What Is The Collective Noun For Cement Mixer Trucks?

I took these pictures on Eldon Street and Moorgate this morning.

Note.

- There was obviously a big pour going on in the rebuilding of Broadgate.

- I suspect those outside the hotel in the street restaurant, we’re too amused by the cabaret.

- Cemex were providing the concrete.

Perhaps in view of the location, the collective noun is a pollution of cement mixer trucks.

In Cummins Agrees To Integrate Its Hydrogen ICE Technology Into Terex® Advance Trucks, I describe the latest design of cement mixer trucks from the United States.

This is the European-sized member of the range.

Note.

- Front is to the right.

- The engine is in the pod at the other end.

- The engine can be one of Cummins’s hydrogen internal combustion engines.

These trucks would be much more city-friendly.

Eastern Green Link 2 Moves Up A Gear Using Low Carbon Fuel For Material Handling Trucks

The title of this post is the same, as that of this press release from National Grid.

These three bullet points act as sub-headings.

- Eastern Green Link 2 (EGL2), a high voltage direct current (HVDC) 436km subsea transmission cable connecting Scotland and England, is being delivered as a joint venture by National Grid Electricity Transmission and SSEN Transmission.

- Project sustainability efforts are accelerating by adopting Hydrogenated Vegetable Oil (HVO) fuelled trucks to move materials in Yorkshire.

- The introduction of HVO fuel will deliver up to 90% reduction in direct CO2 emissions.

The use of HVO fuel is good and the carbon dioxide emission savings are to be welcomed, but there is only so much of this HVO fuel available.

If hydrogen-fueled trucks were available, then this would deliver up to 100% reduction in direct CO2 emissions.

This paragraph from the press release talks about where the HVO fuel will be used.

HVO, a low-carbon biofuel made from waste vegetable oils, will be used at the Wren Hall converter station site in North Yorkshire, where 20-tonne construction trucks will transport approximately 370,000 tonnes of quarry stone from a quarry 27 miles away. This switch from conventional diesel to HVO is expected to deliver up to a 90% reduction in direct CO2 emissions and an 80% reduction in other harmful emissions such as particulate matter.

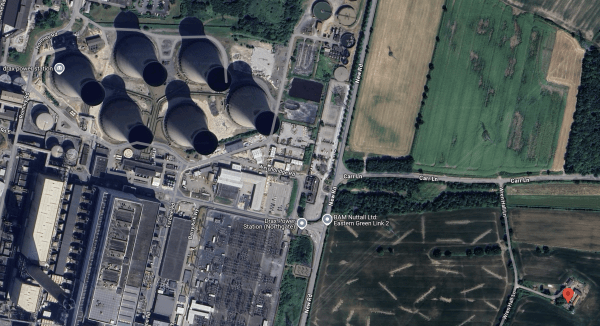

This Google Map shows the location of Wren Hall with respect to Drax power station.

Note.

- The six large cooling towers of the Drax power station are in the North-West corner of the map.

- Google Maps indicate, where they think Wren Hall is, with a red arrow.The lane running North-South to the West of the red arrow is called Wren Hall Lane.

- There is a legend saying BAM Nuttall Ltd Eastern Green Link 2 on the opposite side of the square of lanes to the red arrow.

Click the map to show it to a larger scale.

It looks to me, that if hydrogen could be provided on the Drax site, then the 370,000 tonnes of quarry stone from a quarry 27 miles away could be brought to the site by hydrogen-powered 20-tonne construction trucks.

So how could hydrogen be provided on the Drax site?

- Drax is a 2.6 GW biomass power station, so I’m sure that some electricity could be used to generate hydrogen.

- Drax is a rail-connected site, so hydrogen could be brought in by rail.

- Depending on the amount of hydrogen needed, hydrogen could surely be brought in by road.

I feel that if hydrogen-powered 20-tonne construction trucks were available, this transfer of quarry stone could be performed carbon-free.

Conclusion

This project illustrates a problem with large infrastructure projects all over the UK.

Moving the large amounts of stone, concrete, sand and rubble into and out of construction sites generates a lot of carbon dioxide and pollution from the 20-tonne trucks employed.

If I were to be given Ed Miliband’s job of Secretary of State for Energy Security and Net Zero, one of my first actions, would be to say that all new 20 tonne construction and cement trucks would have to be zero carbon.

I suspect, that zero-carbon with trucks this size, will mean hydrogen, as the weight of the battery would destroy the mathematics of the truck.

This would obviously reduce carbon emissions, but more importantly, what would it do for the health of those working on large construction sites?

In MAN Expands Its Zero-Emission Portfolio, I show MAN’s heavy hydrogen trucks.

This is an articulated heavy hydrogen truck.

I’m sure that MAN could build a hydrogen-powered 20-tonne construction truck.

In Cummins Agrees To Integrate Its Hydrogen ICE Technology Into Terex® Advance Trucks, I talk about the solution to the cement truck problem.

This is a side view of the top-of-the-range monster.

Note.

- Front is to the right.

- I suspect the driver doesn’t have to get out of the cab to discharge the concrete.

- The engine is at the rear with vertical exhausts.

- All axles are driven.

You’d certainly notice one of these if they were to be used in the City of London.

And this is the baby of the range.

Three axles is normal for the UK. so I wonder if this machine will ever make it across the pond.

This last paragraph in the original article describes the X15H hydrogen internal combustion engine.

The X15H was showcased at the Advanced Clean Transportation (ACT) Expo in May (2023), along with its hydrogen ICE-powered concept truck. The X15H features a 700-bar pressure 80kg capacity hydrogen storage system and a range of more than 500 miles, with up to 500 horsepower.

Could one of these trucks really deliver ready-mix concrete from London to Manchester and return?

The trucks would appear to be available, so let’s get a few over and try them out.

Incidentally, if someone had told me ten years ago, there would be rear-wheel drive trucks like Volkswagen Beetles, I’d have said they were wrong in no uncertain terms.

The Wren Hall substation would appear to be an ideal trial project for hydrogen-powered construction trucks and cement trucks.

Cummins Enters Collaboration To Demonstrate Hydrogen Ecosystem

The title of this post, is the same as that of this article from Rental Management.

This is the first three paragraphs.

Cummins®, Columbus, Ind., has signed a Memorandum of Understanding (MoU) with Terex® Advance Mixer, Fort Wayne, Ind., a subsidiary of Terex Corp.; Edge Materials, Cloverdale, Ind.; and PCC Hydrogen, Louisville, Ky., to produce, trial and prove concrete mixer trucks powered by Cummins’ zero-carbon, hydrogen-fueled internal combustion engines.

The project aims to develop a full hydrogen ecosystem together with a hydrogen producer, vehicle manufacturer and end user. It is the first MoU of its kind signed by Cummins.

he four companies will unite their efforts, which will see Cummins’ X15H hydrogen internal combustion engines integrated into the Terex Advance Commander Series of front-discharge concrete mixer trucks. Edge Materials, a ready-mix concrete provider and Terex Advance customers will operate the hydrogen-powered trucks in challenging real-world environments including on construction sites and critical infrastructure projects. PCC Hydrogen, an ultra-low carbon intensity hydrogen producer, will supply the hydrogen fuel as well as stationary storage and dispensing services.

Note.

- The X15H engine also comes in diesel and natural gas versions.

- Cummins also make electrolysers, that can produce hydrogen.

- It looks like the collaboration has all bases covered.

- I suspect similar deals could be done all over the world and with other types of trucks.

It all sounds like a sensible way to go to me.

Should Hydrogen-Powered Trucks Pay A Lower Charge In The Silvertown And Blackwall Tunnels?

London has a lot of heavy diesel trucks, which include.

Cement mixer trucks.

Large eight-wheeler trucks transporting aggregate, building materials and construction spoil to and from construction sites.

Council refuse trucks.

Skip trucks.

Supermarket delivery trucks.

They are large polluters and the only way they will be made zero-carbon, will be to use hydrogen.

In Cummins Agrees To Integrate Its Hydrogen ICE Technology Into Terex® Advance Trucks, I write about how Cummins and Terex are going to be building hydrogen-powered cement mixers.

This picture shows the baby of the range, which could be ideal for a smaller country like the UK.

Note how it is the other way round to traditional cement mixer trucks.

As companies are now selling low-carbon concrete in the UK, I suspect, it won’t be long before they will be delivering it in a hydrogen-powered zero-carbon truck.

If hydrogen-powered trucks could be given an economic boost, by lowering their charges for the Silvertown And Blackwall Tunnels, this might increase their uptake by owners of large trucks, which would in turn reduce pollution.

But this would need the election of a London Mayor, who had a hydrogen policy other than ignore it and hope it goes away.

Cummins Agrees To Integrate Its Hydrogen ICE Technology Into Terex® Advance Trucks

The title of this post, is the same as that of this article on H2 View.

These three paragraphs outline the deal.

Cummins and Terex® Advance have signed a Letter of Intent (LoI) to integrate hydrogen internal combustion engines (ICE) into Terex’s Commander Series.

The Commander Series trucks are currently powered by Cummins’ diesel engines, but the company will now provide its X15H hydrogen ICE when series production of the technology begins later this decade.

The X15H is based on familiar combustion engine technology, with integration into the truck chassis being straightforward and doesn’t require a major overhaul of vehicle design or business operations.

Note.

This page is the Terex Advance web site.

This page on the Terex web site shows the Terex Advance Commander series.

I think it is true to say to UK and European eyes, these trucks are an unusual design.

In Cummins Fuel-Agnostic X Series Platform, there is a link to a Cummins video, which explains Cummins multi-fuel technology.

This is a side view of the top-of-the-range monster.

Note.

- Front is to the right.

- I suspect the driver doesn’t have to get out of the cab to discharge the concrete.

- The engine is at the rear with vertical exhausts.

- All axles are driven.

You’d certainly notice one of these if they were to be used in the City of London.

And this is the baby of the range.

Three axles is normal for the UK. so I wonder if this machine will ever make it across the pond.

This last paragraph in the article describes the X15H hydrogen internal combustion engine.

The X15H was showcased at the Advanced Clean Transportation (ACT) Expo in May (2023), along with its hydrogen ICE-powered concept truck. The X15H features a 700-bar pressure 80kg capacity hydrogen storage system and a range of more than 500 miles, with up to 500 horsepower.

Could one of these trucks really deliver ready-mix concrete from London to Manchester and return?

Conclusion

The article says that integration of the hydrogen technology is straightforward and if you watch the Cummins video, the animation says it is.

But surely the big advantage on construction sites, is that all the workers will not get the dose of pollution, that they would currently get from a diesel cement mixer delivering a load of ready-mixed concrete, that had to be distributed and laid.

I think this could be a very neat application of hydrogen technology and Cummins will be looking for more applications of a similar nature.