Earth Friendly Concrete Spotted On Moorgate

I’ve been hoping to spot one of Capital Concrete’s trucks before, but this is the first one, I’ve seen delivering Earth Friendly Concrete.

I said more about the product in Earth Friendly Concrete.

Building A New Concrete Revolution To Net Zero

he title of this post, is the same as that of this article on Pearls and Irritations.

The article is a good explanation of the contributions concrete makes to global warming and what we should do about it.

At least I can find entrepreneurs and scientists willing to develop concretes that will be friendlier to the planet.

- Low-Carbon Concrete: Separating Greenwash From Reality

- Earth Friendly Concrete

- Carbon-Neutral Concrete Prototype Wins €100k Architecture Prize For UK Scientists

- UK Breakthrough Could Slash Emissions From Cement

- HS2 Reveals Dramatic Carbon Saving With Ambitious Modular Design For Thame Valley Viaduct

I believe that this will be a problem that will be solved by technology.

BW Ideol And Holcim To Explore Use of Low-Carbon Concrete In Floating Offshore Wind

The title of this post, is the same as that of this article on offshoreWIND.biz.

This is the sub-heading.

BW Ideol and Holcim have signed a Memorandum of Understanding (MoU) for a feasibility study on supplying beneficial low-carbon concrete for the floating offshore wind industry, with particular reference to Scotland.

These are the first three paragraphs.

BW Ideol and Holcim aim to collaborate on optimising the supply of the innovative concrete needed for the intended mass production of BW Ideol’s floaters in the Port of Ardersier.

Low-carbon concrete’s advantages as a building material for offshore wind farms include its durability in marine environments, its local availability and its comparatively lower carbon emissions, the companies said.

The collaboration includes developing specific durable maritime low-carbon concrete mixes with enhanced mechanical performance perfectly suited to slipform application.

This is surely a good development.

BW Ideol, ABP To Explore Serial Production Of Floating Wind Foundations At Port Talbot

The title of this post, is the same as that of this article on offshoreWIND.biz.

This is the sub-heading.

BW Ideol and Associated British Ports (ABP) have signed a memorandum of understanding (MOU) that will see the manufacturer of concrete floating wind foundations and ABP investigating the feasibility of serial production at Port Talbot. The MOU has been signed in preparation for the Celtic Sea leasing round, BW Ideol said on Monday (11 December).

These two paragraphs outline the plans of BW Ideol and ABP have for Port Talbot.

According to the company, Port Talbot is the only Celtic Sea port with the scale and technical capabilities to fully maximise the Celtic Sea supply chain opportunity and is ideally located as a manufacturing base since it lies 120-140 kilometres from the floating offshore wind areas outlined by The Crown Estate for the upcoming leasing round.

The news on the MOU between ABP and BW Ideol comes shortly after ABP announced plans to invest around GBP 500 million (approximately EUR 573 million) to upgrade a site in Port Talbot and turn it into a major floating offshore wind hub.

This Google Map shows Port Talbot Port.

Note.

- It also looks like there is a Heidelberg Cement facility at the South side of the port.

- Port Talbot also has a Tata steelworks.

- The railway and the M4 Motorway are nearby.

- There’s certainly a lot of water.

The port appears well-placed for raw materials and there is quite a bit of free space to build and launch the concrete floaters.

This page on the BW Ideol web site describes their Floatgen demonstrator.

The first section is headed by BW Ideol’s First Floater In Operation, where this is said.

Built around a European consortium of 7 partners, Floatgen is a 2MW floating wind turbine demonstrator installed off the coast of Le Croisic on the offshore experimentation site of the Ecole Centrale de Nantes (SEM-REV). This project is being supported by the European Union as part of the FP7 programme. Floatgen is France’s first offshore wind turbine. 5 000 inhabitants are supplied with its electricity.

It looks like it is or almost is a proven system.

The page talks of two large benefits.

- Innovation at all levels.

- The highest local content of any floating wind turbine.

For the second, the following is said

In comparison to other steel floating foundations, which are imported from abroad, the use of concrete for BW Ideol’s floating foundation allows the construction to be located as close as possible to the deployment site. Construction at the Saint-Nazaire port was therefore a natural and optimal solution and has created a lot of local content. Additionally, the mooring system was manufactured by LeBéon Manufacturing in Brittany. For the majority of all other components or logistical activities, the Floatgen partners have also opted for suppliers within the Saint-Nazaire region.

Note.

- Will ABP and BW Ideol use a similar philosophy at Port Talbot?

- Will low-carbon concrete be used to construct the floaters?

I can certainly see the logic of BW Ideol and ABP getting together at Port Talbot.

First Massive ‘Lego Block’ Beams Lifted For HS2’s Pioneering Thame Valley Viaduct

The title of this post, is the same as that of this press release from High Speed Two.

HS2 has begun lifting the first of 72 huge beams that will support the deck of the Thame Valley Viaduct – the first of its kind in the UK to have all major elements manufactured off site.

These paragraphs describe the building of the viaduct.

Engineers at the site near Aylesbury used two massive cranes to lift the beams – 25 metres long and weighing 90 tonnes each – into position on top of the viaduct piers, like giant Lego blocks.

Instead of using a more traditional approach, with multiple smaller beams for each span, the design team opted for a simple structural solution with just two larger hollow u-shaped beams per span, which allows for a lighter structure and simpler construction.

The lighter-weight design, inspired by viaducts on the Spanish high speed rail network, also reduces the amount of carbon-intensive concrete and steel in the structure – cutting its carbon footprint by around a third.

It doesn’t say, if they are using low-carbon concrete for the beams, but High Speed Two have used this material before.

Cummins Agrees To Integrate Its Hydrogen ICE Technology Into Terex® Advance Trucks

The title of this post, is the same as that of this article on H2 View.

These three paragraphs outline the deal.

Cummins and Terex® Advance have signed a Letter of Intent (LoI) to integrate hydrogen internal combustion engines (ICE) into Terex’s Commander Series.

The Commander Series trucks are currently powered by Cummins’ diesel engines, but the company will now provide its X15H hydrogen ICE when series production of the technology begins later this decade.

The X15H is based on familiar combustion engine technology, with integration into the truck chassis being straightforward and doesn’t require a major overhaul of vehicle design or business operations.

Note.

This page is the Terex Advance web site.

This page on the Terex web site shows the Terex Advance Commander series.

I think it is true to say to UK and European eyes, these trucks are an unusual design.

In Cummins Fuel-Agnostic X Series Platform, there is a link to a Cummins video, which explains Cummins multi-fuel technology.

This is a side view of the top-of-the-range monster.

Note.

- Front is to the right.

- I suspect the driver doesn’t have to get out of the cab to discharge the concrete.

- The engine is at the rear with vertical exhausts.

- All axles are driven.

You’d certainly notice one of these if they were to be used in the City of London.

And this is the baby of the range.

Three axles is normal for the UK. so I wonder if this machine will ever make it across the pond.

This last paragraph in the article describes the X15H hydrogen internal combustion engine.

The X15H was showcased at the Advanced Clean Transportation (ACT) Expo in May (2023), along with its hydrogen ICE-powered concept truck. The X15H features a 700-bar pressure 80kg capacity hydrogen storage system and a range of more than 500 miles, with up to 500 horsepower.

Could one of these trucks really deliver ready-mix concrete from London to Manchester and return?

Conclusion

The article says that integration of the hydrogen technology is straightforward and if you watch the Cummins video, the animation says it is.

But surely the big advantage on construction sites, is that all the workers will not get the dose of pollution, that they would currently get from a diesel cement mixer delivering a load of ready-mixed concrete, that had to be distributed and laid.

I think this could be a very neat application of hydrogen technology and Cummins will be looking for more applications of a similar nature.

Concretene Cements Its Future With £8m Funding

The title of this post, is the same as that of this article in The Times.

This is a precis. which explains what Concretene have done.

Concretene combines graphene with concrete to form a “stronger, more sustainable and more cost-effective alternative” to the world’s most-used building material.

The eight million funding is mainly to be used for more tests.

Is Concrete The New Wonder Material?

I once lived in a concrete apartment and although it is now fifty years old, it still looks the same, as it did the day it was built.

Cromwell Tower in The Barbican may have been built to a high specification, but we don’t hear cancer, cladding, damp, fire or mould problems about the City of London’s flagship housing estate.

In the last few years, concrete has been able to be 3D-printed, so it can now be produced in different shapes.

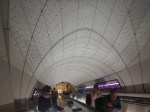

All these wall and roof panels on the Elizabeth Line were made by 3D-printing of concrete.

The technique also seems to be being used on High Speed Two.

These innovative uses of concrete have led to research into the manufacture and use of concrete.

These posts are must-reads.

- Carbon-Neutral Concrete Prototype Wins €100k Architecture Prize For UK Scientists

- UK Cleantech Consortium Awarded Funding For Energy Storage Technology Integrated With Floating Wind

- New HS2 Pilot Project Swaps Steel For Retired Wind Turbine Blades To Reinforce Concrete

- Earth Friendly Concrete

- HS2 Utilising UK-First Pioneering 3D Concrete Printing On Project

- Carbon Capture From Cement Manufacturing Nears Market Readiness

- Mineral Carbonation International Win COP26 Clean Energy Pitch Battle

The number of these posts show how much research is going into cutting the massive amount of carbon dioxide emitted by the concrete industry.

I also feel that some could work together.

Earth Friendly Concrete is a replacement for normal concrete, so perhaps it could be enhanced with graphene, to create an Earth Friendly Concretene.

Carbon-Neutral Concrete Prototype Wins €100k Architecture Prize For UK Scientists

The title of this post, is the same as that of this article on the Architect’s Journal.

Under a picture of two white-coated scientists with their protective boots on concrete samples, the story and their invention is outlined.

A pair of PhD students at Imperial College London have won a global architecture prize for devising a groundbreaking method of creating carbon-neutral concrete

Material scientists Sam Draper and Barney Shanks landed the €100,000 2022 Obel Award with their ‘simple way’ to capture carbon from industrial production processes and create an end product that can eliminate the CO₂ footprint of concrete.

The prototype technology, dubbed Seratech, takes industrial CO₂ emissions directly from flues and produces a carbon-negative cement replacement material (silica). According to the scientists, when this is used in combination with Portland cement, the carbon capture associated with producing the silica means the concrete products can be zero carbon.

One of the products, we will need in the world is concrete and if we can make it in a carbon-neutral manner, then that will surely reduce worldwide carbon emissions.

The Technology Explained

This page on the Seratech website is entitled Our Technology.

It gives this description of the technology.

Seratech has developed a process that consumes olivine and waste CO₂ from flue gases and produces two products which both have significant value in construction.

Silica is produced which can be used as a supplementary cementitious material (SCM) in concrete meaning the amount of Portland cement in the concrete can be reduced by up to 40%. As the silica comes from a process that captures CO₂ it is “carbon negative” and the concrete can become carbon neutral.

Magnesium carbonate is produced that can be used to make a range of zero carbon construction materials and consumer products, including alternatives to building blocks and plasterboard.

The aim is for humanity to be able to continue building robust cities and infrastructure, but without the climate cost of traditional cement mixes and with the Seratech technology this goal is achievable!

Note that olivine in Europe is generally mined in Norway.

Replacement Of Steel By Concrete

Could we also replace steel in some applications with concrete?

In UK Cleantech Consortium Awarded Funding For Energy Storage Technology Integrated With Floating Wind, I talked about some of ground-breaking methods used by a company called RCAM Technologies to create infrastructure using 3D printing of concrete.

If Imperial’s concrete, which is called Seratech can be 3D printed, I can see lots of applications for the technology.

So you could kill two sources of large carbon emissions with one technology.

Conclusion

I have said on this blog before, that we will have to keep or even build more gas-fired power stations, as they can be an efficient source of pure carbon dioxide, that will be needed as a feedstock to create an increasing number of agricultural and building products.

Accelerating The Delivery Of Offshore Wind Farms

It is one of Kwasi Kwarteng’s ambitions to accelerate the delivery of offshore wind farms.

In The Growth Plan 2022, these groups of wind farms are mentioned.

- Remaining Round 3 Projects

- Round 4 Projects

- Extension Projects

- Scotwind Projects

- INTOG Projects

- Floating Wind Commercialisation Projects

- Celtic Sea Projects

My thinking in this post, will probably apply to all of these groups.

These are my thoughts.

Accelerating Delivery Of A Wind Farm

This will have these positive effects.

- Electricity will be delivered earlier.

- Customers will have a more secure supply of electricity.

- The wind farm owner will start to be paid for their electricity.

- The Crown Estate will start to be paid for their leases. Although, these might start at signing.

- National Grid will be paid for the transmission of the electricity.

- An energy storage company could be paid for storing surplus electricity.

- Construction teams and engineers can move on to the next project.

- Expensive construction hardware like ship-mounted cranes will no longer be needed.

- I also suspect that the government will raise some taxes from the various companies involved.

It looks like it’ll be winners all round.

How Will Delivery Be Accelerated?

These are some thoughts.

Overall Project Time

In How Long Does It Take To Build An Offshore Wind Farm?, I came to these conclusions.

- It will take six years or less from planning consent to commissioning.

- It will take two years or less from the start of construction to commissioning.

I suspect that as we have been building offshore wind farms for some years, that it will be very difficult to reduce these times significantly.

But as some wind farms take quite a few years to progress from the initial proposal to planning consent, I suspect that improvements to the planning process may speed up the overall construction time of a wind farm.

Project And Resource Management

Good project and resource management will always help.

Better Design And Construction Methods

I always remember in the early days of North Sea Oil, being told by a very experienced project manager that construction of production platforms was accelerated by the availability of larger and more powerful cranes.

Are we approaching the design of the ultimate wind farm? I doubt it, as in the last few months, I’ve seen two very radical new designs.

In Hexicon Wins UK’s First Ever CfD Auction For Floating Offshore Wind, I show this image of one of their TwinHub turbine installations being towed into place.

The TwinHub home page has a title of The First Floating Offshore Wind Project in The Celtic Sea.

This is the description on the page.

The TwinHub offshore wind demonstration project intends to prove how Hexicon’s innovative design with two turbines on one floating foundation can further reduce the Levelized Cost of Energy (also referred to as LCoE) before large scale commercialisation. The TwinHub project is a stepping stone to help kick-start floating wind in the Celtic Sea, an area identified as a hotspot for floating wind by the UK Government. It will pave the path for larger and larger projects to help support The Crown Estates’ ambitious target of 4GW of floating wind in the Celtic Sea.

Scroll the page down and there is a fascinating short video of a pair of wind turbines in operation.

- It appears that when there is no wind, it automatically goes into a safe parked mode.

- As the wind rises, one turbine starts up.

- The second turbine starts up and the float turns so they face the wind.

It appears to be a classic example of disruptive innovation.

I have a feeling that this type of installation might have generation, assembly and cost advantages over a single turbine mounted on a single float.

RCAM Technologies are also creating interesting designs for mounting turbines and energy storage using 3D-printed concrete.

What Ts The UK Government Doing To Accelerate Projects?

This article on offshoreWIND.biz, was published in late September 2022 and is entitled BREAKING: UK Puts Massive Amount Of New Offshore Wind Capacity On Fast Track and this is the first paragraph.

The UK will speed up planning and development consent processes for projects from the recently completed, currently ongoing, and upcoming (floating) offshore wind leasing rounds to bring new energy capacity online faster and facilitate economic growth and job creation.

The article is based on what Kwasi Kwateng said on the 23rd of September about speeding up projects in the 2022 Growth Plan.

A Quick Summary Of Our Wind Energy

The article has this paragraph, which summarises our wind energy.

For the UK, which currently has around 14 GW of offshore wind capacity in operation and 8 GW under construction, the projects from the listed auction rounds could bring well beyond the targeted capacity for 2030, which was recently raised to 50 GW.

I can see the target being raised again to at least 60 GW.

UK Cleantech Consortium Awarded Funding For Energy Storage Technology Integrated With Floating Wind

The title of this post, is the same as that of this page on the UK Government’s Catapult Offshore Renewable Energy Web Site.

This is the introductory paragraph.

STORE, a UK-based cleantech consortium led by RCAM Technologies Limited, has been awarded £150,000 of funding to develop an advanced subsea energy storage technology manufactured using 3D printed concrete that could help offshore wind farms produce a steady and predictable energy output to the electricity grid.

This paragraph talks of the concept of Marine Pumped Hydro.

STORE is assessing the feasibility of integrating Marine Pumped Hydro (MPH) technology, which stores energy using hollow concrete spheres fitted with a hydraulic turbine and pump, with floating offshore wind plants in UK waters. In addition, the project advances the design of MPH systems and plans a prototype demonstration in the UK.

Note.

- The hollow concrete spheres are 3D-printed in concrete using the technology of RCAM Technologies.

- Spheres are structurally very strong.

- 3D printing of concrete is now mainstream technology and has been extensively used on the Elizabeth Line as I wrote about in The Story Behind The Concrete Panels On The Elizabeth Line.

- There is a visualisation on the Catapult web page, which shows several floating turbines, a floating sub station and several concrete hemispheres sitting on the seabed.

- The energy storage medium is sea water and air, which must be environmentally-friendly.

The technology is described in detail on this page of the STORE consortium web site.

- The spheres are fifteen metres across.

- The spheres can be installed at depths between 150 and 2000 metres.

- The system has a round-trip efficiency is up to 70%, which is similar to pumped storage hydro.

- The design life is 50 to 80 years.

I think that this system has possibilities.

This last paragraph in the Catapult web page gives a look into the future.

As well as improving the reliability and predictability of energy to the electricity grid, the project will support the cross sector transfer of UK offshore expertise and port infrastructure for use in renewable energy and create high-value UK jobs in engineering, construction, and operations and maintenance. This energy storage solution is ideally suited to coupling with floating wind plants and for powering offshore oil and gas assets from renewable energy. The 3D printed concrete also facilitates localized manufacturing and enables low cost fabrication of new and complex shapes that were previously not practical.

I also feel that if the concrete sphere energy storage can be made to successfully work, then the technology can surely be fitted to any offshore wind farm, by just adding the right number of spheres and connecting them to the offshore sub station.

The STORE Consortium

The STORE consortium has a web site, which has a heading of Innovative Subsea Energy Storage.

It describes the technology in this paragraph.

STORE is advancing a subsea energy storage technology called Marine Pumped Hydro (MPH). MPH uses large hollow concrete spheres on the seafloor to store mechanical energy in the form of pressure. MPH charges when seawater is pumped out of the spheres and releases energy to the grid when high-pressure water flows back into the spheres through a turbine. MPH features a patent-pending multi-sphere pod to increase the amount of energy stored and uses efficient 3D concrete printing to reduce manufacturing costs.

It sounds like an engineer with children, has been playing with them and their plastic toys in a bath and has had an Archimedes moment.

The project and its funding is described in this paragraph.

STORE was awarded £150,000 from the Department for Business, Energy & Industrial Strategy Longer Duration Energy Storage Demonstration (LODES) competition. Phase 1 will deliver a Feasibility Study focused on the design and analyses for the UK. Phase 2, if awarded, will design, manufacture, and operate a prototype system at TRL 6.

Note that TRL 6 is Technology Readiness Level 6 and is fully defined on this NASA web page, as having a fully functional prototype or representational model.

There is also an interesting link to the ScotWind N3 wind farm. that I wrote about in ScotWind N3 Offshore Wind Farm.

- This is an unusual floating wind farm with a floating substation.

- Technip and Loch Kishorn port are involved in both the wind farm and STORE.

- Loch Kishorn has a history of building immense concrete structures.

I wouldn’t be surprised if this wind farm would be the location of the prototype system.

Conclusion

This is a brilliant concept.

- It is the ideal energy storage system for offshore wind, as it can turn a wind farm with a variable output into one with a much more constant output.

- It can be retrofitted to existing offshore wind farms.

- It will work with both fixed and floating wind farms.

- The concrete storage spheres can be fully assembled with all their electrical gubbins on shore and towed out, before sinking in the required position.

It also looks like the Department for Business, Energy & Industrial Strategy have got involved and helped with the funding. Someone there seems to know a good idea, when they see it!