Observing Trains At Stafford Station

I’m fairly certain, that I’ve only been to Stafford once in my life, in the past. That would be in 1968, when I went to English Electric in the town, when I was looking for a job on leaving Liverpool University.

In the end, my first job on leaving was at ICI in Runcorn.

As Stafford station, is on the West Coast Main Line, I’ve been through the station many times, on my way to Liverpool, Manchester, Preston, Scotland and other places in the North West of England.

I travelled North to Stafford in one of London Northwestern’s Class 350 trains, which definitely had ironing board seats. Some of these trains are being replaced with new Class 730 trains.

Stafford Station

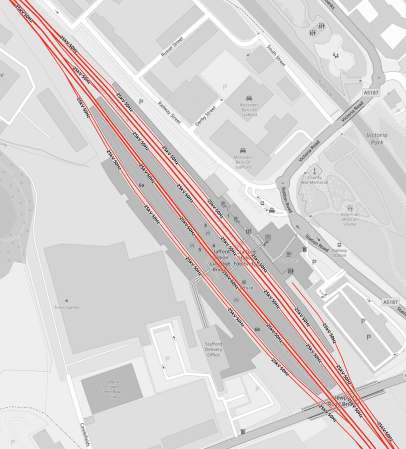

This OpenRailwayMap shows the layout of platforms at the station.

Note.

- Platforms are numbered starting with Platform 1 in the East.

- There are five through tracks for passenger trains and a double-track goods loop.

- All tracks are electrified and bi-directional.

- The platforms are three hundred metres long, but I feel they could be lengthened to take the 400 metre long High Speed Two trains.

- The platforms are certainly long enough for pairs of 200 metre long High Speed Two trains, to split and join at the station.

These pictures show Stafford station.

Note.

- The station was built of concrete in the early 1960s.

- It has a unique feature, in that there is a waiting area above the tracks, so kids of all ages can watch the trains speed through.

- It has been improved several times in recent years.

- It is step-free with several lifts.

I feel, the station could be converted into a major High Speed Two hub station.

High Speed Two Services

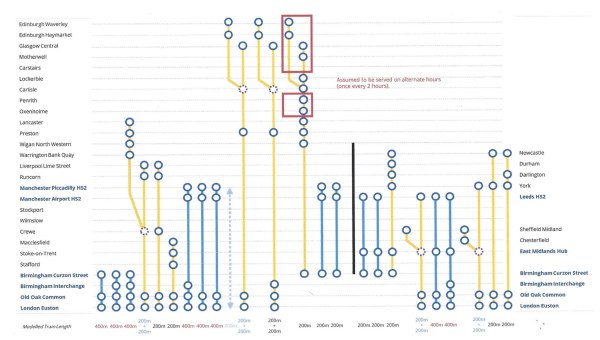

This graphic shows High Speed Two services after Phase 2b is completed.

Note.

- Everything to the right of the vertical black line has now been cancelled

- Services shown in blue are run by High Speed Two Full Size trains.

- Services shown in yellow are run by High Speed Two Classic-Compatible trains.

- Each of these trains will have a frequency of one train per hour (tph).

These High Speed Two trains pass through Stafford.

- London and Lancaster/Liverpool Lime Street – Split/Join at Crewe

- London and Crewe/Runcorn/Liverpool Lime Street

- London and Stafford/Stoke-on-Trent/Macclesfield

- London and Manchester Airport/Piccadilly

- London and Manchester Airport/Piccadilly

- London and Manchester Airport/Piccadilly

- London and Edinburgh/Glasgow – Split/Join at Carlisle

- London and Edinburgh/Glasgow – Split/Join at Carlisle

- Birmingham and Edinburgh/Glasgow

- Birmingham and Manchester Airport/Piccadilly

- Birmingham and Manchester Airport/Piccadilly

In addition space will need to be found for these other services.

- Avanti – London and Chester/North Wales

- Avanti – London and Blackpool

- Freight – London and Liverpool/Manchester and Scotland

That gives a total of at least fourteen tph through Stafford station or one every 257 seconds.

Between Stafford and Crewe, with the completion of the flyover at Norton Bridge, there is effectively four tracks all the way, so this should give enough capacity to allow fourteen tph between Stafford and Crewe.

Between Stafford and Handsacre junction, where High Speed Two will join the Trent Valley Line about half the route is four-track with the rest being just two-track.

Will the two-track section be able to handle fourteen tph? I suspect it will, especially, as it is sandwiched between two four-track sections.

These are my thoughts about making the most of capacity through Stafford station.

Could Pairs Of High Speed Two Trains, Split And Join At Stafford?

Stafford station has 300 metre long platforms and pairs of High Speed Two Trains are 400 metres long.

Looking at maps and pictures of Stafford station, I suspect that lengthening the platforms at Stafford would be possible.

In the provisional High Speed Two service diagram, that I displayed earlier, these are two services.

- London and Crewe/Runcorn/Liverpool Lime Street

- London and Stafford/Stoke-on-Trent/Macclesfield

These could be run as a pair of trains between London and Stafford.

One advantage of running the two services as a pair, is that it would reduce the number of trains between Stafford and Handsacre junction by one, which might help the scheduling of trains through the double-track section, of the Trent Valley Line.

Fitting In The London and Chester/North Wales Services

Consider.

- These important services will soon be run by five-car Class 805 trains.

- The trains are diesel-electric.

- A pair would be 260 m long.

- There are ten trains per day (tpd) on the route.

The service has a few problems.

- It takes up a path between Crewe and Handsacre junction via Stafford, where train paths are at a premium.

- It is not zero-carbon.

- If London and Holyhead times were reduced, it would probably attract more passengers to the route.

As there are plenty of spare paths on High Speed Two, due to the cancellation of the Eastern leg, the easiest way to speed up the service would be to use High Speed Two between Handsacre junction and London.

200 metre long High Speed Two Classic-Compatible trains could be used, but this would need one of the following.

Electrification between Crewe and Holyhead. Although this was promised by the last government, I suspect the antis will stop it.

Partial electrification between Crewe and Holyhead. As Crewe and Holyhead is only 105.5 miles, I suspect a creditable scheme to use battery-electric trains could be developed. These trains could be useful in opening up High Speed Two to other destinations.

Could Other Services Piggy-Back On London and Chester/North Wales Services?

The London and Chester/North Wales services would all be run by 200 metre long High Speed Two trains.

There would be no reason, why on the London end of the journey, they could be paired with another High Speed Two train to and from another destination.

- They could split and join with a Blackpool service at Crewe.

- They could split and join with a Barrow service at Crewe.

- They could split and join with a second Stoke-on-Trent/Macclesfield service at Stafford.

Services like these, would improve the coverage of High Speed Two.

As with the joining of the Liverpool Lime Street and Macclesfield services, the pairing of trains reduces the number of paths needed on the double-track section of the Trent Valley Line to the South of Stafford.

Other Splitting And Joining At Stafford

It may be possible to arrange other splitting and joining at Stafford.

By rearranging the Manchester and/or the Scottish services, it might be possible to reduce the number of trains, through the double-track section of the Trent Valley Line.

There are certainly several possibilities.

Conclusion

Stafford station could be crucial, in making High Speed Two Lite feasible.

Was I One Of The First To Have My Temperature Measured By A Thermometer Reading The Radiation From My Ear?

Last week, a doctor read my body temperature, by using an electronic thermometer, that read the temperature inside my ear.

But it wasn’t the first time!

That must have been in 1968 or 1969, when I was working at ICI in Runcorn.

ICI had a problem, in that they needed to read the temperature of chemical reaction vessels.

- Temperatures could be higher, than 1,000 °C.

- Some mixtures could be highly corrosive.

- Safety needed to be as high as possible.

My colleague; John Baxendale was assigned the problem.

John came up with a solution based on black bodies and their unique black body radiation.

These two paragraphs, from the Wikipedia entry for black body, explain the principle.

A black body or is an idealised physical body that absorbs all incident electromagnetic radiation, regardless of frequency or angle of incidence. The radiation emitted by a black body in thermal equilibrium with its environment is called black-body radiation. The name “black body” is given because it absorbs all colours of light. In contrast, a white body is one with a “rough surface that reflects all incident rays completely and uniformly in all directions.”

A black body in thermal equilibrium (that is, at a constant temperature) emits electromagnetic black-body radiation. The radiation is emitted according to Planck’s law, meaning that it has a spectrum that is determined by the temperature alone, not by the body’s shape or composition.

Note, that I have very mildly edited, what Wikipedia says, to the King’s English.

John had developed some clever electronics, that read the spectrum of the radiation and by decoding the spectrum, he was able to calculate the temperature.

Early on in the testing, John found that nearly all of us, have two black bodies on the side of our heads; our ears, so he could measure the temperature inside them.

The Aerosol Tales

When I left Liverpool University in 1968, I was very familiar with the use of products distributed in aerosol cans.

- I had used aerosol shaving cream, although about that time, I acquired my beard.

- I certainly used aerosol deodorant, as did most in the 1960s.

- Aerosol paints were common for covering scuffs and scratches in your car.

- Aerosols were often used to apply sun protection.

- Aerosols containing cream or a non-dairy alternative for culinary use were not unknown.

- Aweosol lubricants were starting to appear.

Although, I went to work for the chemical giant; ICI, at that time, I had no idea how an aerosol and its can worked.

As ICI at the time, ICI were major manufacturers of aerosol propellants, I quickly learned how they worked.

The Wikipedia entry for Aerosol Spray Dispenser gives a lot of history about aerosol cans and their propellants.

The Wikipedia entry for Propellant has this paragraph describing propellants of the last century.

Chlorofluorocarbons (CFCs) were once often used as propellants, but since the Montreal Protocol came into force in 1989, they have been replaced in nearly every country due to the negative effects CFCs have on Earth’s ozone layer. The most common replacements of CFCs are mixtures of volatile hydrocarbons, typically propane, n-butane and isobutane. Dimethyl ether (DME) and methyl ethyl ether are also used. All these have the disadvantage of being flammable. Nitrous oxide and carbon dioxide are also used as propellants to deliver foodstuffs (for example, whipped cream and cooking spray). Medicinal aerosols such as asthma inhalers use hydrofluoroalkanes (HFA): either HFA 134a (1,1,1,2,-tetrafluoroethane) or HFA 227 (1,1,1,2,3,3,3-heptafluoropropane) or combinations of the two. More recently, liquid hydrofluoroolefin (HFO) propellants have become more widely adopted in aerosol systems due to their relatively low vapor pressure, low global warming potential (GWP), and nonflammability.

Note that the whole range of these chemicals, effect the ozone layer.

Rocksavage Works

ICI’s Rocksavage Works, was an integrated chemical plant by the Mersey,.

- It made all types of CFCs for aerosols and other purposes.

- It also made the fire suppressant and extinguisher; Bromochlorodifluoromethane or BCF.

- Alongside BCF, it made the anaesthetic Halothane or as ICI called it Fluothane.

- The plant was a poisonous place with all those bromine, chlorine and fluorine compounds.

- Despite this, the plant had a remarkable safety record.

I had the pleasure of working at the plant and it was where, I had most of my excellent Health and Safety training, from the amazing site foreman; Charlie Akers.

Some of the wisdom he distributed has proved invaluable in aiding my stroke recovery.

I suspect that since the signing of the Montreal Protocol, the plant has changed greatly or has even been closed.

All that appears to be left is the 800 MW gas-fired Rocksavage power station and a Facebook page.

Aerosol Baked Beans

In those days, I worked most of the time in a lab at Runcorn Heath.

One of the labs near to where I generally worked, in the large research complex, was a lab, where new aerosol products were developed and tested.

One of the standard jokes about that lab, was that they were working on aerosol baked beans. They said, they would develop the product, even of they had to eject them from the can one at a time.

Gift Time

One afternoon, the boss of the aerosol development lab came through with a tray of goodies.

On the tray, which was much like a cinema usherette’s ice cream tray of the sixties was a whole host of partly-labeled aerosol cans. Only clues to what the product might be were written on the outside in felt-tip pen.

I grabbed two, one of which was marked something like lubricating oil and the other was just marked hand cream, which I of course gave to my new wife; C.

We were married for nearly forty years and often, when she bought hand cream, she would remark, that it wasn’t of the same standard as the little can I brought home from work.

It appears to me, that one of the world’s top cosmetic companies and ICI were trying to create the world’s best and probably most expensive hand creams.

DMW

Fast-forward nearly twenty years and I was approached by Lloyds Bank about two individuals, who had developed an aerosol valve, that instead of using CFCs or other ozone-depleting chemicals.

- By the exploitation of the nether end of fluid dynamics, the propellant of the aerosol was nothing more harmless than pure nitrogen.

- I formed a company called DMW with the two inventors.

- John Gummer, who at the time was my MP and Environment Minister, knew of the aerosol valve and he took the details to Montreal.

So did a device developed in Suffolk help push through the Montreal Protocol?

Osbourne Reynolds

I also wonder, if we had some supernatural help. At the time, I lived in the family home of Osbourne Reynolds.

- He did a lot of the early work on fluid dynamics.

- He was the first UK Professor of Engineering.

- He was professor of Engineering at Manchester University for nearly forty years.

- The Reynolds number is named after him.

- Remarkably, students are sill taught on the equipment Reynolds designed.

- Reynolds was certainly one of our great Victorian scientists.

This Wikipedia entry gives more details of his remarkable life and work.

After Montreal the aerosol valve was sold to Johnson & Johnson.

DMW continued to develop other products and we had one, who no-one had any idea about how it worked.

So I discussed it with the Reynolds’s expert at Manchester University and he said he had no idea either.

But he was absolutely certain, that Reynolds would have known.

Are Bodies Cleverer Than We Think?

Because, I had a serious stroke thirteen years ago, I am on Warfarin for life to thin my blood, so that I don’t have another stroke.

INR is short for International Normalized Ratio, which diverts on Wikipedia to the Wikipedia entry for Prothrombin Time, where these is the first two paragraphs.

The prothrombin time (PT) – along with its derived measures of prothrombin ratio (PR) and international normalized ratio (INR) – is an assay for evaluating the extrinsic pathway and common pathway of coagulation. This blood test is also called protime INR and PT/INR. They are used to determine the clotting tendency of blood, in such things as the measure of warfarin dosage, liver damage, and vitamin K status. PT measures the following coagulation factors: I (fibrinogen), II (prothrombin), V (proaccelerin), VII (proconvertin), and X (Stuart–Prower factor).

PT is often used in conjunction with the activated partial thromboplastin time (aPTT) which measures the intrinsic pathway and common pathway of coagulation.

That is very technical and complicated, but what does it mean practically?

Those on Warfarin to thin their blood are generally supposed to keep their INR between 2 and 3.

I test the INR myself with a Coaguchek meter from Roche and have done so for nearly ten years.

Every, so often, I discuss the level of Warfarin with my GP and we adjust the level accordingly.

Typically, NHS patients on Warfarin have their INR checked every few weeks.

But as I am a Graduate Control Engineer, who has written control strategies for chemical plants, I feel this checking every few weeks, is not enough.

At times, I have checked at a higher frequency.

Four times, I have had minor operations.With the first operation, I agreed with the surgeon, that I would lower my INR to 2.1 for the operation and raise it back to 2.5 after the operation.

It all went well and I repeated the exercise for the three other minor operations.

I have checked daily since about the beginning of April, before which, I generally tested on Mondays and Thursdays.

There were two reasons for the change of frequency.

- Regular storms seemed to roll in and for some reason, they tended to lower my INR.

- I also wrote Do Thunderstorms Cause Strokes?, after reading a paper from the United States about the relationship between thunderstorms and strokes.

So I took the prudent decision to test my INR daily.

Then on the 30th May, disaster struck.

My Coaguchek meter found out it had the wrong firmware and Roche implored me to change it.

But I am not a hardware person, so I was left unable to check my INR.

Luckily, I remembered a story from the 1960s about one of ICI’s chemical plants.

This plant was one of the first fully-digitally controlled plants controlled by an IBM 1800 computer.

It also ran 24 hours a day, seven days week.

So in the middle of the night, the plant operators got out all the computer printouts, which showed how the computer had set all the valves and controllers.

One-by-one they reset all the controls on the plant to the settings that the computer had used for the last few days.

Using, this computer-assisted mode the plant was kept running, until engineers could fix the computer.

On the 30th May, my INR was a little bit high at 2.9 and I was using a dosage of Warfarin of 4 mg. one day and 3.5 mg. the next.

The strange dosage was one, that I know from experiment over time produces an INR of 2.5.

My actual average Warfarin dose was 3.73 over the last thirty days and my INR, as measured most days was 2.6 over the same period.

So, I did what the engineers did on the chemical plant, kept calm and carried on.

Yesterday my son fixed the Coaguchek meter and I was able to take my first reading for 17 days. It was 2.7 and only 0.1 higher than the 30-day average on the 30th May.

I had successfully jumped the gap in the readings.

Conclusion

Most systems have an equilibrium. Make sure you know it.

The Chemical Engineer Magazine On Highview Power

This is said in the Wikipedia entry for The Chemical Engineer Magazine.

The Chemical Engineer is a monthly chemical engineering technical and news magazine published by the Institution of Chemical Engineers (IChemE).

I first read the magazine perhaps fifty years ago, when it explained a chemical process, I was working on at ICI.

It is one of several well-respected magazines published by UK scientific, medical and engineering institutions.

This article in the magazine is entitled Energy Stored As Liquefied Air: £300m Investment Triggers Construction Of UK’s First Commercial-Scale Plant.

These three paragraphs introduce the investment.

HIGHVIEW POWER has received £300m (US$379m) in funding to build the UK’s first commercial-scale liquid air energy storage plant (LAES), designed to balance peaks and troughs in power demand as more renewable energy sources are brought online.

Construction of the facility is now underway in Carrington near Manchester. It is scheduled to begin operations in early 2026 and the company predicts it will provide more than 700 jobs in construction and the supply chain.

The plant will have a storage capacity of 300 MWh and an output of 50 MW per hour for six hours.

The rest of the article is just two sections.

- How Will Highview’s New Plant Work?

- Why Is The Technology Needed?

This article in the magazine is an absolute must read.

Bilfinger Drives Highview Power’s Innovative Storage Project, Accelerating The Energy Transition

The title of this post, is the same as that of this press release from Bilfinger, who are a European multinational engineering and services company.

This is the first paragraph of the Wikipedia entry for Bilfinger.

Bilfinger SE (previously named Bilfinger Berger AG) is a European multinational company specialized in civil and industrial construction, engineering and services based in Mannheim, Germany.

Fifty years ago, I was playing a very small part in the designing of complex chemical plants for ICI. My part was mainly to check, the mathematics and dynamics for the designs, the engineers wanted to use.

The experience certainly left me with the belief, that to design a world-class chemical plant is not an easy process.

So if I was needing a complex chemical plant, I would call in the experts.

A Highview Power energy storage system, may not be a chemical plant, but it shares many of the factors of chemical plants, waterworks and sewage plants. So building one, needs a company, with wide experience, which Bilfinger certainly appear to have.

This paragraph from the press release, summarises Bilfinger’s roll in Hghview Power’s Manchester project to create a 50 MW/300 MWh battery based on Highview’s proprietary long duration energy storage system.

The scope of Bilfinger’s services ranges from the procurement of steel to extensive plant construction services, including mechanical, electrical, instrumentation, insulation, painting and structural steel work, along with the overall management of all aspects of construction, including civil works and equipment installation. As principal contractor, Bilfinger is committed to ensuring the highest safety standards on site.

In UK Infrastructure Bank, Centrica & Partners Invest £300M in Highview Power Clean Energy Storage Programme To Boost UK’s Energy Security, I described how Highview Power had recruited high-class backers to fix the companies finances.

It looks like the Bilfinger deal to build the first system, is the last piece of the jigsaw and will see Highview Power on its way.

The Problem Of Waste Plastic And Why Pyrolysis Oil Might Just Contain The Answer

The title of this post, is the same as that of this article on the Chemical Engineer.

These three paragraphs introduce the article.

One of the few technologies that can break down unrecyclable post-consumer waste plastic, pyrolysis is fast becoming a potential recycling route for companies trying to reduce their waste output.

The world produces around 450m t/y of plastic, but only 9% is recycled, with most waste ending up in landfill. Pyrolysis, which involves heating the plastic at extremely high temperatures in the absence of oxygen, breaks down the molecules to produce pyrolysis oil or gas. The oil can then be used to develop new products.

George Huber, a professor of chemical engineering at the University of Wisconsin-Madison, is leading a research team that is investigating the chemistry of pyrolysis oil and its use in polyolefin recycling.

This is a quote from George Huber

Waste plastic should be viewed as a resource we can use to make plastics and other chemicals. We should not be landfilling or burning it, we should be reusing the carbon in waste plastics.

I very much agree with what he said.

These are my thoughts.

Pyrolysis

The Wikipedia entry for pyrolysis starts with this paragraph.

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere.

This paragraph describes the technique’s use in the chemical industry.

The process is used heavily in the chemical industry, for example, to produce ethylene, many forms of carbon, and other chemicals from petroleum, coal, and even wood, or to produce coke from coal. It is used also in the conversion of natural gas (primarily methane) into hydrogen gas and solid carbon char, recently introduced on an industrial scale. Aspirational applications of pyrolysis would convert biomass into syngas and biochar, waste plastics back into usable oil, or waste into safely disposable substances.

I came across pyrolysis in my first job after graduating, when I worked at ICI Runcorn.

ICI were trying to make acetylene in a process plant they had bought from BASF. Ethylene was burned in an atmosphere, that didn’t have much oxygen and then quenched in naphtha. This should have produced acetylene , but all it produced was tonnes of black soot, that it spread all over Runcorn.

I shared an office with a guy, who was using a purpose-built instrument to measure acetylene in the off-gas from the burners.

When he discovered that the gas could be in explosive limits, ICI shut the plant down. The Germans didn’t believe this and said, that anyway it was impossible to do the measurement.

ICI gave up on the process and demolished their plant, but sadly the German plant blew up.

I would assume we have progressed with pyrolysis in the intervening fifty years.

University of Wisconsin-Madison

The University of Wisconsin-Madison is a top-ranked American University and is part of my daily life, as the Warfarin, that stops me having another stroke was developed at the University in the 1940s.

Conclusion

The article is a must-read and I feel that my past experience says, that George Huber and his team could be on to something.

I wish them the best of luck.

Rolls-Royce To Be A Partner In Zero-Carbon Gas-Fired Power Station In Rhodesia

This press release from Rolls-Royce is entitled Rolls-Royce, Landmark And ASCO Collaborate On CO2 Recovery Power Generation Solutions.

These three bullet points serve as sub-headings.

- Cooperation plans to develop solutions for clean power generation with carbon capture from gas reciprocating engines

- Captured CO2 will be available for use in industries such as food, Efuels, sustainable aviation fuels (SAF), cement and plastic production

- First of-its-kind flexible power generation and carbon capture plant currently under construction in Nottinghamshire, UK

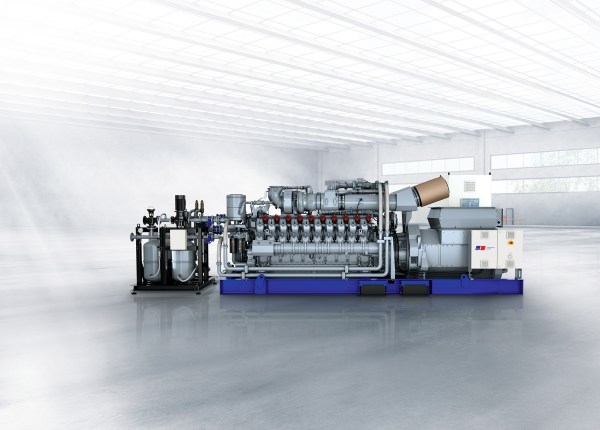

This image shows a Rolls-Royce mtu Series 4000 gas genset.

Note.

- Power is up to 2.5 MW.

- The engine is labelled H2-ready on its web page.

These two paragraphs add some detail to the project.

Rolls-Royce, ASCO Carbon Dioxide Ltd (ASCO), and Landmark Power Holdings Limited (LMPH), have signed a Memorandum of Understanding (MoU) aimed at developing scalable solutions for clean power generation with carbon capture from mtu gas reciprocating engines. This strategic partnership will help enable power generation customers to achieve their net zero ambitions and marks a significant step towards addressing climate change.

“Power generation is a highly attractive, growing market segment and an area of strategic focus for Rolls-Royce, where partnerships can help further grow market position and broaden its power generation offering, as set out at last November’s Capital Markets Day”, said Tobias Ostermaier, President Stationary Power Solutions at Rolls-Royce Power Systems. Rolls-Royce is committed to becoming a net zero company by 2050 and supporting customers to do the same.

These are my thoughts.

Uses Of Carbon Dioxide

The press release from Rolls-Royce lists a few uses of carbon dioxide.

The plan is to make the captured CO2 available (utilisation) for use in various industries such as food production, Efuels, sustainable aviation fuel (SAF), cement and plastic production (utilisation). The captured CO2 will also be ready for transportation should permanent sequestration be preferred (storage).

Carbon dioxide can also be added to the air in greenhouses, that are producing flowers, herbs, salad vegetables, soft fruit and tomatoes.

ASCO Carbon Dioxide

ASCO Carbon Dioxide is a subsidiary of French company; Schneider Electric.

The home page on their web site, describes ASCO Carbon Dioxide like this.

The Swiss ASCO CARBON DIOXIDE LTD is a globally operating company that offers complete solutions for CO2 and dry ice. The range of services includes carbon capture plants, CO2 recovery systems, ASCOJET dry ice blasting machines, dry ice production machines, CO2 cylinder filling systems, CO2 vaporisers, CO2 storage tanks, CO2 dosing systems for water neutralization and various other CO2 and dry ice equipment.

Thanks to this broad product range and more than 130 years of practical experience in the comprehensive CO2 and dry ice sector, the customer benefits from individual, complete CO2 solutions from a single source. ASCO has been part of the international industrial gases company Messer Group since 2007 and is its centre of competence for CO2.

In other words, the world and especially the climate change activists may hate carbon dioxide with a vengeance, but ASCO Carbon Dioxide see it as a way to make money and something that needs love.

It also seems, that if you want to do something with or to carbon dioxide, then ASCO Carbon Dioxide could be one of the first companies that you call.

Landmark Power Holdings Limited

The About page on their web site, describes the mission of Landmark Power Holdings Limited like this.

LMPH was established in 2019 with the purpose to help to build a circular economy, by applying new methodologies to proven technologies in energy production.

We support the transition to net zero by supplying dispatchable, low carbon energy that enables more renewable energy production while contributing to a circular economy, by eliminating inefficiencies in production, ensuring that every input is used to its maximum potential and treating all production waste as a profitable resource.

This Solutions page on their web site, describes their FlexPower Plus system.

These are the two introductory paragraphs.

FLEXPOWER PLUS® is LMPH’s modular approach to optimising the generation of clean flexible power. It is a combination of High Efficiency Flexible Power Generation modules and Carbon Capture Utilisation (CCU) modules.

Each of the modules can be added to the production processes depending on the site and production needs.

This last paragraph describes the result.

When you combine the the High Efficiency Flexible Power Generation modules with the Carbon Capture Utilisation (CCU) modules, the power generation is classified as low carbon and considered to be as clean as wind power but with the capacity to provide baseload power.

They certainly sound like my kind of company, as I was simulating processes like this for ICI in the 1970s.

ICI taught me that only four things should leave a chemical or other process plant.

- Product, that is sold at an advantageous price.

- Pure water

- Clean air

- Everybody who worked there.

It appears a FlexPower Plus system produces three valuable products; electricity, heat and pure food-grade carbon-dioxide.

The Rhodesia Project

The Rhodesia project has its own page on the Landmark Power Holdings web site, where these four paragraphs describe the project.

The Rhodesia project is a joint venture with Victory Hill, a specialist investment firm targeting direct investments in global energy infrastructure that support the UN Sustainable Development Goals.

The Rhodesia project is located in north Nottinghamshire near Worksop and has an electrical capacity of 10MW.

Additional capacity is to be sold through a private wire power supply for local businesses with the intent to facilitate vehicle charging stations.

Construction started in March 2022 and the start of power production is projected for Q3 2024 with the full CO2 capture from Q4 2024.

There is also this paragraph, that lists the partners in the Rhodesia project.

For the development of the Rhodesia project LMPH and Victory Hill have partnered with global industrial groups such as Mitsubishi Turboden S.p.A., MTU Rolls-Royce Solutions UK, ASCO CARBON DIOXIDE LTD, Climeon.

With three of the world’s largest companies amongst the partners, this partnership must have a high chance of success.

Victory Hill Capital Hill Partners

Victory Hill Capital Partners are partners in the Rhodesia project.

Their joint philosophy with Landmark Power Holdings is summed up on this video.

Working Together

The press release from Rolls-Royce says this about the partnership.

Rolls-Royce is contributing its extensive experience and global network in the field of decentralized power generation to the cooperation through its Power Systems division with the mtu product portfolio. The contribution of LMPH, a developer of high-efficiency Combined Heat and Power (CHP) projects, is its patented FLEXPOWER PLUS® concept, combined with technical expertise and patented technologies. ASCO has over 50 years of experience in developing and building carbon capture (or CO2-Recovery) plants and will be providing valuable insights and solutions from the carbon capture industry.

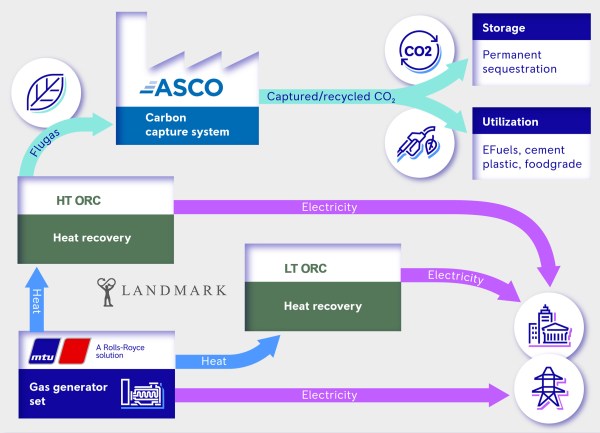

There is also this diagram of the system.

Note.

- The 4000 gas genset is in the bottom-left corner.

- The HT PRC and LT ORC are two Mitsubishi turbo-generators generating electricity from waste heat.

- The ASCO carbon capture system is in the top-left corner.

- Carbon dioxide can either be stored or used.

This system should be zero-carbon, once the design is fully tested.

A View From The Top

This paragraph from the Rolls-Royce press release gives the view of the President Stationary Power Solutions at Rolls-Royce Power Systems.

Tobias Ostermaier, President Stationary Power Solutions at Rolls-Royce Power Systems, said: “We are convinced that CO2 capture and storage systems in combination with our mtu gas gensets are an important building block on the way to Net Zero. As a complement to renewable energy sources, internal combustion engines can already provide clean, cost-effective and extremely reliable power generation.”

I suspect he’s rather pleased.

Application Of Control Engineering Principles To The Calculation Of Pharmaceutical Drug Doses

Today, I was asked by an eminent cardiologist to give my opinion on this scientific paper in the Journal of the American Heart Association, which was entitled Personalized Antihypertensive Treatment Optimization With Smartphone‐Enabled Remote Precision Dosing of Amlodipine During the COVID‐19 Pandemic (PERSONAL‐CovidBP Trial).

This was the background to the study.

The objective of the PERSONAL‐CovidBP (Personalised Electronic Record Supported Optimisation When Alone for Patients With Hypertension: Pilot Study for Remote Medical Management of Hypertension During the COVID‐19 Pandemic) trial was to assess the efficacy and safety of smartphone‐enabled remote precision dosing of amlodipine to control blood pressure (BP) in participants with primary hypertension during the COVID‐19 pandemic.

These were the methods and the results.

This was an open‐label, remote, dose titration trial using daily home self‐monitoring of BP, drug dose, and side effects with linked smartphone app and telemonitoring. Participants aged ≥18 years with uncontrolled hypertension (5–7 day baseline mean ≥135 mm Hg systolic BP or ≥85 mm Hg diastolic BP) received personalized amlodipine dose titration using novel (1, 2, 3, 4, 6, 7, 8, 9 mg) and standard (5 and 10 mg) doses daily over 14 weeks. The primary outcome of the trial was mean change in systolic BP from baseline to end of treatment. A total of 205 participants were enrolled and mean BP fell from 142/87 (systolic BP/diastolic BP) to 131/81 mm Hg (a reduction of 11 (95% CI, 10–12)/7 (95% CI, 6–7) mm Hg, P<0.001). The majority of participants achieved BP control on novel doses (84%); of those participants, 35% were controlled by 1 mg daily. The majority (88%) controlled on novel doses had no peripheral edema. Adherence to BP recording and reported adherence to medication was 84% and 94%, respectively. Patient retention was 96% (196/205). Treatment was well tolerated with no withdrawals from adverse events.

These were the conclusions.

Personalized dose titration with amlodipine was safe, well tolerated, and efficacious in treating primary hypertension. The majority of participants achieved BP control on novel doses, and with personalization of dose there were no trial discontinuations due to drug intolerance. App‐assisted remote clinician dose titration may better balance BP control and adverse effects and help optimize long‐term care.

About Myself

I am a Graduate Control Engineer, who graduated from the University of Liverpool in 1968.

I then worked at ICI in Runcorn for eighteen months, before moving to ICI Plastics Division, because of the untimely death of my father-in-law.

One of my tasks at Welwyn, was to look at control algorithms for chemical plants. For this I often used a PACE 231-R analogue computer.

Note.

- These computers could solve up to a hundred simultaneous differential equations at one time.

- They were programmed by wiring the various amplifiers and potentiometers together to simulate the equations.

- There were only a few transistors in these powerful machines, as all electronics were thermionic valves.

- Two of these machines wired together, were used to calculate the trajectories of the Apollo missions.

They were the unsung heroes of bringing Jim Lovell and Apollo 13 home safely.

Determining Control Algorithms

In a typical problem, I would model the a section of a chemical plant and the control system around it.

This would then lead to recommendations, as to the design and operation of the plant, so that it performed as required.

It could be argued that the body of an animal, is a very complicated integrated chemical plant, with a sophisticated control system.

For instance, if sensors around the body, say you are slightly low on fluids, your brain determines you should have a drink.

Many control loops on a chemical plant are controlled by proportional–integral–derivative controllers, which are commonly known as three-term controllers.

This is the first two paragraphs of the Wikipedia entry for three-term controllers.

A proportional–integral–derivative controller (PID controller or three-term controller) is a control loop mechanism employing feedback that is widely used in industrial control systems and a variety of other applications requiring continuously modulated control. A PID controller continuously calculates an error value

PID systems automatically apply accurate and responsive correction to a control function. An everyday example is the cruise control on a car, where ascending a hill would lower speed if constant engine power were applied. The controller’s PID algorithm restores the measured speed to the desired speed with minimal delay and overshoot by increasing the power output of the engine in a controlled manner.

I wouldn’t be surprised that the app in the smartphone used in the PERSONAL‐CovidBP Trial contained a form of three-term controller.

These are some points about three-term control algorithms.

Changing Of External Factors

One that was the villain in a problem, I dealt with, also affects my body – the weather.

I was asked to look at the problem of a chemical reaction, that overheated in hot weather. But the plant operators solved it by better insulation and ventilation of the plant and the standard three-term controller adjusted itself automatically to the new conditions.

After my stroke, I am on Warfarin for life. I test my own INR with a Roche meter and I have noticed that atmospheric pressure affects my INR. I change my deose accordingly, using a simple algorithm, of my own design.

The More You Test The More Precise The Control

If you take the cruise control example used by Wikipedia, speed is monitored continuously, as I hope, it would be if you were driving yourself.

But obviously, in many systems, where you are using an input with discrete values to control a system, you can’t be as precise as the data you collect.

When my son was dying from pancreatic cancer, he was fitted with a morphine pump, that he could adjust himself to dull the immense pain he was enduring.

- His nerves and his brain ascertained the pain level.

- He then adjusted the morphine level.

- He could get very precise control of his pain, because he was measuring it continuously.

But he was only using simple one-term control (proportional).

Derivative Control Can Be Difficult To Get Right And Can Even Go Unstable

Derivative control is mainly to stop overshoot, but sometimes you will find that it can go unstable, so two-term(proportional+integral) controllers will be used.

How I Control My INR

As I said earlier, I am on Warfarin for life and test my INR with a Roche meter.

The NHS typically tests patients about once every six weeks, which in my opinion as a Control Engineer is too infrequent.

I usually test myself a couple of times a week.

But every so often, I evaluate what daily dose gives me an equilibrium INR level of 2.5.

For the last three years, I have found a dose of 3.75 mg keeps me more or less on 2.5.

- As Warfarin comes in 1, 3, 5 and 10 mg. tablets, I alternate 3.5 and 4 mg.

- Warfarin tablets are easily cut in half using a sharp knife.

- I record INR and dose in a spreadsheet.

I have been doing this now for over ten years.

Is This A Unique Property Of Warfarin?

In this time, I have had five medical procedures, where surgeons were worried, that as I was on Warfarin, I might bleed too much.

For the first, which was to remove a lump from my mouth, the private surgeon wanted to charge extra for an anaesthetist. In the end, I asked what INR he wanted and he said 2.1 should be OK!

- So I reduced the Warfarin level and tested every day.

- I judged it correctly and had an INR of 2.1 on the day of the operation.

- The operation went incredibly well and I went home on public transport.

- The lump turned out to be benign.

- I’ve not had another lump.

After the operation, I increased the Warfarin level and tested every day, until it regained a level of 2.5.

On analysing my doses through the date of the operation, I found that the total amount of Warfarin, I didn’t take to reduce my INR to 2.1, was the same as I took to bring it back up again to 2.5.

Is this a unique property of Warfarin?

Since then I’ve had two cataract operations performed in a private hospital, where the NHS paid. Interestingly, they wouldn’t trust my own INR readings, so I had to get my GP to take the measurement.

I’ve also had gallstones removed by endoscopy at the local Homerton NHS hospital.

- For cases like mine, the hospital hire in a surgeon from the posh Wellington private hospital for one day a week, who brings the specialist tools needed.

- I wrote about this in Goodbye To My Gallstones.

- As it was a more serious procedure, I reduced my INR to a requested 1.0.

Interestingly, I still have my gall bladder, but the surgeon put it on notice to behave.

Conclusion

I would totally agree with the conclusion given in the PERSONAL‐CovidBP Trial.

Personalized dose titration with amlodipine was safe, well tolerated, and efficacious in treating primary hypertension. The majority of participants achieved BP control on novel doses, and with personalization of dose there were no trial discontinuations due to drug intolerance. App‐assisted remote clinician dose titration may better balance BP control and adverse effects and help optimize long‐term care.

I would add some conclusions of my own.

- The app used in the PERSONAL‐CovidBP Trial, seems to have had a good algorithm.

- I suspect the app could also be Internet-based.

These are some general conclusions.

- If you are on Warfarin and have access to a Roche meter, it is possible to lower your INR to the value required by a surgeon for an operation or a procedure.

- Since starting to take Warfarin, I have had four operations or procedures, where others would have had anaesthetic or a sedative.

- In those four operations, I was able to go home on public transport. If I still drove a car, I could have driven home afterwards.

- Private hospitals like to use an anesthetist, as it pumps up the bill.

- Avoiding anaesthesia must save hospitals money.

Well designed apps, based on Control Engineering principles, that help the patient take the best dose of a drug will become more common.