The title of this post, is the same as that of this article on offshoreWIND.biz.

This is the sub-heading.

RWE officially opened its ‘Grimsby Hub’ offshore wind operations and maintenance (O&M) facility in the UK on 9 July. From the new O&M base, located at Associated British Ports’ (ABP) Port of Grimsby, RWE’s teams will maintain and operate the Triton Knoll and Sofia offshore wind farms.

These are the first two paragraphs.

The Grimsby Hub also houses RWE’s new UK Centralised Control Room (CCR), which has been set up to provide 24/7 monitoring of the company’s UK offshore wind farms and can provide services such as marine coordination, turbine operations, alarm management, high voltage monitoring and Emergency Response services with a team of twelve operatives, the developer says.

The O&M facility is already employing over 90 Full-Time Equivalents (FTEs), according to RWE, and is expected to employ around 140 RWE staff by 2027, as well as create approximately 60 new locally sourced jobs through the development of the CCR and ongoing offshore operations.

Note.

- Does RWE’s new UK Centralised Control Room control all their UK offshore wind farms?

- I have added them all up and there are almost 12 GW around our shores.

- I’ve read somewhere, that RWE are the UK’s largest power generator. From these figures, that would not surprise me.

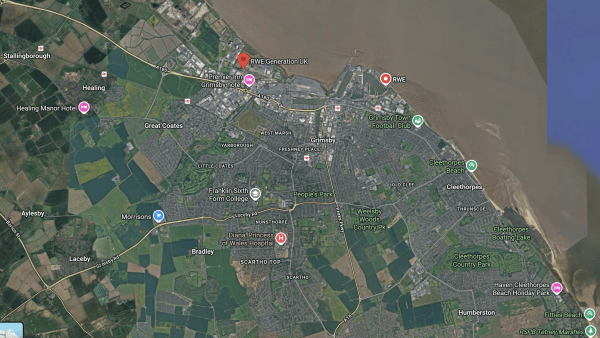

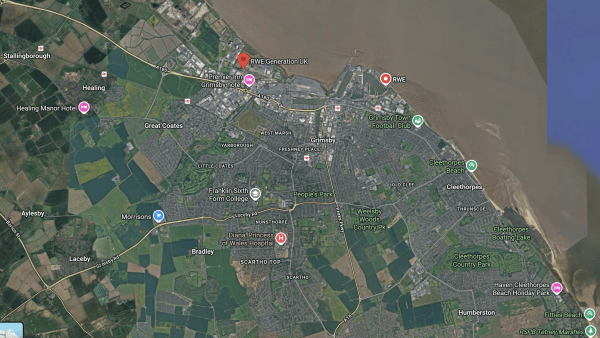

This Google Map shows the location of RWE’s facilities in Grimsby.

Note.

- The bright red arrow at the top of the map indicates RWE Generation UK in Grimsby Docks.

- There is another RWE location to the right of the bright red arrow.

- There is a line of stations along the coast, which from left-to-right are Stallingborough, Healing, Great Coates, Grimsby Town, Grimsby Docks, New Clee and Cleethorpes.

- Cleethorpes is not shown on the map.

- Doncaster and Cleethorpes are 52.1 mile apart, which is within the range of a battery-electric Hitachi and other trains.

- Charging would be at Doncaster, which is fully electrified and at Cleethorpes, by a short length of electrification.

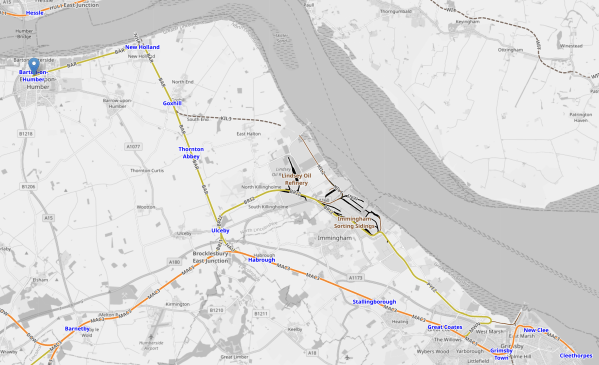

This OpenRailwayMap shows the layout of and the railways around Grimsby Dock.

Note.

- Cleethorpes station is indicated by the blue arrow, in the South-East corner of the map.

- Cleethorpes station has four platforms, but no electrification.

- Grimsby Docks are to the North of the railway to Cleethorpes.

- This Wikipedia entry for Cleethorpes station, shows other railways and light railways served the area. Some were even electric.

These are a few of my thoughts on the development of railways between Sheffield and Cleethorpes.

RWE Will Be A Large Driver Of Employment In Grimsby

Earlier I wrote.

- Does RWE’s new UK Centralised Control Room control all their UK offshore wind farms?

- I have added them all up and there are almost 12 GW around our shores.

- I’ve read somewhere, that RWE are the UK’s largest power generator. From these figures, that would not surprise me.

It’s a long time, since I’ve added resources to a large project, so I asked Google AI, “How many people are needed to support a 1 GW offshore wind farm in the UK?”, and received this answer.

Based on data from large-scale UK offshore wind projects, a 1 GW (1,000 MW) offshore wind farm generally requires between 300 and 600+ people to operate and maintain, depending on whether the staff count includes direct operations, service vessel crews, and long-term supply chain partners.

Operational Staffing: Ørsted’s 1.2 GW Hornsea 1 and 1.3 GW Hornsea 2 projects are supported by an East Coast Hub in Grimsby, which maintains a workforce of over 600 people.

Direct & Indirect Support: For a large-scale project, this often breaks down into approximately 100–150 direct, permanent, high-skilled roles (technicians, engineers, management) and hundreds more in indirect, contracted, or supply chain roles (vessel crews, port operations, logistics).

Industry Average: Studies suggest that for operations and maintenance (O&M), around 50–100 full-time equivalent (FTE) jobs are generated per GW of installed capacity in terms of direct, permanent staff.

Key Takeaways for a 1 GW Farm:

- Direct Technicians/Operators: ~100–200+ (working on-site, turbines, or in control rooms).

- O&M Support Services: ~300–400+ (vessel operators, port logistics, supply chain).

- Total Operations Personnel: 300–600+ people.

Google AI appeared to have borrowed the figure from Ørsted and Hornsea 1 and 2.

So if it’s correct, there will be a total of 7,200 personnel supporting RWE’s wind farms in the UK. Even if only a third were employed in Grimsby, that is still a lot of people to accommodate and who will need to travel to work.

I also think a lot of personnel will come in by train, as the station is close to RWE’s locations.

Will Grimsby Have An Aberdeen-Sized Office-Shortage Problem?

One of the biggest problems, I was always hearing in the 1970s, was the shortage of offices in Aberdeen for the use of the oilmen.

In RWE Goes For An Additional 10 GW Of Offshore Wind In UK Waters In 2030, I talked about RWE’s plans for the future and published this table of new wind farms.

- Sofia – 1,400 MW

- Norfolk Boreas – 1380 MW

- Norfolk Vanguard East – 1380 MW

- Norfolk Vanguard West – 1380 MW

- Dogger Bank South – 3000 MW

- Awel y Môr – 500 MW

- Five Estuaries – 353 MW

- North Falls – 504 MW

Note.

- Sofia is nearly complete.

- Only the three Norfolk and the Dogger Bank South wind farms are on the East side of England and suitable to be serviced from Grimsby., but they still total 7,140 MW.

Has Grimsby got the office-space for all the people needed?

Could The Cleethorpes And Liverpool Lime Street Service Be Run By Battery-Electric Rolling Stock?

The various sections of this route are as follows.

- Cleethorpes and Doncaster – No Electrification – 52.1 miles

- Doncaster and Meadowhall – No Electrification – 15.2 miles

- Meadowhall and Sheffield – No Electrification – 3.4 miles

- Sheffield and Dore & Totley – No Electrification – 4.2 miles

- Dore & Totley and Hazel Grove – No Electrification – 29.2 miles

- Hazel Grove and Stockport – Electrification – 3.3 miles

- Stockport and Manchester Piccadilly – Electrification – 5.9 miles

- Manchester Piccadilly and Deansgate – Electrification – 0.8 miles

- Deansgate and Liverpool South Parkway -Not Electrified – 28.2 miles

- Liverpool South Parkway and Liverpool Lime Street – Electrified – 5.7 miles

Adding the sections together gives.

- Cleethorpes and Hazel Grove – No Electrification – 104.1 miles

- Hazel Grove and Deansgate – Electrification – 10 miles

- Deansgate and Liverpool South Parkway -Not Electrified – 28.2 miles

- Liverpool South Parkway and Liverpool Lime Street – Electrified – 5.7 miles

Note.

- To cover the 104.1 miles to Hazel Grove battery-electric trains would probably need to leave Cleethorpes with full batteries.

- Doncaster is a fully-electrified station and passing trains may be able to have a quick top-up.

- In South Yorkshire Now Has Better North-South Connections, I calculated that Doncaster is a very busy station with 173 express trains per day calling at the station or one every 8.5 minutes.

- Will trains be able to stop for a long period to charge batteries?

- It may be prudent to electrify between Meadowhall and Sheffield, under the Midland Mainline Electrification.

- Sheffield and Dore & Totley is shown that it will be electrified, under the Midland Mainline Electrification.

- Do we really want to have electrification marching along the Hope Valley Line?

- I believe that hydrogen-hybrid locomotives will be a better solution for freight trains on scenic lines like the Hope Valley, as they are zero-carbon, powerful and with a range comparable to diesel.

I believe CAF, Hitachi and Siemens have off the shelf rolling stock and factories in this country, who could build trains for the Cleethorpes and Liverpool Lime Street route.

How Would You Charge Battery-Electric Trains At Cleethorpes?

This picture shows Cleethorpes station

Note.

- The four long platforms without electrification.

- The platforms have recently been refurbished.

- The train in Platform 2 is a TransPennine Express Class 185 Siemens Desiro diesel train.

The simplest way to electrify the station would be to put up enough 25 KVAC overhead wires, so that battery-electric trains needing a charge could put up a pantograph and have a refreshing drink.

In Technology Behind Siemens Mobility’s British Battery Trains Hits The Tracks, I wrote about Siemens Rail Charging Converter.

This is a visualisation of a Siemens Rail Charging Converter in action.

Note.

- The track is electrified with standard 25 KVAC overhead electrification.

- The train is a standard Siemens electric or battery-electric train.

- Siemens Rail Charging Converter, which is the shed in the compound on the left is providing the electricity to energise the catenary.

- I suspect, it could power third rail electrification, if the Office of Rail and Road ever allowed it to be still installed.

- The Siemens Rail Charging Converter does have one piece of magic in the shed. I suspect it uses a battery or a large capacitor to help power the electrification, as it can be powered from any typical domestic grid supply.

- I also wonder, if it has safety devices that cut the power outside the shed if track workers or intruders are detected, where they shouldn’t be?

- It could even cut the power, when trains are not running to save power and increase safety.

This looks to me, that a Siemens Rail Charging Converter could be a superb example of out-of-the-box thinking.

Could The Cleethorpes And Barton-on-Humber Service Be Run By Battery-Electric Rolling Stock?

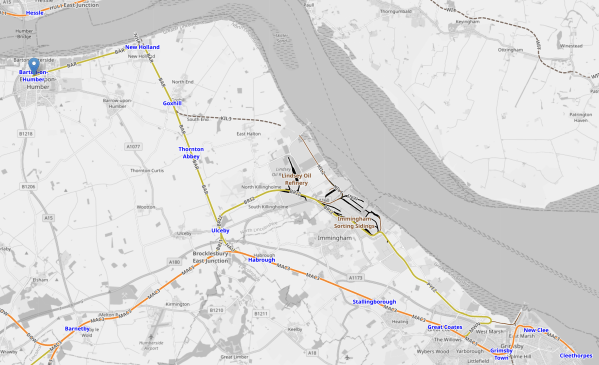

This OpenRailwayMap shows the railways of North-East Lincolnshire.

Note.

- Cleethorpes is in the South-East Corner of the map.

- Barton-on-Humber is in the North-West corner of the map and marked by a blue-arrow.

- Stations from South to North would be New Clee, Grimsby Docks, Grimsby Town, Great Coates, Healing, Stallingborough, Habrough, Ulceby, Thornton Abbey, Goxhill, New Holland and Barrow Haven.

- The line is double track.

- Cleethorpes and Barton-on-Humber is just 22.8 miles.

- A round trip would be under fifty miles, which would be well within range of a full-charge at one end.

- Service is one train per two hours (tp2h), which would only need a single train, shuttling between Cleethorpes and Barton-on-Humber.

- Two trains could provide an hourly service.

I would expect, that well-designed, solid and reliable German engineering could build a Siemens’ Rail Charging Connector that could charge four trains per hour (tph) at Cleethorpes station.

At present services are.

- TransPennineExpress – 1 tph to Liverpool Lime Street.

- East Midlands Railway – 1 tp2h to Barton-on-Humber

- East Midlands Railway – 1 tp2h to Matlock via Lincoln and Nottingham

- Northern Trains – 1 train per day (tpd) Sheffield via Brigg.

That is probably only about two tph.

Could The Cleethorpes And Sheffield Service Be Run By Battery-Electric Rolling Stock?

This is a description of the current Cleethorpes and Sheffield service.

- It is run by Northern Trains.

- The morning train leaves Sheffield at 09:54 and arrives in Cleethorpes at 11:40.

- The afternoon train leaves Cleethorpes at 13:20 and arrives in Sheffield at 15:10.

- The train is a Class 150 diesel train, which is a bit of a Joan Collins of a train – Of a certain age, but still scrubs up extremely well!

- Intermediate stations are Worksop, Retford, Gainsborough Central, Kirton Lindsey, Brigg, Barnetby and Grimsby Town

- The route length is 71.6 miles

- Trains take about 45-50 minutes.

It is also a parliamentary train.

The Wikipedia entry for parliamentary train gives this description of the Cleethorpes and Sheffield service.

Via Kirton Lindsey & Brigg. Became a parliamentary service when weekday services were withdrawn in 1993. Regular trains have operated between Gainsborough and Sheffield for most timetable periods since. Suspended January 2022 by Northern, who cited COVID-19 and staffing issues , but the service was reinstated in December 2022. Changed in May 2023 to be one return journey on weekdays only.

In the 1950s and 1960s I lived in Felixstowe part of the time and in the 1970s and 1980s I lived near Woodbridge and I observed first hand the development of the Port of Felixstowe and the effects it had on the surrounding countryside.

The development of the Port of Felixstowe, has brought the following.

- Improved roads and railways.

- Ipswich is now an hour from London by train.

- Ipswich is now a University town.

- New housing and other developments, both in Ipswich and Felixstowe and the surrounding countryside.

- Employment also has increased considerably, both in the Port and in surrounding towns.

- Ipswich’s football team is very much respected all over Europe and has won the English top division, the FA Cup and the UEFA Cup.

When you consider the jobs that RWE could create in the Port of Grimsby, I believe that this could have similar effects in Grimsby and Cleethorpes, as the Port of Felixstowe had in East Suffolk.

Already, the following are being talked about.

- A direct rail link between Cleethorpes and Grimsby to London.

- Battery-electric trains between Cleethorpes and Grimsby and Doncaster, Manchester and Liverpool Lime Street.

I believe that an improved rail link between Cleethorpes and Sheffield could be the catalyst for much needed housing along the route, which would be to the benefit of Cleethorpres, Grimsby, Sheffield and all the intermediate towns and villages on the route.

and the affects this will have on the countryside around the town, I believe that a strong case can be made out for a more frequent service between Cleethorpes and Sheffield.

July 16, 2025

Posted by AnonW |

Artificial Intelligence, Design, Energy, Sport, Transport/Travel | ABP, Ørsted, Barton Line, Battery-Electric Trains, Class 185 Train, Cleethorpes Station, Development, Dore and Totley Station, East Midlands Railway, Football, Google AI, Grimsby, Grimsby Town, Hitachi Intercity Battery Train, Hope Valley Line, Housing, Innovation, Ipswich Town, Lincoln Station, Liverpool Lime Street Station, Matlock Station, Midland Main Line, Midland Main Line Electrification, North Sea Oil And Gas, Northern Trains, Nottingham Station, Office Of Rail And Road, Offshore Wind Power, Port of Felixstowe, Port Of Grimsby, RWE, RWE Grimsby Hub, Sheffield Station, Siemens Desiro, Siemens' Rail Charging Converter, Sofia Wind Farm, Triton Knoll Wind Farm, UK Port Development, University Of Suffolk, Wind Power |

2 Comments

This title of this post is the same as that of this news item from Siemens, which was published in December 2024.

These three bullet points introduce the news item.

- The Mireo Plus B battery train is rolled out in the East Brandenburg network, Germany, using the same technology as the British Desiro Verve project.

- The Desiro Verve would save £3.5 billion and 12 million tonnes in CO2 emissions for Britain’s railways over 35 years.

- The development marks the latest step of this technology’s journey to Britain’s railways.

No-one, including me, seemed to have spotted this news item, especially, since it is significant to both the UK and Germany.

But then parts of Siemens’s home country; Germany and Yorkshire, where they are building, a train factory to build London’s new Piccadilly Line trains have something big in common – There is a distinct shortage of electric trains and the overhead wires to power them.

So did German engineers, egged on by pints of British real ale, realise that their battery-electric technology for the Mireo Plus B battery-electric train, would turn a Desiro City multiple unit, like the Class 700, 707 or 717 into battery-electric trains.

These are three paragraphs from the Siemens news item.

The innovative technology behind Siemens Mobility’s British battery trains has been rolled out in the East Brandenburg network in Germany.

31 of the company’s Mireo Plus B trains are being phased in to the Berlin Brandenburg metropolitan region, beginning on Sunday (15 December) and is the latest proof point of the technology that underpins the Desiro Verve project in Britain. This follows the debut of this technology on 27 new trains in the Ortenau region of Germany in April, with more set to arrive in Denmark in 2025.

The British Desiro Verve trains would be assembled at Siemens Mobility’s new Train Manufacturing Facility in Goole, East Riding of Yorkshire, formally opened by the Transport Secretary and Mayor of London in October.

I’d always wondered, what Siemens would do with this factory, when it had finished making the Piccadilly Line trains.

It also should be noted, that the boss of Siemens UK, when the Goole factory was planned was Jürgen Maier, who according to his Wikipedia entry has Austrian, British and German citizenship and is now the boss of Great British Energy.

I believe that Siemens have big plans for the Goole factory.

One thing it has, that at the present time could be a problem in Germany, is large amounts of renewable electricity and hydrogen, so will energy-intensive components for trains be made at Goole?

It will be interesting to see how the Goole factory develops.

The Desiro Verve Train For The UK and Ireland

In the Siemens news item, their Joint CEO for the UK and Ireland; Sambit Banerjee, says this.

The Desiro Verve would be assembled at our state-of-the-art Goole Rail Village in Yorkshire and offers an integrated solution to replace Britain’s aging diesel trains without having to electrify hundreds of miles of track, saving the country £3.5 billion over 35 years and providing a practical path to decarbonising British railways.”

In June, Siemens Mobility identified how the Desiro Verve could save Britain’s railways £3.5 billion over 35 years compared with using diesel-battery-electric ‘tri-mode’ trains. This would support the Government’s aim of removing diesel-only trains from Britain’s railways by 2040.

The British trains would be powered by overhead wires on already electrified routes, then switch to battery power where there are no wires. That means only small sections of the routes and/or particular stations have to be electrified with overhead line equipment (OLE), making it much quicker and less disruptive to replace diesel trains compared to full electrification.

I agree with his philosophy.

The Rail Charging Converter

When I wrote Cameron Bridge Station – 15th May 2025, I described how a short length of overhead electrification could be erected at the station to charge passing trains, using their pantographs.

Cameron Bridge station is lucky in that there is already a 132,000 KVAC electricity connection to the distillery next door.

But at other places, where there is no connection, you could wait as long as seven years to be connected to the grid.

So Siemens have come up with the Rail Charging Converter, that provides a local electricity supply to support the charger.

It is described in this paragraph from the news item.

This OLE can also be installed much more quickly using Siemens Mobility’s innovative Rail Charging Converter (RCC), which makes it possible to plug directly into the domestic grid – potentially cutting delivery times for OLE from seven years to as little as 18 months.

This Siemens visualisation shows a Verve train and an RCC.

This arrangement could be used in sensitive countryside or close to historic buildings.

Modern Railways – June 2025

There is an article about the Siemens technology in the June 2025 Edition of Modern Railways.

It is called The Battery Revolution Starts In Long Marston for which this is part of the sub-heading.

New technology being installed by Siemens Mobility at Porterbrook’s test facility paves the way for widespread use of battery trains in the UK.

The article is a must-read.

Conclusion

Siemens appear to have the technology with their Rail Charging Converter and battery-electric trains like the Verve and the Mireo Plus B, to be able to decarbonise lines without electrification all over the world.

Would larger gauge trains be delivered from Germany and smaller gauge ones from Goole?

I wouldn’t be surprised that a version for a German S-Bahn could share more characteristics, with a small British train, than a large German one.

I can also see an underground railway, that was built without power in the tunnels. So if you were building the Waterloo and City Line today, would it be battery-electric and charged at each end of the line using a pantograph?

May 19, 2025

Posted by AnonW |

Energy, Transport/Travel | Battery-Electric Trains, Brandenburg, Class 700 Train, Class 707 Train, Class 717 Train, Desiro City, Desiro Verve, Germany, Innovation, Jürgen Maier, Mireo, Partial Electrification, Siemens Desiro, Siemens' Rail Charging Converter |

7 Comments

The title of this post, is the same as that of this article from Rail Technology Magazine.

This is the sub-heading.

Porterbrook has signed a £1.7 million deal with Siemens Mobility to purchase an innovative Rail Charging Converter (RCC) for its Long Marston Rail Innovation Centre. The cutting-edge technology will make battery charging and 25kV power supply possible in areas of the UK railway where overhead line equipment is not currently available.

This first paragraph describes the system.

The RCC is a modular and containerised system that uses power electronics to provide a fully compliant, standard connection between the modern three-wire electricity grid and the single-wire railway. It essentially reduces the electrification infrastructure needed by being able to plug into existing power cables and deliver the ideal power supply for trains.

These two paragraphs describe how the RCC was designed and funded, and how it will be used in the future.

The original development of the RCC was supported by the Department for Transport through Innovate UK’s First of a Kind programme. The team will install the novel charging solution at Long Marston, enabling the charging of trains with batteries, fed from existing standard local power supply cables.

Compatible with all overhead line equipment powered trains, the small, low-cost design of the RCC enables the removal of diesel passenger train operation on routes without continuous electrification.

I suspect we’ll see other manufacturers like Hitachi ABB Power Grids and Furrer+Frey launch similar products.

This page gives full details of the award to Siemens Mobility.

Project Title: 25kV Battery Train Charging Station Demonstration

Lead Organisation: Siemens Mobility Ltd.

Project Grant: £59,910

Public Description:

The UK rail industry is committed to decarbonisation, including the removal of diesel trains by 2040.

Replacing diesel trains with electric, hydrogen or battery bi-mode rolling stock provides faster, smoother and more reliable journeys, as well as eliminating local pollution and greatly reducing carbon dioxide.

To enable clean, green electric bi-mode operation without continuous electrification requires enhancement of the power supply to existing electrification and novel charging facilities to support bi-mode trains.

No small, low-cost solution is currently available for charging facilities that are compatible with standard UK trains and locally available power supplies and space.

Siemens Mobility, working with ROSCO, TOCs and Network Rail, will deliver a novel AC charging solution enabling simple installation of small, low-cost rapid charging facilities fed from existing standard local power supply cables.

Compatible with all OLE-powered trains, the novel design enables the removal of diesel passenger train operation on non-electrified routes across the UK, while minimising land requirements and modifications required to existing station structures.

£59,910 seems to be good value for the helping with the design of a universal charging system for 25 KVAC battery-electric trains in the UK.

I have a few thoughts.

Will The Rail Charging Converter (RCC) Charge Third Rail Trains?

As new third-rail systems are effectively systems non grata, I suspect that third-rail trains will be charged by fitting a pantograph and the appropriate electrical gubbins.

Most modern third-rail electrical multiple units have a roof that is ready for a pantograph and can be converted into dual-voltage trains.

What Trains Will Be Able To Be Charged Using An RCC?

I suspect it will be any train with a battery, a pantograph and the appropriate electrical gubbins.

Battery-electric trains that could have a pantograph include.

- Alstom Electrostar and Aventra

- CAF Civity

- Hitachi Class 385 train

- Hitachi Class 800 train

- Siemens Desiro and Mireo

- Stadler Class 777 train

- Stadler Flirt and Akku

- Vivarail Class 230 train

I suspect it could charge all trains in the UK, where batteries have been proposed to be added.

What Is Meant By Mobile?

I suspect transportable and temporary would be a better description.

This gallery show Felixstowe station and a Class 755 train, which can be fitted with batteries.

Suppose that testing was to be done at Felixstowe of a battery-electric Class 755 train.

- The containerised electrical system would be placed somewhere convenient.

- A short length of overhead wire would be erected in the platform.

- The system would then be connected together and to the electrical supply.

- After testing, it could be used to charge a train.

It would be very convenient for operation of the railway, if it could be installed and taken out overnight.

Conclusion

It looks a well-designed system.

December 5, 2023

Posted by AnonW |

Transport/Travel | Aventra, CAF Battery-Electric Trains, Charging Battery Trains, Civity Train, Class 230 Train, Electrostar, First Of A Kind 2022, Furrer + Frey, Hitachi ABB Power Grids, Long Marston Rail Innovation Centre, Mireo, Partial Electrification, Porterbrook, Siemens, Siemens Desiro, Stadler FLIRT Akku |

1 Comment