Porterbrook Acquires ‘379s’ For Lease To GTR

The title of this post, is the same as that of a small article in the April 2024 Edition of Modern Railways.

This is the first paragraph.

Porterbrook has successfully bid to acquire the fleet of 30 Class 379 Electrostar EMUs from Akiem and will lease them to Govia Thameslink railway, which will use them on Great Northern services.

Note.

- Will the Class 379 trains replace all or some of the 39 Class 387 trains currently used by Great Northern?

- The Class 379 trains are 25 KVAC overhead only trains, whereas the Class 387 trains are dual-voltage.

- If the Class 379 trains are not modified to run on 750 VDC third rail, they will be restricted to Great Northern routes.

- It may be a problem, that the Class 379 trains are only 100 mph trains, whereas the Class 387 trains are capable of 110 mph, but I suspect that the Class 379 trains can be upgraded to 110 mph.

It looks to me that it is likely that Govia Thameslink Railway will end up with thirty spare Class 387 trains.

The Wikipedia entry for the Class 387 train, says this about the differences between the two classes of Electrostar.

The Class 387 is a variation of the Class 379 with dual-voltage capability which allows units to run on 750 V DC third rail, as well as use 25 kV AC OLE.

This surely has three main ramifications for Govia Thameslink Railway.

- Third rail equipment can probably be fitted to the Class 379 train, if required.

- The Class 379 train can probably be uprated to the 110 mph of the Class 387 train.

- Retraining the drivers to use the new Class 379 trains, will not be a major exercise.

Govia Thameslink Railway will have the luxury of configuring the trains to run, the services their passengers need and want.

But Govia Thameslink Railway may have a collateral benefit.

In 2015, a Class 379 train was modified to do a trial as a battery-electric multiple unit.

This section in the Wikipedia entry for the Class 379 train, describes the trial.

During 2013, the national infrastructure owning company Network Rail announced that unit 379013 would be used as a testbed for a future Battery-Electric Multiple Unit. Following several months of conversion work and non-service testing, the unit was used to carry passengers for the first time on a Manningtree–Harwich Town service on 12 January 2015. Throughout its five-week trial period, data was gathered to assess its performance; it could reportedly operate for up to an hour on battery power alone, while charging via the pantograph took two hours.

Note.

- I feel it would be reasonable to assume, that a Class 387 train could be easily converted to battery electric operation.

- I’ve met commuters, who used the prototype every day between Harwich and Manningtree and it gave a good service.

- In an hour with stops, a typical Southern commuter service does just 35 miles.

Southern have two routes, where Class 171 diesel trains are still used.

- Ashford International and Ore – 25.4 miles

- Hurst Green Junction and Uckfield – 24.7 miles.

A battery-electric train with a range of 30 miles would surely decarbonise these routes.

- Batteries would be charged, where 750 VDC third-rail electrification is installed.

- As the Class 387 trains are dual-voltage, a short length of 25 KVAC overhead electrification, could be used to charge the train at Uckfield, if that was to be needed.

- Alternatively, the Vivarail Fast Charge system could be fitted.

A rough estimate is that ten battery-electric Class 387 trains would be needed to make Govia Thameslink Railway an all-electric railway.

- The now redundant Class 171 trains could be cascaded to someone, who needs them.

- The remaining twenty Class 387 trains could be used to replace twenty Class 377 trains, or converted to battery-electric operation and be cascaded to another operator.

Hopefully though, after all of the musical trains, there will be a reliable procedure to convert late model Electrostars into battery-electric trains.

The Definitive Battery-Electric Electrostar

It could have this specification.

- Based on a Class 377, Class 379 or Class 387 train.

- Three, four or five cars.

- I suspect the batteries would be spread around the cars.

- Dual-voltage or 25 KVAC overhead electrification only.

- Charging by 25 KVAC overhead electrification or Vivarail/GWR Fast Charge system.

Note.

- Battery range appropriate for the route.

- In GTR And Porterbrook Unveil £55 million Fleet Modernisation, I talk about an internal refurbishment of GTR’s trains.

It looks to me, that, whatever route Govia Thameslink Railway takes, there could be another twenty refurbished Class 377 or Class 387 trains, that could be available for conversion to four-car battery-electric trains.

Great Western Routes That Could Be Run By Battery-Electric Electrostars

Great Western Railway have 30 Class 387 trains, which are used on Thames Valley services around the London end of the Great Western Main Line.

Routes that could be suitable for Battery-Electric Electrostars include.

- London Paddington and Didcot Parkway – two trains per hour (tph) – 10 trains

- London Paddington and Oxford – one tph – 5 trains – 10.5 miles x 2

- London Paddington and Newbury – one tph – 5 trains

- Reading and Newbury – one tph – 2 trains

- Newbury and Bedwyn – one tph – 1 train – 13.3 miles x 2

- Reading and Basingstoke – two tph – 2 trains – 13.6 miles x 2

- Reading and Gatwick – two tph – 7 trains – 18.6 miles

Note.

- The number of trains is my rough estimate of the number, that would be needed to run each route.

- The miles is how much running would be needed on batteries.

My estimated total is 32, but there might be savings from more efficient routes. It looks like a range of around thirty miles would be sufficient.

Conclusion

It looks like after decarbonising Govia Thameslink Railway and the Thames Valley Services of Great Western Railway, there will be twenty high quality Electrostars available to decarbonise other routes.

Bedford And Bletchley For £1.30 Return

I am not talking, rubbish, but that is the ticket price, I was charged to go between Bedford and Bletchley stations today.

Note.

- I bought the two tickets from the machine at Bedford station.

- I did get £0.70 pence off for my Senior Railcard.

These are some more pictures I took along the route.

Note.

- Platform 1a at Bedford station is electrified.

- The train was a Class 150 train, that had had a quality refurbishment.

- The stations were neat and tidy.

- The flyover and the extra platforms at Bletchley station seemed ready for the East West Railway.

- There were several level crossings.

- Platform 6 at Bletchley station is electrified.

- Trains took over fifteen minutes to turn at both ends of the journey.

- Bedford and Bletchley is 16.2 miles

- The train was moderately full both ways.

This press release from London Northwestern Railway is entitled London Northwestern Railway: Full Timetable To Resume On Marston Vale Line As £1 tickets Launched.

This is an extract.

The full hourly train service will resume on Monday 19 February. To celebrate its return and encourage passengers to return to the route, LNR is also announcing a major ticket offer today. For three months from Monday, a single journey between any two stations on the Marston Vale Line will cost just £1 (50p for children). The promotion represents a discount of up to 90% on the usual fare, depending on the journey.

Jonny Wiseman, LNR customer experience director, said: “The return of the full timetable to the Marston Vale Line is fantastic news and marks the end of a frustrating period for our customers.

“Our focus now is on encouraging passengers to make full use of their local train service, which is why we have reduced the cost of a trip on the line to £1 for the next three months.

When were tickets between Bedford and Bletchley, last this price?

Will Bedford And Bletchley Be Electrified?

It is not a question of will, as the route already is.

- Platform 1a at Bedford is already electrified.

- Platform 6 at Bletchley is already electrified.

- The schedule gives battery-electric trains sufficient time to charge, whilst the driver changes ends at the two terminal stations.

- Bedford and Bletchley is just 16.2 miles.

- There is even electrified track from Platform 6 at Bletchley station to Bletchley depot, which is being extended.

All it needs is a small fleet of battery-electric trains, which have a 25 KVAC overhead capability.

These pictures show a Class 321 Renatus.

Note.

- The trains were recently refurbished by Greater Anglia.

- In Eversholt Rail And Vivarail To Develop Class 321 BEMU, I talked about how Eversholt Rail planned to get Vivarail to convert the Class 321 Renatus trains into battery-electric multiple units.

- The Class 321 train is a 100 mph four-car train.

- Four-car trains would future proof the route for many years.

- Thirty trains were converted to the Renatus specification.

These trains converted to battery-electric multiple units could certainly handle Bletchley and Bedford services.

Could Four-Car Battery Electric Multiple Units Handle The Next Phase Of East West Rail?

It is likely, when the East West Rail opens that this could be the service.

- Oxford and Milton Keynes – 2 tph – Calling at Oxford Parkway, Bicester Village, Winslow and Bletchley

- Oxford and Bedford – 2 tph – Calling at Oxford Parkway, Bicester Village, Winslow, Bletchley, Woburn Sands, Ridgmont and Bedford St Johns

- Bletchley and Bedford – 2 tph – Calling at Fenny Stratford, Bow Brickhill, Woburn Sands, Aspley Guise, Ridgmont, Lidlington, Millbrook, Stewartby, Kempston Hardwick and Bedford St Johns

Note.

- tph is trains per hour.

- I have assumed that the existing Bletchley and Bedford service is doubled in frequency.

- I estimate that Oxford and Milton Keynes Central is 41.6 miles.

- I estimate that Oxford and Bedford is 54.7 miles.

This would mean the following.

- Oxford and Bletchley would have a frequency of 4 tph.

- Bletchley and Bedford would have a frequency of 4 tph.

- Oxford station would have to charge and turn 4 tph.

- Bedford station would have to charge and turn 4 tph.

- Bletchley station would have to charge and turn 2 tph.

- Milton Keynes Central station would have to charge and turn 2 tph.

There would need to be some form of charging at Oxford.

But Oxford station has two North-facing bay platforms.

These platforms could be electrified or fitted with a Vivarail/GWR Fast Charger.

As it takes less than fifteen minutes to fully-charge a train, two platforms could charge eight tph.

The Bay Platform At Greenford Station

These pictures show Greenford station.

I have some observations to make.

Electrification

Tests for the new battery-electric train would appear to be taking place soon, but there is no electrification or Vivarail/GWR Fast Charge system.

This leads me to the conclusion, that all charging will be done at West Ealing station.

What Length Of Train That Can Be Accommodated In Platform 2 At Greenford Station?

Consider.

- The two-car Class 165 train shown in the pictures is 47 metres long.

- FirstGroup’s test Class 230 train appears from a GWR video, to be three-cars, which would make it 54.663 metres long.

- The test Class 230 train would appear to be nearly eight metres longer, than the current train that works the route.

From the pictures it appears that there is sufficient space in the platform to accommodate the longer train.

Newquay Station – 9/10th February 2024

These pictures show Newquay station.

Note.

- It is a small one-platform station.

- It has a few facilities.

- It is located on the main street in the centre of the town.

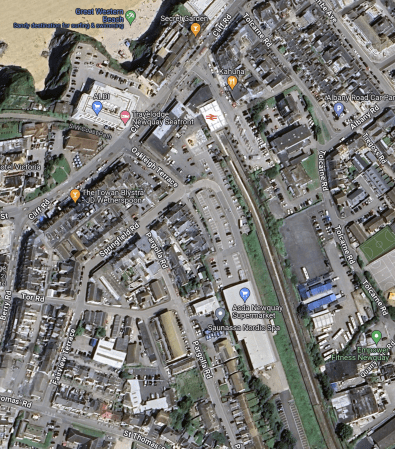

This Google Map shows Newquay station.

Newquay station appears to have a very long platform.

- This page on Railway Data gives a length of 242 metres.

- It should accommodate a nine-car Class 802 train.

- The station is also close to the beach.

It looks to me that Newquay station is ready for a big surfing festival.

I have a few thoughts.

Adding A Second Platform

These pictures show the space alongside the current single track. At least for a five-car train.

Note.

- I would expect that adding a second platform could be easily done by a competent and experienced construction company.

- There would need to be new track and a set of points, so that a train could use either platform.

- Signalling would be added, so both platforms could be used, either separately or at the same time.

I also expect that the Tregoss Loop would need to be commissioned before the second platform.

Adding Charging For Battery-Electric Trains

Consider.

In GWR Trialling Transformative Ultra-Rapid Charging Train Battery, I talked about the installation of the Vivarail/GWR Fast Charge system at West Ealing station.

In Decarbonising The Mid-Cornwall Metro, I talked about using the Vivarail/GWR Fast Charge system or hydrogen to decarbonise the Mid-Cornwall Metro.

This picture shows the Vivarail/GWR Fast Charge system at West Ealing station.

I feel there would be no problem fitting one of these in one or both of the platforms at Newquay.

But I do feel that the best way to decarbonise services to Newquay, would be to fully-electrify Par station with 25 KVAC overhead wires.

- Mid-Cornwall Metro services would charge their batteries using a pantograph, every time that they reversed in the station.

- Long distance battery-electric services through the station would top up their batteries during a stop at the station.

- Locomotives with batteries will be increasingly used on freight services and charging may be needed for the locomotives used from china clay trains.

Note.

- Par and Falmouth Docks is 30.8 miles.

- Par and Newquay is 20.8 miles.

- Par and Penzance is 44.8 miles

- Par and Plymouth is 34.7 miles.

- Par and Truro is 19 miles.

Par would appear to be a station, that could be easy to electrify and is conveniently placed in the heart of services through Cornwall.

GWR Trialling Transformative Ultra-Rapid Charging Train Battery

The title of this post is the same as that of this article on Rail Technology Magazine.

This is the sub-heading.

Great Western Railway (GWR) has begun trialling a potentially groundbreaking battery innovation called FastCharge. If the trial is successful, it is hoped that the technology could transform branch line services and accelerate the decarbonisation of the network.

This is the first paragraph.

This innovative system, which has been developed over three years, eliminates the need for diesel trains on branch lines by powering battery-operated units with ultra-rapid charging. The system boasts an impressive 2,000kW charging capacity, eight times more powerful than a Tesla Supercharger, allowing trains to fully recharge in just 3.5 minutes at West Ealing station, the trial’s first real-world location.

I took these pictures of the trial installation at West Ealing station, this morning.

Note.

- Platform 5 is used by the trains to and from Greenford station.

- Two sets of charging rails have been installed between the rails, in Platform 5.

- The rails in the charging rails could be aluminium. This would not be surprising, as it is a good electrical conductor.

- The two shorter outside charging rails could be connected together.

- The yellow parts of the charging rails are plastic, so are probably for warning purposes.

- Two white containers have been installed alongside the track.

In Great Western Railway Updates EHRT On Its Upcoming Operational Trial Of Fast Charge Tech, I described the components of the Fast Charge system in this paragraph.

The Fast Charge system consists of three key components: retractable charging shoe gear, which is mounted to the underframe of the train; short (4m) charging rails mounted between the underframe of the train; and the Fast Charge Battery Bank (FCBB) installed beside the track, acting as an energy buffer between the train and the grid.

The charging rails are clearly visible in my images and the Fast Charge Battery Bank is probably in the white containers.

These are my thoughts.

The Engineering Is Of A High Quality

Or it certainly appears so from the platform and in the pictures, that I took.

How Much Energy Will Be Taken On Board at Each Charge At West Ealing?

According to the Rail Technology Magazine article, the Fast Charge Battery Bank will have to supply 2,000 KW for 3.5 minutes to fully-charge the train at West Ealing station.

This is 7,000 KW-minutes or 117 KWh.

In D-Train Order For Marston Vale Confirmed, this is said about the batteries on a Class 230 train.

- The train has four battery rafts, each with a capacity of 106 kWh

- Range is up to fifty miles with a ten minute charge at each end of the journey.

- Range will increase as battery technology improves.

I wonder if the Class 230 train, that will run between West Ealing and Greenford, will only have one 106 kWh battery.

- This will be less weight and therefor better acceleration.

- 117 kWh in the Fast Charge Battery Bank will be sufficient to fully-charge the single battery.

- The route is only five miles for a round trip.

I can see costs dropping.

What Batteries Will Be Used In The Fast Charge Battery Bank?

I think there are four main possibilities.

- New lithium-ion batteries

- Refurbished second-hand electric vehicle batteries

- New lead-acid batteries.

- It might be possible to use supercapacitors

Note.

- Lead-acid batteries can lose charge in cold weather.

- Supercapacitors don’t care about the weather.

- The weight of lead-acid batteries would not be a problem in a stationary application.

If there is only one battery on the train, I can see the supercapacitors handling it.

What Voltage Is Used In The Charging Rails?

Consider.

- The Vivarail Class 230 trains are built from redundant London Underground D78 Stock trains.

- The D78 Stock trains were built to run on London Underground lines, when that had voltages of 0 and 630 VDC.

- So I wouldn’t be surprised if the trains were designed around this voltage.

- If the charging rails worked at 630 VDC, then to have a 2,000kW charger, this would mean a charging current of 3175 Amps.

This would explain the fat cables connecting the charging rails to the Fast Charge Battery Bank.

An alternative voltage to use could be 3,000 VDC, as some trains are built to this voltage and therefor the electronics and transformers must be available. This would reduce the charging current to 667 Amps, which might be able to use smaller cables.

It may come down to what is convenient for the output voltage of the batteries.

Why Are There Two Sets Of Charging Rails?

They are both shown in this image.

Note.

- The two sets of charging rails are about forty metres apart.

- The Fast Charge Battery Banks are another twenty metres further on.

It’s not the layout you’d expect for running a single two-car train running every half hour.

But could it be that two separate sets of charging rails can operate a more frequent service with this layout of charging rails?

Great Western Railway Updates EHRT On Its Upcoming Operational Trial Of Fast Charge Tech

The title of this post, is the same as that of this article on Electric and Hybrid Rail Technology.

This is the sub-heading.

Great Western Railway’s senior program manager, Sonya Johns, speaks to Electric & Hybrid Rail Technology about the firm’s progress on developing ex-Vivarail Fast Charge technology for battery-powered trains, ahead of operational trials due to commence in 2024.

The article is a must-read as it describes the progress since First Group, acquired the assets and intellectual property of Vivarail and its Fast Charge battery train technology.

This paragraph describes the components of the Fast Charge technology.

The Fast Charge system consists of three key components: retractable charging shoe gear, which is mounted to the underframe of the train; short (4m) charging rails mounted between the underframe of the train; and the Fast Charge Battery Bank (FCBB) installed beside the track, acting as an energy buffer between the train and the grid.

This paragraph outlines the benefits of the system.

The Fast Charge system has several benefits, according to Johns, including high charging power, enabling the train to be recharged in around 10 minutes; a standard DNO connection, avoiding costly power supply upgrades; full automation, with no driver interaction required; low safety risk (the charging rails are never live unless fully covered by the train); and minimal disruption during installation, as the FCBB is manufactured offsite and the charging rails are attached to existing sleepers.

This sounds like a system, that has been designed by someone fed up with regulators saying no to innovative ideas.

Other points from the article include.

- The shoe gear has been designed to be easily installed on any rolling stock.

- The one-year trial of the Fast Charge technology and the Class 230 battery train on the West Ealing and Greenford line will commence in spring 2024.

- GWR will capture and analyze data during the trial to understand how the technology performs in different conditions.

The article finishes with this paragraph.

The work, according to GWR, is part of its commitment to reduce the carbon emissions of its train fleet with a view to removing all diesel-only traction from the network by 2040, in line with the Government’s Transport Decarbonisation Plan.

Adrian Shooter would have been pleased if he was here to see it.

The Ways First Group, Hitachi, Hyperdrive Innovation and Turntide Technologies Can Enable Electric Trains To Run Between Basingstoke And Exeter

Who Are Turntide Technologies?

The Wikipedia entry for the company starts with this paragraph.

Turntide Technologies is a US-based business that makes intelligent, sustainable motor systems. Turntide applies its Technology for Sustainable Operations across buildings, agriculture, and transportation segments. It maintains operations in the USA, Canada, the United Kingdom, and India.

These three paragraphs from the Technology section of the Wikipedia entry outline their technology.

Turntide’s core product is its Technology for Sustainable Operations, a cloud-based open platform that monitors and automates building and vehicle systems. The platform is powered by its Smart Motor System, a connected hardware-software machine built around a high rotor pole switched reluctance motor.

Southern California Edison utility certified in 2018 that the V01 Smart Motor System reduced energy consumption by 23%-57% compared with a standard AC induction motor, and 11% compared with an induction motor controlled by a variable frequency drive.

In 2019, National Renewable Energy Laboratory certified that Turntide’s motor reduced energy consumption in refrigerator condenser fans by 29%-71%.

Note.

- Turntide’s efficiencies, which appear to have been verified by reputable organisations, if they can be reproduced in traction systems for battery-powered transport could improve range substantially.

- There are also other more efficient electric motors being developed.

- I wrote about Norfolk-based advanced traction motor company; Equipmake in Equipmake Hybrid To Battery Powered LT11.

- Motors like these, are the engineer’s cure for range anxiety.

I have to ask, if Hitachi (, and Stadler) are using more efficient motors to stretch the range of their battery-electric trains.

Initially, Hitachi asked Hyperdrive Innovation to design battery packs for Class 802 and other similar trains.

These three posts give some details about the battery project involving the two companies.

- Hitachi And Eversholt Rail To Develop GWR Intercity Battery Hybrid Train – Offering Fuel Savings Of More Than 20%

- Hitachi Rail And Angel Trains To Create Intercity Battery Hybrid Train On TransPennine Express

- More On Batteries On Class 802 Trains

Consider.

- In June 2021, Turntide acquired Hyperdrive Innovation.

- So did this effectively invite Turntide to the project?

- According to the Internet, Hitachi are one of the largest manufacturers of electric motors.

- Turntide are very-well funded by the likes of Bill Gates, Robert Downey Junior and some big funds.

Has there been some intense design meetings, which have been beneficial to all parties?

In my experience, these groupings don’t often work out how they should!

But this relationship seems to be doing fine.

One of Hitachi’s managers from the battery-train project even appears in the video on Turntide’s home page.

Electrifying Basingstoke And Exeter

Consider these facts about the route.

- Basingstoke and Salisbury is 35.8 miles.

- Salisbury and Exeter is 88.5 miles.

- Basingstoke and Exeter is 124.3 miles.

- There is no electrification.

- There are 14 stops between Salisbury and Exeter.

- There are 4 stops between Basingstoke and Salisbury.

- Trains are up to nine car Class 159 trains.

- Average speeds are not much better than 50 mph.

- Maximum speeds vary between 75 and 90 mph.

To get an estimate of how much energy, a Basingstoke and Exeter train will use, I’ll start with a figure from How Much Power Is Needed To Run A Train At 125 Or 100 mph?.

At 125 mph, a Class 801 train has a usage figure of 3.42 kWh per vehicle mile.

As drag is proportional to the square of the speed, which gives

- At 100 mph, a Class 801 train has a usage figure of 2.19 kWh per vehicle mile.

- At 80 mph, a Class 801 train has a usage figure of 1.40 kWh per vehicle mile.

For this calculation I’ll take the 80 mph figure of 1.40 kWh per vehicle mile.

Assuming a five-car train travelling between Basingstoke and Exeter, which is 124.3 miles gives a figure of 870 kWh.

But this is only one use of energy on the train.

- Every time, the train accelerates it will need power, but it will charge itself using regenerative braking.

- An all-electric Class 803 train has a mass of 228.5 tonnes and carries 400 passengers.

- If I assume that each passenger is 80 Kg including baggage, bikes and buggies, that gives a mass of 32 tonnes or a total mass of 260.5 tonnes.

- Putting these figures into Omni’s Kinetic Energy calculator gives a figure of 46.3 kWh at 80 mph.

As there are eighteen stops along the route and at each stop it could lose up to twenty percent of its energy, this means that the eighteen stops will cost 166.7 KWh.

Adding this to the 870 KWh it takes to maintain speed, it looks like a trip between Basingstoke and Exeter will take 1036.7 kWh.

Could this be a 200 kWh battery in each coach?

Obviously, this is only a rough calculation and with the better figures Hitachi would have, I would suspect much better answers.

But I do believe that it would be possible to run between Basingstoke and Exeter on battery power, if the train was efficient.

Charging The Train

The train would be charged on the third-rail electrification between Waterloo and Basingstoke.

But what would happen at Exeter?

The trains could be bi-modes like Hitachi’s Class 395 trains for Southeastern,

One of Vivarail’s third-rail charging systems, that First Group, acquired from the Receiver of Vivarail could be used.

Getting The Order Right

Would between Basingstoke and Exeter, be a sensible route to convert to battery-electric trains early, as it would release a useful fleet of diesel trains, that might be able to fill in for a couple of years by replacing the Castles!

The Vivarail Fast Charge System At West Ealing – 7th November 2022

I went to West Ealing station today and took these pictures.

At last, it seems something is happening.

Note the concrete pads on the other side of the track for the bay platform. There appear to be eight pads, which could be to support the containers that will hold the Vivarail Fast Charge System.

Are Finally Battery-Electric Trains Going To Enter Service?

In the April 2022 Edition of Modern Railways, there are three articles about battery-electric trains on four different routes.

- Effort To Contain Costs For Hoo Reopening talks about the reopening of the Hoo Branch in Kent.

- Uckfield Third Rail Is NR Priority talks about running battery-electric trains on the Uckfield Branch and the Marshlink Line.

- Vivarail’s Battery ‘230’ For Greenford Branch, talks about the Class 230 train, that will be running on the Greenford branch.

The technology has been a long-term arriving, as I had my first ride in a battery-electric train in February 2015, which I wrote about in Is The Battery Electric Multiple Unit (BEMU) A Big Innovation In Train Design?.

What kept it so long?

The Vivarail Fast Charge System At West Ealing – 4th May 2022

This article on Rail Business UK is entitled UK Railway News Round-Up.

This is the first section.

Vivarail has awarded Sella Controls a contract to supply of Tracklink III Readers and beacons for GWR’s Class 230 battery train fast charging trial on the Greenford branch. As the train enters the station one beacon will initiate the deployment of the train collectors for charging, and another beacon will trigger the charging process when the train is in the correct position.

I went to West Ealing station today and took these pictures.

Note.

- The bay platform is Platform 5.

- I couldn’t see any signs of any Tracklink III Readers.

- I wouldn’t be surprised to find that two Class 230 trains could fit in Platform 5.

I took these pictures of the station in April 2021.

It does appear by comparing the pictures, that the biggest change is that the area on the far side of the track in Platform 5, which has been cleared.