Visiting The Consultation For Ferrybridge Next Generation Power Station At Knottingley

Yesterday, I visited the first meeting for the consultation on Ferrybridge Next Generation Power Station, which was held in the old town hall at Knottingley.

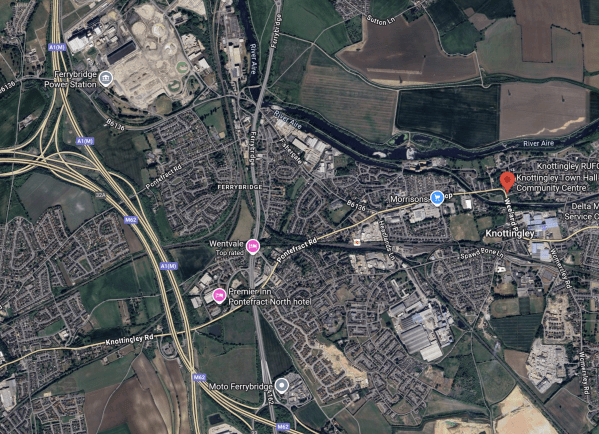

This Google Map shows the power station in relation to Knottingley.

Note.

- The meeting was held in the Knottingley Town Tall Community Centre, which is marked by the red arrow.

- I had arrived by train from Wakefield at Knottingley station and I was lucky enough to be able to get a taxi to the Town Hall.

- Knottingley station is marked on the map about a twenty-minute walk to the West of the Town Hall.

- The Ferrybridge power station site is in the North-West corner of the map and appears to be bordered by the B6136 road.

- The A1 (M) and the M 62 motorways run North-South past the power station site.

- The A (M) motorway continues North-South to Newcastle and Scotland, and London respectively.

- The M62 motorway continues West-East to Liverpool and Manchester, and Hull respectively.

- The well-appointed Moto Ferrybridge services is accessible from both motorways.

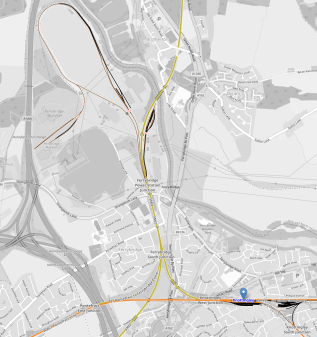

This OpenRailwayMap shows the rail lines in the area.

Note.

- The A 62 and A 1(M) motorways running down the West side of the map.

- Knottingley station is on the Pontefract Line, and is marked by a blue arrow.

- The Pontefract Line could have connections from both East and West to the Ferrybridge power station site via Ferrybridge Power Station junction.

- The loop, where the merry-go-round coal trains turned, appears to be still intact at the North of the power station site.

Will these rail lines be any use in the building and operation of the new power station?

These are my thoughts.

Fuel For The Power Station

The brochure for the consultation says this about the fuel for the Ferrybridge Next Generation Power Station.

Ferrybridge Next Generation Power Station will be designed to run on 100% hydrogen, natural gas or a

blend of natural gas and hydrogen.

The brochure has an informative section, which is entitled Natural Gas Pipeline Corridors.

Additionally, I should say, that I lived within a couple of hundred metres of a major gas pipeline in Suffolk, for over twenty years and it was the most unobtrusive of neighbours.

The brochure also says this about hydrogen safety.

As with all of our sites, appropriate measures will be

in place to ensure safe operation. Hydrogen is not

inherently more dangerous than other fuel sources.Hydrogen is flammable and must be handled with care,

just like other flammable fuels. To ignite, hydrogen

must be combined with an additional oxidising agent,

such as air or pure oxygen, in a specific concentration

and with an ignition source (a spark).

It is nearly sixty years ago now, since I worked as an Instrument Engineer, in ICI’s Castner-Kellner works at Runcorn, where hydrogen, chlorine and caustic soda were produced by the electrolysis of brine.

The plant was an unhealthy one, as it used a lot of mercury and my main task, was to design instruments to detect mercury in air and operators’ urine.

The Wikipedia entry for the Castner-Kellner process is a fascinating read and explains why it is being replaced by much better modern mercury-free processes.

I asked Google AI, if the Castner-Kellner process is still used and received this reply.

No, the Castner-Kellner process, a type of mercury cell for producing chlorine and caustic soda, is now largely obsolete due to occupational health and mercury pollution concerns, though a few plants may still operate globally. Modern chlor-alkali processes primarily use safer diaphragm cell and membrane cell technologies to produce chlorine and other chemicals from brine electrolysis.

I suspect that countries, where life is cheap, still use this process, which is very dangerous to those that work on the plant.

INEOS now own ICI in Cheshire and they still produce a large proportion of the hydrogen, chlorine and caustic soda, that the UK needs, but in a much safer way.

The question has to be asked about how hydrogen will be delivered to the Ferrybridge site.

Consider.

- SSE are developing a large hydrogen store at Aldbrough.

- Centrica are developing a large hydrogen store at Brough.

- Both of these stores could be connected to the German AquaVentus system, as the Germans are short of hydrogen storage.

- There is an East Coast Hydrogen Delivery Plan, which could probably have an extension pipeline to the Ferrybridge site.

- The East Coast Hydrogen Delivery Plan, talks of a hydrogen capacity of 4.4 GW.

I don’t feel, that this is the sort of project, that will be delivered until the mid-2030s, at the earliest.

There is also one other important development, that will require hydrogen at Ferrybridge.

I asked Google AI, if there will be hydrogen-powered coaches by 2030 and received this reply.

Yes, there will be hydrogen-powered coaches and buses by 2030, particularly in the UK and EU, with government strategies and funding promoting their deployment, especially for routes requiring high range and quick refueling where battery-electric models may be less suitable. For example, the EU’s CoacHyfied project is developing fuel cell coaches, and the UK government envisions hydrogen playing a role in its transport decarbonization by 2030, with potential to accelerate its zero-emission bus goals.

The nearest you can get to a hydrogen-powered coach in England, is to take an upmarket Wrightbus upmarket hydrogen-powered bus between Sutton station and Gatwick Airport.

- It is mouse quiet and vibration-free.

- It handles the hills with alacrity.

- I wrote about my journey in Sutton Station To Gatwick Airport By Hydrogen-Powered Bus.

That journey convinced me of the superiority in many ways of a hydrogen bus or coach over its diesel cousins.

I believe that this superiority will see large growth in hydrogen-powered long-distance coaches in the next few years.

But I also feel that some specialist transport, like horse transport, will go the hydrogen route.

As there are services at Ferrybridge, where two important motorways cross, I can envisage that the services will need to be able to refuel passing hydrogen buses, coaches trucks and other heavy vehicles, as well as the occasional car.

So would it be possible to supply hydrogen for the motorway services, by the same route as the power station?

I believe that the hydrogen could come from Saltend to the East of Hull, so I gave Google AI the phrase “Saltend zero-carbon hydrogen” and received this reply.

Saltend is home to several initiatives for producing and utilizing zero-carbon hydrogen, most notably the H2H Saltend project by Equinor, which aims to build the world’s largest hydrogen production plant with carbon capture capabilities by 2026 to supply industrial users at the Saltend Chemicals Park. Additionally, a new green hydrogen facility is planned for the park by Meld Energy with a target operation in early 2027, and a separate low-carbon hydrogen plant by ABP, HiiROC, and px Group is also being developed to meet local industrial demand. These projects collectively contribute to the broader Zero Carbon Humber initiative, which seeks to significantly reduce industrial emissions in the region.

Note.

- Saltend will certainly have enough zero-carbon hydrogen for everybody who wants it.

- Delivery dates in a couple of years are being talked about.

- Local industrial demand could be satisfield using specialised trucks, just as ICI used in the 1960s.

- As the Germans want to connect their AquaVentus system to Humberside, any excess hydrogen, could always be sold across the North Sea.

- OpenRailwayMap shows that Saltend is rail-connected.

But how do you get hydrogen between Saltend and Ferrybridge?

I am sure, that hydrogen could be delivered by truck from Saltend to Ferrybridge, but would the locals allow a stream of hydrogen trucks on the roads.

On the other hand, both Saltend and Ferrybridge are both rail-connected, so would it be possible to deliver the hydrogen by rail?

Google AI says this about railway wagons for hydrogen.

Railway wagons for hydrogen transport include liquid hydrogen tank cars (tankers) for transporting cryogenic liquid hydrogen and compressed gas tank cars for carrying hydrogen in its gaseous state or bound within carrier mediums like ammonia or methanol. Hydrogen fuel cell technology is also being developed for use on trains themselves, with a hydrogen fuel cell generator wagon providing power for main-line, non-electrified freight routes.

I believe that it will be possible to develop trains of an appropriate length to shuttle hydrogen between where it is produced and where it is used.

Such a specially-designed shuttle train would be ideal for moving hydrogen between Saltend and Ferrybridge.

- Once at Ferrybridge, the train would be connected to the local hydrogen system feeding the power station, the motorway services and any local businesses that needed hydrogen.

- The trains could be hydrogen fuel cell powered, so they could use any convenient route.

- Like hydrogen powered buses, I suspect they could be mouse quiet.

- The trains would be sized to perhaps deliver a day’s hydrogen at a time.

- There could only be minor changes needed to the rail system.

- If required, the trains could could deliver their cargo in the dead of night.

It could even be based on the contept of the TruckTrain, which I wrote about in The TruckTrain.

Torvex Energy

Hydrogen And Chlorine Production At ICI Mond Division in The 1960s.

In my time in the late 1960s, when I worked For ICI Mond Division, I spent time in the Castner-Kellner works trying fairly unsuccessfully to develop an analyser to detect mercury-in-air in the Castner-Kellner process, that created chlorine and hydrogen from brine.

The process is not a nice one as it uses a mercury cathode and Wikipedia says this about safety.

The mercury cell process continues in use to this day. Current-day mercury cell plant operations are criticized for environmental release of mercury leading in some cases to severe mercury poisoning (as occurred in Japan). Due to these concerns, mercury cell plants are being phased out, and a sustained effort is being made to reduce mercury emissions from existing plants.

ICI felt that a mercury-in-air analyser would help to make the plant safer.

But ICI did have an alternative way to produce the chlorine they needed for selling as a gas or liquid or using as a base chemical for products like disinfectants, bleaches and dry cleaning fluids, without the use of mercury.

It was only a small plant and I was taken there once.

As with the Castner-Kellner process, it used a series of electrolyser cells.

- These were smaller and had a tub, with a concrete lid.

- The anode and cathode and the pipes collecting the hydrogen and the chlorine went through the lid.

- They were rebuilt regularly.

- As with the Castner-Kellner process, brine is electrolysed.

- The process was old and probably dated from before the Castner-Kellner process.

But of course as there was no mercury, the hydrogen and chlorine were pure and could be used for certain types of manufacture like pharmaceuticals.

Torvex Energy

This article on Hydrogen Fuel News is entitled Stockton R&D Firm Unveils New Hydrogen From Seawater Production Process.

These are some points from the article.

- Torvex Energy, a Stockton research and development company, recently unveiled a new technique for producing hydrogen from seawater.

- This unique method of producing hydrogen from seawater does not result in oxygen gas emissions.

- As such, it is clearly quite different from more traditional water electrolysis methods used for producing green H2.

- The team behind the production method call it an environmentally friendly technique.

- There is no desalination process.

- The firm has patents pending on this unique form of electrochemical process.

- It worked with the Material Processing Institute to establish proof of concept for this purpose.

I originally felt that Torvex Energy may have updated the ancient ICI process, that I saw over forty years ago, but when I asked the company, they said it was different.

It now appears that they haven’t, which means they must have found a totally new process.

There is certainly an ongoing patent application with a number of gb1900680.8.

How Efficient Is The Torvex Energy Process?

This will be key and there is nothing on their web site or on the Internet to indicate, if the Torvex Energy process is more or less efficient than traditional electrolysis.

Offshore Hydrogen Production

The main application for the Torvex Energy process must surely be in the production of hydrogen offshore.

- A fleet of floating wind turbines could surround a mother platform with a Torvex Energy process.

- The hydrogen could then be sent ashore in a pipeline.

- If there to be a handy depleted gas field, this possibly could be used to store the gas.

Depending on the efficiency of the Torvex Energy process, this could be a more cost-effective way to bring energy ashore, as gas pipelines can be more affordable, than HVDC electrical links. Especially, if the pipeline already exists.

Conclusion

Torvex Energy would have appeared to have made a major breakthrough in the production of hydrogen.

Frankfurt Starts Building Fuel Station For World’s Biggest Zero-Emissions Train Fleet

The title of this post, is the same as that of this article on Reuters.

These are the two opening paragraphs.

German regional transport group RMV began construction on Monday of a filling station near Frankfurt that will use hydrogen generated as a by-product of chemicals manufacturing to fuel the world’s largest fleet of zero-emissions passenger trains.

France’s Alstom will deliver 27 hydrogen-powered fuel cell trains to the Infraserv Hoechst industrial park in the Rhine-Main region in mid-2022. Starting regular local services by that winter, the fleet will replace diesel engines.

All the investment will be partly funded by fares.

Chlorine Manufacture

I find it interesting, that the article also states that the hydrogen comes as a by-product of chlorine manufacture. When I worked in a ICI’s electrolysis plant around 1970, their plant used the Castner-Kellner process to produce both gases.

The process uses a lot of mercury and Wikipedia says this about the future of the process.

The mercury cell process continues in use to this day. Current-day mercury cell plant operations are criticized for environmental release of mercury leading in some cases to severe mercury poisoning as occurred in Japan Minamata_disease. Due to these concerns, mercury cell plants are being phased out, and a sustained effort is being made to reduce mercury emissions from existing plants.

Are INEOS, who now own the Runcorn plant, and the Germans still using the Castner-Kellner process?

I remember two stories about the theft of mercury from the Runcorn plant.

Mercury was and probably still is very valuable, and it was always being stolen. So ICI put a radioactive trace in the mercury, which didn’t affect the process. The result was that all legitimate metal dealers on Merseyside bough Geiger counters to check any mercury before they bought it.

One guy thought he had found the ideal way to steal mercury, so he filled his bike frame with the metal and wheeled it to the gate. Whilst he clocked out, he propped the bike against the gate-house. Unfortunately, it fell over and because of the weight of the mercury, he was unable to pick it up.

My work in the plant, involved devising a portable instrument that would detect mercury in air and a colleague’s project was to develop a way of detecting mercury in urine samples from the plant operatives.

Those projects say a lot, about why we should be careful around any process involving mercury.