens Energy our hydrogen fuel cell system, has provided off grid power and heat to National Grid’s UK Viking Link construction site.

The fuel cell system removes the need for diesel generators and provides innovative, sustainable, low carbon energy to the Viking Link interconnector project site.

The interesting thing, is that the heat that the hydrogen fuel cell gives out is collected and used to heat the remote site.

This last paragraph, explains the need for off grid power.

Off grid power is needed as this site didn’t have a grid connection for at least six to eight months, and the fuel cell system provided enough heat and power for the construction village during that time, removing the need for diesel generators.

There’s more in this Siemens Energy report.

HS2 Smashes Carbon Target

The title of this post, is the same as that of this article on Rail Engineer.

This is a must-read article which explains how the various companies building High Speed Two are progressing in making all of the work sites diesel-free.

GeoPura is mentioned in the article and on this page on GeoPura’s case studies, which is entitled HS2 Reveals Successful Results Of Hydrogen Generator Trial, full details of the trial are given.

An HS2 construction site in London has held successful trials for two zero-emissions hydrogen fuel cell-based electricity generators – cutting carbon and improving air quality for workers and the local community.

The two GeoPura 250kVA hydrogen power units (HPUs) were trialled over the last year at HS2’s Victoria Road Crossover Box in Ealing, as a direct replacement for diesel generators to power machinery on the site.

There is also this video from High Speed Two.

Note.

- The use of electric cranes, diggers, dump trucks.

- The red trailer with lots of small cylinders, which is used to supply hydrogen.

- HS2 are also using HVO and flywheels to store energy.

- The video is narrated by HS2’s Air Quality Manager. If every project had one of these, it must surely speed decarbonisation.

We need more electric construction.

National Grid Goes Carbon-Free With Hydrogen-Powered Substation Trial

The title of this post, is the same as that of this press release from National Grid.

These are the main bullet points.

- Hydrogen powered unit (HPU) quietly provided carbon-free electricity to National Grid’s Deeside Centre for Innovation

- Only emission is water

- HPUs could save an estimated 500,000 kg of carbon across all National Grid substation sites

I am an Electrical Engineer and I had never realised that all those electricity substations around the country need a backup electricity generator.

These four paragraphs describe the trial and the generator used.

A GeoPura 250kW hydrogen power unit (HPU) contained within a transportable shipping container measuring 7.2 m by 2.5 m was installed at DCI and produced the energy to power low-voltage equipment needed for National Grid’s innovation testing projects and site operations. The trial tested the capabilities and feasibility of HPUs as direct replacements for backup diesel generators across more than 250 National Grid substation sites, the data will now be analysed and shared later this year.

National Grid currently use diesel generators alongside batteries to provide backup power to a substation for key activities such as cooling fans, pumps, and lighting, enabling it to continue to perform its crucial role in the electricity transmission system.

These backup generators are rarely used and have less than a 1% chance of operating per year, however, on the rare occasion that backup power is required, changing from diesel to low-carbon emission alternatives have the potential to reduce carbon intensity by 90%* and save over 500,000 kg of carbon emissions.

The HPU at Deeside has power capabilities of up to 100 kW in continuous operation mode and up to 250 kW for 45 minutes and uses 100% green hydrogen. The unit is quieter and the hydrogen cannisters used to fuel the generators can be safely stored on site.

I have some thoughts.

Deeside Centre For Innovation

The Deeside Centre for Innovation (DCI), a state-of-the-art testing facility hosting a 400 kV modified substation, designed as a unique environment for development and trial of innovative technologies and practices.

I think there’s something rather cunning about the DCI, as it means that anybody with a good idea will probably approach National Grid for help with the testing.

Visit Deeside Centre for Innovation for more information.

GeoPura

GeoPura has a totally zero-emissions answer to how we’re going to generate, store and distribute the vast amount of energy required to decarbonise our global economies. Or so their web site says!

This page on GeoPura’s web site, gives several case studies of how they work.

They would appear to provide zero-carbon power in widespread locations for Winterwatch, Springwatch etc. for the BBC.