The Ultimate Recycled Electric Local Train

This morning, I took a ride across London to ride in the first Class 230 train in public service in London.

I took these pictures of the new block of flats going up at West Ealing station, the charging system for the train and the train.

Note.

- The train is three-cars with a toilet to suit everybody, except possibly Donald Trump, who’d want it in gold.

- The single train is shuttling between West Ealing and Greenford stations.

- Each journey 2.5 mile journey takes eleven minutes.

I was surprised at the number of tables and the quality of the seats.

These are some extra thoughts.

The Blocks Of Flats

Google AI gave me this.

Several new developments around West Ealing station feature tall blocks, with major proposals ranging from 4 to 26 storeys. Key projects include a 26-storey tower, proposed 19–22 storey towers on Manor Road/Waitrose site, and 7–21 storey student accommodation blocks. These, along with other 9-storey developments, are transforming the area into a high-density “transport hub” cluster.

I think the 26-storey West 55 Tower is shown in the first two pictures.

Google AI also says some of the natives are not happy about all the towers.

But I like the “high density” transport hub.

Integrating The Railway And The Housing

Note.

- This would appear to be a good example of integrating the railway and the housing.

- The second picture appears to show a walkway between the station and Tower 55.

- I met a property developer on a train once and he told me, that housing on top of stations without car parking, had better numbers all round, with more flats, less cost and good profit.

- I wonder, if Tower 55, is one of his? He was certainly enthusiastic about the concept.

- Would a Fast-Charge system be easier and very much safer to squeeze in than traditional overhead wiring?

If the flats all don’t have garages, there must be space for other uses.

The Charger At Work

Note.

- The third to the sixth pictures, show the train coming into the station and charging ready for a trip to Greenford.

- The train acts as a heavy safety guard during the process.

- Anything electrical or dangerous is underneath the train.

I would expect that a health and safety expert, would rate the train no more dangerous than a normal train.

There Seems To Have Been A Lot Of Innovative Recycling On The Train

This certainly seems to apply to the seats, which in some cases are the originals remodeled.

A Stylish And Well-Built Train

This phrase would sum up my overall view of the train.

I have a Korean son-in-law and I know a bit, how Koreans think about design.

I would think, that he would like this as it is a stylish and practical train, so it wouldn’t embarrass you or your Korean boss, if you told him to use this train in the UK, to get to your offices.

Using my Korean example, I suspect, that this train could be one that endears itself to its passengers, with its quirky and practical feel, just like the original Mini did.

Adrian Shooter Would Be Pleased

Most Certainly!

I wish all the team well, as I believe this technology and a few trains like 230001 will make their mark on the world.

A Practical Hundred Mile Battery-Electric Route

The Sheffield and Scunthorpe Line is a Parliamentary Service.

- It is 71.6 miles over 1 hour and 48 minutes, through seven stations of the Lincolnshire countryside, at an average speed of 40 mph.

- Currently, it runs once per day, which is not very ideal for a job, education, training, shopping or visiting grandchildren.

- A two-car version of 230001 could be ideal to perhaps do four round or five trips a day and level-up some of the poorer parts of the UK, that don’t even have a decent bus service.

- A similar two-car train could also serve the 45-mile round-trip Cleethorpes and Barton-on-Humber service.

I am sure that this train could start the right sort of rural or urban revolution.

45 schools Benefit From Rail Safety Resources Supported By Lumo And Hull Trains

The title of this post, is the same as that of this article on The Shields Gazette.

This is the sub-heading.

The UK’s leading open access rail operators, Lumo and Hull Trains, are celebrating supporting the delivery of vital rail safety resources to 45 schools across the UK over the past year.

These three paragraphs add more detail.

In association with the Rail Safe Friendly Programme, the operators’ involvement has led to a social value impact of over £724,000, directly educating thousands of young people.

The programme is dedicated to spreading the vital message of rail safety among young people, educators and parents in schools across the UK. Lumo and Hull Trains have supported the important initiative for the past two years, with their support renewed for a third.

As part of the partnership, Lumo took over the Metrocentre’s ‘mini express train’ to highlight the issue of rail safety to families and children visiting the shopping centre during the school holidays in 2024. The project secured industry recognition at the recent Corporate Engagement Awards.

It’s not just in the UK, that this type of excellent engagement is being setup.

This train is the world’s first hydrogen-powered train to enter passenger service, between Hamburg and Cuxhaven in Germany.

When I rode the train, a German schoolboy told me, that their school had given them safety lessons about hydrogen.

Is Last Energy The Artemis Of Energy?

In Raft Of US-UK Nuclear Deals Ahead Of Trump Visit, I quoted from this article on World Nuclear News.

The article also contains, these two paragraphs, with talk about an MoU between Last Energy and DP World.

An MoU has also been signed between US-based micro-nuclear technology developer Last Energy and DP World, a global leader in logistics and trade, to establish the world’s first port-centric micro nuclear power plant at London Gateway. A proposed PWR-20 microreactor – to begin operations in 2030 – would supply London Gateway with 20 MWe of electricity to power the logistics hub, with additional capacity exported to the grid.

“The initiative represents a GBP80 million (USD109 million), subsidy-free investment for the development of Last Energy’s first unit, unlocking clean power supply for DP World’s ongoing GBP1 billion expansion of London Gateway,” Last Energy said. “The partnership is closely aligned with both UK and US ambitions to increase nuclear capacity and strengthen long-term energy security.”

Note.

- Last Energy are proposing a micro-reactor of just 20 MW.

- DP World own and/or operate sixty ports in over forty countries, so should know their energy requirements well.

- It appears that DP World are investing £80 million in Last Energy’s first unit.

- Thurrock Storage is a 300 MW/600 MWh battery close to London Gateway and the Port of Tilbury.

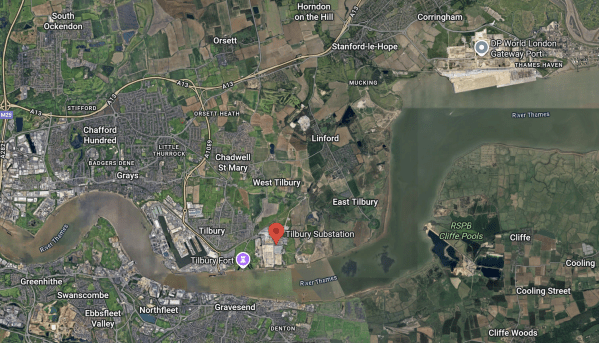

This Google Map shows London Gateway and the Port of Tilbury.

Note.

- DP World London Gateway is in the North-East corner of the map.

- The A13 road runs across the North-West corner of the map and links the area to London and the M25.

- Thurrock Storage is next to the Tilbury substation, which is marked by the red arrow.

- The Port of Tilbury is to the West of the substation.

I wonder if DP World London Gateway have had power supply problems.

The Design Of The First Artemis Project Management Software System

Before Artemis, project management was usually done on a large mainframe computer like an IBM-360-50, that I’d used extensively for solving simultaneous differential equations in a previous job at ICI.

Mainframe computers worked on complex problems, but to put it mildly, they were slow and needed a team to operate them and a big air-conditioned room to keep them happy.

When the four of us decided to create Artemis, our vision was something simpler.

- A processor – something like a PDP-11, which I judged would be big-enough for the computing.

- A visual display unit.

- A printer.

- A standard-size desk to hold the hardware.

- Ability to run from a 13-amp socket.

When it came to writing the software, I took few risks.

- Much of the data decoding software, I’d developed when I left ICI to write a program to solve up to a thousand simultaneous differential equations.

- The scheduling software was generic and I’d first used it for different purposes in two programs at ICI.

- The aggregation software had been devised, whilst I was a consultant at Lloyds Bank over several bottles of wine with their Chief Management Accountant, who was a wizard with numbers. I suspect, but can’t prove it, that if the idiots that programmed the Horizon system for the Post Office had used that algorithm, the problems there would have been much smaller.

- I also spent a lot of time reading old papers from the 1950s in IBM’s library on the South Bank, looking for better algorithms.

- I also made sure, I chose the best hardware and I believe HP did us proud.

- I used HP’s operating system and proprietary database to cut down, what could go wrong.

- Almost all of the first system was written by one person – me!

But we also put the right features into how we supported, delivered and trained users of the system.

I certainly, think we made few mistakes in the design of that first system.

Have Last Energy Used A Similar Cut Back Approach?

Reading their web site, I think they have.

They have obviously chosen, the 20 MW unit size with care.

But from worldwide experience with wind turbines, linking smaller power sources together, is not as difficult as it once was.

These are some of the statements on their web site’s introductory screens.

- Fully Modular, Factory Made

- A Scalable Solution

- <24 Month Delivery

- 100+ Supply Chain Partners

- 300+ Pressurised Water Reactors Operating Globally

- 0.3 acre – Plant Footprint Fits Within A Football Field

But a chain is only as strong as its weakest link.

It should be noted, that I have been over several nuclear power stations.

Three were a tour to show me how Artemis was being used to track and sign off, the problems identified after the Three Mile Island incident.

The other was a trip over Sizewell A, a couple of years before it was decommissioned.

Comparing these experiences with some of the chemical plants, that I’ve worked on, I would prefer to be close to a nuclear power plant.

Network Rail Objects To Wrexham To London Service

The title of this post, is the same as that of this article on the BBC.

This is the sub-heading.

Concerns have been raised about plans for a direct rail service between Wrexham and London, including fears over safety at level crossings.

These three paragraphs add details to the story.

Network Rail warned the line was already congested and there was not enough timetable capacity for extra services.

In a report, it said increased use would raise the risk of a collision at crossings along the route and that it could not support the application, put forward by a new open-access rail operator called the Wrexham, Shropshire and Midlands Railway (WSMR).

The new service would link Wrexham, Gobowen, Shrewsbury, Walsall and Coleshill up with the capital.

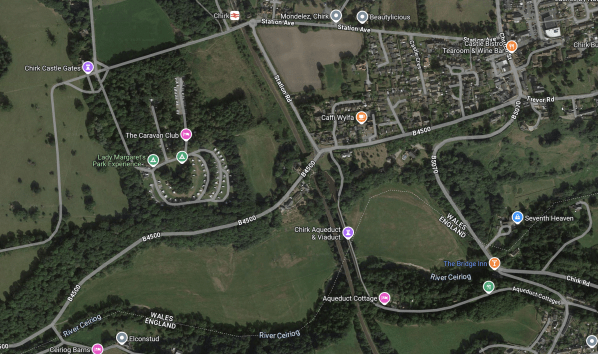

This Google Map shows the area of the crossing.

Note.

- Chirk station, which is fully-accessible via ramps, is at the top of the map.

- The railway between and running down the middle of the map.

- The railway has a maximum speed of 70 mph.

- The Aqueduct and the Viaduct crossing the valley of the River Ceirog together.

- The large caravan park.

- Chirk Castle Park.

If the Viaduct level crossing is in this area, it is a serious accident waiting to happen.

The BBC article says this about the crossing.

They include the Viaduct level crossing in Shropshire, which it said was “used by large groups and is also a hot spot for trespassing and fatalities”.

The operator said work would need to be carried out to make it safe.

North Shropshire MP Helen Morgan has previously spoken out on the safety of the crossing, which is close to the Chirk Viaduct.

She has written to Network Rail to request additional safety measures be put in place.

Network Rail said it had reviewed the safety of the crossing and brought forward plans to install crossing lights, which should be in place in December this year.

Note.

- I hope this is enough. But, I do know that the level crossing lights work well at Thurston station in Suffolk.

- It must help, that there is a bridge at the station.

The line between Wolverhampton and Wrexham, except for a short 15 mph section at Shrewsbury has at least a 70 mph maximum speed.

As electric trains, including battery-electric ones, have fast acceleration and deceleration would it not be possible for them to slow down for the level crossings?

This could even be done automatically using digital signalling.

Conclusion

I believe that this level crossing problem is solvable.

Could A Cross-City Underground Railway Be Run Using Battery-Electric Trains?

Consider.

- Cross-city underground railways like London’s Bakerloo, Central, Jubilee,Northern, Piccadilly and Victoria Lines are usually powered by third-rail technology, which can be dangerous, if someone falls on the track.

- Siemens new London Underground 2024 Stock, which is fully-described in this Wikipedia entry, has the following characteristics.

- A train width of 2.648 metres.

- A train height of 2.844 metres.

- Walk-through carriages

- Air-conditioning

They will also have batteries to support regenerative braking.

But say you were building a new underground line across a city like Birmingham, Leeds or Manchester.

Would the following be possible?

- The tunnel would be built as small as possible, which would probably mean that it was built faster and more economically.

- There would be no electrified rails or overhead wires to power the trains in the tunnel.

- The trains would be powered by batteries.

- Batteries would be charged by a pantograph, that erected to contact with an overhead line outside the tunnel.

- The central tunnel would be bored straight.

- When the train doors opened, passengers would be able to walk on a level surface into and out of the train.

- I believe it would be possible to align the train doors with openings in the tunnel wall at stations to eliminate the need for platform edge doors.

I believe that to design a train and tunnel to literally fit like a glove, could save a lot of money on building a cross-city underground line.

The New Southbound Northern Line Platform At Bank Station

These pictures show the new Southbound Northern Line Platform at Bank Station.

Note.

- This is probably London Underground’s newest platform.

- The step into and out of the train is fairly level.

- This improvement has been achieved with new track and thirty-year-old rolling stock.

Have Siemens redesigned the platform/train interface in the London Underground 2024 Stock, so that the train/platform interface is even better?

- Who’s to know what you can do with modern computer-aided design techniques?

- If the train were to be battery-powered, so that conductor rails were not needed, would the extra space help fit everything in?

- If there were no live rails under the train, would this increase safety, both real and perceived?

I believe it might be possible to design a train/platform interface, that would work with simpler and more affordable platform edge doors.

We probably find out what is possible until the London Underground 2024 Stock enter service later this year.

Level Boarding Included In Rail Innovation Funding Competition

The title of this post, is the same as that of this article in Railway Gazette.

This is the introductory paragraph.

Innovate UK has opened the latest calls for grant funding proposals under the First of a Kind programme, which supports the demonstration of innovative technologies to give them a better chance at being deployed by railway companies.

What annoys me about boarding trains (and some buses for that matter!), is how variable it is.

- Trains in East Anglia, Merseyside and Switzerland are particularly good, but then they have the common Stadler factor.

- Will the Newcastle Metro and the Glasgow Subway be as good?

- Some European countries, including Germany, could do much better!

- Once at Leipzig, I helped four hefty Germans lift a guy and his wheel-chair out of the bottom-deck of a double-deck train.

- In London, the Docklands Light Railway, the Elizabeth Line and some parts of the Overground are acceptable, but there is need for improvement.

- Southeastern, including the HighSpeed is particularly dodgy and I need help at some stations like Clapham Junction and Lewisham.

- Bank has a notorious platform on the Central Line.

- Perhaps the worst in London are some stations on theBakerloo Line, where it shares with the Watford DC Line.

All passengers on buses and trains deserve the best access that designers and bus and train manufacturers can devise.

In one incident, a slight, elderly Indian lady in a sari, was having difficulty getting down from an Overground train on the Watford DC Line at Willesden Junction station.

I was the only person on the platform, so I called out. “Can You Jump?”

Which she did and landed safely on her feet! I caught her and it was smiles all round!

I suspect she’d done that before.

So is one idea to give all passengers, lessons in jumping on and off buses and trains?

Seriously though, could Lego devise a large-scale engineering version of their product, that could be used to create steps and humps, which could be glued together for strength.

Alternatively, 3D printing could be used to create gap-fillers.

I think this challenge from Innovate UK will bring forward some good solutions.

Platform 10 At Clapham Junction Station

These pictures show the step into and out of the Class 455 trains at Platform 10 at Clapham Junction station.

Note.

- Platform 10 at Clapham Junction station is markedly curved with a wide gap to mind!

- There is also quiet a high step up and down.

- The last two pictures, show the safer design at Platform 3 at Dalston Junction station.

On my last two visits to Clapham Junction, I have had to be helped out of the train. None of us, are getting any younger.

Ørsted Evolves Long-Standing Partnership With RNLI

The title of this post, is the same as this news item from Ørsted.

This is the sub-heading.

Ørsted, the global leader in offshore wind power and one of the largest renewable energy companies in the world, has announced the latest phase of its long-standing partnership with the Royal National Lifeboat Institution (RNLI).

These three paragraphs give a few more details of the partnership.

Over the next two years, Ørsted will provide more than £140,000 to help the charity in its mission to save lives at sea.

The RNLI is the charity that saves lives at sea and its volunteers provide a 24-hour search and rescue service across the British Isles.

Established in 2015, the partnership previously focused on supporting seven individual lifeboat stations in areas where Ørsted operates its offshore windfarms and is now evolving to support even more lifeboat stations.

Little is said about what benefits Ørsted get from the partnership.

Although, this is said.

Previously focused on supporting seven individual lifeboat stations in areas where Ørsted operates its offshore windfarms.

Does this mean, that for small incidents, the RNLI can do the rescue or perhaps tow a broken-down workboat to the shore?

In a busy area, the RNLI might even act as backup to Ørsted’s own safety boat, if a second incident occurred.

It might be a more affordable way to ensure safe operation, which is obviously paramount.

Conclusion

As the partnership is being extended, it must surely have been working well.

The Aerosol Tales

When I left Liverpool University in 1968, I was very familiar with the use of products distributed in aerosol cans.

- I had used aerosol shaving cream, although about that time, I acquired my beard.

- I certainly used aerosol deodorant, as did most in the 1960s.

- Aerosol paints were common for covering scuffs and scratches in your car.

- Aerosols were often used to apply sun protection.

- Aerosols containing cream or a non-dairy alternative for culinary use were not unknown.

- Aweosol lubricants were starting to appear.

Although, I went to work for the chemical giant; ICI, at that time, I had no idea how an aerosol and its can worked.

As ICI at the time, ICI were major manufacturers of aerosol propellants, I quickly learned how they worked.

The Wikipedia entry for Aerosol Spray Dispenser gives a lot of history about aerosol cans and their propellants.

The Wikipedia entry for Propellant has this paragraph describing propellants of the last century.

Chlorofluorocarbons (CFCs) were once often used as propellants, but since the Montreal Protocol came into force in 1989, they have been replaced in nearly every country due to the negative effects CFCs have on Earth’s ozone layer. The most common replacements of CFCs are mixtures of volatile hydrocarbons, typically propane, n-butane and isobutane. Dimethyl ether (DME) and methyl ethyl ether are also used. All these have the disadvantage of being flammable. Nitrous oxide and carbon dioxide are also used as propellants to deliver foodstuffs (for example, whipped cream and cooking spray). Medicinal aerosols such as asthma inhalers use hydrofluoroalkanes (HFA): either HFA 134a (1,1,1,2,-tetrafluoroethane) or HFA 227 (1,1,1,2,3,3,3-heptafluoropropane) or combinations of the two. More recently, liquid hydrofluoroolefin (HFO) propellants have become more widely adopted in aerosol systems due to their relatively low vapor pressure, low global warming potential (GWP), and nonflammability.

Note that the whole range of these chemicals, effect the ozone layer.

Rocksavage Works

ICI’s Rocksavage Works, was an integrated chemical plant by the Mersey,.

- It made all types of CFCs for aerosols and other purposes.

- It also made the fire suppressant and extinguisher; Bromochlorodifluoromethane or BCF.

- Alongside BCF, it made the anaesthetic Halothane or as ICI called it Fluothane.

- The plant was a poisonous place with all those bromine, chlorine and fluorine compounds.

- Despite this, the plant had a remarkable safety record.

I had the pleasure of working at the plant and it was where, I had most of my excellent Health and Safety training, from the amazing site foreman; Charlie Akers.

Some of the wisdom he distributed has proved invaluable in aiding my stroke recovery.

I suspect that since the signing of the Montreal Protocol, the plant has changed greatly or has even been closed.

All that appears to be left is the 800 MW gas-fired Rocksavage power station and a Facebook page.

Aerosol Baked Beans

In those days, I worked most of the time in a lab at Runcorn Heath.

One of the labs near to where I generally worked, in the large research complex, was a lab, where new aerosol products were developed and tested.

One of the standard jokes about that lab, was that they were working on aerosol baked beans. They said, they would develop the product, even of they had to eject them from the can one at a time.

Gift Time

One afternoon, the boss of the aerosol development lab came through with a tray of goodies.

On the tray, which was much like a cinema usherette’s ice cream tray of the sixties was a whole host of partly-labeled aerosol cans. Only clues to what the product might be were written on the outside in felt-tip pen.

I grabbed two, one of which was marked something like lubricating oil and the other was just marked hand cream, which I of course gave to my new wife; C.

We were married for nearly forty years and often, when she bought hand cream, she would remark, that it wasn’t of the same standard as the little can I brought home from work.

It appears to me, that one of the world’s top cosmetic companies and ICI were trying to create the world’s best and probably most expensive hand creams.

DMW

Fast-forward nearly twenty years and I was approached by Lloyds Bank about two individuals, who had developed an aerosol valve, that instead of using CFCs or other ozone-depleting chemicals.

- By the exploitation of the nether end of fluid dynamics, the propellant of the aerosol was nothing more harmless than pure nitrogen.

- I formed a company called DMW with the two inventors.

- John Gummer, who at the time was my MP and Environment Minister, knew of the aerosol valve and he took the details to Montreal.

So did a device developed in Suffolk help push through the Montreal Protocol?

Osbourne Reynolds

I also wonder, if we had some supernatural help. At the time, I lived in the family home of Osbourne Reynolds.

- He did a lot of the early work on fluid dynamics.

- He was the first UK Professor of Engineering.

- He was professor of Engineering at Manchester University for nearly forty years.

- The Reynolds number is named after him.

- Remarkably, students are sill taught on the equipment Reynolds designed.

- Reynolds was certainly one of our great Victorian scientists.

This Wikipedia entry gives more details of his remarkable life and work.

After Montreal the aerosol valve was sold to Johnson & Johnson.

DMW continued to develop other products and we had one, who no-one had any idea about how it worked.

So I discussed it with the Reynolds’s expert at Manchester University and he said he had no idea either.

But he was absolutely certain, that Reynolds would have known.

Set Back As Badgers Undermine 11 km Of Railway

The title of this post, is the same as that of this article on Railway Gazette International.

These four paragraphs outline the problems.

Deutsche Bahn reports that burrowing badgers have undermined about 11 km of embankment on the Fröndenberg – Unna railway, and repairs are likely to be very expensive and take a long time as the damage is more extensive than expected.

In some places the repairs will be equivalent to new construction, and DB says the planning and approval phase alone could take several years as the route passes through protected environments. Local media reports that the financial viability of reopening is being questioned.

DB first discovered the damage in 2022, and initiated repairs using a concrete spraying process. It also began to examine the rest of the route and 140 sett entrances have now been discovered, leading to an extensive tunnel system which is believed to have a total length of around 1 500 m spread over the entire length of the embankment.

The line runs through a nature reserve, so investigations had to be suspended over the summer until a special permit was obtained. Trees and bushes also needed to be cut back. Regional train service RB54 remains suspended between Unna and Fröndenberg and replaced by buses, extending journey times by 7 min.

Note.

- The railway appears to be only single-track from Google Maps.

- Unna station is the Easternmost station of the Rhine-Ruhr S-Bahn.

- The RB 54 – Hönnetal-Bahn runs between Fröndenberg and Unna.

I wouldn’t be surprised that this serious problem will be resolved by either closing the railway permanently or by using an expensive rebuild.

How Network Rail Deal With Badgers

I did find this document on the Network Rail web site, which appears to be part of a Safety Course.

There is this page on the Network Rail web site, which is entitled Badgers Sett To Keep Their Homes As Railway Works Around.

Unfortunately for the Germans, they seem to have whole armies of badgers, whereas we seem to have just a couple of families in the second document.

It does look like in the video in the second example, that a certain amopunt of psychology is used to persuade the badgers to do, what Network Rail wants them to do.

Sheep And The M62

When I was at Liverpool University in the 1960s, the Veterinary Department had a contract to design fencing to keep the hardy Pennine sheep off the motorway.

They found that the sheep had little difficulty climbing over a six foot high wire mesh fence.

Perhaps DB should ask Liverpool, if they have any tips!