RCAM Technologies

Wouldn’t it be a good idea to have a wind turbine with built-in energy storage?

This article on Power Engineering, is entitled Five Long-Duration Energy Storage Projects Get Funding In New York.

One of the projects, from RCAM Technologies is described like this.

To develop a 3D concrete-printed marine pumped hydroelectric storage system that integrates directly with offshore wind development in support of grid resiliency and reduced reliance on fossil fuel plants to meet periods of peak electric demand.

That sounds like an offshore wind turbine with built-in energy storage, that is 3D-printed in concrete.

The RCAM Technologies web site is all about 3D-printed concrete.

- It looks like they can build taller wind farm towers, than you can make with steel.

- It appears offshore wind turbine tower with integrated foundations can be built on-site.

- Material can be 100 % locally-sourced.

- The next step could be to build some form of pumped storage into the tower.

- They are experimenting with storing energy as pressure in 3D-printed concrete spheres. The New York grant will help fund this.

- High Speed Two is using 3D-printing of concrete, as I wrote about in HS2 Utilising UK-First Pioneering 3D Concrete Printing On Project.

The company has offices in Colorado, California and Edinburgh.

Conclusion

This technology could be on the right track. Read their web site.

ITOCHU, Taisei Corporation And Mineral Carbonation International Announce Collaboration

This collaboration is reported in this article on Market Screener, which is entitled ITOCHU : Announces Collaboration With Taisei Corporation In Initiative With MCi Testing Uses Of Concrete From Calcium Carbonate With Mineral Carbonation.

This paragraph described MCi’s mineral carbonation technologies.

MCi is a company that has pursued fifteen years of research and development into mineral carbonation and possesses the technology to produce a range of low carbon embodied materials including calcium carbonate by carbonating minerals in slag and other by-products of the steelmaking process (mainly steelmaking slag), coal ash produced by thermal power plants, and other industrial waste materials containing magnesium or calcium (mine tailings: by-products from the collection of metals and ore).

It also appears that ITOCHU invested in MCi last year.

I have read the whole article and I suggest that this collaboration could grow into something very big.

The Story Behind The Concrete Panels On The Elizabeth Line

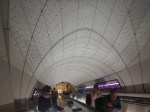

These are a selection of the pictures I took yesterday inside Elizabeth Line stations.

Note.

- The walls and ceilings appear to be covered in light grey panels with holes.

- The material appears to look like concrete.

- Every one is a totally different shape, so how were they manufactured?

This article on Ian Visits is entitled How Crossrail Is Using 3D-Printing To Build Its Stations.

This is the two opening paragraphs.

When you start to use the new Elizabeth line stations, among its many achievements will be the first large scale use of 3D-printing in concrete.

The use of 3D printing has made possible one of the more distinctive features of the future Elizabeth line stations — the curved concrete panels that will line the inside of the passenger tunnels and some stations, and sinuously glide around corners in a way never seen before in a tube station.

There will be a total of something like 36,000 of these panels and although printing each in concrete is possible, Crossrail would probably have been delivered in the 2040s or 2050s.

The contractors used an innovative process called FreeFAB, which had been invented by an Australian architect.

- The process creates a wax mould for each panel using 3D printing.

- This mould is then used to create the actual panel.

- After each panel is cast, the wax is melted off and recycled.

- The panels are made in a factory in Doncaster.

We will see a lot more of this technique used in the construction industry.

Elizabeth Line – Custom House Station – 24th May 2022

I took these pictures at Custom House station on the Elizabeth Line.

Note.

- The station was built in a factory and the concrete beams were assembled on-site. Traditionally, the concrete structure would have been poured on site.

- The quality of the columns is excellent and an engineer I spoke to a few years ago, said that the methods used at Custom House station ensure a high quality building. Look at the last two pictures.

- The two escalators are in-line, rather than side-by-side and it looks like this was done to squeeze in the station.

- There were signs up for toilets, that are visible in picture 4. Are they going to be installed?

The ideas used to create Custom House station, will be borrowed by architects and builders all over the world.

HS2 Reveals Dramatic Carbon Saving With Ambitious Modular Design For Thame Valley Viaduct

The title of this post, is the same as that of this press release on High Speed Two.

This is the first paragraph.

HS2 today revealed the final designs for the Thame Valley Viaduct and the pioneering pre-fabricated construction methods that will see the 880m long structure slotted together like a giant Lego set, cutting its carbon footprint by an estimated 66%.

This is one of the pictures released in this photoset.

This second picture shows a closer view of a pillar and the catenary.

It does appear in these two views that the catenary and the gantries that support it are more elegant than those that tend to be used on most electrification schemes at the present time.

These paragraphs describe how the design saved carbon emissions.

Applying lessons from recent high speed rail projects in Spain, the design team cut the amount of embedded carbon by simplifying the structure of the viaduct so that every major element can be made off site.

In a major step forward for viaduct design in the UK, the team opted for two wide ‘box girder’ beams per span instead of eight smaller beams – to simplify and speed up assembly.

The production of steel and concrete is a major contributor to carbon emissions, with the new lighter-weight structure expected to save 19,000 tonnes of embedded carbon in comparison to the previous design. That’s the same amount of carbon emitted by one person taking a flight from London to Edinburgh and back 70,000 times.

It would appear that saving weight and using less steel and concrete can save a lot of carbon emissions.

I once got a bonus at ICI because I saved ten metres on the height of a chemical plant. My boss said, I’d saved nearly a million. by using a mathematical model on an analogue computer to show that a vessel in the plant wasn’t needed and this eliminated a complete floor of the plant.

How much concrete and steel has been saved by High Speed Two on this viaduct, by making it more basset than Afghan hound?

Ever since I watched the building of Crossrail’s Custom House station, I have been in favour of off-site construction.

I wrote about it in An Express Station and am pleased to see it being used on High Speed Two.

New HS2 Pilot Project Swaps Steel For Retired Wind Turbine Blades To Reinforce Concrete

The title of this post, is the same as that of this press release from High Speed Two.

These are the first three paragraphs.

Worn-out wind turbine blades destined for the incinerator will instead be used to create carbon-friendly reinforced concrete on Britain’s new high speed rail network, HS2 Ltd has said today (12.03.21).

The innovative project will swap steel rebar, traditionally used to reinforce concrete, with sections of glass fibre reinforced polymer turbine blades that have reached the end of their operational lives generating low carbon electricity.

By 2023, around 15,000 turbine blades will have been decommissioned across the UK and EU. Until now, expired blades have either been ground down to be used as building materials or sent to energy-from-waste incinerators.

Replacing reinforcing steel with sections of retired wind turbine blades is claimed to cut up to 90 % of the carbon generated by steel reinforcement.

It would appear to me, that this is a worthwhile process.

- In 2018, 295,000 metric tons of steel reinforcing bars were produced in the UK.

- Retired blades don’t end up in landfill or incinerators.

- Could we export them as eco-friendly reinforcing bars, to countries with smaller wind industries.

As we have more wind farms, than most other countries, we will probably have more blades to recycle, so perhaps we should research other secondary uses for these blades.

Earth Friendly Concrete

I was alerted to this product by this article on New Civil Engineer, which is entitled Keltbray Saves Carbon And Money With Earth Friendly Concrete On East London Job.

The article gave enough clues to find the Earth Friendly Concrete home page.

This is the introduction on the page.

We want to have a positive impact on the environment and supply our customers with an excellent product, that is why we created Earth Friendly Concrete ® by Wagners. It is a concrete that uses no ordinary Portland cement, instead using a geopolymer binder system made from the chemical activation of two industrial waste by-products – blast furnace slag (waste from iron production) and fly ash (waste from coal fired power generation). Our product has ZERO Portland cement and it has a much lower embodied energy compared to ordinary concrete, saving 250kg of CO2 for every cubic metre poured. Importantly, the engineering and construction properties of this environmentally friendly concrete is, in some areas, better than normal concrete. EFC has some significant performance advantages over normal Portland cement concrete, including improved durability, lower shrinkage, earlier strength gain, higher flexural tensile strength and increased fire resistance.

On this page, which is entitled About EFC, this said about the products Environmental Excellence.

EFC is a new class of concrete that contains NO ordinary Cement. Globally, the production of 1 tonne of Portland Cement produces 1 tonne of CO₂ emissions and is responsible for 5 to 8% of manmade greenhouse gas emissions. Instead of cement, EFC has a geopolymer binder that is made from the chemical activation of two recycled industrial wastes, flyash and slag. This recycled binder reduces the CO₂ emissions associated with Portland cement by 80 to 90%.

Every m3 of 40 MPa EFC saves 220kg CO₂ emissions.

Wagners, the company behind the development, are based in Queensland. Australia.

So it’s a case of Well Done The Aussies!

They have appointed Capital Concrete, to deliver Earth Friendly Concrete in the London area.

Conclusion

Does High Speed Two and other large projects that will need large amounts of concrete, know about this development?

Mote – World’s First Carbon Removal Plant Converting Wood Waste To Hydrogen

The title of this post, is the same as that of this article on Hydrogen Central.

This paragraph caught my eye.

Mote is also in discussions with carbon utilization company CarbonCure Technologies on the potential of permanently storing its CO2 in concrete via CarbonCure’s carbon removal technologies, deployed in hundreds of CO2 mineralization systems at concrete plants worldwide.

So I looked up CarbonCure Technologies web site.

This page gives an overview of their technology.

According to their web site, they can add carbon dioxide to precast concrete sections. How much carbon dioxide would it have been possible to bury, if the tunnel linings for Crossrail had used CarbonCure’s technology?

HS2 Utilising UK-First Pioneering 3D Concrete Printing On Project

The title of this post, is the same as that of this article on Rail Technology Magazine.

3D-Printing of concrete has been around for some time and it has been used extensively on Crossrail.

But High Speed Two are printing the heavy components on site, to avoid the problems of transport.

Coming Or Going?

I took the pictures of this lorry carrying concrete staircases in the Balls Pond Road.

I like a good puzzle. So where were these three staircases going on a truck, that was obviously from Cornwall?

- They look to be very well-made, with a quality finish.

- Had they been made in Cornwall and were being delivered to a skyscraper in the City?

- Had they been made in East London and were being taken to Cornwall?

The truck was facing Highbury Corner, so would the second be the most likely?

On the other hand, Google found a company called Cornish Concrete Products at Bissoe, only a few miles from Redruth.