ScottishPower’s Green Hydrogen Project Looks To Build UK’s Largest Electrolyser

The title of this post, is the same as that of this article on Current News.

This is the first paragraph.

ScottishPower has submitted a planning application for the UK’s largest electrolyser as part of the Green Hydrogen for Scotland project.

Other points from the article include, these about the electrolyser.

- It will be built close to the Whitelee wind farm.

- It will be 20 MW.

- It will produce eight tonnes of green hydrogen per day.

- The electrolyser will be built by ITM Power in Rotherham.

- It is hoped that green hydrogen will be produced by 2030.

Other points include.

- The windfarm will be backed up by 40MW of solar panels and a battery capable of supplying 50 MW.

- The capacity and type of the battery is not stated.

The article finishes with a must-read section, about how hydrogen will help the UK meet its decarbonisation targets.

Engine Development At ABC Shaped By Sustainability

The title of this post, is the same as that on this article on Riviera Maritime Media.

This is the introductory paragraph.

Belgian engine manufacturer ABC is supplying the power for a new ‘green’ oceanographic research vessel, while it continues development of a hydrogen engine.

The article then gives a good summary of the progress being made by ABC in developing diesel, dual and hydrogen power for ships, based on their existing diesel technology.

- Their diesel engines will be powering the new Belgian maritime research ship; Belgica.

- They are developing hydrogen engines up to 10 MW.

- They aim to have a hydrogen engine working by Q2 2021.

- They have the capacity to build up to a hundred engines a year.

The company seems to be following an alternative route to decarbonisation, by converting existing large diesel designs to hydrogen.

The article is very much worth a read.

Energy Minister Angus Taylor Launches $50 million Fund For Carbon Capture Projects

The title of this post, is the same as that of this article on ABC News.

This is the first three introductory paragraphs.

The federal government has launched a $50 million fund to support the growth of carbon capture projects, which will include projects that reuse carbon dioxide emissions to make new products.

The launch of the Carbon Capture, Use and Storage fund was in Newcastle at the pilot site for Mineral Carbonisation International (MCI).

The company is using carbon dioxide (CO2) captured from a nearby ammonia plant to make building products like plasterboard and cement.

This sounds like a good idea to me!

They have a web site, which contains this YouTube video.

This could be a novel solution to decarbonisation.

Green Hydrogen To Power First Zero Carbon Steel Plant

The title of this post, is the same as that of this article on renews.biz.

This is the two introductory paragraphs.

A new industrial initiative, backed by EIT InnoEnergy, will build the world’s first large-scale steel production plant powered by green hydrogen, in north Sweden.

The H2 Green Steel industrial initiative, which will mobilise €2.5bn of investment, aims to deliver a project that will create a new green steel producer from inception.

These further points are made.

- There will be downstream steel products manufacture.

- The initiative will create 10,000 direct and indirect jobs.

- Production could start in 2024.

- Up to five million tonnes of steel could be produced by 2030.

The plant will be built in the Boden-Lulea area of Northern Sweden.

Note.

H2 Green Steel has a web site, which explains more.

What About Scunthorpe?

Surely, the obvious location for green steel production plant in the UK would be Scunthorpe.

- The HumberZero network can bring in hydrogen and take away any carbon dioxide.

- The steelworks makes world-class products like railway rails.

- It is a massive site.

- The site has good rail access.

But there don’t seem to be any plans for hydrogen steelmaking at Scunthorpe.

Conclusion

I hope we’ve not missed the boat for hydrogen steelmaking.

- We’ve certainly got the sites, the renewable energy and the hydrogen technology.

- On the other hand, I can remember sensible arguments for lots of much smaller steel plants from fifty years ago, as an alternative to nationalisation of the steel industry by the Wilson Government in 1967.

- I can also remember proposals for nuclear steelmaking.

I just wonder, if a design of hydrogen steelmaking plant could be developed, perhaps even using a small modular nuclear reactor to generate the hydrogen.

If we are going to have a steel industry in the future, we must do something radical.

Luton DART Fly Through

This video does what it says in the title.

It certainly looks like the DART will greatly improve the experience of getting to Luton Airport.

Highview Power Begins 2021 With 4 GWh Of CRYOBattery Storage In Global Pipeline

The title of this post, is the same as that of this article on Solar Builder.

Read the article to find out how Highview Power are progressing with partners, offices and projects all over the world.

Not bad for an idea, that was invented in a garage in Bishops Stortford.

The article points to this video produced by the BBC.

If there’s one new venture, I wish I’d have a share of, it is this one.

- One of the projects, I worked on at ICI was optimising the size of a new plant to make plastic granules. I learned a great deal about how process plants can be scaled and their mathematics and economics.

- I believe that Highview Power’s CRYOBaterries fit with everything I know and are just world-class process engineering arranged in a unique way, which means they can be built in any country, where modern process plant technology is available and can be run and serviced by skilled engineers and technologists.

- Their partnership with the likes of Sumitomo Heavy Industries means, Highview Power, probably has access to the best technology, for some of the components needed.

After reading the article in Solar Builder, I now feel that Highview Power are on their way!

One of the first places, I shall visit after lockdown ends is Carrington near Manchester, to take pictures of the site of Highview Power’s 50 MW/250 MWh system, that is being built at Carrington.

Batteries Could Save £195m Annually By Providing Reserve Finds National Grid ESO Trial

The title of this post, is the same as that of this article on Current News.

The title gives the findings of the Arenko-led trial.

What Is The National Grid Reserve Service?

It’s all about providing capacity for the National Grid Reserve Service, which is described in this Wikipedia entry. This is the introductory paragraph.

To balance the supply and demand of electricity on short timescales, the UK National Grid has contracts in place with generators and large energy users to provide temporary extra power, or reduction in demand. These reserve services are needed if a power station fails for example, or if forecast demand differs from actual demand. National Grid has several classes of reserve services, which in descending order of response time are: Balancing Mechanism (BM) Start-Up, Short-Term Operating Reserve, Demand Management and Fast Reserve.

The Wikipedia entry is very comprehensive.

A Collateral Benefit

This is a paragraph from the article.

Additionally, unlike CCGT plants, batteries do not need to be producing power in order to provide Reserve as they can charge when there is abundant renewable energy on the grid, and then wait to react when needed. As CCGT’s need to be producing power to provide this service, it can led to renewables switched off in favour of the more carbon intensive fossil fuel generation, to ensure Reserve is available if needed.

The article concludes that Reserve from Storage could help National Grid ESO’s reach their target of net-zero operation by 2025.

Could We Replace CCGT Plants With Batteries?

CCGT or combined cycle gas-turbine power plants are efficient ways to turn natural gas into electricity.

- Typical sizes are around 800 MW.

- They are reasonably quick and easy to build.

- As their fuel comes by a pipeline, they don’t need to be connected to the rail network, unlike biomass and coal power plants.

Because they burn methane, they still emit a certain amount of carbon dioxide, although levels much less than an equivalent coal-fired power station.

In Energy In North-East Lincolnshire, I described the three Keadby power stations.

- Keadby – In operation – 734 MW

- Keadby 2 – Under construction – 840 MW

- Keadby 3 – In planning – 910 MW

In total, these three power stations will have a capacity of 2484 MW.

By comparison, Hinckley Point C will have a capacity of 3200 MW.

Add Keadby 4 and the four CCGTs would provide more electricity, than Hinckley Point C.

I think it would be very difficult to replace a cluster of CCGT gas-fired power stations or a big nuclear power plant with the sort of batteries being deployed today. 2.5 to 3 GW is just so much electricity!

I do believe though, that instead of building a 3200 MW nuclear power plant, you could build a cluster of four 800 MW CCGTs.

But What About The Carbon Dioxide?

Using the Keadby cluster of CCGTs as an example.

- Keadby 2 and Keadby 3 are being built to be upgraded with carbon-capture technology.

- The HumberZero gas network will take the carbon dioxide away for storage in worked-out gas fields in the North Sea.

- Some carbon dioxide will be fed to salad vegetables and soft fruits in greenhouses, to promote growth.

- Keadby 2 and Keadby 3 are being built to be able to run on hydrogen.

- The HumberZero network will also be able to deliver hydrogen to fuel the power stations.

I’m certain we’ll see some of the next generation of wind turbines delivering their energy from hundreds of miles offshore, in the form of hydrogen by means of a pipe.

The technology is being developed by ITM Power and Ørsted, with the backing of the UK government.

- Redundant gas pipelines can be used, to bring the hydrogen to the shore

- The engineering of piping hydrogen to the shore is well-understood.

- Redundant gas pipelines can be used if they already exist.

- Gas networks can be designed, so that depleted gas fields can be used to store the gas offshore, in times when it is not needed.

But above all gas pipelines cost less than DC electricity links, normally used to connect turbines to the shore.

I can see very complicated, but extremely efficient networks of wind turbines, redundant gas fields and efficient CCGT power stations connected together by gas pipelines, which distribute natural gas, hydrogen and carbon dioxide as appropriate.

Could Offshore Hydrogen Storage And CCGTs Provide The Reserve Power

Consider.

- Using a CCGT power station to provide Reserve Power is well understood.

- Suppose there is a large worked out gasfield, near to the power station, which has been repurposed to be used for hydrogen storage.

- The hydrogen storage is filled using hydrogen created by offshore wind turbines, that have built in electrolysers, like those being developed by ITM Power and Ørsted.

- One of more CCGTs could run as needed using hydrogen from the storage as fuel.

- A CCGT power station running on hydrogen is a zero-carbon power station.

Effectively, there would be a giant battery, that stored offshore wind energy as hydrogen.

I can see why the UK government is helping to fund this development by ITM Power and Ørsted.

Could We See Cradle-To-Grave Design Of Gas Fields?

I suspect that when a gas field is found and the infrastructured is designed it is all about what is best in the short term.

Suppose a gas field is found reasonably close to the shore or in an area like the Humber, Mersey or Tees Estuaries, where a lot of carbon dioxide is produced by industries like steel, glass and chemicals!

Should these assessments be done before any decisions are made about how to bring the gas ashore?

- After being worked out could the gas field be used to store carbon dioxide?

- After being worked out could the gas field be used to store natural gas or hydrogen?

- Is the area round the gas field suitable for building a wind farm?

Only then could a long-term plan be devised for the gas-field and the infrastructure can be designed accordingly.

I suspect that the right design could save a lot of money, as infrastructure was converted for the next phase of its life.

Conclusion

It does appear that a lot of money can be saved.

But my rambling through the calculations shows the following.

Wind Turbines Generating Hydrogen Give Advantages

These are some of the advantages.

- Hydrogen can be transported at less cost.

- Hydrogen is easily stored if you have have a handy worked-out gas field.

- The technology is well-known.

Hydrogen can then be converted back to electricity in a CCGT power station

The CCGT Power Station Operates In A Net-Zero Carbon Manner

There are two ways, the CCGT station can be run.

- On natural gas, with the carbon-dioxide captured for use or storage.

- On hydrogen.

No carbon-dioxide is released to the atmosphere in either mode.

The Hydrogen Storage And The CCGT Power Station Or Stations Is Just A Giant Battery

This may be true, but it’s all proven technology, that can be used as the Power Reserve.

Power Networks Will Get More Complicated

This will be inevitable, but giant batteries from various technologies will make it more reliable.

Spanish Govt Approves Energy Storage Strategy, Sees 20 GW In 2030

The title of this post, is the same as that of this article on Renewables Now!

This is the introductory paragraph.

The Spanish government on Tuesday approved the energy storage strategy, targeting some 20 GW of storage capacity in 2030 and reaching 30 GW by 2050 from today’s 8.3 GW.

How will Spain increase their storage capacity?

Pumped Storage Systems

Spain already has a couple of large pumped storage systems.

The La Muela II Pumped Storage Power Station

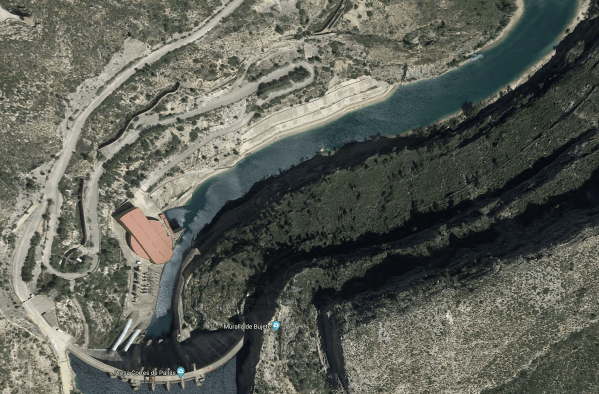

The La Muela II Pumped Storage power station is based on the Cortes-La Muela Reservoir

This Google Map shows the dam.

In terms of generating capacity, it is about the same size as Dinorwig power station in Snowdonia., which is the UK’s largest pumped storage power station.

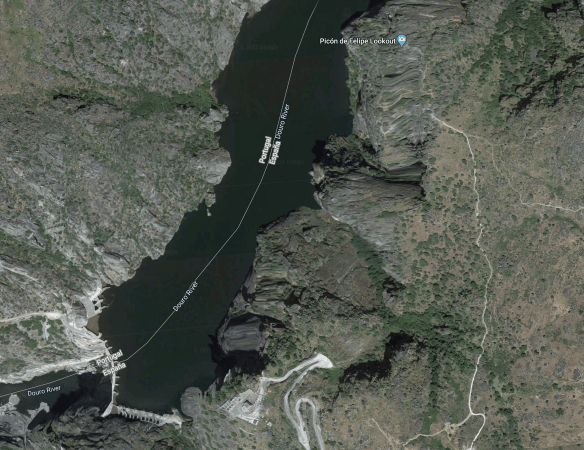

The Aldeadávila Dam

The Aldeadávila Dam is a 1243 MW hydro-electric power station with a pumped storage addition on the River Douro between Spain and Portugal.

This Google Map shows the dam.

It certainly looks like a place to visit.

Both these pumped storage station seem to have been converted from earlier hydro-electric power stations.

I wouldn’t be surprised to learn, that the Spaniards, were going to increase their number of pumped storage power stations.

- Spain certainly has the mountains, with big rivers running through!

- Bolarque dam already uses pumped-storage techniques.

Are there any other existing hydro-electric power stations in Spain, that can be converted to pumped storage or be upgraded?

Concentrated Solar Power

Spain has around thirty concentrated solar power or CSP power stations, either in operation, under construction or planned.

Some also store electricity as heat.

Spain is not short of sun.

Spain is considered a world leader in this technology.

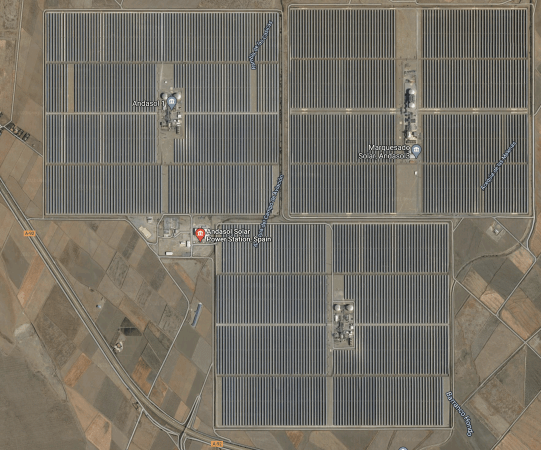

This Google Map shows the Andasol solar power station.

The specification includes.

- It uses technology called a parabolic trough.

- A nameplate capacity of 149.7 MW

- A capacity factor of 37.7 %

- Annual net output of 495 GWh

- a storage capacity of 1.123 GWh

- The energy storage is based on a mixture of potassium and sodium nitrates.

- The power station takes up an area of six square kilometres.

Will Spain build more of these CSP power stations or add energy storage to some of the existing stations?

Batteries

The article has this sentence.

the government wants to add large-scale batteries, behind-the-metre batteries — minimum 400 MW in 2030 — and make the most of the vehicle-to-grid technology, according to the document.

It should be noted that Spain has installed capacity of over 25 GW of wind power, according to this article on Wikipedia, which is entitled Wind Power In Spain.

These are some points from the article.

- Spain has a lot of indigenous wind turbine manufacture.

- The Spanish wind-power industry employs upwards of 60,000 people.

- A central control centre for Spanish wind power needs to be developed.

- There is little opposition to onshore wind, although perhaps somewhat surprisingly, there is some opposition to offshore wind.

After reading what Wikipedia had to say, it appears to me, that Spain needs a ;pt of batteries to support all these wind turbines.

The world’s second largest wind-turbine manufacturer is Siemens Gamesa, who are Spanish-based.

Siemens Gamesa have an innovation storage battery based on hot volcanic rock, which I wrote about in Siemens Gamesa Begins Operation Of Its Innovative Electrothermal Energy Storage System.

This gives a brief description of the pilot plant.

The heat storage facility, which was ceremonially opened today in Hamburg-Altenwerder, contains around 1,000 tonnes of volcanic rock as an energy storage medium. It is fed with electrical energy converted into hot air by means of a resistance heater and a blower that heats the rock to 750°C. When demand peaks, ETES uses a steam turbine for the re-electrification of the stored energy. The ETES pilot plant can thus store up to 130 MWh of thermal energy for a week. In addition, the storage capacity of the system remains constant throughout the charging cycles.

It was taken from this press release from Siemens Gamesa.

This page on the Siemens web site gives the nominal output of the system as 30 MW.

So it would need just over a dozen systems like these to perhaps be strategically-placed near large wind farms to meet Spain’s target of 400 MW of energy storage.

Highview Power’s liquid air systems would be another possibility, but I doubt, they’d perform as well in the heat of Spain, as a system based on hot rocks.

Conclusion

Spain’s plan seems achievable and could create a lot of employment.

It also seems to me, that their natural resources of mountains, big rivers and lots of sun are a great help.

World’s Biggest Battery Storage Project Announced By Australian Renewables Fund

The title of this post, is the same as that of this article on Energy Storage News.

This is the introductory paragraph.

CEP. Energy, a specialist renewable energy fund company in Australia, has just announced the largest proposed grid-scale battery project in the world so far, with up to 1,200MW rated output.

If you read the whole article, you get the impression, that the Australians are going big on energy storage.

But then Australia must be one of the best countries for solar energy in the world.

This paragraph contains an interesting concept.

Construction is anticipated to begin in early 2022 for completion in 2023, so it’s possible even bigger schemes will be announced or even built by then, but for now the project is setting the pace for scale. Another Australian project, proposed by integrated energy company Origin Energy would site 700MW / 2,800MWh of batteries at a retiring coal power station, also in New South Wales and French developer Neoen has filed a plan, to build a 500MW / 1,000MWh battery storage project in the state. New South Wales’s government has implemented an ambitious roadmap to deploying vast shares of renewable energy on its networks, including a handful of multi-gigawatt Renewable Energy Zones.

Note that Origin Energy are replacing a coal-fired power station with a 700 MW/2,800 MWh battery.

We shall see a lot of fossil-fuel-fired power stations replaced by batteries.