Thoughts On Alstom At Derby

In the 1970s, I worked at ICI Plastics in Welwyn Garden City in a section called Computer Techniques.

We had a unique mandate from the Divisional Board, that allowed us to stick our nose into anybody’s business.

We certainly weren’t short of computing power, as in addition to the Division’s IBM 360 and dial-up services to GEISco, we had one of the handful of PACE 231R analogue computers in the UK.

Note.

- These machines didn’t use many semiconductors.

- These beasts could solve up to a hundred simultaneous differential equations and display the answers as graphs on the printers.

- Other UK companies and institutions with a PACE 231 R, included BMC, British Rail Research and Cambridge University.

- Two were linked together and these did the calculations for the Apollo flights.

- Their finest hour would surely have been to use their flexibility and power to bring home the stricken Apollo 13.

I got an interesting introduction to the industrial world in my three years at Welwyn.

One of our problems, was recruiting enough specialist engineers and programming staff.

So in the end, at one of our Monday morning meetings, we wrote our own advert for the Sunday Times.

We got all the staff we needed, but they weren’t the sort of recruits, you’d normally expect in the 1970s. Two were Indian and two were American, but all were recent immigrants. But they were certainly good enough to solve our problems.

I don’t think the Personnel Department were amused at our independent recruitment exercise.

I sometimes wonder if Bombardier (now Alstom) in Derby has a similar recruitment problem.

I am a Control Engineer and all these hybrid systems, that will power the transport of the future, be they trains, planes or automobiles, need lots of engineers with similar skills to myself and those of computer programmers. So do local companies; Rolls-Royce, JCB and Toyota, who probably have their own skill shortages in these areas, nick the best from Alstom.

It should be noted that in the railway press, it has been said that the Aventras from Derby were late because of software problems.

Is Alstom’s Proposal For A Service Between London Euston And Wrexham Part Of A Cunning Plan?

Alstom have built and introduced into service between Buxtehude and Cuxhaven in Germany, the Coradia iLint hydrogen-powered train. The prototype has performed demonstrations in Austria, Canada, The Netherlands and Saudi Arabia.

This picture shows a Coradia iLint in Germany.

In the UK, Alstom had a plan to convert redundant Class 321 trains into a fleet of hydrogen-powered trains called Breeze, which I wrote about in Hydrogen Trains Ready To Steam Ahead, in January 2019.

This visualisation is from Alstom.

I suspect it didn’t appeal to train companies, as no orders appear to have been received.

But you can’t criticise Alstom for not trying, as in November 2021, they signed an agreement with Eversholt Rail Group to develop a hydrogen-powered Aventra, which I wrote about in Alstom And Eversholt Rail Sign An Agreement For The UK’s First Ever Brand-New Hydrogen Train Fleet.

This visualisation is from Alstom.

Visually, it looks just like any other Aventra and much better than the previous Breeze design.

In March 2018, I wrote Bombardier Bi-Mode Aventra To Feature Battery Power, which was based on this article in Rail Magazine.

These are a few points from the article.

- Development has already started.

- Battery power could be used for Last-Mile applications.

- The bi-mode would have a maximum speed of 125 mph under both electric and diesel power.

- The trains will be built at Derby.

- Bombardier’s spokesman said that the ambience will be better, than other bi-modes.

- Export of trains is a possibility.

- Bombardier’s spokesman also said, that they have offered the train to three new franchises. East Midlands, West Coast Partnership and CrossCountry.

Have Alstom looked at what they bought from Bombardier and decided the following train is possible, if they add some of their technology?

- A train the size needed by the customer, up to a length of at least ten cars.

- 125 mph under 25 KVAC overhead electrification.

- 100 mph with 750 VDC third rail electrification.

- Running on hydrogen away from electrification.

- 100 mph maximum speed running on hydrogen.

- A range of perhaps 500 miles, if it can emulate the hydrogen-powered Coradia iLint.

A train with this specification would have several applications in the UK.

- Fully-electric routes.

- Electric routes with perhaps a hundred miles of unelectrified track.

- Scenic routes, where the Nimbies wouldn’t like electrification.

These points should also be born in mind.

- There are now 110 mph Aventras in service with West Midland Trains on the West Coast Main Line.

- I recently came back from Cardiff to London in a twelve-car Class 387 train and there wasn’t too many unhappy passengers. It was certainly better than a rail replacement bus. I wrote about the trip in Cardiff To Reading In A Class 387 Train.

- Alstom believe you can certainly fit their hydrogen gubbins in an Aventra.

- The hydrogen gubbins appear to be from Cummins, who have a worldwide support network.

- Cummins can also supply complete hydrogen support systems. A truck can refuel the train, at one end of the route?

- Alstom have been doing the market research with the hydrogen-powered Coradia iLint, so I suppose they know what the market needs.

Could Alstom, with help from Cummins, have a zero-carbon 200 kph train and support systems, which has a hydrogen range of up to a thousand kms for export markets like the United States, Africa, Australia, India and South America?

Two big world-leading companies are surely better than one!

But Alstom has one big problem!

How do you fully test a 125 mph hydrogen-powered train?

- I know with aircraft, if you change the engine type on an existing aircraft, you only have to certify the engine and this is done on a Supplementary Type Certificate.

- Is it the same with trains, so a 110 mph Class 730 train, which is in service with West Midlands Trains, could be the basis of certifying a hydrogen-powered Aventra?

- The Coradia iLint was only a change from diesel to a hybrid hydrogen-electric engine, so was it certified this way?

- With the Coradia iLint, it seemed to go into service quite quickly, so did it do much of the testing in service?

I looks to me, that London Euston and Wrexham is an ideal route for a hydrogen bi-mode 125 mph train.

- The route has electrified sections, some of which have high operating speeds.

- The route has a convenient hydrogen supply from INEOS at Runcorn at the Northern end.

- Change between hydrogen and electric power would always take place in a station.

- A round trip needs less than 200 miles of running on hydrogen.

- South of Nuneaton, no hydrogen is used, so the train will be like a Class 730 train, that already uses the route.

- There are depots that can service Aventras on the route.

It is certainly a possibility, that the London Euston and Wrexham service will be used to test and showcase Alstom’s new Hydrogen Aventra.

Alstom Plans To Operate Its Own Passenger Train Service In The UK For The First Time

The title of this post, is the same as that of this press release from Alstom.

These two bullet points, act as sub-headings.

- Alstom is partnering with SLC Rail to form a new open access rail operation between North Wales, Shropshire, the Midlands and London

- Formal application now being submitted to the Office of Rail and Road (ORR) with passenger service sought from 2025

These are the first three paragraphs.

Alstom, global leader in smart and sustainable mobility, plans to operate a new passenger rail service across England and Wales. Working in partnership with consultancy SLC Rail, the open access operation will be known as Wrexham, Shropshire and Midlands Railway (WSMR).

As the country’s foremost supplier of new trains and train services, and a leading signalling and infrastructure provider, Alstom will operate its own rail service in the UK for the first time.

WSMR is seeking to introduce direct connectivity to and from North Wales, Shropshire, the Midlands and London that doesn’t exist today, linking growing communities and businesses, and making rail travel more convenient, enjoyable and affordable.

I can’t remember a service proposal being put forward by a train manufacturer since the privatisation of UK’s railways in the 1990s.

This is some more information and my thoughts.

The Route

This paragraph from the press release, describes the route.

The proposal envisages a service of five trains per day in each direction Monday to Saturday, with four travelling both ways on Sundays. Trains will stop at Gobowen, Shrewsbury, Telford Central, Wolverhampton, Darlaston, Walsall, Coleshill Parkway, Nuneaton and Milton Keynes on their journey between Wrexham General and London Euston.

Note.

- The proposed call at the new Darlaston station.

- The route is electrified between Euston and Nuneaton and Walsall and Wolverhampton.

- Much of the route North of Nuneaton is on tracks with a maximum speed of 70-80 mph.

The route is in these sections.

- Euston and Nuneaton – 96.7 miles – electrified

- Nuneaton and Walsall – 26.7 miles

- Walsall and Wolverhampton – 6.7 miles – electrified

- Wolverhampton and Shrewsbury – 29.7 miles

- Shrewsbury and Wrexham General – 30.3 miles

That is a total of 190.1 miles or 380.2 miles round trip.

I suspect that the service will need bi-mode trains.

Should The Service Call At Wellington?

This article on the BBC is entitled Rail Company Urged Not To Forget Wellington.

This is the sub-heading.

A rail company which is bidding to bring back a direct service between Shropshire and London has been urged not to forget a town.

These are the first three paragraphs.

Wrexham, Shropshire and Midlands Railway said it was preparing to apply to the government to run the service.

Trains would stop at Gobowen, Shrewsbury, Telford, Wolverhampton, Walsall, Coleshill and Nuneaton.

But Telford and Wrekin Council said the omission of Wellington as a stop was “short-sighted”.

Although Wellington is smaller than than Shrewsbury and Telford, it looks like a bit of analysis would provide a solution, that would be acceptable for all parties.

The Trains

In the press release, this phrase is used.

positive impact to both communities and the environment.

I can’t see any more electrification being erected on the route, so the trains will need to be bi-mode.

- Bi-mode diesel trains won’t have a positive impact on the environment.

- As the route between Wolverhampton and Wrexham General is not electrified, a battery-electric train would need a range of at least 60 miles or 120 miles for the round trip, if there were no charging at Wrexham General.

- But Alston are developing a Hydrogen Aventra, which I wrote about in Alstom And Eversholt Rail Sign An Agreement For The UK’s First Ever Brand-New Hydrogen Train Fleet.

So could Alstom be using this route to trial and showcase their new Hydrogen Aventra?

I believe that the route will be very suitable for a hydrogen train.

- Changeover between electric and hydrogen power can always take place in a station.

- All hydrogen refuelling could be performed at one end of the route.

- A large proportion of the UK’s green hydrogen is produced by INEOS at Runcorn, which is less than fifty miles from Wrexham. A refuelling tanker could supply the train, as they do on some hydrogen routes in Germany.

- London has only small amounts of hydrogen infrastructure.

I suspect that refuelling will be done at the Wrexham end of the route.

This Alstom visualisation shows the train.

But it is only a three-car train.

- That is not a problem, as Aventras can be lengthened as required to the length required for the number of passengers.

- Some Aventras, like the Class 701 trains for South Western Railway, have even been ordered as ten-car trains.

- Two three-car trains may also be the ideal capacity, running as a six-car train.

So capacity will not be a problem.

If it is assumed that Alstom’s trains for the WSMR route, can use the overhead wires, where they exist, each trip between Wrexham General and London will require a total of 86.7 miles or 140 kilometres of running on hydrogen.

- A round trip will therefor require 280 kilometres of running on hydrogen.

- But between London Euston and Nuneaton, it will just be another electric train.

- I suspect that like the similar Class 730 train, it will be capable of 110 mph on the West Coast Main Line.

- Alstom’s Coradia iLint hydrogen train has a range of around a 500-800 kilometres on hydrogen.

- The WSMR trains will probably be 100 mph trains using hydrogen on a route, where that speed is possible.

So if a Hydrogen Aventra has a similar range to the Coradia iLint, it will be able to do two round trips before refuelling.

How Long Will The Service Take?

West Midlands Trains, who use the similar Class 730 trains take one hour and eleven minutes between London Euston and Nuneaton with a single stop at Milton Keynes Central.

As the WSMR trains will use the same route, I suspect the same time can be used.

As Nuneaton and Wrexham General are 93.4 miles apart a table can be created showing the time for the rest of the journey for different average speeds

- 50 mph – 1 hour 52 minutes – 3 hours 3 minutes.

- 60 mph – 1 hour 33 minutes – 2 hours 44 minutes.

- 70 mph – 1 hour 20 minutes – 2 hours 31 minutes.

- 80 mph – 1 hour 10 minutes – 2 hours 21 minutes.

Note.

- The first time is the Nuneaton and Wrexham General time and the second time is the overall journey time.

- Typical Avanti West Coast services via Crewe and a change at Chester, take between two-and-a-half and three hours.

I suspect, if the WSMR trains can keep the speed up through the Midlands, that two hours and 30 minutes could be possible.

Could The Hydrogen Aventra Run At 125 mph Under The Wires?

In March 2018, I wrote Bombardier Bi-Mode Aventra To Feature Battery Power, which was based on this article in Rail Magazine.

These are a few points from the article.

- Development has already started.

- Battery power could be used for Last-Mile applications.

- The bi-mode would have a maximum speed of 125 mph under both electric and diesel power.

- The trains will be built at Derby.

- Bombardier’s spokesman said that the ambience will be better, than other bi-modes.

- Export of trains is a possibility.

- Bombardier’s spokesman also said, that they have offered the train to three new franchises. East Midlands, West Coast Partnership and CrossCountry.

Have Alstom looked at what they bought from Bombardier and decided the following train is possible?

- Five-cars or what the customer needs.

- 125 mph under the wires.

- Running on hydrogen away from the wires.

- 100 mph on tracks without electrification.

Obviously, maximum speeds would depend on track limits.

Looking at 125 mph Avanti West Coast trains that have a Milton Keynes stop between London Euston and Nuneaton, they can reach Nuneaton ten minutes quicker than West Midlands Trains 110 mph Class 730 trains.

Two hours and 30 minutes between London Euston and Wrexham is looking increasingly possible.

Are we seeing an audacious proposal from Alston to sell new trains to CrossCountry and a host of other franchises?

Conclusion

London Euston and Wrexham would appear to be an excellent route for an Aventra-based hydrogen train.

- It can probably cruise at 110 mph on the West Coast Main Line between London Euston and Nuneaton.

- All switchovers between electrification and hydrogen can be performed in electrified stations.

- Hydrogen would only be used North of Nuneaton.

- The train can be refuelled at Wrexham General, with fuel supplied from INEOS at Runcorn.

- Given the typical 1000 km. range of hydrogen trains, a train can probably do three round trips without refuelling.

I can see this being a service with an excellent operational record.

New Mobile Rail Charging Facility For Long Marston

The title of this post, is the same as that of this article from Rail Technology Magazine.

This is the sub-heading.

Porterbrook has signed a £1.7 million deal with Siemens Mobility to purchase an innovative Rail Charging Converter (RCC) for its Long Marston Rail Innovation Centre. The cutting-edge technology will make battery charging and 25kV power supply possible in areas of the UK railway where overhead line equipment is not currently available.

This first paragraph describes the system.

The RCC is a modular and containerised system that uses power electronics to provide a fully compliant, standard connection between the modern three-wire electricity grid and the single-wire railway. It essentially reduces the electrification infrastructure needed by being able to plug into existing power cables and deliver the ideal power supply for trains.

These two paragraphs describe how the RCC was designed and funded, and how it will be used in the future.

The original development of the RCC was supported by the Department for Transport through Innovate UK’s First of a Kind programme. The team will install the novel charging solution at Long Marston, enabling the charging of trains with batteries, fed from existing standard local power supply cables.

Compatible with all overhead line equipment powered trains, the small, low-cost design of the RCC enables the removal of diesel passenger train operation on routes without continuous electrification.

I suspect we’ll see other manufacturers like Hitachi ABB Power Grids and Furrer+Frey launch similar products.

This page gives full details of the award to Siemens Mobility.

Project Title: 25kV Battery Train Charging Station Demonstration

Lead Organisation: Siemens Mobility Ltd.

Project Grant: £59,910

Public Description:

The UK rail industry is committed to decarbonisation, including the removal of diesel trains by 2040.

Replacing diesel trains with electric, hydrogen or battery bi-mode rolling stock provides faster, smoother and more reliable journeys, as well as eliminating local pollution and greatly reducing carbon dioxide.

To enable clean, green electric bi-mode operation without continuous electrification requires enhancement of the power supply to existing electrification and novel charging facilities to support bi-mode trains.

No small, low-cost solution is currently available for charging facilities that are compatible with standard UK trains and locally available power supplies and space.

Siemens Mobility, working with ROSCO, TOCs and Network Rail, will deliver a novel AC charging solution enabling simple installation of small, low-cost rapid charging facilities fed from existing standard local power supply cables.

Compatible with all OLE-powered trains, the novel design enables the removal of diesel passenger train operation on non-electrified routes across the UK, while minimising land requirements and modifications required to existing station structures.

£59,910 seems to be good value for the helping with the design of a universal charging system for 25 KVAC battery-electric trains in the UK.

I have a few thoughts.

Will The Rail Charging Converter (RCC) Charge Third Rail Trains?

As new third-rail systems are effectively systems non grata, I suspect that third-rail trains will be charged by fitting a pantograph and the appropriate electrical gubbins.

Most modern third-rail electrical multiple units have a roof that is ready for a pantograph and can be converted into dual-voltage trains.

What Trains Will Be Able To Be Charged Using An RCC?

I suspect it will be any train with a battery, a pantograph and the appropriate electrical gubbins.

Battery-electric trains that could have a pantograph include.

- Alstom Electrostar and Aventra

- CAF Civity

- Hitachi Class 385 train

- Hitachi Class 800 train

- Siemens Desiro and Mireo

- Stadler Class 777 train

- Stadler Flirt and Akku

- Vivarail Class 230 train

I suspect it could charge all trains in the UK, where batteries have been proposed to be added.

What Is Meant By Mobile?

I suspect transportable and temporary would be a better description.

This gallery show Felixstowe station and a Class 755 train, which can be fitted with batteries.

Suppose that testing was to be done at Felixstowe of a battery-electric Class 755 train.

- The containerised electrical system would be placed somewhere convenient.

- A short length of overhead wire would be erected in the platform.

- The system would then be connected together and to the electrical supply.

- After testing, it could be used to charge a train.

It would be very convenient for operation of the railway, if it could be installed and taken out overnight.

Conclusion

It looks a well-designed system.

Northern Trains Plans Framework Contract For 450 Multiple-Units

The title of this post, is the same as that of this article on Railway Gazette.

This is the first paragraph.

Northern Trains has invited expressions of interest in a framework contract covering the supply of up to 450 multiple-units to replace ‘significant quantities of its ageing fleet’.

These are other details.

- Firm orders would be placed in phases.

- The initial order would be for ‘multi-mode’ multiple-units.

- Battery-electric or electric-only trains would be included in subsequent orders.

- Trains would have a minimum design life of 35 years from acceptance.

- The ability for the multi-mode units to be converted to electric or battery-electric power as part of an ‘in-life decarbonisation’ programme.

These four paragraphs outline the framework agreement between Northern Trains, the train manufacturer and the owners, who will finance the trains.

The framework agreement would run for eight years, with Northern able to order rolling stock in multiple phases.

Each phase would include a train manufacturing and supply agreement and a technical support and spares supply agreement.

The supplier would provide tools and spare parts, and there would be options for the supply of mock-ups and a cab simulator. Northern is to run a separate procurement for an owning party which would purchase each fleet and lease it to the operator.

The owner would be party to each manufacturing and supply agreement, and there may be different owning parties for each order phase.

This is a well-thought out proposal, that would be worth around a billion pounds to the train manufacturer.

It would probably be based around a family of trains like Alstom’s Aventra, CAF’s Civity or Stadler’s FLIRT.

For a series of orders of such a value, I think we will see some excellent proposals.

The deal will transform rail travel in the North.

I have some thoughts.

Which Trains Will Be Replaced?

Northern Trains fleet includes these ageing trains.

- Class 150/0 diesel trains – 6 x three-car – 18 cars

- Class 150/1 diesel trains – 46 x two-car – 92 cars

- Class 150/2 diesel trains – 26 x two-car – 52 cars

- Class 155 diesel trains – 7 x two-car – 14 cars

- Class 156 diesel trains – 65 x two-car – 130 cars

- Class 158/0 diesel trains – 45 x two-car – 90 cars

- Class 158/9 diesel trains – 8 x three-car – 24 cars

- Class 319 electric trains – 12 x four-car – 48 cars

- Class 323 electric trains – 34 x three-car – 102 cars

- Class 333 electric trains – 16 x four-car – 64 cars

- Class 769 bi-mode trains – 8 x four-car – 32 cars

Note.

- These total to 273 trains and 661 cars.

- If the 16 Class 170 trains, which are of three-cars, were also to be replaced. that would bring the total trains to be replaced to 289 trains and 709 cars.

I would expect the difference between 273-289 current trains and 450 trains in the article, is explained by new services and increased services on certain routes.

Which Trains Could Be Retained?

Northern Trains fleet includes these new trains.

- Class 195 diesel trains – 25 x two-cars – 50 cars

- Class 195 diesel trains – 33 x three-cars – 99 cars

- Class 331 electric trains – 31 x three-cars – 93 cars

- Class 331 electric trains – 12 x four-cars – 48 cars

Note.

- These trains were all built by CAF in the last five years.

- These total to 101 trains and 290 cars.

But if they have an expected life of 35 years, the diesels will have to be converted to zero-carbon trains.

Will The CAF Trains Be Retained?

Consider.

- If all the ageing trains and those not built by CAF were to be replaced then that would be 289 trains and 709 cars.

- If the nearly-new CAF trains were also to be replaced that would be 390 trains and 999 cars.

- Add in a few more trains for expanded services and you’re got the figure of 450 trains given in this article.

- If the CAF trains were to be replaced, then Northern Trains would have an homogenous fleet of new trains from one manufacturer, with all the advantages in operation and maintenance.

On the other hand, I haven’t read any bad criticism of these CAF trains, so I will assume that there is no pressing reason to replace them.

And of course Northern Trains could have an homogenous fleet of new CAF trains.

This is said in the article.

The supplier would provide tools and spare parts, and there would be options for the supply of mock-ups and a cab simulator.

As this is specifically mentioned, do Northern lack a simulator for driver training?

What About The Manchester Bee Network And Other Local Networks?

Will these networks want to take control of their local trains?

If there is an homogenous fleet of new trains from one manufacturer, then surely, it would be easier to give control of some routes to the local transport interests.

Training and driver rostering could be retained in what was left of Northern Trains.

Tram-Trains

Tram trains would be an added complication, but as the South Wales Metro is showing, tram-trains are an interesting way of expanding a network.

Should There Be Five-Car High Speed Two Classic-Compatible Trains?

The High Speed Two Classic-Compatible Trains have the following characteristics.

- Eight cars.

- 200 metres long.

- 550 passengers.

- Two can be coupled together to make a 16-car train, that is 400 metres long.

- Trains can join and split en route.

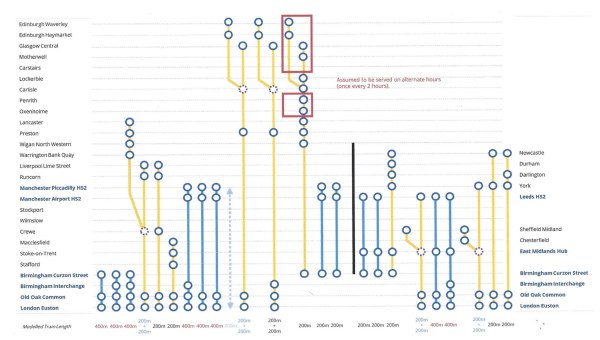

This graphic shows the preliminary schedule.

Note that Train 4, starts as a pair of trains, before splitting at Crewe, with one train going to Lancaster and the other to Liverpool Lime Street.

I wonder, if some trains were to be five-cars, would this give the operator more flexibility, by allowing three trains to be coupled together to serve three destinations.

This could be a simple example.

- A three train formation could leave Euston.

- At Crewe one train would detach and go to Liverpool Lime Street, with stops at Runcorn and Liverpool South Parkway.

- At Preston, the two remaining trains would split, with one train going to Lancaster and the other going to Blackpool with appropriate stops.

Three trains might give the operators more flexibility in providing appropriate capacity to various destinations.

Other Applications

I believe these trains would have other applications.

These are a few thoughts.

Battery-Electric High Speed Train

Battery technology is improving and I believe that a train could be designed with the following specification.

- Five cars

- High-Speed Two Classic-Compatible performance.

- A battery pack in each car.

- Up to maximum operating speed of digitally-signalled high speed lines.

- 140 mph on digitally-signalled classic high speed lines, like the East and West Coast Main Lines. the Midland Main Line and the Great Western Railway.

- Range on battery of around 120 miles at 100 mph.

- Ability to work with fully-electric versions.

Note.

- I suspect that like current Hitachi AT-300s and Bombardier Aventras, the onboard computer would know what cars have been coupled together and what the train can do.

- A battery in each car would distribute the extra weight of the batteries equally and not affect the handling too much.

- These trains would allow High Speed Two services to be extended onto non-electrified lines.

I suspect that an eight car battery-electric High-Speed Two Classic-Compatible train would also be possible for working with the standard length trains.

Cambridgeshire Company’s Self-Charging Trains Project Wins Government Funds

The title of this post, is the same as that of this article on the BBC.

These four paragraphs outline what the company is developing and how they received government funding.

Echion Technologies, based in Sawston near Cambridge, is creating train batteries that can charge from overheard wires, the Department for Transport said.

The trains would be able to use the batteries on unelectrified track.

The project was among the winners of the government’s First of a Kind competition.

The competition aims to award funding to projects that could transform the future of transport.

I have a few thoughts.

The Description In The First Of A Kind 2022 Winners Document

In this document, this is said.

Project No: 10039100

Project title: UBER – Ultra-high power Battery for low Emission Rail

Lead organisation: ECHION TECHNOLOGIES LTD

Project grant: £59,917

Public description: Project UBER (Ultra-high power Battery for low Emission Rail), aims to demonstrate for the first time, Echion’s XNO(tm) battery chemistry as the preferred battery technology for certain classes of battery electric trains. It targets Theme 1 of this competition.

Specifically, UBER aims to demonstrate the suitability of XNO(tm) for passenger trains that can be powered by the AC overhead electrification and charge a battery from the overhead wire (or another form of ‘standard’ trackside power — e.g. 3rd rail), to then run in battery-only mode on unelectrified section of a route. An example of such a train is the Revolution Very Light Rail (Revolution VLR) developed by Transport Design International (TDI), who is a partner in UBER.

Applying The Echion Technologies Batteries To Electric Trains

Consider.

- The BBC article is accompanied by a picture of a Class 717 train, which like the Class 700 train is dual voltage.

- Southeastern have thirty similar Class 707 trains, which are third-rail, although according to Wikipedia, were tested as dual-voltage trains.

- Most modern trains, like these Desiro City units made by Siemens, have a mix of motored and trailer cars, with one or more pantograph cars between the two driver cars.

- Because power is needed in all cars, there will be an electrical bus from one end of the train to distribute power.

- All trains in the family appear to have at least one trailer car, which will also be connected to the electrical bus.

With a family of trains like the Desiro City, Alstom’s Aventra, CAF’s Civity, Hitachi’s AT-200 or AT-300 or Stadler’s FLIRTs, train manufacturers assemble various cars, interiors and electrical gubbins together, to get the train performance and capability.

I would expect that the battery would be placed, where there is space and the most likely place is under the trailer car.

In some ways, it would work like the battery in a laptop computer, where operation is as follows.

- If there is external power, the computer runs on that power and the battery is also charged, if it is not fully-charged.

- If there is no external power, the computer runs on battery power, until the battery goes flat.

With a battery-electric train, operation is similar, with an important addition.

- If there is external power, the train runs on that power and the battery is also charged, if it is not fully-charged.

- If there is no external power, the train runs on battery power, until the battery goes flat.

- Desiro City and many other electric trains have regenerative braking and under braking, the electricity generated is is stored in the battery, if it is not fully-charged.

It could be considered by some, that regenerative braking is self-charging. But unfortunately, regenerative braking doesn’t recover all energy during braking. But it can be up to 70-80 % efficient.

Connecting The Echion Technologies Battery To The Train

The battery will have to be connected to the electrical bus, that runs the full length of the train.

As a Control Engineer, I suspect there will be a sophisticated control system, that will switch the battery between various modes and control the pantograph and third-rail shoes.

Perhaps, Echion Technologies have developed an all-purpose controller that could fit all trains?

HS2 Ltd Awards Landmark Rolling Stock Contracts To Hitachi-Alstom Joint Venture

The title of this post, is the same as that of this press release from High Speed Two.

The press release gives two major bullet points.

- Major boost for UK train-building as HS2’s state-of-the-art fleet of 225mph (360km/h) high speed trains will be built by Alstom and Hitachi Rail at their factories in County Durham, Derby and Crewe

- Landmark contract set to support 2,500 jobs across the UK and boost the economy by over £157m each year

The press release then gives a link to this video clip.

The video doesn’t appear to show much.

These are my thoughts.

The Train Specification

This document on the Government web site is the Train Technical Specification for High Speed Two Classic-Compatible Trains.

The Bare Bones Of The Contract

These three paragraphs in the press release outline the contract.

HS2 Ltd today confirmed that a Hitachi/Alstom JV has been awarded the contracts to build Britain’s next generation of high speed trains at their factories in Derby and County Durham in a major deal set to support 2,500 jobs across the UK.

The landmark contracts – worth around £2bn – will see the JV design, build and maintain a fleet of 54 state-of-the-art high speed trains that will operate on HS2 – the new high-speed railway being built between London, the West Midlands and Crewe.

Capable of speeds of up to 225mph (360km/h), the fully electric trains will also run on the existing network to places such as Glasgow, Liverpool, Manchester and the North West. Building on the latest technology from the Japanese Shinkansen ‘bullet train’ and European high-speed network, they will be some of the fastest, quietest and most energy efficient high-speed trains operating anywhere in the world.

The third paragraph is probably the most significant, with the last few words standing out.

They will be some of the fastest, quietest and most energy efficient high-speed trains operating anywhere in the world.

That is a high bar and let’s hope the joint venture achieves it.

The Fastest Trains?

In Wikipedia’s section on High Speed Rail, this is said.

China has the fastest conventional high-speed rail in regular operation, with the Beijing–Shanghai high-speed railway reaching up to 350 km/h (217 mph).

It may not be the fastest, when it opens, but the Hitachi/Alstom JV train will certainly put the wind up the Chinese.

The Quietest Trains?

In Class 345 Trains Really Are Quiet!, which I wrote in May 2017, I said this.

This morning I was sitting waiting on Platform 8 at Stratford station.

Platform 8 is separated from Platform 9 by just two tracks, so you notice a train, when it goes through Platform 9 at speed.

Usually, the trains that go through Platform 9 at speed towards Liverpool Street station are Class 321 trains or rakes of Mark 3 coaches oulled by a Class 90 locomotives.

Today, a new Class 345 train went through and the level of noise was extremely low compared to other trains.

Bombardier have applied world class aviation aerodynamics to these trains. Particularly in the areas of body shape, door design, car-to-car interfaces, bogies and pantographs.

Remember too, that low noise means less wasted energy and greater energy efficiency.

I have since confirmed the quietness of Aventras many times.

I know the Aventra is only a suburban trundler, but have the JV applied all the knowledge that makes an Aventra such a quiet train to their new high speed train.

One of the best ways to cut noise on a vehicle or train, is to make sure all the components are as quiet as possible.

On a train, a surprising amount of high-frequency noise comes from the pantograph.

This article from Rail Technology Magazine is entitled HS2 Ltd Awards Hitachi-Alstom JV Landmark Rolling Stock Contracts. This is said about the pantograph.

The new trains will utilise a pioneering low noise pantograph, the arm which collects power from the overhead wires developed by Hitachi Rail. The technology was first developed in Japan and will make the new HS2 trains quieter than comparable high speed trains.

There’s nothing wrong with that logic.

The Most Energy Efficient Trains?

There are several clues to the energy efficiency of these trains.

The Rail Technology Magazine article also says this.

Regenerative braking to boost energy efficiency.

Nothing is said about whether the energy is returned to the track in any of the articles on the train.

But in the specification for the train, in Section 7.3 Braking, this is said.

The Unit shall be capable of achieving this deceleration for any payload up to Normal

Payload (HDL) without regenerating to the 25kV power supply.

So what does the train do with the energy?

It must be stored on the train and reused to accelerate the train or provide hotel power, which means the train must have integrated battery storage.

This would contribute to the train’s energy efficiency.

Other factors, that would contribute are a lighter weight and good aerodynamics.

Relationship To The Zefiro 300

The Zefiro 300 is a high speed train, that was built by a consortium of Bombardier and Hitachi Rail in Italy.

This is said in the Wikipedia entry for the Zefiro 300.

An evolution of the Italian version of the Zefiro 300 was also offered by Bombardier (joined with Hitachi Rail) for High Speed 2 commercial tender.

Note.

- The Zefiro 300 uses FLEXX Eco bogies.

- The Zefiro 300 is a 300 kph train.

- The Zefiro 300 is called a Frecciarossa 1000 in Italy.

There is also a Zefiro 380 in China, which is a 380 kph train.

I’ve ridden one of these trains and describe it in Riding The Frecciarossa.

I think the High Speed Two trains will have level boarding.

Bogies

The bogies are one of the most important parts of the train. Like the Zefiro 300, will the train have FLEXX Eco bogies?

This article on Global Railway Review is entitled FLEXX Eco: The Leading Lightweight Passenger Bogie Design and it gives details on the bogie and its history.

Some of the concepts were developed at British Rail Research and some were applied to the bogies of the legendary British Rail Mark 3 and Mark 4 coaches, which ride better than some of today’s trains.

The Rail Technology Magazine article says this about the bogies.

Further supporting the UK rail supply chain, all of the bogies for the new trains will be assembled and maintained at Alstom’s facility in Crewe – which is the first time since 2004 that both jobs have been done in the UK.

It sounds sensible to have one factory to assemble and maintain the bogies.

Will this factory also supply the bogies for Aventras, which are also FLEXX Eco?

Assembly

The press release says this about assembly.

- The first stages including vehicle body assembly and initial fit-out will be done at Hitachi Rail’s facility at Newton Aycliffe, County Durham.

- The second stage of fit out and testing will be done at Alstom’s Litchurch Lane factory in Derby.

Conclusion

I find it interesting, how improvements in one area help another.

The JV has worked hard to perfect this design.