Gatwick Second Runway Plan Approved By Transport Secretary

The title of this post is the same as that of this article on the BBC.

This is the sub-heading.

Transport Secretary Heidi Alexander has approved plans for a second runway at London Gatwick Airport, as the government looks for economic growth opportunities.

These four introductory paragraphs add some detail.

The £2.2bn privately-financed project involves in effect moving the current Northern Runway 12 metres to bring it into regular use, as well as other developments, including extending the size of terminals.

The airport says its plans will bring jobs and boost the local economy. But there has long been opposition from campaigners and groups worried about the impact on the surrounding area.

Gatwick currently handles about 280,000 flights a year. It says the plan would enable that number to rise to around 389,000 by the late 2030s.

A government source has described the plans as a “no-brainer for growth,” adding that “it is possible that planes could be taking off from a new full runway at Gatwick before the next general election.”

Over the last fifty years, I’ve been involved in many large projects, as I used to write project management software and at one period in the 1980s, half of all the world’s major projects, were being managed by the Artemis software, that I wrote in a Suffolk attic.

I am starting this post by asking Google AI, when Gatwick’s Northern Runway was built. This was the answer I received.

Gatwick’s Northern Runway was built in 1979 by widening an existing taxiway to serve as an emergency runway. While the main runway is known as 08R/26L, the standby or emergency runway is designated as 08L/26R and is located just to the north of the main runway.

Note.

- 08 means that the runway is aligned at 080 degrees, which is almost due East.

- 26 means that the runway is aligned at 260 degrees, which is almost due West.

- Normally, when landing and taking off at Gatwick, your aircraft will use the Southern runway, which points to the West or Runway 26L.

This Google Map shows the layout of the airport.

Note.

- The longer Southern 08R/26L runway.

- The shorter Northern 08L/26R runway.

- The station in the North-East corner of the map is Horley.

- The station to the East of the runways is Gatwick Airport station.

- Both stations are on the Brighton Main Line, which runs North-South past the Airport.

- As when it was built, the Airport envisaged that the Northern runway would be turned into a runway that would meet all standards, I doubt there will be any problems rebuilding the Northern Runway, the required twelve metres to the North.

It was a cunning plan, when it was executed in the late 1970s and worthy of Baldrick at his best.

I do wonder, if it had been developed using Artemis!

What Is The Collective Noun For Cement Mixer Trucks?

I took these pictures on Eldon Street and Moorgate this morning.

Note.

- There was obviously a big pour going on in the rebuilding of Broadgate.

- I suspect those outside the hotel in the street restaurant, we’re too amused by the cabaret.

- Cemex were providing the concrete.

Perhaps in view of the location, the collective noun is a pollution of cement mixer trucks.

In Cummins Agrees To Integrate Its Hydrogen ICE Technology Into Terex® Advance Trucks, I describe the latest design of cement mixer trucks from the United States.

This is the European-sized member of the range.

Note.

- Front is to the right.

- The engine is in the pod at the other end.

- The engine can be one of Cummins’s hydrogen internal combustion engines.

These trucks would be much more city-friendly.

Eastern Green Link 2 Moves Up A Gear Using Low Carbon Fuel For Material Handling Trucks

The title of this post is the same, as that of this press release from National Grid.

These three bullet points act as sub-headings.

- Eastern Green Link 2 (EGL2), a high voltage direct current (HVDC) 436km subsea transmission cable connecting Scotland and England, is being delivered as a joint venture by National Grid Electricity Transmission and SSEN Transmission.

- Project sustainability efforts are accelerating by adopting Hydrogenated Vegetable Oil (HVO) fuelled trucks to move materials in Yorkshire.

- The introduction of HVO fuel will deliver up to 90% reduction in direct CO2 emissions.

The use of HVO fuel is good and the carbon dioxide emission savings are to be welcomed, but there is only so much of this HVO fuel available.

If hydrogen-fueled trucks were available, then this would deliver up to 100% reduction in direct CO2 emissions.

This paragraph from the press release talks about where the HVO fuel will be used.

HVO, a low-carbon biofuel made from waste vegetable oils, will be used at the Wren Hall converter station site in North Yorkshire, where 20-tonne construction trucks will transport approximately 370,000 tonnes of quarry stone from a quarry 27 miles away. This switch from conventional diesel to HVO is expected to deliver up to a 90% reduction in direct CO2 emissions and an 80% reduction in other harmful emissions such as particulate matter.

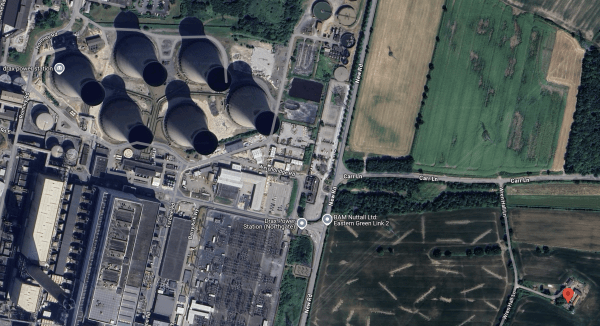

This Google Map shows the location of Wren Hall with respect to Drax power station.

Note.

- The six large cooling towers of the Drax power station are in the North-West corner of the map.

- Google Maps indicate, where they think Wren Hall is, with a red arrow.The lane running North-South to the West of the red arrow is called Wren Hall Lane.

- There is a legend saying BAM Nuttall Ltd Eastern Green Link 2 on the opposite side of the square of lanes to the red arrow.

Click the map to show it to a larger scale.

It looks to me, that if hydrogen could be provided on the Drax site, then the 370,000 tonnes of quarry stone from a quarry 27 miles away could be brought to the site by hydrogen-powered 20-tonne construction trucks.

So how could hydrogen be provided on the Drax site?

- Drax is a 2.6 GW biomass power station, so I’m sure that some electricity could be used to generate hydrogen.

- Drax is a rail-connected site, so hydrogen could be brought in by rail.

- Depending on the amount of hydrogen needed, hydrogen could surely be brought in by road.

I feel that if hydrogen-powered 20-tonne construction trucks were available, this transfer of quarry stone could be performed carbon-free.

Conclusion

This project illustrates a problem with large infrastructure projects all over the UK.

Moving the large amounts of stone, concrete, sand and rubble into and out of construction sites generates a lot of carbon dioxide and pollution from the 20-tonne trucks employed.

If I were to be given Ed Miliband’s job of Secretary of State for Energy Security and Net Zero, one of my first actions, would be to say that all new 20 tonne construction and cement trucks would have to be zero carbon.

I suspect, that zero-carbon with trucks this size, will mean hydrogen, as the weight of the battery would destroy the mathematics of the truck.

This would obviously reduce carbon emissions, but more importantly, what would it do for the health of those working on large construction sites?

In MAN Expands Its Zero-Emission Portfolio, I show MAN’s heavy hydrogen trucks.

This is an articulated heavy hydrogen truck.

I’m sure that MAN could build a hydrogen-powered 20-tonne construction truck.

In Cummins Agrees To Integrate Its Hydrogen ICE Technology Into Terex® Advance Trucks, I talk about the solution to the cement truck problem.

This is a side view of the top-of-the-range monster.

Note.

- Front is to the right.

- I suspect the driver doesn’t have to get out of the cab to discharge the concrete.

- The engine is at the rear with vertical exhausts.

- All axles are driven.

You’d certainly notice one of these if they were to be used in the City of London.

And this is the baby of the range.

Three axles is normal for the UK. so I wonder if this machine will ever make it across the pond.

This last paragraph in the original article describes the X15H hydrogen internal combustion engine.

The X15H was showcased at the Advanced Clean Transportation (ACT) Expo in May (2023), along with its hydrogen ICE-powered concept truck. The X15H features a 700-bar pressure 80kg capacity hydrogen storage system and a range of more than 500 miles, with up to 500 horsepower.

Could one of these trucks really deliver ready-mix concrete from London to Manchester and return?

The trucks would appear to be available, so let’s get a few over and try them out.

Incidentally, if someone had told me ten years ago, there would be rear-wheel drive trucks like Volkswagen Beetles, I’d have said they were wrong in no uncertain terms.

The Wren Hall substation would appear to be an ideal trial project for hydrogen-powered construction trucks and cement trucks.

Redevelopment Of Scottish Port Begins As Owner Secures GBP 400 Million For Offshore Wind Upgrade

The title of this post, is the same as that of this article on offshoreWIND.biz.

This is the sub-heading.

Haventus, the owner of the Ardersier Port in the Moray Firth, Scotland, has taken a final investment decision and kicked off construction work on redeveloping the port to serve both fixed-bottom and floating offshore wind projects. The revamped port is expected to open in the second half of 2025.

These are the first two paragraphs.

This month, Haventus was granted a GBP 100 million (approximately 117 million) joint credit facility from the Scottish National Investment Bank and UK Infrastructure Bank with GBP 50 million (approx. EUR 58.5 million) investment from each.

This follows a GBP 300 million (approx. 351 million) investment commitment by the energy investment firm Quantum Capital Group in 2023 when Haventus began the redevelopment of Ardersier Port.

This page on the Haventus web site, gives more details of the Port of Ardersier.

Included are.

- Access channel width – 160 m.

- Access channel depth – 12.4 m.

- Landside area – 350 acres.

- 420m main quay.

- 80 m Ro/Ro capable berth.

- People-friendly midges

- Green Freeport tax site designation

- More space is available if required.

There is also an informative video.

Haventus say they are delivering a world-leading energy transition facility. I can go along with that!

These are my thoughts.

The Location Of The Port of Ardersier

This Google Map shows the location of the Port of Ardersier.

Note.

- The large expanse of water in the middle of the map is Moray Firth.

- The blue arrow at the bottom of the map indicates Inverness Airport.

- Inverness Airport, has a railway station on the Aberdeen and Inverness Line.

- The village of Ardersier is on the the Eastern bank of the Moray Firth

- The Port of Ardersier is in the North-East corner of the map.

The city of Inverness, with a population of around 48,000, is a few miles South-West of the South-West corner of the map.

Which Windfarms Will Be Built And Serviced From The Port Of Ardersier?

This map shows the various ScotWind leases, around the North of Scotland.

The numbers are Scotwind’s lease number in their documents.

These are the Scotwind wind farms to the North-East of Scotland, that could reasonably be assumed to be built and served from the Port of Ardersier.

- 7 – DEME Concessions Wind – 200 km² – 1.0 GW – Floating

- 8 – Falck Renewables Wind – 256 km² – 1.0 GW – Floating

- 9 – Ocean Winds – 429 km² – 1.0 GW – Fixed

- 10 – Falck Renewables Wind – 134 km² – 0.5 GW – Floating

- 11 – Scottish Power Renewables – 684 km² – 3.0 GW – Floating

- 12 – BayWa r.e. UK – 330 km² – 1.0 GW – Floating

These are the Scotwind wind farms to the North-West of Scotland, that could reasonably be assumed to be built and served from the Port of Ardersier.

- 13 – Offshore Wind Power – 657 km² – 2.0 GW – Fixed or Floating

- 14 – Northland Power – 390 km² – 1.5 GW – Floating

- 15 – Magnora – 103 km² – 0.5 GW – Floating

- 16 – Northland Power – 161 km² – 0.8 GW – Floating

These ten wind farms add up to 12.3 GW.

Transport

Consider.

- Obviously, heavy components will be brought in by sea, using the Ro/Ro capable berth or using a crane to unload a barge.

- Personnel will be able to fly in for the day.

- Will some visitors rom London use the Caledonian Sleeper to and from Inverness station to get a full day on site and a good night’s sleep, whilst travelling.

But I do see a problem with local traffic to and from the site.

Hydrogen Buses

This page on the Sizewell C web site, discusses how they will use hydrogen buses.

I could see the Port of Ardersier taking a leaf out of Sizewell C’s book and run hydrogen buses to Inverness, Inverness Airport and other nearby towns.

The North of Scotland certainly won’t be short of green hydrogen to power the buses.

Hydrogen

Conclusion

If you thought that the only useful wind-driven thing to come out of Scotland was bagpipes, you had better think again.

The Port of Ardersier will be the factory and operation and maintenance port for one of the largest offshore wind industries in the world.

How Hydrogen Will Power The Green Construction Eevolution

The title of this post, is the same as that of this news item from Ryze Hydrogen.

These two paragraphs introduce the news item.

According to the International Energy Agency buildings operations and construction emissions account for more than one-third of global energy-related emissions, significantly contributing to environmental degradation, with heavy machinery and standby power solutions relying heavily on fossil fuels.

Yet here at Ryze we know the industry stands on the brink of a green revolution, as clean energy solutions lead the charge towards decarbonisation.

The news item, is a must-read for anybody involved in construction.

Recently, a gas leak killed the roadside tree outside my house. I wrote about the incident in It Looks Like The Gas Leak Has Killed The Tree Outside My House.

What I didn’t say, was that when they cleaned up the mess, I had an eight-wheeled diesel truck with a grab, working outside my house for a couple of hours, spewing fumes everywhere.

Hopefully, green construction is friendlier to the neighbours and the workers on site.

High Speed Two is using green construction for this reason in sensitive locations.

TCP Is Using Hydrogen To Create Cleaner Construction Sites

The title of this post, is the same as that of this article on the Eastern Daily Press.

This is the sub-heading.

Air and noise pollution are challenges for every construction project. For green energy infrastructure developers especially, cutting emissions is a pressing conundrum.

These are the first four paragraphs.

Large-scale construction demands diesel-guzzling heavy plant and noisy diesel generators powering off-grid site work for years before a project generates its first clean energy.

Back in 2012, Andrew Barker identified hydrogen as a fuel of the future and a solution to pollution issues during construction projects in his Essex-based family business, Taylor Construction Plant (TCP Group).

His concerns about health issues caused by carbon emissions, combined with a drive to make a difference, led to game changing inventions using hydrogen to transform power for site operations – making sites better neighbours, with fewer health dangers to site workers and helping the drive against climate change.

He developed his first hydrogen powered product more than a decade ago – mobile lighting towers that are the flagship product for the business and first choice for building and maintenance projects across the UK on the mission to net zero.

It appears now Andrew Barker has a strong business, which can be found at this web site.

Seratech’s Technology Explained

I first wrote about Seratech in Carbon-Neutral Concrete Prototype Wins €100k Architecture Prize For UK Scientists, after reading about this carbon-neutral concrete in the Architect’s Journal.

I have just received Seratech’s October 2023 Newsletter, which contains two must-read articles.

Olivine In The Age Of Climate Crisis

I’d never heard of olivine until I read about the architecture prize, that was won by Seratech.

This is the Wikipedia entry for olivine.

These are the first three paragraphs of Seratech’s article.

On the west coast of Norway, a few kilometres from the village of Åheim, is an open excavation pit – home to the largest commercial olivine deposit in the world.

This seaside quarry, run by Belgian industrial minerals company, Sibelco, works to extract olivine from the earth’s crust by drilling, blasting and crushing. A single blast (used to break up the rocks) removes up to 40,000 tonnes of olivine.

The site is predominantly powered by hydroelectricity and boasts a 4km conveyor system for transport which limits the need for heavy vehicle or double-handling of materials in a bid to reduce emissions.

This is Sibelco’s video of their impressive mining process.

Note.

The mining operation is fully-integrated with its own ort.

- The video does the mining operation justice.

- Sibelco aim to make the mining of olivine carbon-neutral.

Olivine has this Wikipedia entry, which gives more information.

This Google Map shows the port complex at Åheim.

It looks like mine, processing and port all on one site.

The Big Interview With Mike Eberlin

This is the sub-heading.

Former Managing Director of Tarmac Cement & Lime and chair of MPA Cement, Mike Eberlin, became Seratech’s business advisor in June this year. He was intrigued by the novel technology Sam Draper and Barney Shanks had uncovered

These paragraphs are a summary of what Mike Eberlin said.

As we begin to talk, Mike is quick to point out there are two big advantages to Seratech: “They are using magnesium silicate as a starting material which produces silica as a cement replacement and magnesium oxide which can then absorb CO2”.

The CO2 absorption is what fascinates Mike as the type of magnesium carbonate Seratech produces is a “slightly unstable” version which when cured, becomes stable and reverts to the rock-like substance you would find in nature. “This came as a surprise because the chemistry wouldn’t indicate that was possible,” he explains.

Following this discovery, and as Seratech’s research progressed, it soon became apparent that the magnesium carbonate lends itself well as a binder and can be used in applications like building blocks and plasterboard: “It’s effectively carbon capture and use, not carbon capture and storage because you are mineralising the CO2 into a product.

“We end up in this clever situation whereby it’s not that we don’t emit the CO2, it’s better than that, we absorb CO2 and create two binders that replace cement”.

That’s what I call an endorsement.

Conclusion

I have this feeling that Seratech will be a very significant company in a couple of years.

Low-Carbon Concrete: Separating Greenwash From Reality

The title of this post is the same as that of this article from Construction Management.

This is the sub-heading.

Tales of low-carbon concrete abound, but what exactly does that mean? Kristina Smith looks at what’s in the mix.

This is a paragraph, which shows the scale of the problem.

The oft-quoted statistic is that cement contributes to 7% of the world’s carbon emissions. However, MPA says that in the UK concrete and cement account for just 1.5% of emissions. “From 1990 we have reduced our absolute emissions by 53%, which is faster than the overall economy, mainly by improving energy efficiency at the plants,” says Khosravi.

Noushin Khosravi, is sustainable construction manager at the Concrete Centre, which is part of Mineral Products Association (MPA).

Companies mentioned include.

- Capital Concrete with their Earth Friendly Concrete.

- CarbonCure Technologies, which I wrote about in Mote – World’s First Carbon Removal Plant Converting Wood Waste To Hydrogen.

- Seratech, which I wrote about in Carbon-Neutral Concrete Prototype Wins €100k Architecture Prize For UK Scientists.

I find the Seratech process amazing as it takes carbon dioxide straight from flues to make the cement.

Could we fit a Seratech cement process on the back of a gas-fired power station?

The article is a must-read summary of where the technology is with respect to low-carbon concrete.

UK Consortium To Develop Mobile Hydrogen Refuelling For Construction Sites

The title of this post, is the same as that of this article on H2 View.

These first two paragraphs outline the project.

A UK consortium has secured over £3m ($3.7m) in government funding to develop mobile hydrogen refuelling for construction sites.

The Ryze-led consortium, made up of iGAS, Wrightbus, Skanska, Mace Dragados and Sizewell C, has been awarded £3.2m ($3.99m) from the Department of Energy Security and Net Zero’s Red Diesel Replacement Programme to develop and demonstrate a new suite of production-ready hydrogen refuelling equipment suitable for construction sites.

It appears to be a very comprehensive project and everything will be tested in a working quarry.

Having recently had a diesel-powered truck outside my house, that was clearing up the mess left by a dead tree, I feel that the health benefits of zero-carbon construction sites could be immense.

Sizewell C

I find it interesting that Sizewell C is part of the consortium.

Does this mean, that all construction on Suffolk’s new nuclear power station will use hydrogen and electric power, to lower the carbon footprint?

In Ryze Hydrogen’s Suffolk Freeport Hydrogen Vision Takes Shape, I gave this quote from this article on S & P Global.

Ryze Hydrogen plans to install a 6 MW electrolyzer at the Sizewell nuclear site in Suffolk as a launchpad for mass production of low carbon hydrogen in and around the future freeport of Felixstowe, company founder Jo Bamford told S&P Global Platts March 3.

As Sizewell C is to be built by a consortium led by EDF Energy and the French company operates Sizewell B, will the Sizewell electrolyser be built first and powered by Sizewell B, so that the hydrogen can be used to lower the carbon footprint of Sizewell C?

The Zero-Carbon Toilet

In Cadent’s Hydrogen-Hybrid Solar Toilet, I describe how Cadent are looking after their workers on a site in London.

These ideas will inspire a lot more.