Hydrogen And Electric Propulsion Compared

Stadler have given us an interesting way of comparing the range and other properties of hydrogen-powered and battery-electric trains, as their Flirt H2 and Akku trains have both set Guinness World Records for distance travelled.

The Hydrogen-Powered Flirt-H2

In Stadler’s FLIRT H2 Sets World Record For Hydrogen Powered Train, I write about how a Stadler Flirt-H2 had set a record of 2803 kilometres, without refilling.

This page on the Stadler web site gives details of the Flirt-H2.

- Hydrogen Range – 460 km.

- Operating Speed – 127 kph

- Refuelling Time – < 30 minutes

- Seats – 116

This graphic clipped from the Stadler web site shows the Flirt-H2.

Like Greater Anglia’s Class 755 train, it has a PowerPack in the middle, which contains a fuel cell and the hydrogen tank, instead of the Class 755 train’s diesel engines.

The Battery-Electric Akku

In Flirt Akku And Class 755 Train Compared, I compare a Flirt Akku and Greater Anglia’s Class 755 train, after the battery-electric Akku had set a record of 224 kilometres, with recharging.

This page on the Stadler web site gives details of the Flirt Akku.

- Battery Range – 150 km

- Operating Speed – 160 kph

- Chrging Time – 15 minutes

- Seats – 120-180

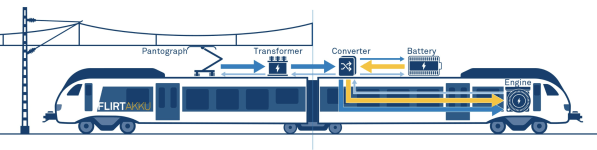

This graphic clipped from the Stadler web site shows the Flirt Akku.

At a quick glance, the trains seem to be fairly similar, with the exception of the PowerPack.

- Both have regenerative braking.

- Both have the battery and the power converter on the roof.

- I would expect that the Flirt-H2 could be fitted with a pantograph and a transformer.

- Both trains have two passenger carriages.

I also suspect, both trains can be lengthened by adding extra coaches.

These are my thoughts.

Thoughts On The PowerPack In A Flirt-H2

This picture shows the PowerPark car of a Class 755 train.

Note.

- These PowerPacks have slots for up to four 480 Kw diesel engines.

- PowerPacks on a Class 788/4 train with four diesel engines weighs 27.9 tonnes.

- PowerPacks on a Class 788/3 train has two diesel engines.

- In the UK, trains with PowerPacks have up to four passenger cars.

- The PowerPack has a walkway from one end of the car to the other.

As customers, might like to replace their diesel PowerPacks, with something that was zero-carbon, I would expect, that the hydrogen PowerPack would have the following properties.

- Hydrogen and diesel PowerPacks would be interchangeable.

- The hydrogen PowerPack would come in two handy sizes of hydrogen fuel cell; 0ne and two MW.

- The weight of both hydrogen and diesel PowerPacks would be similar, as if power and weight were similar, then this could help certification.

- The Flirt-H2 for California, which would only have two passenger cars, would have the smaller hydrogen fuel cell.

I would expect that a conservative designer would use any spare space for hydrogen storage.

- Perhaps, there would be one tank either side of the walkway.

- The quoted range of 450 kilometres for the Flirt-H2 is just under 300 miles, so it would probably cover most regional round trips in Europe without refuelling.

- On many routes refuelling would only need to be done once-per-day.

- Refuelling can be some distance from operation.

- Large tanks would explain the thirty minutes refuelling time.

Obviously, large tanks have the collateral benefit of setting distance records.

The Kinetic Energy Of A Flirt-H2 Train

In My First Rides In A Class 755 Train, I calculated the kinetic energy of a Class 755/4 train.

I said this.

I will use my standard calculation.

The basic train weight is 114.3 tonnes.

If each of the 229 passengers weighs 90 kg with Baggage, bikes and buggies, this gives a passenger weight of 20.34 tonnes.

This gives a total weight of 134.64 tonnes.

Using Omni’s Kinetic Energy Calculator gives these figures for the Kinetic energy.

- 60 mph – 13.5 kWh

- 100 mph – 37.4 kWh

- 125 mph – 58.4 kWh

If we are talking about the Greater Anglia Class 755 train, which will be limited to 100 mph, this leads me to believe, that by replacing one diesel engine with a plug compatible battery of sufficient size, the following is possible.

- On all routes, regenerative braking will be available under both diesel and electric power.

- Some shorter routes could be run on battery power, with charging using existing electrification.

- Depot and other short movements could be performed under battery power.

The South Wales Metro has already ordered tri-mode Flirts, that look like Class 755 trains.

The calculation for a Flirt-H2 train is as follows.

Train Weight – 82.3 tonnes

Passenger Weight – 10.4 tonnes

Total Weight – 92.7 tonnes

This gives these kinetic energies

- 60 mph – 9.3 kWh

- 79 mph – 16.0 kWh

- 100 mph – 25.7 kWh

It looks like the 79 mph; Flirt-H2 would only need a 16 KWh battery.

It seems when a battery is not for traction and only handles the regenerative braking, it can be surprisingly small.

Mathematical Advantages Of Hydrogen

I do wonder that on balance, there may be mathematical advantages to hydrogen; long range, less frequent refuelling and small batteries.

But as I indicated in Zillertalbahn Hydrogen Plan Dropped In Favour Of Battery Traction, the decision doesn’t always go hydrogen’s way!

Conclusion

I feel Stadler have the right approach of a modular concept that incorporates both hydrogen-powered and battery-electric trains.

I also think, if you have a route, you want to decarbonise, Stadler have the train for you.

Freightliner Partners With Zero To Decarbonise Critical Transport Operations

The title of this post, is the same as that of this news item from Freightliner.

This is the sub-heading.

Today, Freightliner and Zero, a breakthrough energy company that develops and manufactures whole-blend synthetic, non-biological fuels, announced a partnership to achieve a fossil-free locomotive operation by 2040 and overall Net Zero by 2050, representing a major evolution for one of the world’s oldest, safest and most reliable forms of freight transport. To successfully meet these ambitious emissions targets, Freightliner is exploring alternatives to diesel, such as Zero’s carbon-neutral synthetic diesel, which will eliminate fossil-carbon emissions and improve air quality and environmental wellbeing.

These are my thoughts.

Freightliner

Freightliner is a rail-freight company, that you see regularly hauling freight trains all over the UK.

The picture shows two of their Class 90 electric locomotives in their latest livery.

These posts talk about the company and lower or zero carbon operation.

- Clean Air Power Adds Hydrogen To Class 66 Fuel Mix

- Freightliner Continue Trials On New Low Carbon Fuel

- Freightliner Secures Government Funding For Dual-Fuel Project

- The Ultimate Bi-Mode

The current post fits that pattern.

Zero Petroleum

Zero Petroleum is one of those companies that gives Elon Musk nightmares.

But when you have backers like Babcock, Boeing, Intertek, Rolls-Royce and the Royal Air Force, you must be doing something right.

The Wikipedia entry for the company has this first paragraph.

Zero is a manufacturer of non-biological carbon-neutral synthetic fuel (also known as e-fuel) co-founded by former Formula One engineer Paddy Lowe. Its product has been developed as an alternative to fossil-based fuels and a more scalable sustainable alternative to waste and bio-fuels. The Royal Air Force used its fuel in November 2021 to achieve a World Record first flight powered by synthetic fuel. In July 2022, Zero entered a new partnership with the Royal Air Force to move towards mass production of sustainable aviation fuel.

The company is often known as just Zero.

These two and a half paragraphs from the Wikipedia entry describe the technology.

Zero uses Direct FT (a proprietary and specialised version of Fischer-Tropsch) to directly manufacture target fuels (gasoline, kerosene and diesel) at high yield and with no need for refinery upgrading.

When manufactured using renewable energy, synthetic fuel can be used as a carbon neutral or carbon negative direct drop-in replacement for fossil fuels, particularly for operations that require high energy densities – such as air travel, shipping and farming – and to ensure the continued use of legacy vehicles. It can also be used as a raw material to produce various forms of plastic.

It is manufactured using a process known as petrosynthesis, in which carbon dioxide and hydrogen are combined to create hydrocarbons. The process involves direct air capture of carbon dioxide from the atmosphere and the electrolysis of water to obtain hydrogen.

The Fischer-Tropsch process, despite its association in the past with dodgy regimes, seems to be at the heart of things, as it is with Velocys.

I describe the Velocys process and its link to Fischer-Tropsch in Grant Shapps Announcement On Friday.

Surely, the carbon-neutral fuel produced by Zero, are the ideal stop-gap fuel until true full zero-carbon fuels are available.

But Zero’s fuels will always be available for heritage and legacy trains, planes and automobiles and for applications, where older technology must be used.

As an example of older technology still being used on UK’s railways, Network Rail operate, the New Measurement Train to check all tracks in Great Britain.

The train may have been manufactured in the 1970s, but it has modern engines and is the ideal train to carry the wide variety of sophisticated equipment to ensure the safety of Britain’s railways.

Synthetic diesel like that produced by Zero could keep the New Measurement Train running for some years yet.

Freightliner Have Made A Pragmatic Decision

I believe that Freightliner have made a pragmatic decision, that allows them to go carbon neutral without without taking risks or spending millions on new equipment, that is not fully-developed.

As new zero-carbon technology is developed, like say hydrogen-electric hybrid locomotives, these may take over certain tasks, which will reduce some of the need for synthetic diesel.

But synthetic diesel from Zero will always be there as a fuel of last resort.

Wind Farm: Yorkshire Moors Could Get England’s Biggest Wind Farm

The title of this post, is the same as that, of this article on the BBC.

This is the sub-heading.

The largest onshore wind farm in England could be built on moorland in the Pennines if plans get the go-ahead.

These are the first two paragraphs.

Calderdale Windfarm Ltd is exploring options for 65 turbines on Walshaw Moor, near the Walshaw Dean reservoirs above Hebden Bridge in Calderdale.

The company said the scheme would generate enough electricity to power more than 286,000 homes a year.

The Calderdale Wind Farm has a web site, which adds these details about the proposals.

- The 65 wind turbines will generate up to 302 MW of electricity.

- There will be a 150 MW battery on site.

- £2.5 million per year will be put in a Community Benefit Fund.

- Up to 300,000 trees will be planted across the site.

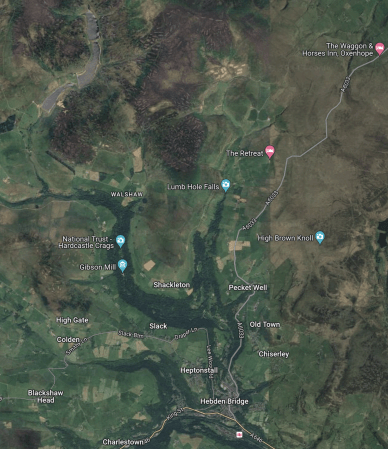

This Google Map shows the Walshaw Dean reservoirs and Hebden Bridge.

Note.

- Walshaw Dean reservoirs are in the North-West corner of the map.

- Hebden Bridge is at the bottom of the map.

- Hebden Bridge station on the Calder Valley Line is also marked.

- This will be a very unusual wind farm for England.

It could also be a controversial wind farm.

These are some of my thoughts and those of the BBC article.

Environmental Opinions

These five paragraphs indicate both sides of the environmental argument.

Environmental campaigners warned the development would disturb peat bogs, releasing carbon into the atmosphere.

A spokesperson for Calderdale Windfarm, which is backed by Worldwide Renewable Energy (WWRE), said the proposal was an “incredibly exciting opportunity”.

“During a cost-of-living crisis, with ongoing energy security challenges and the climate emergency, the UK needs to explore how it can generate more carbon-free renewable electricity,” the firm said.

“But our proposals are at a very early stage and we recognise there will be a range of views about the merits of our proposal.

“We look forward to continuing to work with the local community, environmental groups, local councillors and others over the coming months to help shape the final design of the project.”

The £2.5 million per year Community Benefit Fund could be the clincher.

The Site Has A Battery

In my view, it is good practice to fit every wind farm with a battery, if this is practical and cost-effective.

As most batteries associated with wind farms, seem to be able to replace the wind farm for two hours, I wouldn’t be surprised to see the battery specified as a 150 MW/300 MWh unit.

A battery this size would improve the stability of the electricity supply in the area.

How Will Calderdale Wind Farm Be Connected To The Grid?

This question is answered in the page of FAQs.

We already have an offer from the Distribution Network Operator Energy North West to connect into the local electricity network substation at Padiham. Negotiations are also ongoing about an alternative connection via a new substation and that would go into National Grid which would connect into existing 440 KV pylons.

Padiham is a few miles away to the West, so the second option may need a smaller number of pylons.

The grid connection and associated infrastructure would be subject to a separate planning application to the wind farm.

Is Calderdale Wind Farm Just Wind Turbines?

This question is answered in the page of FAQs.

- No. Alongside our proposals for onshore wind we are also exploring the potential for the inclusion of battery storage and solar panels on southern slopes.

- As we develop the proposals further, we will be able to confirm whether we will be including other renewable technologies as part of the proposals.

I wouldn’t be surprised to see solar panels floated on the reservoirs. This also has the secondary benefit of reducing evaporation.

How Will Calderdale Wind Farm Benefit Calderdale?

This question is answered in the page of FAQs.

If consented, Calderdale Wind Farm would represent an investment of circa £500m into the local economy. Calderdale Wind Farm will support the local economy and present many opportunities for years to come.

Community Benefit Fund

Around 16,500 households in Calderdale are living in fuel poverty, with around 1,200 of these being in the HX7 postcode area. As part of our proposals for Calderdale we are exploring a community benefit fund to provide support to these households across the 30-year operational lifetime of Calderdale Wind Farm.

This fund would represent £75m worth of funding across a 30-year timeframe that would be paid to Calderdale Council to help relieve fuel poverty for the operational lifetime of the Calderdale Wind Farm.

We want to work closely with the communities in and around Calderdale to ensure they benefit from the project to help address identified local challenges such as the current energy and cost of living crisis.

Socio Economic Impacts

A socio-economic report produced by Biggar Economics suggests that the project would be a significant boost to both the Calderdale and wider regional economy if it goes ahead. The report estimates that Calderdale Wind Farm would generate at least £2.2million GVA for Calderdale through the design, build and operational lifetime of the windfarm.

This is surely going to level-up Calderdale.

Is This Going To Impact My Walking Route?

This question is answered in the page of FAQs.

As we develop our proposals, we will design the scheme and placement of the wind turbines and associated infrastructure to minimise any disruption to existing paths and trails. Our team has taken into consideration the importance of preserving the natural beauty and accessibility of the area in our early stage designs, which will evolve as we undertake further work ahead of a planning submission.

While there might be temporary adjustments or diversions to certain paths during the construction phase to ensure safety, these changes will be communicated well in advance, and we will strive to keep any inconveniences to a minimum.

Once operational the moor will continue to be accessible to members of the public.

As part of our commitment to community consultation, we want to hear your thoughts on the proposals, if you have any specific concerns about how the wind farm might affect your walking routes please let us now, community input is vital to designing a scheme that works seamlessly with the local environment.

It does look like the impact will not be all that great.

Is Grouse Shooting On Walshaw Moor Expected To Continue If Calderdale Wind Farm Is Approved?

This question is answered in the page of FAQs.

WWRE and Calderdale Wind Farm Ltd are pleased to confirm that the approval of the wind farm would result in the end of grouse shooting on Walshaw Moor.

This could face a lot of opposition from the shooting lobby.

Who Are WWRE?

The Calderdale wind farm has a page of FAQs.

In response to who are the funding partners of the project, this is said.

WWRE Global is a UK based company that was looking at projects in Spain and registered with Companies House in Gibraltar. With its investors and opportunities its current operations are focused on helping to deliver new renewable energy infrastructure in locations across the UK, which is why the business is now listed at Companies House in London.

WWRE Global is responsible for delivering investment opportunities for Energy Horizon II Investment Company and managing the planning and consenting process.

WWRE Global has a web site.

When Will The Wind Farm Be Built?

This question is answered in the page of FAQs.

Calderdale Wind Farm is a fully funded project, and it is envisaged the construction would commence within 12 months of any planning permission being granted and conditions being discharged. At this stage it is expected that construction could take up to two years.

WWRE Global certainly seem to want to get on with it.

Objectors

Use Google to search for news about Calderdale wind farm and you get a lot of objectors.

Conclusion

This is a bold and scientifically-correct proposal and it will be a close decision, as to whether the wind farm gets built or not!

Porterbrook Acquires ‘379s’ For Lease To GTR

The title of this post, is the same as that of a small article in the April 2024 Edition of Modern Railways.

This is the first paragraph.

Porterbrook has successfully bid to acquire the fleet of 30 Class 379 Electrostar EMUs from Akiem and will lease them to Govia Thameslink railway, which will use them on Great Northern services.

Note.

- Will the Class 379 trains replace all or some of the 39 Class 387 trains currently used by Great Northern?

- The Class 379 trains are 25 KVAC overhead only trains, whereas the Class 387 trains are dual-voltage.

- If the Class 379 trains are not modified to run on 750 VDC third rail, they will be restricted to Great Northern routes.

- It may be a problem, that the Class 379 trains are only 100 mph trains, whereas the Class 387 trains are capable of 110 mph, but I suspect that the Class 379 trains can be upgraded to 110 mph.

It looks to me that it is likely that Govia Thameslink Railway will end up with thirty spare Class 387 trains.

The Wikipedia entry for the Class 387 train, says this about the differences between the two classes of Electrostar.

The Class 387 is a variation of the Class 379 with dual-voltage capability which allows units to run on 750 V DC third rail, as well as use 25 kV AC OLE.

This surely has three main ramifications for Govia Thameslink Railway.

- Third rail equipment can probably be fitted to the Class 379 train, if required.

- The Class 379 train can probably be uprated to the 110 mph of the Class 387 train.

- Retraining the drivers to use the new Class 379 trains, will not be a major exercise.

Govia Thameslink Railway will have the luxury of configuring the trains to run, the services their passengers need and want.

But Govia Thameslink Railway may have a collateral benefit.

In 2015, a Class 379 train was modified to do a trial as a battery-electric multiple unit.

This section in the Wikipedia entry for the Class 379 train, describes the trial.

During 2013, the national infrastructure owning company Network Rail announced that unit 379013 would be used as a testbed for a future Battery-Electric Multiple Unit. Following several months of conversion work and non-service testing, the unit was used to carry passengers for the first time on a Manningtree–Harwich Town service on 12 January 2015. Throughout its five-week trial period, data was gathered to assess its performance; it could reportedly operate for up to an hour on battery power alone, while charging via the pantograph took two hours.

Note.

- I feel it would be reasonable to assume, that a Class 387 train could be easily converted to battery electric operation.

- I’ve met commuters, who used the prototype every day between Harwich and Manningtree and it gave a good service.

- In an hour with stops, a typical Southern commuter service does just 35 miles.

Southern have two routes, where Class 171 diesel trains are still used.

- Ashford International and Ore – 25.4 miles

- Hurst Green Junction and Uckfield – 24.7 miles.

A battery-electric train with a range of 30 miles would surely decarbonise these routes.

- Batteries would be charged, where 750 VDC third-rail electrification is installed.

- As the Class 387 trains are dual-voltage, a short length of 25 KVAC overhead electrification, could be used to charge the train at Uckfield, if that was to be needed.

- Alternatively, the Vivarail Fast Charge system could be fitted.

A rough estimate is that ten battery-electric Class 387 trains would be needed to make Govia Thameslink Railway an all-electric railway.

- The now redundant Class 171 trains could be cascaded to someone, who needs them.

- The remaining twenty Class 387 trains could be used to replace twenty Class 377 trains, or converted to battery-electric operation and be cascaded to another operator.

Hopefully though, after all of the musical trains, there will be a reliable procedure to convert late model Electrostars into battery-electric trains.

The Definitive Battery-Electric Electrostar

It could have this specification.

- Based on a Class 377, Class 379 or Class 387 train.

- Three, four or five cars.

- I suspect the batteries would be spread around the cars.

- Dual-voltage or 25 KVAC overhead electrification only.

- Charging by 25 KVAC overhead electrification or Vivarail/GWR Fast Charge system.

Note.

- Battery range appropriate for the route.

- In GTR And Porterbrook Unveil £55 million Fleet Modernisation, I talk about an internal refurbishment of GTR’s trains.

It looks to me, that, whatever route Govia Thameslink Railway takes, there could be another twenty refurbished Class 377 or Class 387 trains, that could be available for conversion to four-car battery-electric trains.

Great Western Routes That Could Be Run By Battery-Electric Electrostars

Great Western Railway have 30 Class 387 trains, which are used on Thames Valley services around the London end of the Great Western Main Line.

Routes that could be suitable for Battery-Electric Electrostars include.

- London Paddington and Didcot Parkway – two trains per hour (tph) – 10 trains

- London Paddington and Oxford – one tph – 5 trains – 10.5 miles x 2

- London Paddington and Newbury – one tph – 5 trains

- Reading and Newbury – one tph – 2 trains

- Newbury and Bedwyn – one tph – 1 train – 13.3 miles x 2

- Reading and Basingstoke – two tph – 2 trains – 13.6 miles x 2

- Reading and Gatwick – two tph – 7 trains – 18.6 miles

Note.

- The number of trains is my rough estimate of the number, that would be needed to run each route.

- The miles is how much running would be needed on batteries.

My estimated total is 32, but there might be savings from more efficient routes. It looks like a range of around thirty miles would be sufficient.

Conclusion

It looks like after decarbonising Govia Thameslink Railway and the Thames Valley Services of Great Western Railway, there will be twenty high quality Electrostars available to decarbonise other routes.

Sumitomo Mitsui Trust Bank Makes Substantial Investment In Australia’s MCi Carbon

The title of this post, is the same as that of this article on the Carbon Herald.

This is the introductory paragraph.

MCi Carbon, an Australian clean technology platform revolutionising the carbon recycling industry, proudly announces the addition of esteemed Japanese investor, Sumitomo Mitsui Trust Bank, to its investor roster. This significant investment from the Japanese giant, with assets under management totalling $617 billion marks a pivotal moment in MCi Carbon’s journey towards global leadership in carbon capture and utilisation and underscores the growing international recognition of Australia’s role in the transition to a zero-carbon world economy.

I believe that MCi Carbon, will be a very successful company.

I first wrote about this company in March 2021 in Energy Minister Angus Taylor Launches $50 million Fund For Carbon Capture Projects.

£400k For National Grid Innovation Projects As Part Of Ofgem Fund To Help Shape Britain’s Net Zero Transition

The title of this post, is the same as that, of this press release from National Grid.

These three bullet points, act as sub-headings.

- Three transmission and distribution network innovation projects receive green light

- Funding kickstarts projects for the discovery phase of Ofgem innovation scheme

- 14 National Grid projects worth £4m have won innovation funding since scheme began

These are the three projects.

HIRE – Hybrid-Network Improvement & Reliability Enhancement

This is National Grid’s description of the £135,000 project.

Researching new state-of-the-art condition monitoring to improve the commissioning and operation of offshore cables. This new, robust system will mitigate the risk of failure, overcome the limitations of existing techniques (e.g. cable length) and aid network operators in decision making for a more flexible grid. PROJECT PARTNERS: University of Manchester, DNV, Monitra, SSEN Transmission.

With all the offshore cables, that have been laid around the UK, Europe and the world in recent years, I am surprised that such a system has not been developed before.

But I suspect, that the project partners know that if they can develop a superior cable monitoring system, then it could be a nice little earner in addition to its job with UK offshore cables.

According to their web site, Monitra seem to be the monitoring experts.

This is the mission statement on their home page.

Our aim is to maximise the uptime of every high voltage asset worldwide.

I like this company’s attitude and it should make the world a better place.

I certainly think that the £135,000 will be well spent.

REACH – Rural Energy And Community Heat

This is National Grid’s description of the £120,000 project.

Working with rural community energy groups to develop a modular rural energy centre that will help communities make cost effective decarbonisation plans. The solution will offer shared low carbon heating, rapid EV charging, and renewable generation in areas not served by commercial markets, and where there is limited electricity network capacity.

Rolls-Royce mtu seem to have a system, that might go some way to satisfy National Grid’s ambitions, that I wrote about in Would You Buy A Battery Energy Storage System From Rolls-Royce?.

Road to Power

This is National Grid’s description of the £140,000 project.

Developing specific tools to forecast future energy consumption and infrastructural impact of works, to support the street and road works sector as it decarbonises 7.8TWh of energy demand across 700,000 major works in the sector’s pivotal transition to net zero by 2030.

This sounds like an excellent idea. Especially, if it makes street and road works quieter and less polluting.

Conclusion

I like these three projects and have already added them to my list of Google Alerts.

Bidders Circle ‘Elvis Airport’ A Decade After The SNP Bought It For £1

The title of this post, is the same as that of this article in The Times.

This is the sub-heading.

Prestwick has cost taxpayers millions since it was nationalised by the SNP in 2013. A consortium plans a bid, but can the Nats let go of Sturgeon-era stateism?

These are the first two paragraphs.

It was always going to be difficult keeping a lid on the arrival of Elvis Presley at a US military base in Prestwick, Ayrshire. “Where am I?” he asked as he stepped off the plane and into the biting wind that whipped off the Firth of Clyde.

March 3, 1960 was a momentous day for the screaming youngsters who engulfed the American singer as he set foot on British soil for the first and only time. For Presley, it was his last stop on his return from Germany after two years of military service. For Prestwick, it meant being immortalised in British trivia for its brief flirtation with The King.

But now it appears that a consortium has a plan for the airport and has made a bid.

These are my thoughts.

Prestwick Airport

Prestwick Airport, which is 32 miles SouthWest of Glasgow, is an airport that has seen busier times.

This OpenRailwayMap shows the Airport.

Note.

- The airport has two runways at right angles.

- The longer runway is 3,000 metres long.

- The red line is the electrified Ayrshire Coast Line, which runs between Glasgow Central and Ayr.

- There is a station at the airport.

- The black line going across the map is an unelectrified railway line, which eventually leads to the West Coast Main Line.

The airport does have four very useful assets.

- A very long runway capable of handling the largest and heaviest aircraft.

- A railway station.

- Plenty of space.

- The airport has plenty of available landing and take-off slots.

I also suspect that a rail connection could be developed to the West Coast Main Line.

Prestwick As A Cargo Airport

Someone commenting in The Times, suggested that Prestwick could become a cargo airport.

- The main runway could accommodate the largest and heaviest cargo aircraft.

- There is space for stands for large aircraft and warehouses.

- A rail link to the electrified West Coast Main Line could be built.

The airport could have a very high capacity.

A Rail Connection To The West Coast Main Line

This could be very beneficial for air-cargo at Prestwick.

- It would be less than ninety miles to the West Coast Main Line.

- It is only single-track as British Rail removed the second track.

- Cargo Services could be run all over the UK mainland.

- There could even be an airport service from Carlisle.

A zero-carbon rail service for freight, passengers and staff from both Glasgow and Carlisle would enhance the green credentials of the airport.

Where Would Planes Fly?

It looks like a modern freighter aircraft like a Boeing 747-8F could fly at maximum weight to nearly all the USA.

But because Prestwick Airport is further North, It does possibly have a wider range of airports, it can reach.

What Is The Closest Airport In North America?

The two airports on Newfoundland; Gander and St. John’s are probably the two closest being about 2,000 miles from Prestwick.

- Both airports have long runways.

- I suspect a rail terminal could be arranged at the airport to take cargo through the Chunnel to Europe.

- Could USAF Galaxies even be used to bring over American tanks and guns for Ukraine? The range of a Galaxy at maximum weight is 2,600 miles.

- They could be delivered by rail to Ukraine.

I suspect there will be times, where the shorter routes could be useful.

Could Cargo Change Planes At Prestwick?

On some routes like perhaps New York and India, might it be more efficient to change planes at Prestwick.

Could Cargo Planes Refuel At Prestwick?

Planes can only fly so far and is Prestwick in the right place to refuel a long flight?

Prestwick Could Be A Viable Cargo Airport For North America?

I am convinced that Prestwick and North American could be a viable air cargo route.

Zero-Carbon Air Cargo

In the next few years, Scotland will have much more electricity, than it needs, due to all the wind farms in the seas around the country and much of the spare electricity could be converted into hydrogen.

So does a cargo operator plan to run zero-carbon aircraft powered by hydrogen between North America and Prestwick?

- Remember it’s only 2,000 miles between St. John’s or Gander and Prestwick.

- The ideal aircraft to convert to hydrogen, must surely be an Airbus A 380, as there’s a lot of space in the fuselage for a hydrogen tank.

- Cargo could be brought to Prestwick in zero-carbon trains from all over the UK.

Amazon might like the idea of zero-carbon parcels across the pond!

Could An Airbus A380 Be Converted To Hydrogen?

This article on Simple Flying is entitled Airbus Plans A380 Hydrogen Flights In 2026 After Successful Power On Of ZEROe Engine.

The header picture shows a visualisation of an Airbus A 380, with a fifth engine with a propeller mounted on the top of the fuselage. The A 380 will be testing this electric engine, so that it can be fitted in the ZEROe Turboprop sometime around 2030.

This is a visualisation of the ZEROe Turboprop.

Note,

- The hydrogen tank will probably be behind the passenger compartment.

- The A 380, that will be testing the engine is no ordinary A 380. It is the very first and Airbus use it as a flying laboratory for new technology.

- I wouldn’t bet against one of its next jobs, is to test turbofan engines running on hydrogen.

I wouldn’t be surprised that in a few years, Airbus demonstrate an A 380 flying between Europe and North America on hydrogen.

A Zero-Carbon Air Bridge Between Europe And North America

Or does Westjet fancy a zero-carbon shuttle service, which would appeal to the Gretas of this world?

It has been rumoured, that the possible buyers of Prestwick are linked to Westjet.

As soon, as someone announces, a flight like this across the Atlantic, I’ll be signing up!

If the worse should happen, which I think would be unlikely, it would surely be a less painful death, than that of my wife’s from a rare cancer.

Conclusion

There are certainly, possibilities at Prestwick.

Ørsted Secures Exclusive Access To Lower-Emission Steel From Dillinger

The title of this post, is the same as that of this article on offshoreWIND.biz.

This is the sub-heading.

Ørsted will be offered the first production of lower-emission steel from German-based Dillinger, subject to availability and commercial terms and conditions. The steel plates are intended to be used for offshore wind monopile foundations in future projects.

These three paragraphs outline the deal.

Under a large-scale supply agreement entered into in 2022, Ørsted will procure significant volumes of regular heavy plate steel from 2024, giving the company access at scale to and visibility of the most crucial raw material in offshore wind while supporting Dillinger to accelerate investments in new lower-emission steel production, according to Ørsted.

The Danish renewable energy giant expects to be able to procure lower-emission steel produced at Dillinger’s facility in Dillingen, Germany, from 2027-2028.

Taking the current technology outlook into account, the reduction of the process-related carbon emissions from production is expected to be around 55-60 per cent compared to conventional heavy plate steel production, Ørsted said.

Increasingly, we’ll see lower emission steel and concrete used for wind turbine foundations.

This press release on the Dillinger web site is entitled Historic Investment For Greater Climate Protection: Supervisory Boards Approve Investment Of EUR 3.5 billion For Green Steel From Saarland.

These are two paragraphs from the press release.

Over the next few years leading up to 2027, in addition to the established blast furnace route, the new production line with an electric arc furnace (EAF) will be built at the Völklingen site and an EAF and direct reduced iron (DRI) plant for the production of sponge iron will be built at the Dillinger plant site. Transformation branding has also been developed to visually represent the transformation: “Pure Steel+”. The message of “Pure Steel+” is that Saarland’s steel industry will retain its long-established global product quality, ability to innovate, and culture, even in the transformation. The “+” refers to the carbon-neutrality of the products.

The availability of green hydrogen at competitive prices is a basic precondition for this ambitious project to succeed, along with prompt funding commitments from Berlin and Brussels. Local production of hydrogen will therefore be established as a first step together with the local energy suppliers, before connecting to the European hydrogen network to enable use of hydrogen to be increased to approx. 80 percent. The Saarland steel industry is thus laying the foundation for a new hydrogen-based value chain in the Saarland, in addition to decarbonizing its own production. In this way, SHS – Stahl-Holding-Saar is supporting Saarland on its path to becoming a model region for transformation.

It sounds to me, that Tata Steel could be doing something similar at Port Talbot.

- Tata want to build an electric arc furnace to replace the blast furnaces.

- There will be plenty of green electricity from the Celtic Sea.

- RWE are planning a very large hydrogen electrolyser in Pembroke.

- Celtic Sea offshore wind developments would probably like a supply of lower emission steel on their door-step.

I would suspect, that Welsh steel produced by an electric arc furnace will match the quality of the German steel, that is made the same way.

Aurizon Secures Funding To Develop Next-Generation Freight Trains Using Renewable Energy

The title of this post, is the same as that of this press release from Aurizon.

These five paragraphs outline the project.

Australia’s largest rail freight company Aurizon, today received a major boost to its program to develop the next generation of Australian freight trains, aiming to replace diesel fuel with renewable energy sources on its locomotive fleet.

Aurizon has secured a $9.4 million grant from the Australian Renewable Energy Agency (ARENA) to develop, test and trial a battery electric tender (BET) to be used in conjunction with a modified locomotive. (refer graphic below).

The tender – essentially a big battery-pack on wheels – will couple with the modified locomotive to operate as a hybrid unit using both diesel and battery-electric power sources. The tender’s battery will also harness re-generative energy captured as the train travels down grades and brakes as part of normal operation.

The ARENA grant represents half of the required funding for the ‘Battery Powered Tender for Heavy Haul Fleet Decarbonisation’ project, with the balance of the investment to be funded by Aurizon. The battery-electric tender and modified locomotive project will be built by Aurizon and technology project partner, Alta Battery Technology (Alta) at a facility in Australia, with design and technology inputs from Alta.

Aurizon appreciates the Federal Government making funding available to support the development of a range of new zero emissions technologies in the transport sector, including technologies that can be developed for application in rail-based freight supply chains that are integral to Australia’s export and domestic industries that rely on transport services.

At a first glance it appears to be suited to Aurizon and its long routes with heavy freight trains across Australia.

These are some more specific thoughts.

Alstom Have Built A Train With a Hydrogen Tender

In From 2025, Nestlé Waters France Will Use The First Hydrogen-Powered Freight Train Through An Innovative Solution Developed by Alstom and ENGIE, I describe a train powered by an electric locomotive with an attached hydrogen power unit.

The Future Of The Class 68 Locomotives

Could these be given a reduced-carbon second life, by developing a specialised tender?

I wrote about this in The Future Of The Class 68 Locomotives.

I suspect Stadler, who seem to be excellent innovators will be watching.

There Seems To Be A Lot Going On In Australia

I have written several posts about decarbonisation of freight trains in Australia.

- BHP To Trial Battery Locos On Pilbara Iron Ore Network

- Battery-Electric Power Rides The Rails

- Wabtec And Roy Hill Unveil The First FLXdrive Battery Locomotive

- Fortescue Unveils World-First Electric Train Using Gravity To Recharge

- BHP Joins The Party On Electric Rail

- Rio Tinto Orders Wabtec FLXdrive Battery Locomotives To Reduce Emissions

The big mining companies certainly seem keen to decarbonise.

Third Rail Or Batteries Could Replace Southern Diesel Trains

The title of this post, is the same as that of this article on Railway Gazette International.

I first wrote about the Uckfield Branch eight years ago, in Future-Proofing The Uckfield Branch.

Since then I have written about this branch several times and I have also read several articles in the railway press.

These are some of my posts.

- Discontinuous Electrification Using IPEMUs – April 30th, 2016

- Will Innovative Electrification Be Used On The Uckfield Line? – August 24th, 1917

- Battery Trains On The Uckfield Branch – August 26th, 2018

- Battery Electrostars And The Uckfield Branch – September 30th, 2019

- Alstom Hydrogen Aventras And The Uckfield Branch – November 12th, 2021

- Electroflex Battery EMU Plan To End Southern Diesel Operation – January 22nd, 2020

- Uckfield Third Rail Is NR Priority – May 2nd, 2022

- Southeastern Keen On Battery EMUs – August 12th. 2023

It is an utter disgrace that no decision has been made in eight years about how to decarbonise to Uckfield.

The Railway Gazette article says this about third-rail electrification.

GTR is one of two operators participating in a Rail Safety & Standards Board project reviewing the safety, legal and regulatory issues around third rail electrification infill projects. This is looking at whole transport system safety, project and economic risks.

Bi-monthly South of England Diesel Replacement Programme meetings are held by DfT, Network Rail and GTR to review progress and options for third rail electrification of the Uckfield line or battery train trials. This includes reviewing the lessons learned from the use of bi-mode trains by GWR and LNER, and the failed attempt to deploy tri-mode Class 769 units on GWR’s North Downs services.

Could it just be that there is such fear that there will be a major incident, where several people are killed, that third-rail electrification is always turned down, by the Office of Road and Rail?

The Railway Gazette article also says this about battery trains, under a heading of Batteries Viable.

In the absence of electrification, GTR says battery powered trains are also a viable option for its diesel routes. Batteries can be charged while trains are running on electrified lines or through a rapid recharging facility at a terminus, although additional infrastructure and electrical upgrades may be needed.

I suspect that after a few teething troubles, Merseyrail would agree.

Hydrogen is also dismissed with this paragraph.

GTR has considered hydrogen but says it can only be considered a net zero-compliant fuel if it is produced from low or zero-carbon energy sources. It is also relatively inefficient with studies indicating an efficiency rate of around 35% to 40%.

It looks to me, that battery-electric trains are a viable solution.

So would it not be a good idea to take the decision to create a battery-electric prototype from a four-car Electrostar or a Class 350 train, so that the final decision can be taken after everybody on the committee has have a ride first?

Better still, why not stage a competition, where manufacturers, leasing companies or remanufacturers can build a four-car train and enter.

Allow the public to ride in them and then see what is best against a range of criteria.

The King could even get involved, as he’s probably one of the few people left, who rode the original British Rail BEMU between Aberdeen and Ballater, to get to Balmoral.