Are Zero- And Low-Alcohol Beers Cutting Road Accidents?

In The Times today, there is an article, which is entitled Drink-Driving ‘Effectively Legalised’ As Number Of Breath Tests Falls, where these are the first three paragraphs.

Drink-driving has effectively been legalised due to plummeting rates of breathalyser tests and light punishments for offenders, campaigners have warned.

The number of breath tests conducted by police has fallen by more than 62 per cent over the past decade as dangerously inebriated drivers receive short bans.

In 2009, police carried out 647,380 breath tests, but by 2023, that figure had fallen to just 240,322.

This later paragraph, adds a few more statistics.

In 2002, 18 per cent of breath tests were positive, compared to 16 per cent in 2023, while the number of drivers prosecuted for drink-driving offences has significantly decreased. Convictions for drink-driving fell from 55,300 in 2012 to 40,292 in 2023, coinciding with the sharp decline in breath testing.

Note, that in both extracts the latest comparison date is 2023, whereas the earliest date is 2009 and 2002.

This analysis is not the full picture, as there are two big differences between drinking in 2002 or 2009 and 2023.

The first difference is that 2002 and 2009 are pre-Covid, but 2023 is post-Covid.

So did Covid alter our drinking habits, which could have perhaps meant more people drank at home?

The second difference is that in 2023, zero and low alcohol beer was readily available.

I don’t drive, after a stroke ruined my eyesight, but I do drink up to four bottles a day of 0.5 % real ale. The beer I drink has been regularly available since 2017.

I wonder how many nominated drivers are now drinking these beers?

A serious survey and analysis needs to be done.

AI Forecast To Fuel Doubling In Data Centre Electricity Demand By 2030

The title of this post, is the same as that as this article in The Times.

This is the sub-heading.

International Energy Agency predicts that artificial intelligence could help reduce total greenhouse gas emissions

These are the first two paragraphs.

Data centres will use more than twice as much electricity by 2030 than they do today as artificial intelligence drives demand, the International Energy Agency predicts.

The agency forecast that all data centres globally will use about 945 terawatt-hours of electricity each year by 2030, roughly three times as much as the UK’s total annual demand of 317 terawatt-hours in 2023.

I am very much an optimist, that here in the UK, we will be able to satisfy demand for the generation and distribution of electricity.

- Our seas can accommodate enough wind turbines to provide the baseload of electricity we will need.

- Roofs and fields will be covered in solar panels.

- SSE seem to be getting their act together with pumped storage hydro in Scotland.

- I am confident, that new energy storage technologies like Highview Power with the packing of companies like Centrica, Goldman Sachs, Rio Tinto and others will come good, in providing power, when the wind doesn’t blow and the sun doesn’t shine.

- Hopefully, Hinckley Point C and Sizewell C will be online and soon to be joined by the first of the new small modular nuclear reactors.

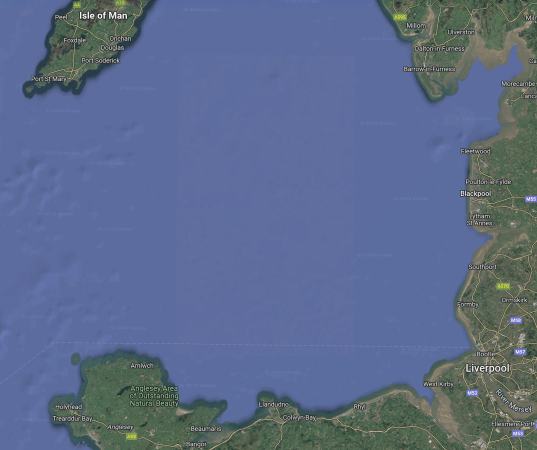

- Hopefully, Mersey Tidal Power will be operating.

- There will be innovative ideas like heata from Centrica’s research. The economical water heater even made BBC’s One Show last week.

The only problem will be the Nimbies.

Tea Removes Toxic Heavy Metals From Water, Study Suggests

The title of this post, is the same as that of this article on The Times.

This is the sub-heading.

The longer tea is steeped, the more contaminants are removed

These are the first three paragraphs, which give a flavour of the research.

A daily cup of tea may do more than just perk you up — it can also purge the water of toxic heavy metals, a study suggests.

Researchers found that tea leaves will trap lead, cadmium, and other unwanted contaminants during the brewing process. These metals bind to the leaves and remain there until they are thrown away.

Benjamin Shindel of Northwestern University, Illinois, who led the research, said that while other materials might achieve a similar effect, tea’s popularity made it unique. “What is special about tea is that it’s the most consumed beverage in the world,” he explained.

My late wife was a coffee drinker and I only have the odd cup of cappuccino, although, I do drink lots of zero-alcohol beer, hot chocolate and decaffeinated tea.

I would assume that from his name Professor Benjamin Shindel is quite likely to be Jewish.

So did he ask all his friends and relatives round for a tea party?

The Professor certainly wouldn’t have had to have stinted on the cakes, as they wouldn’t have got near the water, which was the real subject of the research.

But he wouldn’t have been short of volunteers to brew their favourite tea!

DOE Funds Research Into Long-Duration Energy Storage Using Lead-Acid Batteries

The title of this post, is the same as that of this article on Best Magazine.

This is the sub-heading

US federal cash is on its way to fund research into long-duration energy storage using lead-acid batteries.

These two paragraphs give more details.

A consortium backed by industry bodies Battery Council International and the Consortium for Battery Innovation, will conduct pre-competitive research aimed at improving lead battery performance. Companies participating in the consortium include Advanced Battery Concepts, C&D/Trojan, Clarios, Crown Battery, East Penn Manufacturing, EnerSys, Gridtential and Stryten Energy. The collaborating national laboratories are Argonne, Oak Ridge and Pacific Northwest (PNNL).

The $5 million award from the US Department of Energy, announced on 27 September, will support work to develop lead batteries capable of 10+ hours of storage with a pathway to $0.05/kWh levelised cost of storage by 2030.

Note.

- The companies involved have names that indicate they could be battery makers.

- The collaborating national laboratories are world-class Premier League players.

- Over the nearly fifty years, that I drove cars, lead-acid batteries improved a lot and there might be more to come.

- The last paragraph is ambitious, unless they know more than I do about lead-acid batteries. Which is likely!

This is also said in one of Highview Power’s news items.

Highview Power, the global leader in long-duration energy storage solutions, is pleased to announce that it has developed a modular cryogenic energy storage system, the CRYOBattery, that is scalable up to multiple gigawatts of energy storage and can be located anywhere. This technology reaches a new benchmark for a levelized cost of storage (LCOS) of $140/MWh for a 10-hour, 200 MW/2 GWh system. Highview Power’s cryogenic energy storage system is equivalent in performance to, and could potentially replace, a fossil fuel power station. Highview Power’s systems can enable renewable energy baseload power at large scale, while also supporting electricity and distribution systems and providing energy security.

The battery researchers are saying $0.05/kWh levelised cost of storage by 2030 and Highview Power are saying $0.14/kWh for the same parameter.

Could Elon Musk’s Relationship With Donald Trump Be The Fly In The Ointment?

Would Musk want research to go on, that might weaken the use of his lithium-ion batteries for stationary applications?

Gluten And Heart Disease

Type “Gluten And Heart Disease” into Dr. Google and you find two major peer-reviewed studies.

This study is entitled Effects Of A Gluten-Reduced Or Gluten-Free Diet For The Primary Prevention Of Cardiovascular Disease.

These are the authors’ conclusions.

Very low-certainty evidence suggested that it is unclear whether gluten intake is associated with all-cause mortality. Our findings also indicate that low-certainty evidence may show little or no association between gluten intake and cardiovascular mortality and non-fatal myocardial infarction.

There would appear to be no strong link, between gluten and heart disease.

This British study is entitled Long Term Gluten Consumption In Adults Without Celiac Disease And Risk Of Coronary Heart Disease: Prospective Cohort Study.

These were the authors’ conclusions.

In these two large, prospective cohorts, the consumption of foods containing gluten was not significantly associated with risk of coronary heart disease. Although people with and without celiac disease may avoid gluten owing to a symptomatic response to this dietary protein, these findings do not support the promotion of a gluten restricted diet with a goal of reducing coronary heart disease risk. In addition, the avoidance of dietary gluten may result in a low intake of whole grains, which are associated with cardiovascular benefits. The promotion of gluten-free diets for the purpose of coronary heart disease prevention among asymptomatic people without celiac disease should not be recommended.

As before there would appear to be no strong link between gluten and heart disease.

To me, this is the most important sentence.

In addition, the avoidance of dietary gluten may result in a low intake of whole grains, which are associated with cardiovascular benefits.

So can we do something about it?

Enter The First Great Ethiopian Marathon Runner

I used to run a bit (badly) at school and my three heroes were Chris Brasher, Bruce Tulloh and Abebe Bikula.

The Ethiopian; Abebe Bikula was a double Olympic marathon champion.

- In 1960, he won in Rome, running barefoot.

- In 1964, he won in Tokyo, a few days after leaving hospital after having his appendix removed.

Both wins were in world record time.

Since 1964, three Olympic men’s marathons have been won by Ethiopians.

Ethiopian women have also won two gold and one bronze medals since the women’s marathon was inaugurated in 1984.

And then there’s the Kenyans, who’ve won a hatful of marathon medals.

Their competence is generally put down to living at altitude and I wouldn’t disagree with that.

My Experience Of Kenya

Soon after C died, I went on holiday to Kenya.

In one part of the holiday, I was riding horses in the Masai Mara and in the other I was glamping.

The second part was upmarket and one evening the chef approached me to find out more about my gluten-free diet. At breakfast next day, he presented me with a couple of rolls made from a local flour, which was probably something like millet or perhaps, teff from Ethiopia.

I had no adverse reaction. and he said, I could eat like a true African, as Western flour had no place in the local diet.

Conclusion

If we are worried about the lack of whole grains in gluten-free food, then perhaps we should add gluten-free whole grains from East Africa.

As a manager in a Marks and Spencer store, told me that they used Ethiopian flour in their gluten-free breads, I suspect this is already happening.

The Aerosol Tales

When I left Liverpool University in 1968, I was very familiar with the use of products distributed in aerosol cans.

- I had used aerosol shaving cream, although about that time, I acquired my beard.

- I certainly used aerosol deodorant, as did most in the 1960s.

- Aerosol paints were common for covering scuffs and scratches in your car.

- Aerosols were often used to apply sun protection.

- Aerosols containing cream or a non-dairy alternative for culinary use were not unknown.

- Aweosol lubricants were starting to appear.

Although, I went to work for the chemical giant; ICI, at that time, I had no idea how an aerosol and its can worked.

As ICI at the time, ICI were major manufacturers of aerosol propellants, I quickly learned how they worked.

The Wikipedia entry for Aerosol Spray Dispenser gives a lot of history about aerosol cans and their propellants.

The Wikipedia entry for Propellant has this paragraph describing propellants of the last century.

Chlorofluorocarbons (CFCs) were once often used as propellants, but since the Montreal Protocol came into force in 1989, they have been replaced in nearly every country due to the negative effects CFCs have on Earth’s ozone layer. The most common replacements of CFCs are mixtures of volatile hydrocarbons, typically propane, n-butane and isobutane. Dimethyl ether (DME) and methyl ethyl ether are also used. All these have the disadvantage of being flammable. Nitrous oxide and carbon dioxide are also used as propellants to deliver foodstuffs (for example, whipped cream and cooking spray). Medicinal aerosols such as asthma inhalers use hydrofluoroalkanes (HFA): either HFA 134a (1,1,1,2,-tetrafluoroethane) or HFA 227 (1,1,1,2,3,3,3-heptafluoropropane) or combinations of the two. More recently, liquid hydrofluoroolefin (HFO) propellants have become more widely adopted in aerosol systems due to their relatively low vapor pressure, low global warming potential (GWP), and nonflammability.

Note that the whole range of these chemicals, effect the ozone layer.

Rocksavage Works

ICI’s Rocksavage Works, was an integrated chemical plant by the Mersey,.

- It made all types of CFCs for aerosols and other purposes.

- It also made the fire suppressant and extinguisher; Bromochlorodifluoromethane or BCF.

- Alongside BCF, it made the anaesthetic Halothane or as ICI called it Fluothane.

- The plant was a poisonous place with all those bromine, chlorine and fluorine compounds.

- Despite this, the plant had a remarkable safety record.

I had the pleasure of working at the plant and it was where, I had most of my excellent Health and Safety training, from the amazing site foreman; Charlie Akers.

Some of the wisdom he distributed has proved invaluable in aiding my stroke recovery.

I suspect that since the signing of the Montreal Protocol, the plant has changed greatly or has even been closed.

All that appears to be left is the 800 MW gas-fired Rocksavage power station and a Facebook page.

Aerosol Baked Beans

In those days, I worked most of the time in a lab at Runcorn Heath.

One of the labs near to where I generally worked, in the large research complex, was a lab, where new aerosol products were developed and tested.

One of the standard jokes about that lab, was that they were working on aerosol baked beans. They said, they would develop the product, even of they had to eject them from the can one at a time.

Gift Time

One afternoon, the boss of the aerosol development lab came through with a tray of goodies.

On the tray, which was much like a cinema usherette’s ice cream tray of the sixties was a whole host of partly-labeled aerosol cans. Only clues to what the product might be were written on the outside in felt-tip pen.

I grabbed two, one of which was marked something like lubricating oil and the other was just marked hand cream, which I of course gave to my new wife; C.

We were married for nearly forty years and often, when she bought hand cream, she would remark, that it wasn’t of the same standard as the little can I brought home from work.

It appears to me, that one of the world’s top cosmetic companies and ICI were trying to create the world’s best and probably most expensive hand creams.

DMW

Fast-forward nearly twenty years and I was approached by Lloyds Bank about two individuals, who had developed an aerosol valve, that instead of using CFCs or other ozone-depleting chemicals.

- By the exploitation of the nether end of fluid dynamics, the propellant of the aerosol was nothing more harmless than pure nitrogen.

- I formed a company called DMW with the two inventors.

- John Gummer, who at the time was my MP and Environment Minister, knew of the aerosol valve and he took the details to Montreal.

So did a device developed in Suffolk help push through the Montreal Protocol?

Osbourne Reynolds

I also wonder, if we had some supernatural help. At the time, I lived in the family home of Osbourne Reynolds.

- He did a lot of the early work on fluid dynamics.

- He was the first UK Professor of Engineering.

- He was professor of Engineering at Manchester University for nearly forty years.

- The Reynolds number is named after him.

- Remarkably, students are sill taught on the equipment Reynolds designed.

- Reynolds was certainly one of our great Victorian scientists.

This Wikipedia entry gives more details of his remarkable life and work.

After Montreal the aerosol valve was sold to Johnson & Johnson.

DMW continued to develop other products and we had one, who no-one had any idea about how it worked.

So I discussed it with the Reynolds’s expert at Manchester University and he said he had no idea either.

But he was absolutely certain, that Reynolds would have known.

UK Breakthrough Could Slash Emissions From Cement

The title of this post. is the same as that of this article on the BBC.

This is the sub-heading.

Scientists say they’ve found a way to recycle cement from demolished concrete buildings.

These five paragraphs outline, why cement is such an environmental problem.

Cement is the modern world’s most common construction material, but it is also a huge source of planet-warming gas emissions.

That is because of the chemical reactions when you heat limestone to high temperatures by burning fossil fuels.

Recycling cement would massively reduce its carbon footprint. Researchers say that if they switched to electric-powered furnaces, and used renewable energy like wind and solar rather than fossil fuels, that could mean no greenhouse gases would be released at all.

And that would be a big deal. Cement forms the foundation of the modern economy, both literally and metaphorically.

It is what binds the sand and aggregate in concrete together, and concrete is the most widely used material on the planet after water.

If cement was a country, it would be the third biggest source of emissions after China and the US, responsible for 7.5% of human-made CO2.

This article shows how by applying chemical magic to two effectively unrelated processes; the recycling of steel and the recycling of concrete to make new cement, very high rewards are possible.

Cambridge University are calling their new product electric cement.

As large amounts of electricity are used in an arc furnace, to produce the two products

These paragraphs outline the innovative Cambridge process.

Cement is made by heating limestone to up 1600 Celsius in giant kilns powered by fossil fuels.

Those emissions are just the start. The heat is used to drive carbon dioxide from the limestone, leaving a residue of cement.

Add both these sources of pollution together and it is estimated that about a tonne of carbon dioxide is produced for every tonne of cement.

The team of scientists,, has found a neat way to sidestep those emissions.

It exploits the fact that you can reactivate used cement by exposing it to high temperatures again.

The chemistry is well-established, and it has been done at scale in cement kilns.

The breakthrough is to prove it can be done by piggybacking on the heat generated by another heavy industry – steel recycling.

When you recycle steel, you add chemicals that float on the surface of the molten metal to prevent it reacting with the air and creating impurities. This is known as slag.

The Cambridge team spotted the composition of used cement is almost exactly the same as the slag used in electric arc furnaces.

They have been trialling the process at a small-scale electric arc furnace at the Materials Processing Institute in Middlesbrough.

These are my thoughts.

The Only Inputs Are Steel Scrap, Green Electricity And Used Cement

Consider.

- We probably need to increase the percentage of steel scrap we collect.

- Gigawatts of green electricity in a few years, will be available in those places like Port of Ardersier, Port Talbot, Scunthorpe and Teesside, where large amounts of steel will be needed.

- I can envisage large steel users having their own hybrid electric cement/electric arc furnace plants.

- Used cement would be collected and brought to the plants.

- Years ago, I used to live next door to an old World War II airfield. The farmer who owned the airfield, told me, that the concrete was his pension, as when he needed money, he called a company, who crushed it up for aggregate.

I can see a whole new integrated industry being created.

Conclusion

This could be one of the best inventions since sliced bread.

The Problem Of Waste Plastic And Why Pyrolysis Oil Might Just Contain The Answer

The title of this post, is the same as that of this article on the Chemical Engineer.

These three paragraphs introduce the article.

One of the few technologies that can break down unrecyclable post-consumer waste plastic, pyrolysis is fast becoming a potential recycling route for companies trying to reduce their waste output.

The world produces around 450m t/y of plastic, but only 9% is recycled, with most waste ending up in landfill. Pyrolysis, which involves heating the plastic at extremely high temperatures in the absence of oxygen, breaks down the molecules to produce pyrolysis oil or gas. The oil can then be used to develop new products.

George Huber, a professor of chemical engineering at the University of Wisconsin-Madison, is leading a research team that is investigating the chemistry of pyrolysis oil and its use in polyolefin recycling.

This is a quote from George Huber

Waste plastic should be viewed as a resource we can use to make plastics and other chemicals. We should not be landfilling or burning it, we should be reusing the carbon in waste plastics.

I very much agree with what he said.

These are my thoughts.

Pyrolysis

The Wikipedia entry for pyrolysis starts with this paragraph.

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere.

This paragraph describes the technique’s use in the chemical industry.

The process is used heavily in the chemical industry, for example, to produce ethylene, many forms of carbon, and other chemicals from petroleum, coal, and even wood, or to produce coke from coal. It is used also in the conversion of natural gas (primarily methane) into hydrogen gas and solid carbon char, recently introduced on an industrial scale. Aspirational applications of pyrolysis would convert biomass into syngas and biochar, waste plastics back into usable oil, or waste into safely disposable substances.

I came across pyrolysis in my first job after graduating, when I worked at ICI Runcorn.

ICI were trying to make acetylene in a process plant they had bought from BASF. Ethylene was burned in an atmosphere, that didn’t have much oxygen and then quenched in naphtha. This should have produced acetylene , but all it produced was tonnes of black soot, that it spread all over Runcorn.

I shared an office with a guy, who was using a purpose-built instrument to measure acetylene in the off-gas from the burners.

When he discovered that the gas could be in explosive limits, ICI shut the plant down. The Germans didn’t believe this and said, that anyway it was impossible to do the measurement.

ICI gave up on the process and demolished their plant, but sadly the German plant blew up.

I would assume we have progressed with pyrolysis in the intervening fifty years.

University of Wisconsin-Madison

The University of Wisconsin-Madison is a top-ranked American University and is part of my daily life, as the Warfarin, that stops me having another stroke was developed at the University in the 1940s.

Conclusion

The article is a must-read and I feel that my past experience says, that George Huber and his team could be on to something.

I wish them the best of luck.