Europe’s Biggest Battery Storage Project Goes Live In Scotland

The title of this post, is the same, as this article in The Times.

This is the sub-heading.

Zenobe’s site at Blackhillock can store surplus generation for when the wind doesn’t blow and the sun doesn’t shine

These are the first two paragraphs.

Europe’s biggest battery storage project has entered commercial operation in Scotland, promising to soak up surplus wind power and prevent turbines being paid to switch off.

Zenobe said the first phase of its project at Blackhillock, between Inverness and Aberdeen, was now live with capacity to store enough power to supply 200 megawatts of electricity for two hours. It is due to be expanded to 300 megawatts by next year.

I believe we can do better, than install large lithium-ion batteries.

We need to get the pumped storage like Coire Glas, the liquid air like Highview Power and the gravity batteries like Gravitricity going as fast as we can.

They are more environmentally friendly than Tesla’s lithium ion tiddlers and a second generation liquid air battery appears to be 200 MW and 2.5 MWh, so they can supply 200 MW for 12.5 hours.

The Blackhillock battery can do just two hours.

Two of them working as a pair, with a 1 GW wind farm, are as big as a small modular nuclear reactor, so could do the same job, with respect to power supply, using machinery and tank designs, that have been used for decades.

I suspect, that like 1960s coal-fired power stations, they would keep running for fifty years and be simply recycled as steel, copper and other scrap.

Highview Power could make Bishops Stortford famous!

Ørsted Breaks Ground On Innovative UK Battery Energy Storage System

The title of this post, is the same as that, as this news item from Ørsted.

This is the sub-heading.

Ørsted, a global leader in offshore wind energy, has marked breaking ground for its first large-scale UK battery energy storage system (BESS) with a golden shovel ceremony.

These four paragraphs give more details of the project.

Located alongside Ørsted’s Hornsea 3 Offshore Wind Farm, near Norwich, Norfolk, the system will have a capacity of 600 MWh (and a 300 MW power rating), equivalent to the daily power consumption of 80,000 UK homes.

The golden shovel ceremony officially kicks off the construction phase of the project, known as Iceni after the Norfolk-based warrior tribe of the Roman era. It is expected to be operational by the end of 2026.

Preparatory works are now complete and the Ørsted, Knights Brown and Tesla Iceni team will continue with the remainder of the installation.

When completed, the battery energy storage system will be one of the largest in Europe.

Note.

- The batteries themselves are from Tesla.

- The project was previously known as the Swardeston BESS.

- The project will be located near to the Swardeston substation to the South of Norwich.

- The project doesn’t seem very innovative to me, as it appears to be a BESS built from Tesla batteries.

Like many batteries, it is designed to supply power for two hours.

Another Possible Reason Not To Buy An Electric Car!

As some will have noticed from this blog; I don’t drive and I don’t even have a car.

But then I wouldn’t buy an electric car.

- The range is pathetic and totally out of my comfort zone after sixty years of driving.

- Like my father I like lightweight vehicles and the weight of an electric car is just too heavy.

- The price of an electric car is totally unsustainable when compared to that of a petrol or diesel car.

- The environmental profile of a large lithium-ion battery is not good and could be improved.

I would say, that an electric car’s payload/price/range/weight profile is totally inferior to that of your average petrol or diesel car today. If petrol or diesel fuel were still available, I wouldn’t give an electric car house room. Luckily because a stroke ruined my eyesight, it’s a choice I don’t have to make.

Yesterday evening, another reason not to buy an electric car reared its ugly head.

Opposite my house is a public charging point for electric vehicles, that was installed by a company in co-operation with Hackney Council.

A driver parked their Tesla by the charger and plugged it in.

When they returned to the car, the charger cable had been stolen.

I suspect that a new cable and getting going again wasn’t very affordable.

Don’t Live In Islington If You’re A Pedestrian!

On Sunday, I went to lunch with my son in Walthamstow.

To catch the bus, I have to negotiate these these traffic lights at Southgate and Balls Pond Roads.

Note that to operate the lights, you must push the button to cross.

As I reached forward to push the button to cross, a car came racing up from Dalston Junction.

- Seeing me standing there with my hand forward, he thought it would be funny to give me a good splashing, which he did by going through the deep water.

- His girlfriend was laughing as she passed close by me in the nearside seat.

- Unfortunately, I didn’t get to read the car’s registration number.

- But I did see the Tesla logo on the boot.

If I had though, judging by the look of the guy and his girl, he might not have been the sort of guy, you report to the police.

What really annoyed me, was having to walk back to my house to change into dry clothes.

I do hope though, that the Borough of Islington fix the levels of the roads to eliminate the flooding.

But they are not good as street presentation as I wrote about in Islington Socialism At Work!

Lakeside Facility Connects To Grid And Becomes UK’s Largest Transmission Connected Battery

The title of this post, is the same as that of this press release from National Grid.

These three bullet points, act as sub-headings.

- National Grid plugs TagEnergy’s 100MW battery project in at its Drax substation.

- Following energisation, the facility in North Yorkshire is the UK’s largest transmission connected battery energy storage system (BESS).

- The facility is supporting Britain’s clean energy transition, and helping to ensure secure operation of the electricity system.

This paragraph introduces the project.

A battery storage project developed by TagEnergy is now connected and energised on the electricity transmission network, following work by National Grid to plug the facility into its 132kV Drax substation in North Yorkshire.

- Lakeside Energy Park’s 100MW/200MWh facility is now the largest transmission connected BESS project in the UK following energisation.

- The new facility will boost the capacity and flexibility of the network, helping to balance the system by soaking up surplus clean electricity and discharging it back when the grid needs it.

- To ensure a safe connection, National Grid, working with its contractor Omexom, upgraded its Drax 132kV substation to accommodate the additional clean power.

- Works included extending the busbars – which enable power flows from generation source on to power lines – upgrading busbar protection and substation control systems, and installing an operational tripping scheme, all of which helps keep the network stable and operating securely.

Owned and operated by TagEnergy – with Tesla, Habitat Energy and RES as project partners – the newly-connected battery will help exploit the clean electricity potential of renewable projects in the region, storing and releasing green energy to power homes and businesses and also helping to relieve any system constraints.

National Grid’s adjacent Drax 400kV substation already hosts the connection for Drax power station – the UK’s largest biomass facility – and will also connect the Eastern Green Link 2 electrical superhighway when it starts importing clean energy from Scotland in 2029.

Drax power station seems to be growing into a large node with several gigawatts of electricity, the UK’s largest BESS, a large biomass power station and the Eastern Green Link 2 electrical superhighway which will import clean energy from Scotland from 2029.

Drax appears to be transforming from the dirty man of the UK into a Jolly Green Giant.

I can see further power stations and sources, storage devices and technology joining the party at Drax.

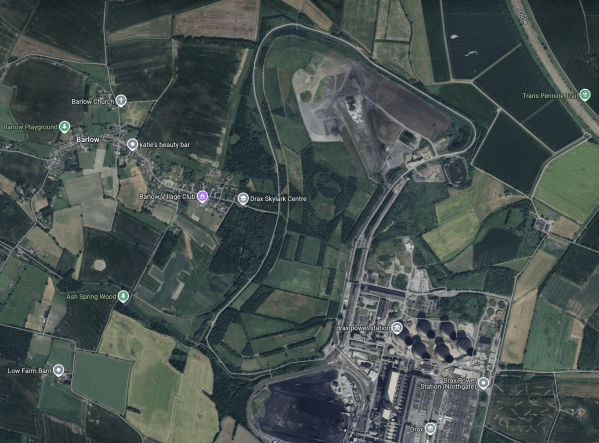

This Google Map shows the Drax site.

Note.

- The cooling towers can be picked out in the South-East quarter of the map.

- The site is rail and road connected, with the River Ouse nearby.

- There is a lot of space.

Surely, Drax would have a big enough space, with a high quality and high capacity electrical connection for Ørsted and Highview Power to put one of their three 200 MW/2.5 GWh batteries, that I talked about in Centrica Business Solutions And Highview Power.

Tesla Megapack Battery Caught Fire At PG & E Substation In California

The title of this post, is the same as that of this article on CNBC, which was published in September 2022.

The article starts with these three key points.

- A Tesla Megapack caught fire at a PG&E energy storage facility in Monterey, California on Tuesday.

- The fire caused road closures and shelter-in-place orders for residents nearby.

- Richard Stedman, an air pollution control officer for the Monterey Bay Air Resources District (MBARD) said in general lithium ion battery fires can emit toxic constituents like hydrochloric and hydrofluoric acid.

The article goes on to say, that there were no power outages and no on-site personnel were injured.

In the late 1960s, I worked for ICI at Runcorn.

One of the instruments, I helped to develop was a detector for water in bromochlorodifluoromethane or BCF, as it is commonly known.

- You may have seen BCF on a fire-extinguisher, as that is the chemical’s main use.

- In those days, ICI made BCF on a plant that also manufactured the anaesthetic; Fluothane.

- The plant was in Rocksavage works by the Mersey.

It should be noted, that Rocksavage works had one of the best safety records in the whole of the company.

When the instrument was ready, I was told to go to the plant and see Charlie Akers, who was the foreman electrician on the plant. He would arrange fitting the instrument to the plant.

- Charlie was a short stout man and the first thing he did was to get a proper mug out of a box of perhaps two dozen new ones and write my name on it.

- He then made us both mugs of fresh tea with fresh milk from a bottle.

- He said something like. “Now you’ve got no excuse to come and see me before you go on the plant or have any questions!”

- He also said that everybody, who worked in Rocksavage was very proud of its safety record and proceeded to give me a tour of the plant pointing out its hazards.

One lesson, I learned that day and still do was to walk up stairs in a hazardous environment using the stanchions of the rails. You never know what has fallen on the handrails. On the BCF plant this could have been hydrochloric and hydrofluoric acid.

- At one point to illustrate the danger of the latter, he took a pair of tweezers and put a spec of hydrofluoric acid (HF) dust on the tip of my finger, which was painful.

- He also said that HBr was a lot more dangerous.

I didn’t disgrace myself on that plant and the lessons, I learned that day have stayed with me all my life. I even think, that they have had positive effects on my stroke recovery, as I was given tips about how to get out of a chemical plant, after a fire or serious spillage.

Thank you Charlie!

One of the key points in the CNBC article, is that lithium-ion battery fires can emit hydrochloric and hydrofluoric acid.

It makes me wonder, if our high levels of usage of these batteries for where there is an alternative is a good idea.

Nikola Highlights Its Integrated Hydrogen Solution And Introduces New Hydrogen Energy Brand “HYLA”

The title of this post, is the same as that of this press release from Nikola Motor.

This is the first paragraph.

Nikola Corporation, a global leader in zero-emission transportation and energy supply and infrastructure solutions, announced at a special event today that it has created a new global brand, HYLA, to encompass the company’s energy products for producing, distributing and dispensing hydrogen to fuel its zero-emissions trucks. More than 300 fleet, government, supplier, energy and media representatives were on site for the announcement at Nikola’s U.S. headquarters in Phoenix, which highlighted the progress made by Nikola’s energy and truck businesses.

The CEO is also quoted as saying.

Nikola is the only company that is successfully integrating a revolutionary new product, the hydrogen fuel cell truck, and the full hydrogen energy infrastructure supply chain under one roof

I suspect that other companies are or will be making similar claims, about similar products.

JCB are certainly showing everything you need for hydrogen-powered construction and agricultural equipment on their web site, as I pointed out in JCB: Building A Hydrogen Future.

When I see anything about Nikola Motor, I feel Elon Musk made a big mistake.

He chose well with the name Tesla, but shouldn’t he have registered Nikola and all its derivatives.

The Stadler Data Sheet For A Class 777 IPEMU

This data sheet is now available on the Stadler web site.

These are my observations.

Battery Charging

The datasheet says this about battery charging.

While an IPEMU is running on the electrified network, the batteries can be charged from the third rail, as well as through regenerative braking.

I’m glad to see the trains have regenerative braking, which in a train with frequent stops saves electricity.

Battery Charging Time

The datasheet says this about battery charging time.

IPEMUs can be recharged in less than 15 minutes.

That time compares favourably with Hitachi’s time.

Expected Battery Life

The datasheet says this about expected battery life.

The IPEMU battery can undergo more than 10,000 charge/discharge cycles, which is about four times the lifetime of a battery used in EVs.

Stadler also give the battery a minimum expected life of eight years.

Transition Between Electrification And Battery

The datasheet says this about this important transition.

Transition between electrified and non-electrified networks without interruption, reducing travel times.

Stadler certainly do the changeover from electric to diesel smoothly on a Class 755 train.

A Comparison To Tesla

This is a paragraph in the introduction of the data sheet.

The battery/vehicle weight-ratio of a Tesla is about 25 per cent, while the ratio of the IPEMU is only about 6 per cent.

I suspect the rolling resistance, is also a lot less, than the rolling resistance of a Tesla, due to the superior properties of steel wheels on rail, as opposed to rubber tyres on road.

Battery Range

The data sheet gives the following.

- Installed battery capacity – 320 KWh

- Maximum speed (IPEMU mode) – 62 mph

- Range in battery operation – 34 miles

- Maximum demonstrated range – 84 miles

Note.

- I would assume the 55 km given for range on the datasheet is a guaranteed range.

- The maximum demonstrated range is from New Merseyrail Train Runs 135km On Battery.

- All other figures are from the datasheet.

In an article in the October 2017 Edition of Modern Railways, which is entitled Celling England By The Pound, Ian Walmsley says this in relation to trains running on the Uckfield Branch, which is not very challenging.

A modern EMU needs between 3 and 5 kWh per vehicle mile for this sort of service.

I don’t think the terrain of Merseyrail’s services are much different from the Uckfield branch, so what are the figures for the Class 777 trains on battery power?

- 55 km range – 2.353 kWh per vehicle mile

- 135 km range – 0.952 kWh per vehicle mile

The train appears to be very miserly with electricity.

But if the attention to detail in the electrical system of the train is of the standard of a Swiss watch, I don’t think they are unreasonable.

Operation With 25 kV Overhead Electrification

The datasheet says nothing about this, but the Wikipedia entry for the Class 777 train says this under Design.

Because current regulatory policy makes it unlikely that future extensions of Merseyrail’s unshielded third rail traction power supply will be approved, Class 777 units will be delivered with provision for the future installation of 25 kV 50 Hz AC overhead line traction equipment.

This is probably needed for charging at locations without third-rail electrification.

Second Life Energy Storage Firm Smartville Inc On Modules vs Packs, Ramp-Up Plans And Tesla’s Approach

The title of this post, is the same as that of this article on Energy Storage News.

I like the concept of taking the life-expired batteries out of electric vehicles and giving them a second life as grid batteries.

Smartville seem to have taken this simple and useful idea to a new level.

These are my thoughts.

The Internet Of Batteries

By the use of clever software, it appears, that they can control different types of battery packs, in a manner that could be called the Internet of Batteries.

They can also measure the state and performance and calculate the replacement date of each battery pack.

The Mother Of All Batteries

The implementation of this concept in their MOAB product allows the controlling software to manage a number of battery packs precisely to deliver a battery of the precise number of MWh, that the customer ordered.

- Provided an interface driver can be written, any type and make of battery pack can be incorporated.

- Nearly new, salvaged or elderly battery packs cab be used.

- The operating system can predict, when a battery pack must be replaced.

- Smartville are planning to install a 4MWh grid battery in central California that will be co-located with an existing power plant.

In some ways, the controlling software, is like the Chief Coach of a tug-of-war team, of mixed sexes, weights and strengths, that by asking for the right level of power from each member, gets the required performance.

Working With Tesla

The article talks about why, they don’t work with Tesla, where this is said.

Our experience in the US is that Tesla does not seem to be interested in working with outside partners. They’ve also publicly stated that they’re not focused on battery repurposing, not in their current business model at least, which I think might change over time. But that’s their public stance at the moment. We’re absolutely open to working directly with them but the opportunity hasn’t presented itself.

Does this indicate, that Tesla and Elon Musk are not the easiest people to deal with?

Conclusion

I shall be following Smartville.

Harmony Energy Income Trust Eyes IPO To Develop 213.5MW Of Tesla Battery Storage

The title of this post, is the same as that of this article on Solar Power Portal.

The article is a very detailed look at Harmony and their development of energy storage, using Tesla hardware and software.

It also has things to say about the energy storage market in general.

This is a paragraph.

Paul Mason, managing director of the Investment Adviser, said battery energy storage offers exciting growth potential, with an expected requirement of up to 43GW by 2050 from just 1.2GW now.

It is certainly looking that companies like Harmony Energy Income Trust will be important in funding this extreme growth of energy storage.