Hydrogen Coaches? Setra Begins Testing Of A Technology Carrier With Cellcentric Fuel Cell Module

The title of this post, is the same as that of this article on Sustainable Bus.

This paragraph introduces the article.

Daimler Buses has started test drives of its first Setra coach equipped with a hydrogen fuel cell drive, named the technology carrier “H2 Coach.” The 13.9-meter high-decker, model S 517 HD, combines two hydrogen tanks with a total capacity of 46 kilograms and a fuel cell module capable of as many as 300 kW, developed.

Dailmler have also said this about the interim approval for the H2 Coach.

This approval allows test drives both on Daimler Buses’ internal testing grounds and on public roads. The vehicle is intended to offer a zero-emission alternative to diesel-powered coaches, with lower noise, higher range, and shorter refueling times compared with battery-electric vehicles, contributing to improved air quality in cities and holiday regions.

I’ll go along with that.

As Wrightbus and others are developing hydrogen coaches, I believe this could be the first big hydrogen application in road transport.

Which Companies Are Developing Hydrogen-Powered Coaches?

Google AI gave me this answer.

Companies actively developing or deploying hydrogen-powered coaches include Wrightbus (UK), partnering with Symbio, and Temsa and Caetanobus (Turkey). Toyota is converting used coaches with fuel cell modules, while Daimler Buses is road-testing its H2 Coach precursor. Other companies in the broader hydrogen transport space with relevant technology are Hyundai, Volvo, and Tata Motors.

As Symbio’s Wikipedia entry is in French, I am fairly certain, that Symbio is a French company in Grenoble.

This press release from Symbio is entitled Symbio And Wrightbus Unveil TThe Successful Outcome Of Their UK Government-Funded Partnership At CENEX EXPO 2024: A 300 kW Hydrogen-Powered Demonstrator Coach.

This is the sub-heading.

A partnership to develop a 300 kW, zero-emission demonstrator fuel cell coach and future 75 kW city bus applications.

These two introductory paragraphs add more details.

Symbio and Wrightbus signed a partnership to develop and demonstrate a zero-emission, hydrogen fuel cell coach designed for on-road public transportation in the UK. The joint project started in January 2024 with the delivery by Symbio to Wrightbus of four 75 kW StackPack™ fuel cell systems, forming a 300-kW power unit that Wrightbus integrated and tested into one of its single-deckers. The tests enabled the innovation teams on both sides to adjust and define the optimal settings for the vehicle’s powertrain. Having successfully completed this objective, the demonstrator is displayed for the first time at the Cenex Expo, starting Sept. 4, and will be operational and hit the road shortly.

This successful project sets the basis for future development of hydrogen-powered city buses equipped with Symbio 75 kW StackPack™ fuel cell systems, specifically designed for bus applications.

Symbio’s approach is different.

- Many drivers of my generation had a Ford XR3i hatchback.

- This sporty car had an 80 kW engine, a top speed of 115 mph and an acceleration time of 0-60 mph, of under 9 seconds.

- It was also great fun!

I do wonder if one of Symbio’s 75 kW StackPack™ fuel cell systems could be developed and fitted into a small hatchback, to create an afffordable zero-carbon runabout.

Already the press release says that Wrightbus and Symbio are co-operating with each other on 75 kW city bus applications.

Lord Bamford’s company ; JCB found Hyperdrive Innovation to develop batteries for their diggers. These batteries are now used in Hitachi’s Battery Intercity Express Trains.

Now, it looks like his son’s company have found Symbio to develop the fuel-cells needed for their innovative buses and coaches. Would one or two 75kW fuel cells be idea for smaller tractors and diggers?

Rolls-Royce And Duisport Launch CO2-Neutral, Self-Sufficient Energy System For New Port Terminal

The title of this port is the same as that of this press release from Rolls-Royce.

These two bullet points act as sub-headings.

- First mtu hydrogen CHP units, battery storage systems and fuel cell systems from Rolls-Royce in operation.

- Benchmark for sustainable energy supply in logistics centers worldwide.

These three paragraphs give more details of the project.

Rolls-Royce and Duisburger Hafen AG have opened a CO2-neutral and self-sufficient energy system for the new Duisburg Gateway Terminal, located in the Rhine-Ruhr industrial region of Germany. The core components are two mtu combined heat and power units designed for operation with 100 percent hydrogen, which are being used here for the first time worldwide. The system is supplemented by an mtu battery storage system, mtu fuel cell systems and a photovoltaic system integrated via an intelligent energy management system.

The Enerport II flagship project, funded by the German Federal Ministry for Economic Affairs and Energy, is setting new standards for sustainable energy supply in large logistics centers and is considered a model for other ports, infrastructure projects and industrial facilities. Project partners include the Fraunhofer Institute UMSICHT, Westenergie Netzservice GmbH, Netze Duisburg GmbH, Stadtwerke Duisburg AG, and Stadtwerke Duisburg Energiehandel GmbH.

“The launch of this carbon-neutral energy system at the Duisburg Gateway Terminal is a big step toward a more climate-friendly, resilient energy supply. Together with our partner duisport, we’re showing how scalable technologies from Rolls-Royce can really help transform critical infrastructure – and help make the energy transition happen,” said Dr. Jörg Stratmann, CEO of Rolls-Royce Power Systems.

Note.

- It is carbon-neutral.

- The system uses both hydrogen and solar power.

- What has been created at the Port of Duisburg is considered by the German Federal Ministry for Economic Affairs and Energy to be a model for other ports, infrastructure projects and industrial facilities.

- It surely must help sales, that the flagship project is up and running.

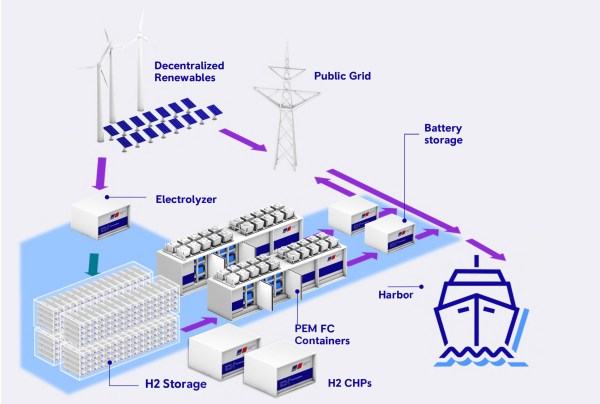

In November 2021, I wrote about this project in Rolls-Royce Makes Duisburg Container Terminal Climate Neutral With MTU Hydrogen Technology, which included this graphic.

It seems that Heathrow Airport could have a use for this technology.

I have one important thought.

Where Will The Port Of Duisburg Get The Hydrogen It Needs?

In the graphic an Electrolyser and H2 Storage are clearly shown, as are the two H2 Combined Heat and Power Units.

So it looks like the Port of Duisburg will be generating their own green hydrogen.

Alternatively in April 2021, I wrote Uniper To Make Wilhelmshaven German Hub For Green Hydrogen; Green Ammonia Import Terminal.

Uniper’s plans for the Wilhelmshaven hydrogen hub include a 410 MW hydrogen electrolyser.

The Germans are also developing a project called AquaVentus to bring green hydrogen to Germany from the North Sea.

I asked Google AI, where AquaVentus would make landfall in Germany and got this answer.

The AquaVentus project’s planned offshore hydrogen pipeline, AquaDuctus, is intended to make landfall in the greater Wilhelmshaven or Büsum area in Germany, according to the AquaDuctus website. This pipeline is part of a larger plan to transport green hydrogen produced from offshore wind farms in the North Sea to the German mainland for distribution and use.

Wilhelmshaven and Duisburg is 194 miles.

Hydrogen could be delivered onward from Ludwigshaven to Southern Germany by a pipeline network called H2ercules.

I asked Google AI if the H2ercules hydrogen pipeline will connect to Duisburg and got this answer.

Yes, the H2ercules hydrogen network will connect to Duisburg. Specifically, a new 40-kilometer pipeline will be constructed from Dorsten to Duisburg-Walsum, connecting to the steelworks there, as part of the GET H2 pipeline extension according to thyssenkrupp Steel. This connection is part of the larger H2ercules project, which aims to create a hydrogen infrastructure backbone for Germany and beyond. The pipeline is scheduled to be operational in 2027, with thyssenkrupp Steel being connected in 2028.

It would appear that at some date in the not too distant future that the Port of Duisburg could be powered by green hydrogen from the North Sea, imported into Germany at Wilhelmshaven.

The German plans for hydrogen are extensive and it appears that the Port of Duisburg could have two sources for the hydrogen it needs.

Ricardo’s Hydrogen Fuel Cell Module Successfully Reaches Full Power

The title of this post is the same as that of this press release from Ricardo.

This is the sub-heading.

Ricardo, a global strategic, environmental, and engineering consulting company, today announces a significant milestone in clean energy innovation with its new high-powered, multi-stack hydrogen fuel cell module technology successfully reaching 393kW of net electrical power, achieved within three months development from initial start-up.

These are the first two paragraphs.

This achievement was made possible due to Ricardo’s virtual engineering toolchain, which reduces physical prototyping costs and risks, accelerates development timelines, and provides a deeper understanding of system behaviours under diverse conditions.

Initially developed as part of the Sustainable Hydrogen Powered Shipping (sHYpS) Horizon Europe project for the maritime sector, Ricardo’s multi-stack hydrogen fuel cell module is designed to deliver high energy output with zero emissions. Its modular architecture integrates multiple fuel cell stacks to provide unmatched power density, and scalability while meeting the evolving energy demands of diverse applications, such as maritime, stationary power generation, rail and off-highway.

It certainly looks like Ricardo have developed a heavy end hydrogen fuel cell, that can be applied to a range of applications, in a very short time. Now that’s what I call world class engineering.

The last paragraph of the press release indicates what is possible.

To support the adoption of hydrogen technology, Ricardo has also developed a containerised solution, able to combine multiple fuel cell modules, enabling power output to be scaled up to 3MW per container, with the DC-DC power conversion on board, all without sacrificing efficiency or durability. When scaled up to incorporate multiple fuel cell modules housed within two bespoke containers, a total net electrical plant output of 6MW can be delivered. This is sufficient to power a 50,000 tonne 1,000 passenger cruise ship through important zero-emission mission cycles.

Although, this family of fuel cells, was originally developed for maritime applications, as an example of the flexibility of the system, it would surely be applicable for replacing any diesel engine from 2 MW upwards in a large number of rail, stationary and on and off-road applications.

This picture shows one of several hundred Class 66 locomotives on UK railways.

As they have an electric transmission, the 2 MW diesel engine could be fairly easily changed for a hydrogen fuel-cell of an appropriate size.