Heathrow Shutdown Caused By Problem Found Seven Years Ago

The title of this post, is the same as that of this article on the BBC.

This is the sub-heading.

Issues at an electrical substation which caused a fire that resulted in Heathrow Airport closing were first detected seven years ago but not fixed, a report has found.

These two paragraphs, explain the problem.

The National Energy System Operator (NESO) said moisture entering electrical components at the North Hyde substation caused the blaze at the site that supplies the UK’s biggest airport with power.

It revealed an elevated moisture reading had been first detected in July 2018, but that “mitigating actions appropriate to its severity were not implemented”, with basic maintenance cancelled.

This was a failure of National Grid’s management and I suspect the company will received a severe punishment.

But what worries me, is that power networks are built from a series of standard components.

So how many other North Hydes are waiting to happen?

National Grid Pioneers UK-First Trial Of 3D Printed Technology For Low-Carbon Substations

The title of this post, is the same as that of this press release from National Grid.

These three bullet points act as sub-headings.

- Collaboration with Hyperion Robotics and the University of Sheffield will trial low-carbon 3D-printed concrete foundations including at National Grid’s Deeside Centre for Innovation in North Wales

- Innovation could reduce waste, carbon emissions and costs to consumers of network construction

- If rolled out across National Grid substations the technology could save up to 705 tons of concrete and 323 tons of CO2 and deliver £1.7 million in consumer savings versus traditional methods over a 10-year period

These two paragraphs give more details.

National Grid is working with Hyperion Robotics and the University of Sheffield on a UK-first trial to manufacture, install and test 3D-printed substation foundations, which have the potential to reduce construction-driven carbon emissions and reduce costs to consumers of network construction. This is part of National Grid’s commitment to leverage innovation to future-proof the network.

If the project is successful and the technology is rolled out across all National Grid substations, it is estimated it could save up to 705 tons of concrete and 323 tons of CO2 over a 10-year period, and deliver £1.7 million in consumer savings versus traditional methods.

The foundation design will deliver significant savings across the entire value chain.

- 70% reduction in concrete usage

- 80% less soil displacement

- 65% decrease in embodied carbon emissions

- 70% weight reduction compared to typical foundations

- 50% reduction in site operative hours, streamlining production

The foundations will be designed and produced in Finland by Hyperion Robotics, and tested at full-scale by the University of Sheffield. Further field testing will then be carried out at National Grid’s state-of-the-art testing facility, the Deeside Centre for Innovation in North Wales, later in 2025.

Conclusion

I like this technology and I suspect there are many other applications of 3D Concrete Printing.

Grid Powers Up With One Of Europe’s Biggest Battery Storage Sites

The title of this post, is the same as that of this article in The Times.

This is the sub-heading.

Orsted’s huge facility in Norfolk will store energy generated by its offshore wind farm

These three paragraphs give more details of the project.

The world’s largest developer of offshore wind farms is planning to build a vast battery storage facility near Norwich.

Orsted will install the energy storage system, which will be one of the largest in Europe, on the same site as the onshore converter station for its Hornsea 3 wind farm in Swardeston, Norfolk.

The project will store energy generated by Hornsea 3 when weather conditions are windy and when electricity supply exceeds demand so that it can be discharged later to help to balance the nation’s electricity grid.

Note.

- There is also a visualisation and a map.

- Tesla batteries will be used.

- The The battery will have an output of 300 MW, with a capacity of 600 MWh. So it is another two-hour BESS.

- It should be operational in 2026.

- The battery is on a 35-acre site.

- Cost is given as £8.5 billion, but that would appear to include the 2852 MW Hornsea 3 wind farm.

The BBC is reporting that local residents are worried about fire safety.

I have some thoughts of my own.

The Location Of The Swardeston Substation

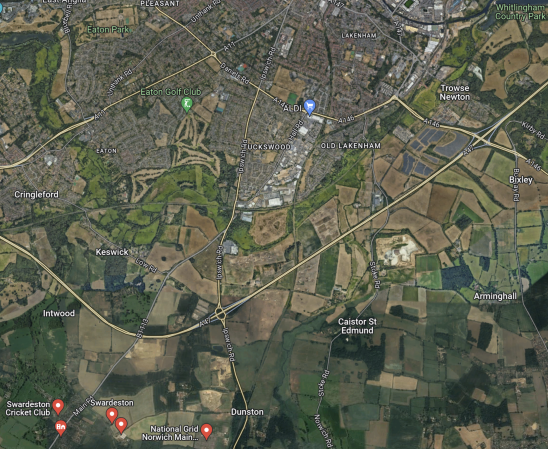

This Google Map shows the location of the Swardeston substation, which will also host the Swardeston BESS.

Note.

- The East-West road is the A 47 Norwich by-pass.

- Norwich is to the North of the by-pass.

- Just to the left-centre of the map, the main A 140 road runs between Norwich and Ipswich, which has a junction with the A 47.

- The A 140 passes through the village of Dunston, which is to the East of the National Grid sibstation, which will host the connection to the Hornsea Three wind farm.

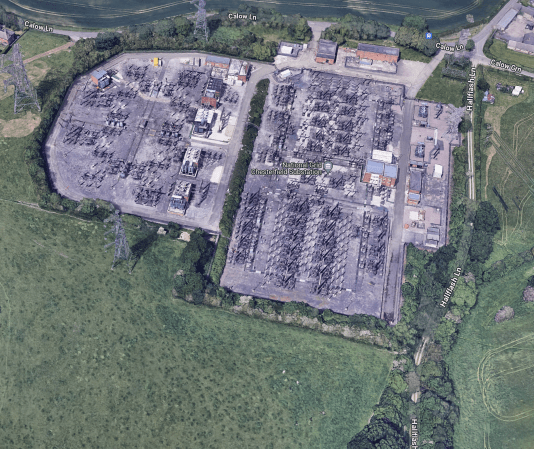

This second Google Map shows the A 140 in detail from the junction to the A 47 to the Swardeston substation.

Note.

- The Swardeston substation is on a substantial site.

- The Norwich to Tilbury transmission line will have its Northern end at Swardeston substation.

- Once the infrastructure is complete at Swardeston substation, Hornsea Three wind farm will be connected to the electricity infrastructure around London.

There would appear to be plenty of space at the site for all National Grid’s plans.

Capital Cost Compared To Big Nuclear

Hornsea Three is a 2852 MW wind farm, that will cost with the battery and a few extras £8.5 billion or around around £ 3 billion per gigawatt.

Hinckley Point C on the other hand will cost between £ 31-35 billion or £ 9.5-10.7 billion per gigawatt.

Conclusion

National Grid would appear to be using a BESS at Swardeston substation to improve the reliability and integrity of the Hornsea Three wind farm.

How many other big batteries will be placed, where large wind farms connect to the National Grid?

As an Electrical and Control Engineer, I certainly, believe that energy storage at major substations, is a proven way to improve the grid.

Ameresco And Envision Energy To Deploy 624MWh UK BESS For Atlantic Green

The title of this post, is the same as that of this article on Energy Storage News.

These three paragraphs describe the project.

Developer-operator Atlantic Green has enlisted system integrator Ameresco and clean energy manufacturer Envision Energy for a 300MW/624MWh BESS project in the UK.

The Cellarhead battery energy storage system (BESS) project will be connected to National Grid’s Cellarhead substation in the West Midlands and have a maximum energy capacity of 624MWh. Construction is expected to begin this year, with final connection to the grid slated for the end of 2026.

The deal between the parties is worth £196.5 million (US$250 million). Ameresco will build the project via an engineering, procurement and construction (EPC) and operation & maintenance (O&M) agreement while Envision Energy will supply the BESS units.

Note.

- It is another battery, that can provide full power for two hours.

- It is another battery, that is located near to one of National Grid’s substations.

As batteries seem to be made by different companies, it looks to me, that National Grid are possibly checking out, which batteries are best.

Gresham House BESS Fund Energises 50MWh Asset

The title of this post, is the same as that of this article on Solar Power Portal.

These three paragraphs detail the project.

Gresham House Energy Storage Fund has energised a 50MW/50MWh battery energy storage system (BESS) in Lancashire.

Situated in Penwortham, south-west of the county capital Preston, the 1-hour duration BESS is set to be expanded to 2-hours in the summer, meaning its capacity would be 50MW/100MWh.

With the commencement of this new BESS, Gresham House Energy Storage Fund’s operational capacity has now reached 790MW/926MWh. The project is the fund’s 25th operational asset since IPO.

Note.

- The battery will be upgraded to a two-hour battery in the summer.

- The average battery would appear to be 32 MW/37 MWh.

- The average full-power duration for all Gresham House’s batteries appears to be around 70 minutes.

This Google Map shows the battery, which is located next to National Grid’s Penwortham substation.

Note.

- The battery is the two rows of green containers at the top of the map.

- The substation appears to be large.

Co-location like this, must surely bring design, construction and operational advantages.

This page on the National Grid web site is entitled Network And Infrastructure, where this is said.

We own the national electricity transmission system in England and Wales. The system consists of approximately 4,500 miles of overhead line, over 900 miles of underground cable and over 300 substations.

If every substation in the UK were to be fitted with a 32 MW/64 MWh two hour battery, these would have a total capacity of 9.6 GW/19.2 GWh.

Compare that with these operational batteries and pumped-storage systems in the UK.

- Cruachan – 1000 MW/7.1 GWh – Pumped Storage

- Dinorwig – 1800 MW/9.1 GWh – Pumped Storage

- Ffestiniog – 360 MW/1.44 GWh – Pumped Storage

- Minety -150 MW/266 MWh – BESS

- Pillswood – 98 MW/196 MWh – BESS

And these systems are under development

- Coire Glas – 1.5GW/30 GWh – Pumped Storage

- Loch Na Cathrach/Red John – 450 MW/2.8 GWh – Pumped Storage

- London Gateway – 320 MW/640 MWh – BESS

There are at least another four substantial pumped storage systems under development.

Conclusion

A twin-track approach of grid-batteries at sub-stations and a few larger grid batteries and pumped storage hydroelectric schemes should be able to provide enough storage.

New National Grid Substation Fully Operational, Transmitting Clean Power To 1.5 Million Homes

he title of this post, is the same as that of this press release from National Grid.

These three bullet points act as sub-headings.

- National Grid’s new Littlebrook 400kV substation in Dartford, Kent is now fully energised.

- The facility enables the transmission of 2GW of low carbon and renewable energy from interconnectors and offshore wind farms off the coast of Kent to power around 1.5 million homes.

- New technology deployed to reduce emissions at the site.

This is the first three paragraphs, which outline the project.

National Grid has successfully commissioned a new, state-of-the-art substation, in Dartford, Kent, enabling 2 gigawatts (GW) of low carbon and renewable energy to power around 1.5 million homes.

National Grid and its contractors Balfour Beatty and GE Vernova’s Grid Solutions have been working since June 2019 to build a replacement for Littlebrook 400kV substation.

The new facility will help to reduce the use of sulphur hexafluoride (SF₆), a gas commonly used in the electrical industry to prevent short circuits and to keep the network safe and reliable.

These two paragraphs explain how the new substation fits in with National Grid’s SF₆ policy.

Engineers are using GE Vernova Grid Solutions’ innovative g3 gas-insulated busbar equipment which is SF6- free. A total of 5.6 tonnes of SF₆ gas has been saved, forming part of National Grid’s ambition to reduce its SF₆ emissions by 50% by 2030 and removing all SF₆ gas from electrical assets by 2050.

Teams have also deployed net zero construction methods throughout the project to reduce the environmental impact of the works, including steel manufactured in Britain, solar powered electrics, electric vehicle charging points, biodiversity net gain plan for the local area and an onsite biodigester to manage wastewater, all saving 5229 tonnes of CO₂ emissions during construction.

National Grid have this page on their web site, which is entitled What Is SF6? Sulphur Hexafluoride Explained, where this is the first paragraph.

Sulphur hexafluoride – also known as SF6 – is a ‘greenhouse gas’ that has long played a part in global warming, similar to that of carbon dioxide (CO2).

Hence the need for its removal.

Conclusion

Removal of sulphur hexafluoride from the world’s electricity substations and switchgear will be a very large task.

Opportunity For Communities To Have Their Say On New Clean Energy Substation Proposed Near Chesterfield

The title of this post, is the same as that of this article on National Grid.

These three bullet points act as sub-headings.

- National Grid is consulting communities from 22 April to 20 May 2024 on its plans for a new electricity substation which will strengthen its network and connect clean energy to the grid – part of The Great Grid Upgrade

- Substation crucial to upgrade critical infrastructure and ensure a secure and reliable supply of clean energy

- Local people invited to attend consultation events to learn more about the proposals

This is the first paragraph.

National Grid is making changes to its network of electricity infrastructure that transports power around the country, in order to connect new sources of power generated from offshore wind and other low carbon sources to the homes and business across Britain.

These two paragraphs detail the work at Chesterfield.

The Great Grid Upgrade is the largest overhaul of the grid in generations. It will play a large part in the UK government’s plan to boost homegrown power, helping the UK switch to clean energy and make sure our electricity network is fit for the future; carrying more clean, secure energy from where it’s generated to where it is needed.

As part of the Brinsworth to High Marnham project, National Grid is proposing to build and operate a new 400kV substation which will extend to the south of its existing substation site off Calow Lane in Cock Alley, near Chesterfield in Derbyshire. The new substation, which forms a key part of The Great Grid Upgrade, will play an important role in building a more secure and resilient future energy system and provide the ability to transport cleaner energy from the North of England to homes and businesses across the Midlands and beyond, helping to reduce our reliance on fossil fuels.

This is a 3D Google Map of the current sub-station.

Note.

- Four pylons can be seen.

- The image is shown looking North.

- The new substation will be on this side of the current substation.

It certainly will be a large substation.

The Consultation

There is a web site, a webinar and a local in-person meeting.

The local meeting is on Friday 10 May from 2pm – 7pm and Saturday 11 May from 9am – 2pm at Calow Community Centre, Allpits Road, Calow, Chesterfield S44 5AT

- Friday 26 April from 2pm – 7pm at South Clifton Coronation Hall, South Clifton, Newark, Nottinghamshire, NG23 7BG

- Saturday 27 April from 9am – 2pm at Normanton on Trent Village Hall, South Street, Normanton on Trent, NG23 6RQ

This is the third Opportunity For Communities To Have Their Say in a few days.

This is probably sufficient consultation.

GeoPura’s Construction World First

On the GeoPura web site there is a case study, which is entitled Construction World First.

These two paragraphs outline what was done.

Working in partnership with Siemens Energy our hydrogen fuel cell system, has provided off grid power and heat to National Grid’s UK Viking Link construction site.

The fuel cell system removes the need for diesel generators and provides innovative, sustainable, low carbon energy to the Viking Link interconnector project site.

The interesting thing, is that the heat that the hydrogen fuel cell gives out is collected and used to heat the remote site.

This last paragraph, explains the need for off grid power.

Off grid power is needed as this site didn’t have a grid connection for at least six to eight months, and the fuel cell system provided enough heat and power for the construction village during that time, removing the need for diesel generators.

There’s more in this Siemens Energy report.

National Grid Goes Carbon-Free With Hydrogen-Powered Substation Trial

The title of this post, is the same as that of this press release from National Grid.

These are the main bullet points.

- Hydrogen powered unit (HPU) quietly provided carbon-free electricity to National Grid’s Deeside Centre for Innovation

- Only emission is water

- HPUs could save an estimated 500,000 kg of carbon across all National Grid substation sites

I am an Electrical Engineer and I had never realised that all those electricity substations around the country need a backup electricity generator.

These four paragraphs describe the trial and the generator used.

A GeoPura 250kW hydrogen power unit (HPU) contained within a transportable shipping container measuring 7.2 m by 2.5 m was installed at DCI and produced the energy to power low-voltage equipment needed for National Grid’s innovation testing projects and site operations. The trial tested the capabilities and feasibility of HPUs as direct replacements for backup diesel generators across more than 250 National Grid substation sites, the data will now be analysed and shared later this year.

National Grid currently use diesel generators alongside batteries to provide backup power to a substation for key activities such as cooling fans, pumps, and lighting, enabling it to continue to perform its crucial role in the electricity transmission system.

These backup generators are rarely used and have less than a 1% chance of operating per year, however, on the rare occasion that backup power is required, changing from diesel to low-carbon emission alternatives have the potential to reduce carbon intensity by 90%* and save over 500,000 kg of carbon emissions.

The HPU at Deeside has power capabilities of up to 100 kW in continuous operation mode and up to 250 kW for 45 minutes and uses 100% green hydrogen. The unit is quieter and the hydrogen cannisters used to fuel the generators can be safely stored on site.

I have some thoughts.

Deeside Centre For Innovation

The Deeside Centre for Innovation (DCI), a state-of-the-art testing facility hosting a 400 kV modified substation, designed as a unique environment for development and trial of innovative technologies and practices.

I think there’s something rather cunning about the DCI, as it means that anybody with a good idea will probably approach National Grid for help with the testing.

Visit Deeside Centre for Innovation for more information.

GeoPura

GeoPura has a totally zero-emissions answer to how we’re going to generate, store and distribute the vast amount of energy required to decarbonise our global economies. Or so their web site says!

This page on GeoPura’s web site, gives several case studies of how they work.

They would appear to provide zero-carbon power in widespread locations for Winterwatch, Springwatch etc. for the BBC.