Centrica Re-Opens Rough Storage Facility

The title of this post, is the same as that of this press release from Centrica.

It has this sub-heading.

Rough Operational For Winter And Increases UK’s Storage Capacity By 50%.

On the face of it, this sounds like good news and these two paragraphs give more details.

Centrica has announced the reopening of the Rough gas storage facility, having completed significant engineering upgrades over the summer and commissioning over early autumn.

The initial investment programme means the company has made its first injection of gas into the site in over 5 years and is in a position to store up to 30 billion cubic feet (bcf) of gas for UK homes and businesses over winter 2022/23, boosting the UK’s energy resilience.

Note.

- The Rough gas storage facility has been able to hold up to 100 billion cubic feet of gas in the past.

- Rough is a complex field with two platforms and thirty wells transferring gas to and from the facility.

- Additionally, there is an onshore gas-processing terminal at the Easington Gas Terminal, where it connects to the UK gas network.

It appears to be a comprehensive gas storage facility, that should get us through the 2022/3 winter.

These two paragraphs from the press release, which are the thoughts of the Centrica Chief Executive are significant.

Centrica Group Chief Executive, Chris O’Shea, said “I’m delighted that we have managed to return Rough to storage operations for this winter following a substantial investment in engineering modifications. Our long-term aim remains to turn the Rough field into the world’s biggest methane and hydrogen storage facility, bolstering the UK’s energy security, delivering a net zero electricity system by 2035, decarbonising the UK’s industrial clusters, such as the Humber region by 2040, and helping the UK economy by returning to being a net exporter of energy.

“In the short term we think Rough can help our energy system by storing natural gas when there is a surplus and producing this gas when the country needs it during cold snaps and peak demand. Rough is not a silver bullet for energy security, but it is a key part of a range of steps which can be taken to help the UK this winter.”

Note.

- Effectively, in the short term, Rough is a store for gas to help us through the winter.

- In the long-term, Rough will be turned into the world’s largest gas storage facility.

- It will be able to store both methane (natural gas) and hydrogen.

Having worked with project managers on complex oil and gas platforms and chemical plants, I wouldn’t be surprised to find, that when the design of this facility is released, it will be something special.

Centrica certainly seem to have upgraded Rough to be able to play a significant short term role this winter and they also seem to have developed a plan to give it a significant long-term role in the storage of hydrogen.

Aldbrough Gas Storage

A few miles up the coast is SSE’s and Equinor’s Aldbrough Gas Storage, which is being developed in salt caverns to hold natural gas and hydrogen.

Blending Of Hydrogen And Natural Gas

I believe that we’ll see a lot of blending of hydrogen and natural gas.

- Up to 20 % of hydrogen can be blended, without the need to change appliances, boilers and processes.

- This cuts carbon dioxide emissions.

I wrote about this in a post called HyDeploy.

It might be convenient to store hydrogen in Aldbrough and natural gas in Rough, so that customers could have the blend of gas they needed.

With two large gas stores for hydrogen under development, the HumberZero cluster is on its way.

Can We Move The Equilibrium Point Of The Energy Market?

Equilibrium In Systems

As a Control Engineer, I believe that most systems eventually end up in a state of equilibrium.

How many football batches have you watched between two evenly-matched teams that have ended, where the statistics are even and the match has ended in a nil-nil draw or a win by one goal.

Now suppose one manager makes an inspired substitution, one important player gets injured or one player gets sent off.

One team will have an advantage, the statistics will no longer be even and one team will probably win.

The equilibrium point will have been shifted.

Zopa’s Stable Peer-to-Peer Lending System

I used Zopa’s peer-to-peer lending system for several years and found it a very stable system, that over the years paid a steady return of between four and five percent before tax.

I even developed a method to maximise my savings income, which I wrote about in The Concept Of Hybrid Banking.

It was a sad day for me, when Zopa closed its ground-breaking peer-to-peer lending system.

As a Control Engineer, I believe that Zopa’s strength was a well-written computerised algorithm, that matched lenders and borrowers and spread the risk.

- There was no bias in the system, introduced by personal prejudices.

- The algorithm was agnostic and judged all borrowers on their profiles and credit ratings alone.

- Money was allocated under fair rules for borrowers.

- I never borrowed from Zopa, but from my experience of owning half of a finance company, their terms were the most customer-friendly I’ve ever seen.

Someone will go back to the basics of peer-to-peer lending and it can’t be soon enough for both savers and borrowers.

Zopa In Troubled Times

Over the years that I invested in Zopa, my returns stayed very much the same, as the algorithm seemed to be able to maintain sufficient difference between lenders’ returns and borrowers’ rates. I also suspect the dynamics of savvy lenders and borrowers helped to stabilise both the system and the difference between rates.

It even worked through the Banking Crisis of 2008 and other mini-hiccups along the way.

My Conclusion About Zopa

As someone, who knows computing well, I would rate Zopa, one of the best computer systems, I’ve ever seen.

But it showed how a large transactional system can work well.

One of the keys to its success and smooth operation was that the computer was totally in control and it took all transaction decisions without direct human intervention.

The Energy Market

The energy market is a network of energy providers and users.

It is controlled by complicated rules and it has settled into an equilibrium, which involves.

- Importation of energy, which I suspect is not at a low price

- Some high priced energy generators, based on gas, which has a high-price, due to Putin’s war.

- Waste of wind energy due to lack of energy storage.

- The intermittency of renewable sources.

- A lack of gas storage, means that we probably get the wrong end of fluctuations in the gas price.

This results in a high price to consumers.

Can We Move The Equilibrium Point Of The Energy Market?

And we also need to move it quickly to a more favourable place, which benefits everybody!

As a Control Engineer, I believe that there are five ways to move the equilibrium point.

- Stop Putin’s war.

- Increase gas storage.

- Generate more low-cost electricity.

- Increase electricity storage.

- Improve the control algorithm.

I will now look at each in more detail.

Stopping Putin’s War

Giving in to Putin’s ambitions, would be an easy way to solve our energy crisis. But at what cost?

My parents generation, watched as Nazi Germany took over Austria and Czechoslovakia, whilst the world did nothing.

- We mustn’t repeat that mistake.

- We must not flinch in our support of the Ukraine.

- We must be ready to support Moldova, Finland and the Baltic States if Putin expands his ambitions.

I do wonder, if Boris will turn up with Churchillian-style anti-Putin rhetoric all over Eastern Europe.

Increasing Gas Storage

The major gas storage facility is Rough, which is handily close to the Easington gas terminal.

The facility needs maintenance and this paragraph from the Wikipedia entry gives the current status.

In May 2022, the Secretary of State for Business, Energy and Industrial Strategy, Kwasi Kwarteng, began talks with the site’s owners with a view to reopening the site to help ease the ongoing cost-of-living crisis in the United Kingdom. In June 2022, owners Centrica submitted an application to the North Sea Transition Authority (NSTA), the licencing authority for the UK Government, to reopen the facility. Approval was granted in July. Subsequently, Centrica indicated that they are working hard to restore storage operations at Rough which would depend on securing subsidies from the British government. Centrica was aiming to have some capacity available for the winter of 2022/23 against an overall plan to increase storage capacity gradually over time.

Note.

- Rough can store around 2832 million cubic metres of gas.

- This article on Energy Live News is entitled Reopening Of Rough Storage Gets The All-Clear.

Less well-known is SSE and Equinor’s Aldborough Gas Storage.

These three paragraphs from SSE web site, describe the gas storage.

The Aldbrough Gas Storage facility, in East Yorkshire, officially opened in June 2011. The last of the nine caverns entered commercial operation in November 2012.

The facility, which is a joint venture between SSE Thermal (66%) and Equinor, has the capacity to store around 330 million cubic metres (mcm) of gas.

SSE Thermal and Equinor have consent to increase the storage capacity at the Aldbrough site (Aldbrough Phase 2) and during the last couple of years have been working to involve the local community where appropriate to refine aspects of this project, which has not been progressed to date due to market conditions.

Future plans for the facility, may include converting it to one of the world’s largest hydrogen stores.

In the grand scheme of things, Rough and Aldborough, when you consider that the UK uses 211 million cubic metres of gas every day, will only keep us going for a few days.

But it should be noted, that the Easington gas terminal is connected to the Norwegian gas fields, by the Langeled pipeline.

So Yorkshire and Humberside will be alright.

Generating More Low-Cost Electricity

The only low-cost electricity of any size to come on stream will be wind-power.

This article on Renewables Now is entitled UK Hits 25.5 GW Of Wind Power Capacity.

These wind farms seem to be coming on stream soon or have been commissioned recently.

- Dogger Bank A – 1200 MW – Commissioning 2023 expected

- Dogger Bank B – 1200 MW – Commissioning 2024/25 expected

- Dogger Bank C – 1200 MW – Commissioning 2024/25 expected

- Hornsea Two – 1386 MW – Commissioned 2022

- Moray East – 950 MW – Commissioning 2022 expected

- Neart Na Gaoithe – 450 MW – Commissioning 2024 expected

- Seagreen – 1075 MW – Commissioning 2023 expected

- Triton Knoll – 857 MW – Commissioning 2022 expected

That is expected to be over 5 GW of offshore wind by the end of 2023.

In case there is some double counting, I’ll only say that wind power capacity could be near to 30 GW by December 2023, with perhaps another 3 GW by December 2024.

Other large wind farms in the future include.

- Berwick Bank – 4100 MW – Commissioning 2028 expected

- East Anglia Two – 900 MW – Commissioning 2026 expected

- East Anglia Three – 1400 MW – Commissioning 2027 expected

- Inch Cape Phase 1 – 1080 MW – Commissioning 2027 expected

- Hornsea Three – 2800 MW – Commissioning 2027 expected

- Moray West – 294 MW – Commissioning 2027 expected

- Morgan and Mona – 3000 MW – Commissioning for 2028 expected

- Morven – 2900 MW – Commissioning for 2028 expected

- Norfolk Boreas – 1400 MW – Commissioning 2027 expected

- Norfolk Vanguard – 1400 MW – Construction start planned for 2023

- Sofia – 1400 MW – Commissioning 2026 expected

That is over 14 GW of wind power.

I should also take note of solar and onshore wind power detailed in this document from the Department of Business, Industry and Industrial Strategy that lists all the Contracts for Difference Allocation Round 4 results for the supply of zero-carbon electricity.

It gives these figures and dates.

- Solar – 251 MW – Commissioning 2023/24 expected

- Solar – 1958 MW – Commissioning 2024/25 expected

- Onshore Wind – 888 MW – Commissioning 2024/25 expected

I can now build a yearly table of renewables likely to be commissioned in each year.

- 2022 – 3193 MW

- 2023 – 2275 MW

- 2024 – 701 MW

- 2025 – 5246 MW

- 2026 – 2300 MW

- 2027 – 6974 MW

- 2028 – 11400 MW

Note.

- Where a double date has been given, I’m taking the latter date.

- I have assumed that Norfolk Vanguard will be commissioned in 2028.

- I have ignored Hinckley Point C, which should add 3.26 GW in mid-2027.

- I have only taken into account one of the Scotwind wind farms in Scotland, some of which could be commissioned by 2028.

- I have assumed that BP’s Mona, Morgan and Morven will all be commissioned by 2028.

This is a total of 32 GW or an average of nearly 5 GW per year.

Increasing Electricity Storage

Big schemes like the 1.5 GW/ 30 GWh Coire Glas and 600 MW Cruachan 2 will help, but with 32 GW of renewable energy to be installed before 2028 and energy prices rocketing, we need substantial energy storage in the next couple of years.

One feasible plan that has been put forward is that of Highview Power’s CEO; Rupert Pearce,, that I wrote about in Highview Power’s Plan To Add Energy Storage To The UK Power Network.

The plan is to build twenty of Highview Power’s CRYOBatteries around the country.

- Each CRYOBattery will be able to store 30 GWh.

- Each CRYOBattery will be one of the largest batteries in the world.

- They will have three times the storage of the pumped storage hydroelectric power station at Dinorwig.

- They will be able to supply 2.5 GW for twelve hours, which is more output than Sizewell B nuclear power station.

Note.

- The first 30 GWh CRYOBattery is planned to be operational by late 2024.

- 600 GWh distributed around the country would probably be sufficient.

I believe that as these batteries are made from standard proven components, they could be built fairly quickly.

Paying For The Energy Storage

This press release from Highview Power is entitled New Analysis Reveals Extent Of UK Renewable Energy Waste, which makes these three bullet points.

- Enough renewable energy to power 500,000 homes a day wasted since the energy crisis began.

- 8 out of 10 Britons want more investment in boosting Britain’s energy resilience.

- UK spent £390 million turning off wind farms and using gas since September 2021.

Note.

- As the press release was published in July 2022, was the £390 million for ten months.

- Will this level of spend continue, as we’re not creating any electricity storage or building any factories that will start in a year or so, that will need large amounts of electricity?

- The Germans are at least building the NeuConnect interconnector between the Isle of Grain and Wilhelmshaven.

- As we’re adding up to 5 GW per year to our renewable energy systems, this problem will surely get worse and we’ll spend more money switching off wind turbines.

We have the money to build a very large amount of energy storage.

Improving The Control Algorithm

A better control algorithm would always help and politicians should only be allowed to set objectives.

Conclusion

There is a chance we’ll have an oversupply of electricity, but this will have effects in the UK.

- Gas-fired power-stations will be retired from front-line service to produce electricity.

- Some will question the need for nuclear power.

- Gas may even be used selectively to provide carbon dioxide for agricultural, scientific and industrial processes.

- Industries that need a lot of electricity may build factories in the UK.

- We will have a large supply of green hydrogen.

But it should bring the price of electricity down.

Significant Step Forward For Keadby 3 Carbon Capture Power Station

The title of this post, is the same as that of this press release from SSE.

These three paragraphs outline the project.

A landmark project in the Humber which could become the UK’s first power station equipped with carbon capture technology has taken a major leap forward following an announcement by the UK Government today.

Keadby 3 Carbon Capture Power Station, which is being jointly developed by SSE Thermal and Equinor, has been selected to be taken forward to the due diligence stage by the Department for Business, Energy and Industry Strategy (BEIS) as part of its Cluster Sequencing Process.

This process will give the project the opportunity to receive government support, allowing it to deploy cutting edge carbon capture technology, and to connect to the shared CO2 pipelines being developed through the East Coast Cluster, with its emissions safely stored under the Southern North Sea. The common infrastructure will also supply low-carbon hydrogen to potential users across the region.

The press release also says this about the power station.

- Keadby 3 power station could have a generating capacity of up to 910MW.

- It could be operational by 2027.

- It would capture up to one and a half million tonnes of CO2 a year.

It would provide low-carbon, flexible power to back-up renewable generation.

The H2H Saltend Project

The press release also says this about the H2H Saltend project.

Equinor’s H2H Saltend project, the ‘kick-starter’ for the wider Zero Carbon Humber ambition, has also been taken to the next stage of the process by BEIS. The planned hydrogen production facility could provide a hydrogen supply to Triton Power’s Saltend Power Station as well as other local industrial users. In June, SSE Thermal and Equinor entered into an agreement to acquire the Triton Power portfolio.

I wrote about H2H Saltend and the acquisition of Triton Power in SSE Thermal And Equinor To Acquire Triton Power In Acceleration Of Low-Carbon Ambitions.

In the related post, I added up all the power stations and wind farms, that are owned by SSE Thermal and it came to a massive 9.1 GW, which should all be available by 2027.

Collaboration Between SSE Thermal And Equinor

The press release also says this about collaboration between SSE Thermal and Equinor.

The two companies are also collaborating on major hydrogen projects in the Humber. Keadby Hydrogen Power Station could be one of the world’s first 100% hydrogen-fuelled power stations, while Aldbrough Hydrogen Storage could be one of the world’s largest hydrogen storage facilities. In addition, they are developing Peterhead Carbon Capture Power Station in Aberdeenshire, which would be a major contributor to decarbonising the Scottish Cluster.

This collaboration doesn’t lack ambition.

I also think, that there will expansion of their ambitions.

Horticulture

Lincolnshire is about horticulture and it is a generally flat county, which makes it ideal for greenhouses.

I wouldn’t be surprised to see a large acreage of greenhouses built close to the Humber carbon dioxide system, so that flowers, salad vegetables, soft fruit, tomatoes and other plants can be grown to absorb the carbon dioxide.

It should also be noted that one of the ingredients of Quorn is carbon dioxide from a fertiliser plant, that also feeds a large tomato greenhouse.

We would have our carbon dioxide and eat it.

Other Uses Of Carbon Dioxide

Storing carbon dioxide in depleted gas fields in the North Sea will probably work, but it’s a bit like putting your rubbish in the shed.

Eventually, you run out of space.

The idea I like comes from an Australian company called Mineral Carbonation International.

- I wrote about their success at COP26 in Mineral Carbonation International Win COP26 Clean Energy Pitch Battle.

- The company has developed the technology to convert carbon dioxide into building products like blocks and plasterboard.

- Their mission is to remove a billion tonnes of CO2 by 2040 safely and permanently.

We would have our carbon dioxide and live in it.

I also think other major uses will be developed.

A Large Battery

There is the hydrogen storage at Aldbrough, but that is indirect energy storage.

There needs to be a large battery to smooth everything out.

In Highview Power’s Second Commercial System In Yorkshire, I talk about Highview Power’s proposal for a 200MW/2.5GWh CRYOBattery.

This technology would be ideal, as would several other technologies.

Conclusion

Humberside will get a giant zero-carbon power station.

The Massive Hydrogen Project, That Appears To Be Under The Radar

This page on the SSE Thermal web site, is entitled Aldbrough Gas Storage.

This is the introductory paragraph.

The Aldbrough Gas Storage facility, in East Yorkshire, officially opened in June 2011. The last of the nine caverns entered commercial operation in November 2012.

This page on Hydrocarbons Technology is entitled Aldbrough Underground Gas Storage Facility, Yorkshire.

It gives these details of how Aldbrough Gas Storage was constructed.

The facility was originally planned to be developed by British Gas and Intergen in 1997. British Gas planned to develop Aldbrough North as a gas storage facility while Intergen planned to develop Aldbrough South.

SSE and Statoil became owners of the two projects in 2002 and 2003. The two companies combined the projects in late 2003. Site work commenced in March 2004 and leaching of the first cavern started in March 2005.

The storage caverns were created by using directional drilling. From a central area of the site, boreholes were drilled down to the salt strata located 2km underground.

After completion of drilling, leaching was carried out by pumping seawater into the boreholes to dissolve salt and create a cavern. Natural gas was then pumped into the caverns and stored under high pressure.

Six of the nine caverns are already storing gas. As of February 2012, dewatering and preparation of the remaining three caverns is complete. Testing has been completed at two of these caverns.

The facility is operated remotely from SSE’s Hornsea storage facility. It includes an above ground gas processing plant equipped with three 20MW compressors. The gas caverns of the facility are connected to the UK’s gas transmission network through an 8km pipeline.

Note.

- The caverns are created in a bed of salt about two kilometres down.

- It consists of nine caverns with the capacity to store around 370 million cubic metres (mcm) of gas.

- Salt caverns are very strong and dry, and are ideal for storing natural gas. The technique is discussed in this section in Wikipedia.

As I worked for ICI at Runcorn in the late 1960s, I’m very familiar with the technique, as the company extracted large amounts of salt from the massive reserves below the Cheshire countryside.

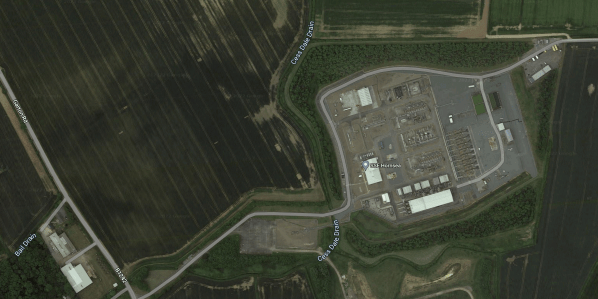

This Google Map shows the location of the Aldbrough Gas Storage to the North-East of Hull.

Note.

- The red-arrow marks the site of the Aldbrough Gas Storage.

- It is marked on the map as SSE Hornsea Ltd.

- Hull is in the South-West corner of the map.

This Google Map shows the site in more detail.

It appears to be a compact site.

Atwick Gas Storage

This page on the SSE Thermal web site, is entitled Atwick Gas Storage.

This is said on the web site.

Our Atwick Gas Storage facility is located near Hornsea on the East Yorkshire coast.

It consists of nine caverns with the capacity to store around 325 million cubic metres (mcm) of gas.

The facility first entered commercial operation in 1979. It was purchased by SSE in September 2002.

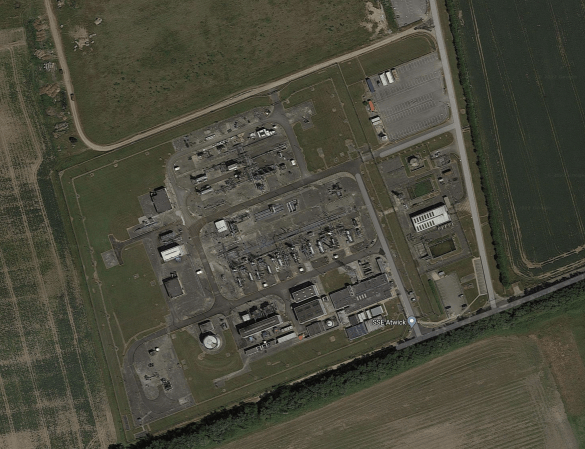

This Google Map shows the location of the Atwick Gas Storage to the North-East of Beverley.

Note.

- The red-arrow marks the site of the Atwick Gas Storage.

- It is marked on the map as SSE Atwick.

- Beverley is in the South-West corner of the map.

This Google Map shows the site in more detail.

As with the slightly larger Aldbrough Gas Storage site, it appears to be compact.

Conversion To Hydrogen Storage

It appears that SSE and Equinor have big plans for the Aldbrough Gas Storage facility.

This page on the SSE Thermal web site is entitled Plans For World-Leading Hydrogen Storage Facility At Aldbrough.

These paragraphs introduce the plans.

SSE Thermal and Equinor are developing plans for one of the world’s largest hydrogen storage facilities at their existing Aldbrough site on the East Yorkshire coast. The facility could be storing low-carbon hydrogen as early as 2028.

The existing Aldbrough Gas Storage facility, which was commissioned in 2011, is co-owned by SSE Thermal and Equinor, and consists of nine underground salt caverns, each roughly the size of St. Paul’s Cathedral. Upgrading the site to store hydrogen would involve converting the existing caverns or creating new purpose-built caverns to store the low-carbon fuel.

With an initial expected capacity of at least 320GWh, Aldbrough Hydrogen Storage would be significantly larger than any hydrogen storage facility in operation in the world today. The Aldbrough site is ideally located to store the low-carbon hydrogen set to be produced and used in the Humber region.

Hydrogen storage will be vital in creating a large-scale hydrogen economy in the UK and balancing the overall energy system by providing back up where large proportions of energy are produced from renewable power. As increasing amounts of hydrogen are produced both from offshore wind power, known as ‘green hydrogen’, and from natural gas with carbon capture and storage, known as ‘blue hydrogen’, facilities such as Aldbrough will provide storage for low-carbon energy.

I have a few thoughts.

Will Both Aldbrough and Atwick Gas Storage Facilities Be Used?

As the page only talks of nine caverns and both Aldbrough and Atwick facilities each have nine caverns, I suspect that at least initially only Aldbrough will be used.

But in the future, demand for the facility could mean all caverns were used and new ones might even be created.

Where Will The Hydrogen Come From?

These paragraphs from the SSE Thermal web page give an outline.

Equinor has announced its intention to develop 1.8GW of ‘blue hydrogen’ production in the region starting with its 0.6GW H2H Saltend project which will supply low-carbon hydrogen to local industry and power from the mid-2020s. This will be followed by a 1.2GW production facility to supply the Keadby Hydrogen Power Station, proposed by SSE Thermal and Equinor as the world’s first 100% hydrogen-fired power station, before the end of the decade.

SSE Thermal and Equinor’s partnership in the Humber marks the UK’s first end-to-end hydrogen proposal, connecting production, storage and demand projects in the region. While the Aldbrough facility would initially store the hydrogen produced for the Keadby Hydrogen Power Station, the benefit of this large-scale hydrogen storage extends well beyond power generation. The facility would enable growing hydrogen ambitions across the region, unlocking the potential for green hydrogen, and supplying an expanding offtaker market including heat, industry and transport from the late 2020s onwards.

Aldbrough Hydrogen Storage, and the partners’ other hydrogen projects in the region, are in the development stage and final investment decisions will depend on the progress of the necessary business models and associated infrastructure.

The Aldbrough Hydrogen Storage project is the latest being developed in a long-standing partnership between SSE Thermal and Equinor in the UK, which includes the joint venture to build the Dogger Bank Offshore Wind Farm, the largest offshore wind farm in the world.

It does seem to be, a bit of an inefficient route to create blue hydrogen, which will require carbon dioxide to be captured and stored or used.

Various scenarios suggest themselves.

- The East Riding of Yorkshire and Lincolnshire are agricultural counties, so could some carbon dioxide be going to help greenhouse plants and crops, grow big and strong.

- Carbon dioxide is used as a major ingredient of meat substitutes like Quorn.

- Companies like Mineral Carbonation International are using carbon dioxide to make building products like blocks and plasterboard.

I do suspect that there are teams of scientists in the civilised world researching wacky ideas for the use of carbon dioxide.

Where Does The Dogger Bank Wind Farm Fit?

The Dogger Bank wind farm will be the largest offshore wind farm in the world.

- It will consist of at least three phases; A, B and C, each of which will be 1.2 GW.

- Phase A and B will have a cable to Creyke Beck substation in Yorkshire.

- Phase C will have a cable to Teesside.

Creyke Beck is almost within walking distance of SSE Hornsea.

Could a large electrolyser be placed in the area, to store wind-power from Dogger Bank A/B as hydrogen in the Hydrogen Storage Facility At Aldbrough?

Conclusion

SSE and Equinor may have a very cunning plan and we will know more in the next few years.