Network Rail’s Test Track Take Centre Stage As Hydrogen Is Delivered By Rail For The First Time

The title of this post, is the same as that of this press release from GeoPura.

These three paragraphs introduce the story.

Network Rail, working with rail and energy partners Freightliner and GeoPura, has transported hydrogen for the first time on Britain’s rail network, marking a major step forward for both the rail and energy sectors.

The milestone was achieved yesterday (Wednesday 3 December) at Network Rail’s Test Tracks* site in Tuxford, where freight operator Freightliner hauled a train of gas containers from Doncaster to High Marnham – marking Britain’s first shipment of hydrogen by rail.

It was part of a rail and energy industry innovation event showcasing several hydrogen initiatives. This included the first re-engineered hydrogen-powered shunting locomotive – seen as a step towards replacing diesel – another milestone towards the rail industry’s goal of becoming net zero. The event also demonstrated HPU hydrogen-powered generators, lighting towers and support vehicles.

These two paragraphs describe Network Rail’s test track at Tuxford and GeoPura’s hydrogen production facility at High Marnham.

Network Rail’s site at Tuxford runs all the way to High Marnham, where it sits adjacent to HyMarnham Power, the UK’s largest green hydrogen production facility operated by GeoPura and JG Pears. Built on the site of a former coal-fired power station, HyMarnham Power is one of the world’s first rail-connected hydrogen production facilities, and Network Rail’s Tuxford site will be the world’s first net-zero railway testing facility.

Currently, hydrogen is transported by road. This breakthrough marks a major step towards the rail network becoming a ready-made hydrogen distribution system, a rolling pipeline, with connections to all major industrial and urban centres across Britain – proving the practical capability of rail to transport hydrogen at scale. Hydrogen will also be utilised to decarbonise wider rail operations, from construction to ongoing maintenance and off-grid operations.

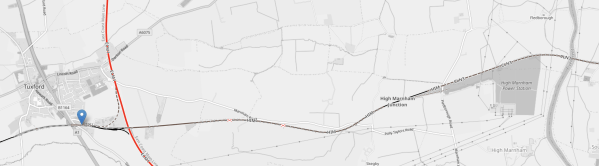

This OpenRailwayMap shows Tuxford and High Marnham.

Note.

- The blue arrow is Tuxford West junction.

- The North-South red track is the East Coast Main Line. East-West track indicated by the blue arrow is Network Rail’s Test Track

- The grey area, to the South of the Test Track in the East is the former site of High Marnham power station, where GeoPura have their hydrogen facility.

- If you continue East on the Test Track it connects to the Sheffield and Lincoln Line at Pye Wipe junction.

Sheffield could be the sort of city, that would need a lot of hydrogen to decarbonise.

Has Hydrogen Been Transported From ICI’s Former Site At Runcorn By Rail

I ask this question, as I used to work at Runcorn in the 1960s, and I don’t remember seeing any hydrogen railway wagons.

I asked Google AI, the question in the title of this section and received this answer.

Hydrogen is typically transported from the INEOS (formerly ICI) site in Runcorn via pipeline or by road in cryogenic liquid tanker trucks or gaseous tube trailers, but it has not been historically transported by rail from that specific site.

The first ever trial shipment of hydrogen by rail on Britain’s network took place only very recently, in December 2025, as part of an industry innovation event. This trial involved transporting hydrogen containers from Doncaster to High Marnham, adjacent to the HyMarnham Power green hydrogen production facility.

It looks like my memory and Google AI agree.

Freightliner Offers Single Container Transport By ‘Carbon Reduced’ Trains

The title of this post, is the same as that of this article on Railway Gazette.

These two paragraphs explain the service.

Freightliner has launched its ECO90 booking service which enables customers of any size to reduce their carbon emissions by sending as little as one container on trains powered by alternative fuels.

The trains currently use hydrotreated vegetable oil, and Freightliner told Rail Business UK that other options could be available in the future, A certificate confirms that the fuel is fully traceable and from sustainable sources, and a Scope 3 carbon emissions report is provided.

It will be interesting to see if this service succeeds.

I suspect that in the future, the service’s biggest competitor will be the hydrogen-or electric- powered truck, which will offer an end-to-end zero-carbon service with minimal cargo handling.

Freightliner Partners With Zero To Decarbonise Critical Transport Operations

The title of this post, is the same as that of this news item from Freightliner.

This is the sub-heading.

Today, Freightliner and Zero, a breakthrough energy company that develops and manufactures whole-blend synthetic, non-biological fuels, announced a partnership to achieve a fossil-free locomotive operation by 2040 and overall Net Zero by 2050, representing a major evolution for one of the world’s oldest, safest and most reliable forms of freight transport. To successfully meet these ambitious emissions targets, Freightliner is exploring alternatives to diesel, such as Zero’s carbon-neutral synthetic diesel, which will eliminate fossil-carbon emissions and improve air quality and environmental wellbeing.

These are my thoughts.

Freightliner

Freightliner is a rail-freight company, that you see regularly hauling freight trains all over the UK.

The picture shows two of their Class 90 electric locomotives in their latest livery.

These posts talk about the company and lower or zero carbon operation.

- Clean Air Power Adds Hydrogen To Class 66 Fuel Mix

- Freightliner Continue Trials On New Low Carbon Fuel

- Freightliner Secures Government Funding For Dual-Fuel Project

- The Ultimate Bi-Mode

The current post fits that pattern.

Zero Petroleum

Zero Petroleum is one of those companies that gives Elon Musk nightmares.

But when you have backers like Babcock, Boeing, Intertek, Rolls-Royce and the Royal Air Force, you must be doing something right.

The Wikipedia entry for the company has this first paragraph.

Zero is a manufacturer of non-biological carbon-neutral synthetic fuel (also known as e-fuel) co-founded by former Formula One engineer Paddy Lowe. Its product has been developed as an alternative to fossil-based fuels and a more scalable sustainable alternative to waste and bio-fuels. The Royal Air Force used its fuel in November 2021 to achieve a World Record first flight powered by synthetic fuel. In July 2022, Zero entered a new partnership with the Royal Air Force to move towards mass production of sustainable aviation fuel.

The company is often known as just Zero.

These two and a half paragraphs from the Wikipedia entry describe the technology.

Zero uses Direct FT (a proprietary and specialised version of Fischer-Tropsch) to directly manufacture target fuels (gasoline, kerosene and diesel) at high yield and with no need for refinery upgrading.

When manufactured using renewable energy, synthetic fuel can be used as a carbon neutral or carbon negative direct drop-in replacement for fossil fuels, particularly for operations that require high energy densities – such as air travel, shipping and farming – and to ensure the continued use of legacy vehicles. It can also be used as a raw material to produce various forms of plastic.

It is manufactured using a process known as petrosynthesis, in which carbon dioxide and hydrogen are combined to create hydrocarbons. The process involves direct air capture of carbon dioxide from the atmosphere and the electrolysis of water to obtain hydrogen.

The Fischer-Tropsch process, despite its association in the past with dodgy regimes, seems to be at the heart of things, as it is with Velocys.

I describe the Velocys process and its link to Fischer-Tropsch in Grant Shapps Announcement On Friday.

Surely, the carbon-neutral fuel produced by Zero, are the ideal stop-gap fuel until true full zero-carbon fuels are available.

But Zero’s fuels will always be available for heritage and legacy trains, planes and automobiles and for applications, where older technology must be used.

As an example of older technology still being used on UK’s railways, Network Rail operate, the New Measurement Train to check all tracks in Great Britain.

The train may have been manufactured in the 1970s, but it has modern engines and is the ideal train to carry the wide variety of sophisticated equipment to ensure the safety of Britain’s railways.

Synthetic diesel like that produced by Zero could keep the New Measurement Train running for some years yet.

Freightliner Have Made A Pragmatic Decision

I believe that Freightliner have made a pragmatic decision, that allows them to go carbon neutral without without taking risks or spending millions on new equipment, that is not fully-developed.

As new zero-carbon technology is developed, like say hydrogen-electric hybrid locomotives, these may take over certain tasks, which will reduce some of the need for synthetic diesel.

But synthetic diesel from Zero will always be there as a fuel of last resort.

The Ultimate Bi-Mode

This picture shows, what could be an experiment by Freightliner at Shenfield.

Unfortunately, I didn’t have a chance to ask the driver, if the Class 66 locomotive was running dead-in-train or helping the Class 90 locomotive with a very heavy load.

The picture shows, that the electric and diesel locomotives can work together, at the front of a train.

Note.

- The Class 66 locomotive has a power of 1,850 kW and the Class 90 locomotive has 3,730 kW.

- Did the Class 66 locomotive pull the train out of Felixstowe?

Since I took this picture, I’ve never seen a similar pairing again.

A Heavy Load From Felixstowe To Manchester

As I waited for my train at Canonbury station this morning, this very long train went through.

After I got home, I found that it was going from the Port of Felixstowe to Trafford Park Freightliner Terminal.

The journey will take around nine-and-a-half hours.

- This time includes a sixty-five minute stop at Ipswich to change the diesel locomotive or locomotives used to haul the train out of the Port of Felixstowe for the pair of Class 90 electric locomotives for the rest of the journey to the North-West.

- The two locomotives together have a power output of about 7.5 MW.

- The train will pick up the West Coast Main Line at Primrose Hill and then take the Trent Valley Line between Rugby and Stafford before approaching Trafford Park, using the Castlefield Corridor through Manchester Piccadilly and Oxford Road stations.

- As I write this, the train is on time as it approaches Tamworth.

The train has done well as at Watford, it was running twenty minutes late. The train crew have used the 7.5 MW well to claw back the time.

Did it help the crew to regain the schedule, that they had 7.5 MW on hand, as opposed to the less than 3 MW from the UK’s largest diesel locomotive?

To my mind, this illustrates one of the reasons, why long distance trains are best run by powerful electric locomotives.

In Do Cummins And Stadler Have a Cunning Plan?, I describe the new Class 99 locomotive.

- It is an electro-diesel locomotive.

- It has 6 MW available on 25 KVAC overhead electrification.

- It has a 1.8 MW Cummins diesel engine, which may be powerful enough to haul the largest trains in and out of the Port of Felixstowe, where the route is not electrified.

Thirty of these locomotives have been ordered by GB Railfreight.

I believe that one of these locomotives could handle a very heavy freight train between the Port of Felixstowe and Trafford Park Freightliner Terminal.

- The locomotive working alone could handle the train on the unelectrified line between Felixstowe and Ipswich.

- There would be no need to electrify the lines in the Port of Felixstowe.

- There would be no need for a prolonged stop in Ipswich.

- An hour on the journey could be saved.

- There might be a saving in the number of crew.

The Class 99 locomotive seems to be well-designed for handling freight trains out of Felixstowe.

Were Freightliner experimenting with what they needed from an electro-diesel locomotive, when I took this picture at Shenfield?

Note.

- The Class 90 electric locomotive has 3.7 MW of power.

- The Class 66 diesel locomotive has 2.4 MW of power.

Was what I saw an affordable electro-diesel locomotive?

Clean Air Power Adds Hydrogen To Class 66 Fuel Mix

The title of this post, is the same as that of this article on the International Rail Journal.

This is the first two paragraphs.

Fuel injection technology developed by Clean Air Power that enables a class 66 locomotive to run on a combination of diesel, biogas and hydrogen has successfully completed nine months of trials with British freight operator Freightliner.

This is the first time that the injection technology has been tested by the rail freight sector and, according to Clean Air Power, paves the way for reducing the emissions of other class 66 locomotives.

Note.

- There are 450 Class 66 locomotives in service in the UK, with more in service in Europe.

- Freightliner was Clean Air Power’s main project partner.

- Nothing was disclosed about carbon savings.

- The trial was backed by £400,000 of Government money.

- The locomotive has completed a nine month trial.

This would appear to be a good professional start to decarbonisation of rail freight.

It’s also rather ironic, that this successful trial of a diesel-saving locomotive was announced on the day of Vlad the Mad’s big parade.

Freightliner Continue Trials On New Low Carbon Fuel

The title of this post, is the same as that of this article on Rail Technology Magazine.

This is the first paragraph.

As part of their commitment to carbon reduction Freightliner will conduct operational trials of a new low carbon fuel supplied by Green Biofuels Ltd (GBF).

And this paragraph described the fuel.

GBF are the UK’s leading provider of Hydrogenated Vegetable Oil (HVO) and the new fuel consists of 55% Shell GTL (gas to liquids) Fuel and 45% Gd+ HVO.

It does appear that hydrotreated vegetable oil or HVO, could be becoming an intermediate step on the route to decarbonisation, as I’ve posted about the fuel before in Powered By HVO.

The other promising route to decarbonisation must surely be that of producing fuel from waste, as pioneered by Velocys and others.

But they are only intermediate steps before hydrogen becomes the preferred zero-carbon fuel for rail freight services.

Railfreight Goes Back To Diesel As Electricity Costs Soar

The title of this post, is the same as that of this article on Railnews.

This is the first paragraph.

Some rail freight operators have abandoned electric traction, at least for now, because the price of electricity has been rising sharply. The electricity tariffs include a 40 per cent renewable energy tax, and following the latest rises diesel traction is now cheaper. The drivers’ union ASLEF is calling for the government to intervene, but Freightliner has already taken action.

This quote from the article is from ASLEF General Secretary; Mick Whelan.

Moving freight by rail rather than road is, inherently, a carbon-efficient mode of transport and an environmentally-friendly way of doing business. Electric-hauled freight services reduce emissions by 99 per cent; even moving goods by diesel traction reduces emissions by 76 per cent.

It looks to me, that a reputable and trusted environmental economist could come up with a compromise price and possibly a solution to improve the situation.

Possible solutions could include.

- Use of Biodiesel or Hydrotreated Vegetable Oil

- More energy storage.

Surely, though, the long term solution is hydrogen-powered locomotives. or dual-fuel locomotives, as I wrote about in Freightliner Secures Government Funding For Dual-Fuel Project.

Wagons Roll For Freightliner UK

The title of this post, is the same as that of this article on railfreight.com.

This is the first paragraph.

UK operator Freightliner has taken delivery of the first batch of new FFA-G wagons for UK operations. The forty wagons have arrived in the UK from Poland, adding to the intermodal fleet of the operator. The entire order, for 230 wagons will be delivered by the end of November 2021.

The wagons have been designed for efficiency and being able to take a forty foot container anywhere on the UK’s network with a loading gauge of W10.

New 775m-Long Freight Trains Begin Operating On UK’s Rail Network

The title of this post, is the same as that as this article on Global Railway Review.

This is the first paragraph.

DP World have announced that its two deep-water ports at Southampton and London Gateway have become the first in the UK capable of handling Freightliner’s new 775m-long intermodal container trains.

It appears from the article that Birmingham, Manchester and Leeds can also handle these longer trains.