National Grid Pioneers UK-First Trial Of 3D Printed Technology For Low-Carbon Substations

The title of this post, is the same as that of this press release from National Grid.

These three bullet points act as sub-headings.

- Collaboration with Hyperion Robotics and the University of Sheffield will trial low-carbon 3D-printed concrete foundations including at National Grid’s Deeside Centre for Innovation in North Wales

- Innovation could reduce waste, carbon emissions and costs to consumers of network construction

- If rolled out across National Grid substations the technology could save up to 705 tons of concrete and 323 tons of CO2 and deliver £1.7 million in consumer savings versus traditional methods over a 10-year period

These two paragraphs give more details.

National Grid is working with Hyperion Robotics and the University of Sheffield on a UK-first trial to manufacture, install and test 3D-printed substation foundations, which have the potential to reduce construction-driven carbon emissions and reduce costs to consumers of network construction. This is part of National Grid’s commitment to leverage innovation to future-proof the network.

If the project is successful and the technology is rolled out across all National Grid substations, it is estimated it could save up to 705 tons of concrete and 323 tons of CO2 over a 10-year period, and deliver £1.7 million in consumer savings versus traditional methods.

The foundation design will deliver significant savings across the entire value chain.

- 70% reduction in concrete usage

- 80% less soil displacement

- 65% decrease in embodied carbon emissions

- 70% weight reduction compared to typical foundations

- 50% reduction in site operative hours, streamlining production

The foundations will be designed and produced in Finland by Hyperion Robotics, and tested at full-scale by the University of Sheffield. Further field testing will then be carried out at National Grid’s state-of-the-art testing facility, the Deeside Centre for Innovation in North Wales, later in 2025.

Conclusion

I like this technology and I suspect there are many other applications of 3D Concrete Printing.

RWE Acquires 4.2-Gigawatt UK Offshore Wind Development Portfolio From Vattenfall

The title of this post, is the same as that of this press release from RWE.

These three bullet points, act as sub-headings.

- Highly attractive portfolio of three projects at a late stage of development, with grid connections and permits secured, as well as advanced procurement of key components

- Delivery of the three Norfolk Offshore Wind Zone projects off the UK’s East Anglia coast will be part of RWE’s Growing Green investment and growth plans

- Agreed purchase price corresponds to an enterprise value of £963 million

These two paragraphs outline the deal.

RWE, one of the world’s leading offshore wind companies, will acquire the UK Norfolk Offshore Wind Zone portfolio from Vattenfall. The portfolio comprises three offshore wind development projects off the east coast of England – Norfolk Vanguard West, Norfolk Vanguard East and Norfolk Boreas.

The three projects, each with a planned capacity of 1.4 gigawatts (GW), are located 50 to 80 kilometres off the coast of Norfolk in East Anglia. This area is one of the world’s largest and most attractive areas for offshore wind. After 13 years of development, the three development projects have already secured seabed rights, grid connections, Development Consent Orders and all other key permits. The Norfolk Vanguard West and Norfolk Vanguard East projects are most advanced, having secured the procurement of most key components. The next milestone in the development of these two projects is to secure a Contract for Difference (CfD) in one of the upcoming auction rounds. RWE will resume the development of the Norfolk Boreas project, which was previously halted. All three Norfolk projects are expected to be commissioned in this decade.

There is also this handy map, which shows the location of the wind farms.

Note that there are a series of assets along the East Anglian coast, that will be useful to RWE’s Norfolk Zone development.

- In Vattenfall Selects Norfolk Offshore Wind Zone O&M Base, I talked about how the Port of Great Yarmouth will be the operational base for the Norfolk Zone wind farms.

- Bacton gas terminal has gas interconnectors to Belgium and the Netherlands lies between Cromer and Great Yarmouth.

- The cable to the Norfolk Zone wind farms is planned to make landfall between Bacton and Great Yarmouth.

- Sizewell is South of Lowestoft and has the 1.25 GW Sizewell B nuclear power station, with the 3.2 GW Sizewell C on its way, for more than adequate backup.

- Dotted around the Norfolk and Suffolk coast are 3.3 GW of earlier generations of wind farms, of which 1.2 GW have connections to RWE.

- The LionLink multipurpose 1.8 GW interconnector will make landfall to the North of Southwold

- There is also the East Anglian Array, which currently looks to be about 3.6 GW, that connects to the shore at Bawdsey to the South of Aldeburgh.

- For recreation, there’s Southwold.

- I can also see more wind farms squeezed in along the coast. For example, according to Wikipedia, the East Anglian Array could be increased in size to 7.2 GW.

It appears that a 15.5 GW hybrid wind/nuclear power station is being created on the North-Eastern coast of East Anglia.

The big problem is that East Anglia doesn’t really have any large use for electricity.

But the other large asset in the area is the sea.

- Undersea interconnectors can be built to other locations, like London or Europe, where there is a much greater need for electricity.

- In addition, the UK Government has backed a consortium, who have the idea of storing energy by using pressurised sea-water in 3D-printed concrete hemispheres under the sea. I wrote about this development in UK Cleantech Consortium Awarded Funding For Energy Storage Technology Integrated With Floating Wind.

A proportion of Russian gas in Europe, will have been replaced by Norfolk wind power and hydrogen, which will be given a high level of reliability from Suffolk nuclear power.

I have some other thoughts.

Would Hydrogen Be Easier To Distribute From Norfolk?

A GW-range electrolyser would be feasible but expensive and it would be a substantial piece of infrastructure.

I also feel, that placed next to Bacton or even offshore, there would not be too many objections from the Norfolk Nimbys.

Hydrogen could be distributed from the site in one of these ways.

- By road transport, as ICI did, when I worked in their hydrogen plant at Runcorn.

- I suspect, a rail link could be arranged, if there was a will.

- By tanker from the Port of Great Yarmouth.

- By existing gas interconnectors to Belgium and the Netherlands.

As a last resort it could be blended into the natural gas pipeline at Bacton.

In Major Boost For Hydrogen As UK Unlocks New Investment And Jobs, I talked about using the gas grid as an offtaker of last resort. Any spare hydrogen would be fed into the gas network, provided safety criteria weren’t breached.

I remember a tale from ICI, who from their refinery got a substantial amount of petrol, which was sold to independent petrol retailers around the North of England.

But sometimes they had a problem, in that the refinery produced a lot more 5-star petrol than 2-star. So sometimes if you bought 2-star, you were getting 5-star.

On occasions, it was rumoured that other legal hydrocarbons were disposed of in the petrol. I was once told that it was discussed that used diluent oil from polypropylene plants could be disposed of in this way. But in the end it wasn’t!

If hydrogen were to be used to distribute all or some of the energy, there would be less need for pylons to march across Norfolk.

Could A Rail Connection Be Built To The Bacton Gas Terminal

This Google Map shows the area between North Walsham and the coast.

Note.

- North Walsham is in the South-Western corner of the map.

- North Walsham station on the Bittern Line is indicated by the red icon.

- The Bacton gas terminal is the trapezoidal-shaped area on the coast, at the top of the map.

ThisOpenRailwayMap shows the current and former rail lines in the same area as the previous Google Map.

Note.

- North Walsham station is in the South-West corner of the map.

- The yellow track going through North Walsham station is the Bittern Line to Cromer and Sheringham.

- The Bacton gas terminal is on the coast in the North-East corner of the map.

I believe it would be possible to build a small rail terminal in the area with a short pipeline connection to Bacton, so that hydrogen could be distributed by train.

There used to be a branch line from North Walsham station to Cromer Beach station, that closed in 1953.

Until 1964 it was possible to get trains to Mundesley-on-Sea station.

So would it be possible to build a rail spur to the Bacton gas terminal along the old branch line?

In the Wikipedia entry for the Bittern Line this is said.

The line is also used by freight trains which are operated by GB Railfreight. Some trains carry gas condensate from a terminal at North Walsham to Harwich International Port.

The rail spur could have four main uses.

- Taking passengers to and from Mundesley-on-Sea and Bacton.

- Collecting gas condensate from the Bacton gas terminal.

- Collecting hydrogen from the Bacton gas terminal.

- Bringing in heavy equipment for the Bacton gas terminal.

It looks like another case of one of Dr. Beeching’s closures coming back to take a large chunk out of rail efficiency.

Claire Coutinho And Robert Habeck’s Tete-a-Tete

I wrote about their meeting in Downing Street in UK And Germany Boost Offshore Renewables Ties.

- Did Habeck run the RWE/Vattenfall deal past Coutinho to see it was acceptable to the UK Government?

- Did Coutinho lobby for SeAH to get the contract for the monopile foundations for the Norfolk Zone wind farms?

- Did Coutinho have a word for other British suppliers like iTMPower.

Note.

- I think we’d have heard and/or the deal wouldn’t have happened, if there had been any objections to it from the UK Government.

- In SeAH To Deliver Monopiles For Vattenfall’s 2.8 GW Norfolk Vanguard Offshore Wind Project, I detailed how SeAH have got the important first contract they needed.

So it appears so far so good.

Rackheath Station And Eco-Town

According to the Wikipedia entry for the Bittern Line, there are also plans for a new station at Rackheath to serve a new eco-town.

This is said.

A new station is proposed as part of the Rackheath eco-town. The building of the town may also mean a short freight spur being built to transport fuel to fire an on-site power station. The plans for the settlement received approval from the government in 2009.

The eco-town has a Wikipedia entry, which has a large map and a lot of useful information.

But the development does seem to have been ensnared in the planning process by the Norfolk Nimbys.

The Wikipedia entry for the Rackheath eco-town says this about the rail arrangements for the new development.

The current rail service does not allow room for an extra station to be added to the line, due to the length of single track along the line and the current signalling network. The current service at Salhouse is only hourly during peak hours and two-hourly during off-peak hours, as not all trains are able to stop due to these problems. Fitting additional trains to this very tight network would not be possible without disrupting the entire network, as the length of the service would increase, missing the connections to the mainline services. This would mean that a new 15-minute shuttle service between Norwich and Rackheath would have to be created; however, this would interrupt the main service and cause additional platforming problems. Finding extra trains to run this service and finding extra space on the platforms at Norwich railway station to house these extra trains poses additional problems, as during peak hours all platforms are currently used.

In addition, the plans to the site show that both the existing and the new rail station, which is being built 300m away from the existing station, will remain open.

. As the trains cannot stop at both stations, changing between the two services would be difficult and confusing, as this would involve changing stations.

I feel that this eco-town is unlikely to go ahead.

Did RWE Buy Vattenfall’s Norfolk Zone To Create Green Hydrogen For Europe?

Consider.

- Vattenfall’s Norfolk Zone is a 4.2 GW group of wind farms, which have all the requisite permissions and are shovel ready.

- Bacton Gas terminal has gas pipelines to Europe.

- Sizewell’s nuclear power stations will add security of supply.

- Extra wind farms could be added to the Norfolk Zone.

- Europe and especially Germany has a massive need for zero-carbon energy.

The only extra infrastructure needing to be built is the giant electrolyser.

I wouldn’t be surprised if RWE built a large electrolyser to supply Europe with hydrogen.

Neptune Energy, Ørsted And Goal7 Explore Powering Integrated Energy Hubs With Offshore Wind

The title of this post, is the same as that of this press release from Neptune Energy.

These four paragraphs outline the agreement.

Neptune Energy today announced it has signed a Memorandum of Understanding with Ørsted and Goal7 to explore powering new integrated energy hubs in the UK North Sea with offshore wind-generated electricity.

Integrated energy hubs have the potential to combine multiple energy systems, including existing oil and gas production assets, carbon storage and hydrogen production facilities. They could extend the life of producing fields and support the economic case for electrification with renewable energy, to keep carbon emissions low.

The agreement will see the companies examine the potential to supply renewable electricity from Ørsted’s Hornsea offshore windfarm projects to power future Neptune-operated hubs in the UK North Sea.

Goal7 will provide project management support and technical input.

Note.

- Neptune Energy has three oil and gas fields in the UK North Sea; Cygnus (operational), Isabella (exploration) and Seagull (development)

- Gas from Cygnus comes ashore at the Bacton Gas Terminal.

- Ørsted owns the Hornsea wind farm, which when fully developed will have a capacity of around 6.5 GW.

- Cygnus and Hornsea could be not much further than 50 km apart.

- Seagull and Isabella are further to the North and East of Aberdeen.

- Ørsted has an interest in the Broadshore wind farm, which was numbered 8 in the ScotWind Leasing round.

These are my thoughts.

The Cygnus Gas Field And The Hornsea Wind Farm

This could be like one of those stories where boy meets the girl next door and they hit it off from the first day.

This page on the Neptune web site says this about the Cygnus gas field.

The biggest natural gas discovery in the southern North Sea in over 30 years is now the largest single producing gas field in the UK, typically exporting over 250 million standard cubic feet of gas daily. Cygnus contributes six per cent of UK gas demand, supplying energy to the equivalent of 1.5 million UK homes. It has a field life of over 20 years.

Two drilling centres target ten wells. Cygnus Alpha consists of three bridge-linked platforms: a wellhead drilling centre, a processing/utilities unit and living quarters/central control room. Cygnus Bravo, an unmanned satellite platform, is approximately seven kilometres northwest of Cygnus Alpha.

In 2022, we plan to drill two new production wells at Cygnus, with the first of these expected to come onstream in 4Q. The second well is due to be drilled in the fourth quarter and is expected onstream in the first quarter of 2023, with both wells helping to maintain production from the field and offset natural decline.

Gas is exported via a 55 km pipeline. Cygnus connects via the Esmond Transmission System (ETS) pipeline to the gas-treatment terminal at Bacton, Norfolk. Neptune Energy has a 25% minority interest in ETS.

Note.

- Cygnus with a twenty year life could be one of the ways that we bridge the gap until we have the two Cs (Hinckley Point and Sizewell) and a few tens of offshore wind gigawatts online.

- The two extra wells at Cygnus will help bridge the gap.

- The gas field has a pipeline to Bacton.

So what can the gas field and the wind farm, do for each other?

Hornsea Can Supply The Power Needs Of Cygnus

Typically, ten percent of the gas extracted from the wells connected to a gas platform, will be converted into electricity using one or more gas-turbine engines; which will then be used to power the platform.

So, if electricity from the Hornsea wind farm, is used to power the platform, there are two benefits.

- More gas will be sent through the pipeline to Bacton.

- Less carbon dioxide will be emitted in recovering the gas.

Effectively, electricity has been turned into gas.

Electricity Can Be Stored On The Sea-Bed

The Hornsea One wind farm has an area in the order of 150 square miles and it is only one wind farm of four, that make up the Hornsea wind farm.

I would argue that there is plenty of space between the turbines and the wells of the Cygnus gas field to install some form of zero-carbon underwater battery to store electricity.

But does this technology exist?

Not yet! But in UK Cleantech Consortium Awarded Funding For Energy Storage Technology Integrated With Floating Wind, I described a technique called Marine Pumped Hydro, which is being developed by the STORE Consortium.

- Energy is stored as pressurised water in 3D-printed hollow concrete spheres fitted with a hydraulic turbine and pump.

- The spheres sit on the sea-bed.

- This page on the STORE Consortium web site, describes the technology in detail.

- The technology is has all been used before, but not together.

I think it is excellent technology and the UK government has backed it with £150,000 of taxpayers’ money.

I also believe that Marine Pumped Hydro or something like it, could be the solution to the intermittency of wind farms.

Excess Electricity Can Be Converted Into Hydrogen

Any spare electricity from the wind farm can drive an electrolyser to convert it into hydrogen.

The electrolyser could be mounted on one of the Cygnus platforms, or it could even float.

The hydrogen produced would be blended with the gas and sent to Bacton.

Carbon Dioxide Can Be Stored In The Depleted Cygnus Gas Field

As the gas field empties of natural gas, the gas pipes to the Cygnus gas field can be reversed and used to bring carbon dioxide to the gas field to be stored.

The Cygnus gas field has gone full circle from providing gas to storing the same amount of carbon that the gas has produced in its use.

These are two paragraphs from the press release.

Neptune Energy’s Director of New Energy, Pierre Girard, said: “The development of integrated energy hubs is an important part of Neptune’s strategy to store more carbon than is emitted from our operations and the use of our sold products by 2030.

“Neptune has submitted three applications under the recent Carbon Dioxide Appraisal and Storage Licensing Round, and securing the licences would enable us to develop future proposals for integrated energy hubs in the UK North Sea.

I can envisage a large gas-fired power-station with carbon capture being built in Norfolk, which will do the following.

- Take a supply of natural gas from the Cygnus gas field via the Bacton gas terminal.

- Convert the hydrogen in the gas into electricity.

- Convert the carbon in the gas into carbon dioxide.

- Store the carbon dioxide in the Cygnus gas field via Bacton.

- I also suspect, that if a Norfolk farmer, manufacturer or entrepreneur has a use for thousands of tonnes of carbon dioxide, they would be welcomed with open arms.

Would the ultra-greens of this world, accept this power station as zero-carbon?

The Isabella And Seagull Gas Fields And The Broadshore Wind Farm

Could a similar set of projects be applied to the Isabella and Seagull gas fields, using the Broadshore wind farm?

I don’t see why not and they could work with the Peterhead power stations.

Concretene Cements Its Future With £8m Funding

The title of this post, is the same as that of this article in The Times.

This is a precis. which explains what Concretene have done.

Concretene combines graphene with concrete to form a “stronger, more sustainable and more cost-effective alternative” to the world’s most-used building material.

The eight million funding is mainly to be used for more tests.

Is Concrete The New Wonder Material?

I once lived in a concrete apartment and although it is now fifty years old, it still looks the same, as it did the day it was built.

Cromwell Tower in The Barbican may have been built to a high specification, but we don’t hear cancer, cladding, damp, fire or mould problems about the City of London’s flagship housing estate.

In the last few years, concrete has been able to be 3D-printed, so it can now be produced in different shapes.

All these wall and roof panels on the Elizabeth Line were made by 3D-printing of concrete.

The technique also seems to be being used on High Speed Two.

These innovative uses of concrete have led to research into the manufacture and use of concrete.

These posts are must-reads.

- Carbon-Neutral Concrete Prototype Wins €100k Architecture Prize For UK Scientists

- UK Cleantech Consortium Awarded Funding For Energy Storage Technology Integrated With Floating Wind

- New HS2 Pilot Project Swaps Steel For Retired Wind Turbine Blades To Reinforce Concrete

- Earth Friendly Concrete

- HS2 Utilising UK-First Pioneering 3D Concrete Printing On Project

- Carbon Capture From Cement Manufacturing Nears Market Readiness

- Mineral Carbonation International Win COP26 Clean Energy Pitch Battle

The number of these posts show how much research is going into cutting the massive amount of carbon dioxide emitted by the concrete industry.

I also feel that some could work together.

Earth Friendly Concrete is a replacement for normal concrete, so perhaps it could be enhanced with graphene, to create an Earth Friendly Concretene.

Carbon-Neutral Concrete Prototype Wins €100k Architecture Prize For UK Scientists

The title of this post, is the same as that of this article on the Architect’s Journal.

Under a picture of two white-coated scientists with their protective boots on concrete samples, the story and their invention is outlined.

A pair of PhD students at Imperial College London have won a global architecture prize for devising a groundbreaking method of creating carbon-neutral concrete

Material scientists Sam Draper and Barney Shanks landed the €100,000 2022 Obel Award with their ‘simple way’ to capture carbon from industrial production processes and create an end product that can eliminate the CO₂ footprint of concrete.

The prototype technology, dubbed Seratech, takes industrial CO₂ emissions directly from flues and produces a carbon-negative cement replacement material (silica). According to the scientists, when this is used in combination with Portland cement, the carbon capture associated with producing the silica means the concrete products can be zero carbon.

One of the products, we will need in the world is concrete and if we can make it in a carbon-neutral manner, then that will surely reduce worldwide carbon emissions.

The Technology Explained

This page on the Seratech website is entitled Our Technology.

It gives this description of the technology.

Seratech has developed a process that consumes olivine and waste CO₂ from flue gases and produces two products which both have significant value in construction.

Silica is produced which can be used as a supplementary cementitious material (SCM) in concrete meaning the amount of Portland cement in the concrete can be reduced by up to 40%. As the silica comes from a process that captures CO₂ it is “carbon negative” and the concrete can become carbon neutral.

Magnesium carbonate is produced that can be used to make a range of zero carbon construction materials and consumer products, including alternatives to building blocks and plasterboard.

The aim is for humanity to be able to continue building robust cities and infrastructure, but without the climate cost of traditional cement mixes and with the Seratech technology this goal is achievable!

Note that olivine in Europe is generally mined in Norway.

Replacement Of Steel By Concrete

Could we also replace steel in some applications with concrete?

In UK Cleantech Consortium Awarded Funding For Energy Storage Technology Integrated With Floating Wind, I talked about some of ground-breaking methods used by a company called RCAM Technologies to create infrastructure using 3D printing of concrete.

If Imperial’s concrete, which is called Seratech can be 3D printed, I can see lots of applications for the technology.

So you could kill two sources of large carbon emissions with one technology.

Conclusion

I have said on this blog before, that we will have to keep or even build more gas-fired power stations, as they can be an efficient source of pure carbon dioxide, that will be needed as a feedstock to create an increasing number of agricultural and building products.

Accelerating The Delivery Of Offshore Wind Farms

It is one of Kwasi Kwarteng’s ambitions to accelerate the delivery of offshore wind farms.

In The Growth Plan 2022, these groups of wind farms are mentioned.

- Remaining Round 3 Projects

- Round 4 Projects

- Extension Projects

- Scotwind Projects

- INTOG Projects

- Floating Wind Commercialisation Projects

- Celtic Sea Projects

My thinking in this post, will probably apply to all of these groups.

These are my thoughts.

Accelerating Delivery Of A Wind Farm

This will have these positive effects.

- Electricity will be delivered earlier.

- Customers will have a more secure supply of electricity.

- The wind farm owner will start to be paid for their electricity.

- The Crown Estate will start to be paid for their leases. Although, these might start at signing.

- National Grid will be paid for the transmission of the electricity.

- An energy storage company could be paid for storing surplus electricity.

- Construction teams and engineers can move on to the next project.

- Expensive construction hardware like ship-mounted cranes will no longer be needed.

- I also suspect that the government will raise some taxes from the various companies involved.

It looks like it’ll be winners all round.

How Will Delivery Be Accelerated?

These are some thoughts.

Overall Project Time

In How Long Does It Take To Build An Offshore Wind Farm?, I came to these conclusions.

- It will take six years or less from planning consent to commissioning.

- It will take two years or less from the start of construction to commissioning.

I suspect that as we have been building offshore wind farms for some years, that it will be very difficult to reduce these times significantly.

But as some wind farms take quite a few years to progress from the initial proposal to planning consent, I suspect that improvements to the planning process may speed up the overall construction time of a wind farm.

Project And Resource Management

Good project and resource management will always help.

Better Design And Construction Methods

I always remember in the early days of North Sea Oil, being told by a very experienced project manager that construction of production platforms was accelerated by the availability of larger and more powerful cranes.

Are we approaching the design of the ultimate wind farm? I doubt it, as in the last few months, I’ve seen two very radical new designs.

In Hexicon Wins UK’s First Ever CfD Auction For Floating Offshore Wind, I show this image of one of their TwinHub turbine installations being towed into place.

The TwinHub home page has a title of The First Floating Offshore Wind Project in The Celtic Sea.

This is the description on the page.

The TwinHub offshore wind demonstration project intends to prove how Hexicon’s innovative design with two turbines on one floating foundation can further reduce the Levelized Cost of Energy (also referred to as LCoE) before large scale commercialisation. The TwinHub project is a stepping stone to help kick-start floating wind in the Celtic Sea, an area identified as a hotspot for floating wind by the UK Government. It will pave the path for larger and larger projects to help support The Crown Estates’ ambitious target of 4GW of floating wind in the Celtic Sea.

Scroll the page down and there is a fascinating short video of a pair of wind turbines in operation.

- It appears that when there is no wind, it automatically goes into a safe parked mode.

- As the wind rises, one turbine starts up.

- The second turbine starts up and the float turns so they face the wind.

It appears to be a classic example of disruptive innovation.

I have a feeling that this type of installation might have generation, assembly and cost advantages over a single turbine mounted on a single float.

RCAM Technologies are also creating interesting designs for mounting turbines and energy storage using 3D-printed concrete.

What Ts The UK Government Doing To Accelerate Projects?

This article on offshoreWIND.biz, was published in late September 2022 and is entitled BREAKING: UK Puts Massive Amount Of New Offshore Wind Capacity On Fast Track and this is the first paragraph.

The UK will speed up planning and development consent processes for projects from the recently completed, currently ongoing, and upcoming (floating) offshore wind leasing rounds to bring new energy capacity online faster and facilitate economic growth and job creation.

The article is based on what Kwasi Kwateng said on the 23rd of September about speeding up projects in the 2022 Growth Plan.

A Quick Summary Of Our Wind Energy

The article has this paragraph, which summarises our wind energy.

For the UK, which currently has around 14 GW of offshore wind capacity in operation and 8 GW under construction, the projects from the listed auction rounds could bring well beyond the targeted capacity for 2030, which was recently raised to 50 GW.

I can see the target being raised again to at least 60 GW.

UK Cleantech Consortium Awarded Funding For Energy Storage Technology Integrated With Floating Wind

The title of this post, is the same as that of this page on the UK Government’s Catapult Offshore Renewable Energy Web Site.

This is the introductory paragraph.

STORE, a UK-based cleantech consortium led by RCAM Technologies Limited, has been awarded £150,000 of funding to develop an advanced subsea energy storage technology manufactured using 3D printed concrete that could help offshore wind farms produce a steady and predictable energy output to the electricity grid.

This paragraph talks of the concept of Marine Pumped Hydro.

STORE is assessing the feasibility of integrating Marine Pumped Hydro (MPH) technology, which stores energy using hollow concrete spheres fitted with a hydraulic turbine and pump, with floating offshore wind plants in UK waters. In addition, the project advances the design of MPH systems and plans a prototype demonstration in the UK.

Note.

- The hollow concrete spheres are 3D-printed in concrete using the technology of RCAM Technologies.

- Spheres are structurally very strong.

- 3D printing of concrete is now mainstream technology and has been extensively used on the Elizabeth Line as I wrote about in The Story Behind The Concrete Panels On The Elizabeth Line.

- There is a visualisation on the Catapult web page, which shows several floating turbines, a floating sub station and several concrete hemispheres sitting on the seabed.

- The energy storage medium is sea water and air, which must be environmentally-friendly.

The technology is described in detail on this page of the STORE consortium web site.

- The spheres are fifteen metres across.

- The spheres can be installed at depths between 150 and 2000 metres.

- The system has a round-trip efficiency is up to 70%, which is similar to pumped storage hydro.

- The design life is 50 to 80 years.

I think that this system has possibilities.

This last paragraph in the Catapult web page gives a look into the future.

As well as improving the reliability and predictability of energy to the electricity grid, the project will support the cross sector transfer of UK offshore expertise and port infrastructure for use in renewable energy and create high-value UK jobs in engineering, construction, and operations and maintenance. This energy storage solution is ideally suited to coupling with floating wind plants and for powering offshore oil and gas assets from renewable energy. The 3D printed concrete also facilitates localized manufacturing and enables low cost fabrication of new and complex shapes that were previously not practical.

I also feel that if the concrete sphere energy storage can be made to successfully work, then the technology can surely be fitted to any offshore wind farm, by just adding the right number of spheres and connecting them to the offshore sub station.

The STORE Consortium

The STORE consortium has a web site, which has a heading of Innovative Subsea Energy Storage.

It describes the technology in this paragraph.

STORE is advancing a subsea energy storage technology called Marine Pumped Hydro (MPH). MPH uses large hollow concrete spheres on the seafloor to store mechanical energy in the form of pressure. MPH charges when seawater is pumped out of the spheres and releases energy to the grid when high-pressure water flows back into the spheres through a turbine. MPH features a patent-pending multi-sphere pod to increase the amount of energy stored and uses efficient 3D concrete printing to reduce manufacturing costs.

It sounds like an engineer with children, has been playing with them and their plastic toys in a bath and has had an Archimedes moment.

The project and its funding is described in this paragraph.

STORE was awarded £150,000 from the Department for Business, Energy & Industrial Strategy Longer Duration Energy Storage Demonstration (LODES) competition. Phase 1 will deliver a Feasibility Study focused on the design and analyses for the UK. Phase 2, if awarded, will design, manufacture, and operate a prototype system at TRL 6.

Note that TRL 6 is Technology Readiness Level 6 and is fully defined on this NASA web page, as having a fully functional prototype or representational model.

There is also an interesting link to the ScotWind N3 wind farm. that I wrote about in ScotWind N3 Offshore Wind Farm.

- This is an unusual floating wind farm with a floating substation.

- Technip and Loch Kishorn port are involved in both the wind farm and STORE.

- Loch Kishorn has a history of building immense concrete structures.

I wouldn’t be surprised if this wind farm would be the location of the prototype system.

Conclusion

This is a brilliant concept.

- It is the ideal energy storage system for offshore wind, as it can turn a wind farm with a variable output into one with a much more constant output.

- It can be retrofitted to existing offshore wind farms.

- It will work with both fixed and floating wind farms.

- The concrete storage spheres can be fully assembled with all their electrical gubbins on shore and towed out, before sinking in the required position.

It also looks like the Department for Business, Energy & Industrial Strategy have got involved and helped with the funding. Someone there seems to know a good idea, when they see it!

RCAM Technologies

Wouldn’t it be a good idea to have a wind turbine with built-in energy storage?

This article on Power Engineering, is entitled Five Long-Duration Energy Storage Projects Get Funding In New York.

One of the projects, from RCAM Technologies is described like this.

To develop a 3D concrete-printed marine pumped hydroelectric storage system that integrates directly with offshore wind development in support of grid resiliency and reduced reliance on fossil fuel plants to meet periods of peak electric demand.

That sounds like an offshore wind turbine with built-in energy storage, that is 3D-printed in concrete.

The RCAM Technologies web site is all about 3D-printed concrete.

- It looks like they can build taller wind farm towers, than you can make with steel.

- It appears offshore wind turbine tower with integrated foundations can be built on-site.

- Material can be 100 % locally-sourced.

- The next step could be to build some form of pumped storage into the tower.

- They are experimenting with storing energy as pressure in 3D-printed concrete spheres. The New York grant will help fund this.

- High Speed Two is using 3D-printing of concrete, as I wrote about in HS2 Utilising UK-First Pioneering 3D Concrete Printing On Project.

The company has offices in Colorado, California and Edinburgh.

Conclusion

This technology could be on the right track. Read their web site.

The Story Behind The Concrete Panels On The Elizabeth Line

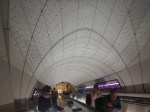

These are a selection of the pictures I took yesterday inside Elizabeth Line stations.

Note.

- The walls and ceilings appear to be covered in light grey panels with holes.

- The material appears to look like concrete.

- Every one is a totally different shape, so how were they manufactured?

This article on Ian Visits is entitled How Crossrail Is Using 3D-Printing To Build Its Stations.

This is the two opening paragraphs.

When you start to use the new Elizabeth line stations, among its many achievements will be the first large scale use of 3D-printing in concrete.

The use of 3D printing has made possible one of the more distinctive features of the future Elizabeth line stations — the curved concrete panels that will line the inside of the passenger tunnels and some stations, and sinuously glide around corners in a way never seen before in a tube station.

There will be a total of something like 36,000 of these panels and although printing each in concrete is possible, Crossrail would probably have been delivered in the 2040s or 2050s.

The contractors used an innovative process called FreeFAB, which had been invented by an Australian architect.

- The process creates a wax mould for each panel using 3D printing.

- This mould is then used to create the actual panel.

- After each panel is cast, the wax is melted off and recycled.

- The panels are made in a factory in Doncaster.

We will see a lot more of this technique used in the construction industry.

HS2 Utilising UK-First Pioneering 3D Concrete Printing On Project

The title of this post, is the same as that of this article on Rail Technology Magazine.

3D-Printing of concrete has been around for some time and it has been used extensively on Crossrail.

But High Speed Two are printing the heavy components on site, to avoid the problems of transport.