Hydrogen And Electric Propulsion Compared

Stadler have given us an interesting way of comparing the range and other properties of hydrogen-powered and battery-electric trains, as their Flirt H2 and Akku trains have both set Guinness World Records for distance travelled.

The Hydrogen-Powered Flirt-H2

In Stadler’s FLIRT H2 Sets World Record For Hydrogen Powered Train, I write about how a Stadler Flirt-H2 had set a record of 2803 kilometres, without refilling.

This page on the Stadler web site gives details of the Flirt-H2.

- Hydrogen Range – 460 km.

- Operating Speed – 127 kph

- Refuelling Time – < 30 minutes

- Seats – 116

This graphic clipped from the Stadler web site shows the Flirt-H2.

Like Greater Anglia’s Class 755 train, it has a PowerPack in the middle, which contains a fuel cell and the hydrogen tank, instead of the Class 755 train’s diesel engines.

The Battery-Electric Akku

In Flirt Akku And Class 755 Train Compared, I compare a Flirt Akku and Greater Anglia’s Class 755 train, after the battery-electric Akku had set a record of 224 kilometres, with recharging.

This page on the Stadler web site gives details of the Flirt Akku.

- Battery Range – 150 km

- Operating Speed – 160 kph

- Chrging Time – 15 minutes

- Seats – 120-180

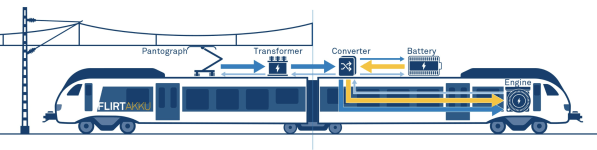

This graphic clipped from the Stadler web site shows the Flirt Akku.

At a quick glance, the trains seem to be fairly similar, with the exception of the PowerPack.

- Both have regenerative braking.

- Both have the battery and the power converter on the roof.

- I would expect that the Flirt-H2 could be fitted with a pantograph and a transformer.

- Both trains have two passenger carriages.

I also suspect, both trains can be lengthened by adding extra coaches.

These are my thoughts.

Thoughts On The PowerPack In A Flirt-H2

This picture shows the PowerPark car of a Class 755 train.

Note.

- These PowerPacks have slots for up to four 480 Kw diesel engines.

- PowerPacks on a Class 788/4 train with four diesel engines weighs 27.9 tonnes.

- PowerPacks on a Class 788/3 train has two diesel engines.

- In the UK, trains with PowerPacks have up to four passenger cars.

- The PowerPack has a walkway from one end of the car to the other.

As customers, might like to replace their diesel PowerPacks, with something that was zero-carbon, I would expect, that the hydrogen PowerPack would have the following properties.

- Hydrogen and diesel PowerPacks would be interchangeable.

- The hydrogen PowerPack would come in two handy sizes of hydrogen fuel cell; 0ne and two MW.

- The weight of both hydrogen and diesel PowerPacks would be similar, as if power and weight were similar, then this could help certification.

- The Flirt-H2 for California, which would only have two passenger cars, would have the smaller hydrogen fuel cell.

I would expect that a conservative designer would use any spare space for hydrogen storage.

- Perhaps, there would be one tank either side of the walkway.

- The quoted range of 450 kilometres for the Flirt-H2 is just under 300 miles, so it would probably cover most regional round trips in Europe without refuelling.

- On many routes refuelling would only need to be done once-per-day.

- Refuelling can be some distance from operation.

- Large tanks would explain the thirty minutes refuelling time.

Obviously, large tanks have the collateral benefit of setting distance records.

The Kinetic Energy Of A Flirt-H2 Train

In My First Rides In A Class 755 Train, I calculated the kinetic energy of a Class 755/4 train.

I said this.

I will use my standard calculation.

The basic train weight is 114.3 tonnes.

If each of the 229 passengers weighs 90 kg with Baggage, bikes and buggies, this gives a passenger weight of 20.34 tonnes.

This gives a total weight of 134.64 tonnes.

Using Omni’s Kinetic Energy Calculator gives these figures for the Kinetic energy.

- 60 mph – 13.5 kWh

- 100 mph – 37.4 kWh

- 125 mph – 58.4 kWh

If we are talking about the Greater Anglia Class 755 train, which will be limited to 100 mph, this leads me to believe, that by replacing one diesel engine with a plug compatible battery of sufficient size, the following is possible.

- On all routes, regenerative braking will be available under both diesel and electric power.

- Some shorter routes could be run on battery power, with charging using existing electrification.

- Depot and other short movements could be performed under battery power.

The South Wales Metro has already ordered tri-mode Flirts, that look like Class 755 trains.

The calculation for a Flirt-H2 train is as follows.

Train Weight – 82.3 tonnes

Passenger Weight – 10.4 tonnes

Total Weight – 92.7 tonnes

This gives these kinetic energies

- 60 mph – 9.3 kWh

- 79 mph – 16.0 kWh

- 100 mph – 25.7 kWh

It looks like the 79 mph; Flirt-H2 would only need a 16 KWh battery.

It seems when a battery is not for traction and only handles the regenerative braking, it can be surprisingly small.

Mathematical Advantages Of Hydrogen

I do wonder that on balance, there may be mathematical advantages to hydrogen; long range, less frequent refuelling and small batteries.

But as I indicated in Zillertalbahn Hydrogen Plan Dropped In Favour Of Battery Traction, the decision doesn’t always go hydrogen’s way!

Conclusion

I feel Stadler have the right approach of a modular concept that incorporates both hydrogen-powered and battery-electric trains.

I also think, if you have a route, you want to decarbonise, Stadler have the train for you.

Zillertalbahn Hydrogen Plan Dropped In Favour Of Battery Traction

The title of this post, is the same as that of this article on Railway Gazette.

I wrote about this order in Zillertalbahn Orders Stadler Hydrogen-Powered Trains.

I didn’t blog about it but I remembered an article a few years ago about Stadler getting an order from the Zillertalbahn.

It appears the change is down to improvements in battery technology.

Narrow-gauge battery-electric multiple units must be right up Stadler’s street, as they built the new trains for the narrow gauge Glasgow Subway.

Glasgow Subway’s New Trains Enter Service

The title of this post, is the same as that of this article on the BBC.

These two paragraphs outline the story.

New modernised trains have come into passenger service on Glasgow’s subway.

The first two trains were introduced by Strathclyde Partnership for Transport (SPT) on Monday.

Note.

- Modernised is probably the wrong word. Surely, it should be modern, as the others are nearly fifty years old.

- The new trains will have wheelchair spaces and air-conditioning.

- The BBC has a video in their article.

They look good and I can’t wait to get up to Glasgow to see them.

UK Rail Operations Group Gets The Keys To Their Tri-Mode Locomotive

The title of this post, is the same as that of this article on RailFreight.com.

This is the sub-heading.

A Green Milestone, in every sense. Delivered in an eye-catching livery reminiscent of British Racing Green, Rail Operations Group may well have called the delivery of their first Class 93 tri-mode locomotive, a leap forward in reshaping the future of operations. It is certainly an environmental first strike on behalf of the rail industry in the race to a net-zero carbon economy.

Note.

- There are thirty on order.

- It can haul both freight and passenger trains.

- It has a maximum speed of 110 mph.

- The development history in the Wikipedia entry is a good read.

It certainly looks an impressive locomotive and the livery will get it noticed. But then you don’t hide your best light under a bushel!

Operations

This section in the Wiki9pedia entry is entitled Proposed Use, where this is said.

ROG intends to pair the locomotive with a new generation of freight wagons that would run at a maximum speed of 100 mph (160 km/h), comparable to that of contemporary passenger trains. Trains formed of such wagons would be easier to insert into timetables around and between existing passenger trains, increasing flexibility and potentially creating capacity for more freight trains on the national network.

In addition to freight, the Class 93 has also been designed to accommodate the haulage of passenger stock, including a variable-height Dellner coupling and a three-step Westcode brake in addition to its conventional two-pipe air brake.

The Class 93 locomotives will surely be very impressive hauling freight heavy trains to and from Felixstowe, on the electrified Great Eastern Main Line sandwiched between the 100 mph express passenger trains.

- What weight and length of train, these locomotives can haul in and out of Felixstowe?

- What destinations will they be able to reach using the electrification from Ipswich?

- Will they be able to take shorter trains to the Midlands via Ely and Leicester?

It will be interesting to see where these locomotives operate.

Southeastern Keen On Battery EMUs

The title of this post, is the same as that of a small section in the August 2023 Edition of Modern Railways.

This is said.

Southeastern is to seek pre-qualification interest from manufacturers and leasing companies for a replacement fleet for the Networker Class 465 and 466 inner-suburban stock, now over 30 years old. The company intends to compare the price of new and cascaded stock.

Southeastern MD Steve White told Modern Railways his preference is for a bi-mode EMU, capable of working off both the third rail supply and batteries. Battery EMUs were originally proposed for the Networker replacements so they could work through services to the unelectrified Isle of Grain branch, after Medway Council put forward plans to restore passenger services on the Hoo peninsular to serve new housing there.

Despite the extension of services to Sharnal Street on the Isle of Grain having since been put on hold by Medway Council on cost grounds (p13, May issue).

Southeastern is still pursuing battery EMUs, even though the company’s existing network is all electrified on the third rail system.

Merseyrail is already adopting battery EMU technology, with seven of the new fleet of 53×4-car Class 777 units being equipped with batteries to enable them to serve the unelectrified extension to Headbolt Lane (p82, July 2022 issue).

Mr. White says there are a number of reasons battery EMUs are attractive.

-

- Increasing levels of mental health issues in society have led to trespass being a major issue the railway: battery EMUs would make it feasible to keep trains moving at slow speed when the current supply has to be switched off to protect a trespasser.

- Battery EMUs would be able to keep moving on occasions when the third rail supply fails, due to technical failures or ice on the conductor rail. This would avoid the compounding of problems, as when delayed passengers got out on the track at Lewisham in March 2018 when the third rail iced up, forcing Network Rail to cut the electricity supply and making it more difficult to get trains moving again.

- Battery EMUs would make it feasible to remove third rail from depots, making them safer places in which to work. A train cleaner was electrocuted and died at West Marina depot in St. Leonards in May 2014, and the Office of Road and Rail has well-publicised concerns on safety grounds about any extensions to the third rail system.

- Battery EMUs would be able to cater for service extensions on unelectrified lines, such as the Isle of Grain.

Mt. White says the trespass issue is the major driver, and if the principle of battery EMUs becomes established it might prove feasible to remove the third rail from platform areas at inner-suburban stations with a persistent trespass problem. He points out this approach might unlock extension of third rail to routes such as the Uckfield line, allowing station areas to be left unelectrified. Replacement of DMUs by electric stock on the Uckfield branch would eliminate diesel working at London Bridge, with air-quality and carbon removal benefits for the capital.

I will now look at the problem in detail.

Range Of A Battery EMU

I discuss range of battery EMUs in these posts.

- Stadler FLIRT Akku Battery Train Demonstrates 185km Range

- New Merseyrail Train Runs 135km On Battery

Note.

- Both trains are built by Stadler.

- 135 km. is 84 miles.

- A Bombardier engineer told me eight years ago, that the battery-electric Class 379 train had a range of sixty miles.

I feel it is reasonable to assume that a 100 mph battery-electric train, designed to replace Southeastern’s Networkers could have a range of at least sixty miles.

Distances Of Cannon Street Metro Services

These are distances of services from Cannon Street.

- Erith Loop via Greenwich, Woolwich Arsenal and Bexleyheath – 28.5 miles

- Gravesend – 24.5 miles

- Orpington – 12.6 miles

- Grove Park – 7.1 miles

- Slade Green – 14.5 miles

Note.

- The Erith Loop services start and finish at Cannon Street station.

- The Gravesend service terminates in an electrified bay platform.

- The Orpington service terminates in an electrified bay platform.

- Grove Park and Slade Green are depots.

If trains could be fully charged at Cannon Street station, all services out of the station could be worked by a battery EMU with a range of forty miles.

Charging At Cannon Street

Consider.

- All Cannon Street services arrive at the station via London Bridge station.

- All Cannon Street services leave the station via London Bridge station.

- Trains typically take 4-5 minutes between Cannon Street and London Bridge station.

- Trains typically wait at least 7 minutes in Cannon Street station before leaving.

- Typically, a battery EMU takes fifteen minutes to charge.

A train running from London Bridge to London Bridge would probably take a minimum of fifteen minutes, which should be enough to charge the train.

The track between London Bridge and Cannon Street would need a strong level of protection from trespassers.

I suspect that with some slight timetable adjustments, all Cannon Street services could be run using battery EMUs.

Distances Of Charing Cross Metro Services

These are distances of services from Charing Cross.

- Maidstone East – 38.9 miles

- Dartford – 17.1 miles

- Gravesend – 23.8 miles

- Hayes – 14.3 miles

- Sevenoaks – 22.2 miles

- Grove Park – 8 miles

Note.

- The Gravesend service terminates in an electrified bay platform, which could be used to charge the train before return.

- The Maidstone East service terminates in an electrified platform.

- Grove Park is a depot.

If trains could be fully charged at Charing Cross station, all services out of the station could be worked by a battery EMU with a range of fifty miles.

Charging At Charing Cross

Consider.

- All Charing Cross services arrive at the station via London Bridge station.

- All Charing Cross services leave the station via London Bridge station.

- Trains typically take 10 minutes between Cannon Street and London Bridge station.

- Trains typically wait at least 7 minutes in Cannon Street station before leaving.

- Typically, a battery EMU takes fifteen minutes to charge.

A train running from London Bridge to London Bridge would probably take a minimum of twenty minutes, which should be enough to charge the train.

The track between London Bridge and Charing Cross would need a strong level of protection from trespassers.

I suspect that with some slight timetable adjustments, all Charing Cross services could be run using battery EMUs.

Distances Of Victoria Metro Services

These are distances of services from Victoria.

- Gillingham – 37.2 miles

- Orpington – 14.7 miles

- Dartford – 18.9 miles

Note.

- The Orpington service terminates in an electrified bay platform.

- The Gillingham service terminates in an electrified bay platform.

- The Dartford service terminates in an electrified platform.

If trains could be fully charged at Victoria station, all services out of the station could be worked by a battery EMU with a range of fifty miles.

Charging At Victoria

Consider.

- All Victoria services arrive at the station via Shepherds Lane junction.

- All Charing Cross services leave the station via Shepherds Lane junction.

- Trains typically take five minutes between Victoria and Shepherds Lane junction.

- Trains typically wait at least 7 minutes in Victoria station before leaving.

- Typically, a battery EMU takes fifteen minutes to charge.

A train running from Shepherds Lane junction to Shepherds Lane junction would probably take a minimum of seventeen minutes, which should be enough to charge the train.

The track between Shepherds Lane junction and Victoria would need a strong level of protection from trespassers.

Conclusion

It certainly appears that if the Networker Class 465 and Class 466 trains were replaced by new trains with the following specification.

- 100 mph operating speed.

- Range of fifty miles on battery power.

- Ability to charge batteries in fifteen minutes.

- Third-rail operation

- It might be an idea to add a pantograph, so the trains could use 25 KVAC overhead wires where necessary and charge batteries on a short length of overhead electrification.

Then a substantial part of the Southeastern Metro network could be made safer, by selective removal of third rail at trespassing hot spots.

Wales’ Inaugural Hybrid Train Service Launches On The Borderlands Line

The title of this post, is the same as that of this article on Rail Technology Magazine.

These are the first two paragraphs.

Today marks a historic day for the Welsh rail sector, seeing the introduction of the first battery-hybrid trains used in regular passenger service on the Borderlands Line between Wrexham and Bidston, as announced by Transport for Wales (TfW).

The inaugural service for the Class 230 trains left Wrexham Central at 07:31, following months of testing and crew training.

Unfortunately, it didn’t go very well, as some trains were late and there were several rail replacement buses and cancellations.

I’m afraid, Vivarail’s ambitious project is starting to look like a heroic failure.

Could Stadler Rescue The Borderlands Line?

Perhaps the solution for the Borderlands Line, which is only 27.5 miles each way, is to ask Stadler for an estimate to extend Merseyrail’s Class 777 trains to Wrexham Central station.

- Trains would use battery power between Bidston and Wrexham.

- Passengers would not need to change trains to go between Liverpool and Wrexham.

- Trains would go round the rail loop under Liverpool, where they would charge their batteries.

- There may need to be some form of charging in Wrexham.

I’m sure the good people Merseyside and North Wales wouldn’t object, but the politicians in Cardiff might!

The UK-Wide Need For Self-Powered Trains

Consider.

- The UK needs a substantial number of two-, three- and four-car self-powered trains.

- A proportion of these trains will run on partially-electrified routes.

- 100 mph trains would be preferable.

- Some routes would need trains capable of using third-rail electrification.

They are also needed urgently.

Will Mark 3’s Save The Day?

Consider.

- The only Mark 3 electric multiple units still running or in a state good enough to be converted are the thirty-four three-car Class 320 trains and perhaps fifty four-car Class 321 trains.

- Class 317 and Class 318 trains are probably too old to convert.

- A Class 319 train is a very inferior train from a passengers point of view to the Class 321 Renatus.

As some of these like the thirty Class 321 Renatus have been refurbished and given AC transmissions, it might be a good idea to build a few prototypes and try them out on various routes to assess their quality, reliability and performance.

But this route would only give about eighty three- and four-car trains.

It wouldn’t supply any two-car trains.

Sadly, the twenty-four two-car Class 456 trains, which could have been converted have all been recently scrapped.

Are There Any Other Trains That Can Be Converted?

There are several fleets of modern trains, that might be available.

- Four-car Class 350 trains

- Four-car Class 360 trains

- Four-car Class 379 trains

- Four-car Class 386 trains

There may also be some three- and four-car Bombardier Electrostars.

Again, there is a shortage of two-car trains, except for thirty-nine Class 466 trains.

- They are Networkers.

- They were built in the 1990s.

- They were refurbished ten years ago.

- They are third-rail trains.

- They are not in bad condition.

- Their operating speed is only 75 mph.

But they would probably be a hard train to convert and would only be a stopgap.

Conclusion

I am led to the conclusion, that there is a large gap in the UK rail network for a two-car train with this specification.

- Battery-electric operation.

- 100 mph operation

- Battery range of at least eighty miles.

- Quality interior.

- Ability to run on 25 KVAC overhead and/or 750 VDC third-rail electrification.

- Ability to add a third-car in the middle to create a three-car train.

Effectively, they would be a replacement for the Class 170 diesel trains.

Universal Hydrogen And Railway Locomotives

On the product page of the Universal Hydrogen web site, there is a section, which is entitled Other Transportation Applications, where this is said.

Our lightweight, aviation-grade modular hydrogen capsules can be used in a wide range of transportation applications where weight, safety, and speed of refueling are important. We are working with partners in automotive, heavy equipment, maritime, and railroad domains. If you have an application that can benefit from our global modular green hydrogen distribution network, please get in touch!

I believe that the railway locomotive of the future will be hydrogen-electric. And so do some of the UK’s rail freight companies, judging, by some of their press releases.

- It would have an electric transmission. like most locomotives today, such as the UK’s Class 66, Class 68, Class 70, Class 88, Class 93 and the upcoming Class 99 locomotives.

- It will be able to use 25 KVAC overhead electrification, where it exists.

- Hydrogen-power will be used, where there is no electrification.

The lowest-carbon of the locomotives, that I listed, will probably be the Class 99 locomotive.

- Thirty have been ordered by GB Railfreight, from Swiss company; Stadler.

- The locomotives will be built at Valencia in Spain.

- It will have up to 6 MW, when running using electrification.

- It will have up to 1.6 MW, when running using a Cummins diesel, with a rating of 2,150 hp.

- Because a proportion of UK freight routes are electrified, it is likely that these locomotives will substantially reduce carbon emissions for many locomotive-hauled operations.

It should be noted that Cummins are heavily into hydrogen and their philosophy seems to embrace families of engines, which are identical below the cylinder head gasket, but with appropriate cylinder heads and fuel systems, they can run on diesel, natural gas or hydrogen.

I wouldn’t be surprised to find out that the Class 99 locomotive will have a diesel engine, that has a hydrogen-powered sibling under development at Cummins.

With perhaps a power on hydrogen of about 2.5 MW, these zero-carbon locomotives would be able to handle upwards of ninety percent of all heavy freight trains in the UK.

These are further thoughts.

Alternatives To Cummins Hydrogen Internal Combustion Engines

There are two main alternatives, in addition to similar engines from companies like Caterpillar, JCB, Rolls-Royce mtu and others.

- Fuel cells

- Gas-turbine engines.

Note.

- Universal Hydrogen and others have fuel cells, that can probably deliver 2.5 MW.

- Universal Hydrogen use Plug Power fuel cells.

- Rolls-Royce have developed a 2.5 MW electrical generator, based on the engine in a Super Hercules, that is about the size of a typical beer-keg. I wrote about this generator in What Does 2.5 MW Look Like?.

Cummins may be in the pole position with Stadler, but there are interesting ideas out there!

Cummins have also indicated, they will build hydrogen internal combustion engines at Darlington in the UK.

Would One Of Universal Hydrogen’s Hydrogen Capsules Fit In A Railway Locomotive?

These are various widths.

- Class 66 locomotive – 2.63 metres.

- ATR72 airliner – 2.57 metres.

- DHC Dash-8 airliner – 2.52 metres

- Class 43 power car – 2.74 metres

I suspect that even if it was a bit smaller a hydrogen capsule could be made for a UK locomotive.

How Big Is The Market?

The UK has around five hundred diesel railway locomotives.

Stadler To Supply Norwegian Long Distance Trains Making The Journey An ‘Experience In Itself’

The title of this post, is the same as that of this article on the Railway Gazette.

This is the introductory paragraph.

State-owned rolling stock company Norske Tog has selected Stadler as the winner of a contract to supply 17 long distance trainsets to be branded as Flirtnex, with options for 100 more.

The article is very much a must-read or should I say must-look-at?

Partnership To Develop North American Battery Train

The title of this post, is the same as that of this article on Railway Gazette.

This is the first paragraph.

A contract for the development and testing of a battery multiple-unit for the North American market based on Stadler’s Flirt Akku design for Europe has been signed by the Swiss manufacturer, Utah State University and the Advancing Sustainability through Powered Infrastructure for Roadway Electrification engineering research centre.

After my recent visit to Liverpool, after which I wrote Riding In A Train Designed To Run On Battery Power, I am certainly of the belief that Stadler know where they are going.

The Stadler Data Sheet For A Class 777 IPEMU

This data sheet is now available on the Stadler web site.

These are my observations.

Battery Charging

The datasheet says this about battery charging.

While an IPEMU is running on the electrified network, the batteries can be charged from the third rail, as well as through regenerative braking.

I’m glad to see the trains have regenerative braking, which in a train with frequent stops saves electricity.

Battery Charging Time

The datasheet says this about battery charging time.

IPEMUs can be recharged in less than 15 minutes.

That time compares favourably with Hitachi’s time.

Expected Battery Life

The datasheet says this about expected battery life.

The IPEMU battery can undergo more than 10,000 charge/discharge cycles, which is about four times the lifetime of a battery used in EVs.

Stadler also give the battery a minimum expected life of eight years.

Transition Between Electrification And Battery

The datasheet says this about this important transition.

Transition between electrified and non-electrified networks without interruption, reducing travel times.

Stadler certainly do the changeover from electric to diesel smoothly on a Class 755 train.

A Comparison To Tesla

This is a paragraph in the introduction of the data sheet.

The battery/vehicle weight-ratio of a Tesla is about 25 per cent, while the ratio of the IPEMU is only about 6 per cent.

I suspect the rolling resistance, is also a lot less, than the rolling resistance of a Tesla, due to the superior properties of steel wheels on rail, as opposed to rubber tyres on road.

Battery Range

The data sheet gives the following.

- Installed battery capacity – 320 KWh

- Maximum speed (IPEMU mode) – 62 mph

- Range in battery operation – 34 miles

- Maximum demonstrated range – 84 miles

Note.

- I would assume the 55 km given for range on the datasheet is a guaranteed range.

- The maximum demonstrated range is from New Merseyrail Train Runs 135km On Battery.

- All other figures are from the datasheet.

In an article in the October 2017 Edition of Modern Railways, which is entitled Celling England By The Pound, Ian Walmsley says this in relation to trains running on the Uckfield Branch, which is not very challenging.

A modern EMU needs between 3 and 5 kWh per vehicle mile for this sort of service.

I don’t think the terrain of Merseyrail’s services are much different from the Uckfield branch, so what are the figures for the Class 777 trains on battery power?

- 55 km range – 2.353 kWh per vehicle mile

- 135 km range – 0.952 kWh per vehicle mile

The train appears to be very miserly with electricity.

But if the attention to detail in the electrical system of the train is of the standard of a Swiss watch, I don’t think they are unreasonable.

Operation With 25 kV Overhead Electrification

The datasheet says nothing about this, but the Wikipedia entry for the Class 777 train says this under Design.

Because current regulatory policy makes it unlikely that future extensions of Merseyrail’s unshielded third rail traction power supply will be approved, Class 777 units will be delivered with provision for the future installation of 25 kV 50 Hz AC overhead line traction equipment.

This is probably needed for charging at locations without third-rail electrification.