£1.5 billion Enables UK-US Pair To Get Their Hands On Europe’s Giant LNG Terminal

The title of this post, is the same as that of this article on Offshore Energy.

This is the sub-heading.

UK-based energy player Centrica and U.S. investment firm Energy Capital Partners (ECP), part of Bridgeport Group, have brought into their fold a liquefied natural gas (LNG) terminal in Kent County, United Kingdom.

This paragraph gives Centrica’s view of the Grain LNG Terminal.

The UK firm portrays the terminal as Europe’s largest LNG regasification facility, with a capacity of 15 million tonnes of LNG a year. Located on the UK’s Isle of Grain, the terminal features unloading infrastructure, regasification equipment, and truck-loading facilities.

In a press release, which is entitled Investment in Grain LNG, that was published in August 2025, Centrica said this.

Opportunities for efficiencies to create additional near-term value, and future development options including a combined heat and power plant, bunkering, hydrogen and ammonia.

The tone of the article in Offshore Energy and the press release is unmistakable. – Centrica intend to make good use of their investment.

I suggest you read both documents fully.

- Europe’s largest LNG regasification facility, with a capacity of 15 million tonnes of LNG a year, will certainly need a large combined heat and power plant.

- Will any spare power from the CHP plant, be sent to Germany, through the 1.4 GW NeuConnect interconnector, which should be commissioned by 2028?

- Hydrogen, ammonia and LNG are the three low-carbon fuels used by modern ships, so I suspect hydrogen and ammonia will be produced on the island.

- Centrica are investors in the efficient hydrogen-generation process ; HiiROC.

- Hydrogen and nitrogen are the two feedstocks for ammonia.

Centrica certainly have big plans for the Grain LNG Terminal.

I shall be following Centrica closely.

Rolls-Royce Successfully Tests First Pure Methanol Marine Engine – Milestone For More Climate-Friendly Propulsion Solutions

The title of this post, is the same as that of this press release from Rolls-Royce.

These four bullet points act as sub-headings.

- World first: first high-speed 100 percent methanol engine for ships successfully tested

- Cooperation: Rolls-Royce, Woodward L’Orange and WTZ Roßlau are developing sustainable propulsion technology in the meOHmare research project

- Green methanol: CO2-neutral, clean and safe marine fuel

- Dual-fuel engines as a bridging technology on the road to climate neutrality

Rolls-Royce has successfully tested the world’s first high-speed marine engine powered exclusively by methanol on its test bench in Friedrichshafen. Together with their partners in the meOHmare research project, Rolls-Royce engineers have thus reached an important milestone on the road to climate-neutral and environmentally friendly propulsion solutions for shipping.

“This is a genuine world first,” said Dr. Jörg Stratmann, CEO of Rolls-Royce Power Systems AG. “To date, there is no other high-speed engine in this performance class that runs purely on methanol. We are investing specifically in future technologies in order to open up efficient ways for our customers to reduce CO2 emissions and further expand our leading role in sustainable propulsion systems.”

Rolls-Royce’s goal is to offer customers efficient ways to reduce their CO2 emissions, in-line with the ‘lower carbon’ strategic pillar of its multi-year transformation programme. The project also aligns with the strategic initiative in Power Systems to grow its marine business.

These are some questions.

Why Methanol?

Rolls-Royce answer this question in the press release.

Green methanol is considered one of the most promising alternative fuels for shipping. If it is produced using electricity from renewable energies in a power-to-X process, its operation is CO2-neutral. Compared to other sustainable fuels, methanol is easy to store, biodegradable, and causes significantly fewer pollutants.

“For us, methanol is the fuel of the future in shipping – clean, efficient, and climate-friendly. It burns with significantly lower emissions than fossil fuels and has a high energy density compared to other sustainable energy sources,” said Denise Kurtulus.

Note that Denise Kurtulus is Senior Vice President Global Marine at Rolls-Royce.

Could Methanol-Powered Engines Be Used In Railway Locomotives?

Given, there are hundreds of railway locomotives, that need to be decarbonised, could this be handled by a change of fuel to methanol?

I asked Google AI, the question in the title of this section and received the following answer.

Yes, methanol-powered engines can be used in railway locomotives, but they require a modification like high-pressure direct injection (HPDI) technology to be used in traditional compression ignition (CI) diesel engines. These modified engines typically use methanol as the primary fuel with a small amount of diesel injected to act as a pilot fuel for ignition, a process known as “pilot ignition”. Research and simulations have shown that this approach can achieve performance and thermal efficiencies close to those of standard diesel engines

From the bullet points of this article, it looks like Rolls-Royce have this pilot ignition route covered.

How Easy Is Methanol To Handle?

Google AI gave this answer to the question in the title of this section.

Methanol is not easy to handle safely because it is a highly flammable, toxic liquid that can be absorbed through the skin, inhaled, or ingested. It requires rigorous safety measures, proper personal protective equipment (PPE), and good ventilation to mitigate risks like fire, explosion, and severe health consequences, including blindness or death.

It sounds that it can be a bit tricky, but then I believe with the right training much more dangerous chemicals than methanol can be safety handled.

How Easy Is Green Methanol To Produce?

Google AI gave this answer to the question in the title of this section.

Producing green methanol is not easy; it is currently more expensive and capital-intensive than traditional methods due to high production costs, feedstock constraints, and the need for specialized infrastructure. However, new technologies are making it more feasible, with methods that combine renewable energy with captured carbon dioxide and renewable hydrogen to synthesize methanol.

Production methods certainly appear to be getting better and greener.

Which Companies Produce Methanol In The UK?

Google AI gave this answer to the question in the title of this section.

While there are no major, existing methanol production companies in the UK, Proman is planning to build a green methanol plant in the Scottish Highlands, and other companies like Wood PLC and HyOrc are involved in the engineering and construction of methanol production facilities in the UK. Several UK-based companies also act as distributors or suppliers for products, such as Brenntag, Sunoco (via the Anglo American Oil Company), and JennyChem.

It does appear, that we have the capability to build methanol plants and supply the fuel.

How Is Green Methanol Produced?

Google AI gave this answer to the question in the title of this section.

Green methanol is produced by combining carbon dioxide and hydrogen under heat and pressure, where the hydrogen is created using renewable electricity and the carbon dioxide is captured from sustainable sources like biomass or industrial emissions. Two main pathways exist e-methanol uses green hydrogen and captured carbon dioxide, while biomethanol is made from the gasification of biomass and other organic waste.

Note.

- We are extremely good at producing renewable electricity in the UK.

- In Rolls-Royce To Be A Partner In Zero-Carbon Gas-Fired Power Station In Rhodesia, I discuss how carbon dioxide is captured from a power station in Rhodesia, which is a suburb of Worksop.

In the Rhodesia application, we have a Rolls-Royce mtu engine running with carbon-capture in a zero-carbon manner, producing electricity and food-grade carbon-dioxide, some of which could be used to make methanol to power the Rolls-Royce mtu engines in a marine application.

I am absolutely sure, that if we need green methanol to power ships, railway locomotives and other machines currently powered by large diesel engines, we will find the methods to make it.

What Are The Green Alternatives To Methanol For Ships?

This press release from Centrica is entitled Investment in Grain LNG, and it gives hints as to their plans for the future.

This heading is labelled as one of the key highlights.

Opportunities for efficiencies to create additional near-term value, and future development options including a combined heat and power plant, bunkering, hydrogen and ammonia.

Bunkering is defined in the first three paragraphs of its Wikipedia entry like this.

Bunkering is the supplying of fuel for use by ships (such fuel is referred to as bunker), including the logistics of loading and distributing the fuel among available shipboard tanks. A person dealing in trade of bunker (fuel) is called a bunker trader.

The term bunkering originated in the days of steamships, when coal was stored in bunkers. Nowadays, the term bunker is generally applied to the petroleum products stored in tanks, and bunkering to the practice and business of refueling ships. Bunkering operations take place at seaports and include the storage and provision of the bunker (ship fuels) to vessels.

The Port of Singapore is currently the largest bunkering port in the world. In 2023, Singapore recorded bunker fuel sales volume totaling 51,824,000 tonnes, setting a new industry standard.

Note.

- After Rolls-Royce’s press release, I suspect that methanol should be added to hydrogen and ammonia.

- I don’t think Centrica will be bothered to supply another zero-carbon fuel.

- I can see the Isle of Grain providing a lot of fuel to ships as they pass into London and through the English Channel.

- Centrica have backed HiiROC technology, that makes hydrogen efficiently.

I can see the four fuels ammonia, hydrogen, LNG and methanol competing with each other.

What Are The Green Alternatives To Methanol For Railway Locomotives?

The same fuels will be competing in the market and also Hydrotreated Vegetable Oil (HVO) will be used.

Centrica And X-energy Agree To Deploy UK’s First Advanced Modular Reactors

The title of this post, is the same as that of this press release from Centrica.

This is the sub-heading.

Centrica and X-Energy, LLC, a wholly-owned subsidiary of X-Energy Reactor Company, LLC, today announced their entry into a Joint Development Agreement (JDA) to deploy X-energy’s Xe-100 Advanced Modular Reactors (“AMR”) in the United Kingdom.

These three paragraphs add more details.

The companies have identified EDF and Centrica’s Hartlepool site as the preferred first site for a planned U.K. fleet of up to 6 gigawatts.

The agreement represents the first stage in a new trans-Atlantic alliance which could ultimately mobilise at least £40 billion in economic value to bring clean, safe and affordable power to thousands of homes and industries across the country and substantive work for the domestic and global supply chain.

A 12-unit Xe-100 deployment at Hartlepool could add up to 960 megawatts (“MW”) of new capacity, enough clean power for 1.5 million homes and over £12 billion in lifetime economic value. It would be developed at a site adjacent to Hartlepool’s existing nuclear power station which is currently scheduled to cease generating electricity in 2028. Following its decommissioning, new reactors would accelerate opportunities for the site and its skilled workforce. The site is already designated for new nuclear under the Government’s National Policy Statement and a new plant would also play a critical role in generating high-temperature heat that could support Teesside’s heavy industries.

This is no toe-in-the-water project, but a bold deployment of a fleet of small modular reactors to provide the power for the North-East of England for the foreseeable future.

These are my thoughts.

The Reactor Design

The Wikipedia entry for X-energy has a section called Reactor Design, where this is said.

The Xe-100 is a proposed pebble bed high-temperature gas-cooled nuclear reactor design that is planned to be smaller, simpler and safer when compared to conventional nuclear designs. Pebble bed high temperature gas-cooled reactors were first proposed in 1944. Each reactor is planned to generate 200 MWt and approximately 76 MWe. The fuel for the Xe-100 is a spherical fuel element, or pebble, that utilizes the tristructural isotropic (TRISO) particle nuclear fuel design, with high-assay LEU (HALEU) uranium fuel enriched to 20%, to allow for longer periods between refueling. X-energy claims that TRISO fuel will make nuclear meltdowns virtually impossible.

Note.

- It is not a conventional design.

- Each reactor is only about 76 MW.

- This fits with “12-unit Xe-100 deployment at Hartlepool could add up to 960 megawatts (“MW”) of new capacity” in the Centrica press release.

- The 960 MW proposed for Hartlepool is roughly twice the size of the Rolls-Rpoyce SMR, which is 470 MW .

- Safety seems to be at the forefront of the design.

- I would assume, that the modular nature of the design, makes expansion easier.

I have no reason to believe that it is not a well-designed reactor.

Will Hartlepool Be The First Site?

No!

This page on the X-energy web site, describes their site in Texas, which appears will be a 320 MW power station providing power for Dow’s large site.

There appear to be similarities between the Texas and Hartlepool sites.

- Both are supporting industry clustered close to the power station.

- Both power stations appear to be supplying heat as well as electricity, which is common practice on large industrial sites.

- Both use a fleet of small modular reactors.

But Hartlepool will use twelve reactors, as opposed to the four in Texas.

How Will The New Power Station Compare With The Current Hartlepool Nuclear Power Station?

Consider.

- The current Hartlepool nuclear power station has two units with a total capacity of 1,185 MW.

- The proposed Hartlepool nuclear power station will have twelve units with a total capacity of 960 MW.

- My instinct as a Control Engineer gives me the feeling, that more units means higher reliability.

- I suspect that offshore wind will make up the difference between the power output of the current and proposed power stations.

As the current Hartlepool nuclear power station is effectively being replaced with a slightly smaller station new station, if they get the project management right, it could be a painless exercise.

Will This Be The First Of Several Projects?

The press release has this paragraph.

Centrica will provide initial project capital for development with the goal of initiating full-scale activities in 2026. Subject to regulatory approval, the first electricity generation would be expected in the mid-2030s. Centrica and X-energy are already in discussions with additional potential equity partners, as well as leading global engineering and construction companies, with the goal of establishing a UK-based development company to develop this first and subsequent projects.

This approach is very similar to the approach being taken by Rolls-Royce for their small modular reactors.

Will Centrica Use An X-energy Fleet Of Advanced Modular Reactors At The Grain LNG Terminal?

This press release from Centrica is entitled Investment In Grain LNG Terminal.

This is one of the key highlights of the press release.

Opportunities for efficiencies to create additional near-term value, and future development options including a combined heat and power plant, bunkering, hydrogen and ammonia.

Note.

- Bunkering would be provided for ships powered by LNG, hydrogen or ammonia.

- Heat would be needed from the combined heat and power plant to gasify the LNG.

- Power would be needed from the combined heat and power plant to generate the hydrogen and ammonia and compress and/or liquify gases.

Currently, the heat and power is provided by the 1,275 MW Grain CHP gas-fired power station, but a new nuclear power station would help to decarbonise the terminal.

Replacement Of Heysham 1 Nuclear Power Station

Heysham 1 nuclear power station is part-owned by Centrica and EdF, as is Hartlepool nuclear power station.

Heysham 1 nuclear power station is a 3,000 MW nuclear power station, which is due to be decommissioned in 2028.

I don’t see why this power station can’t be replaced in the same manner as Hartlepool nuclear power station.

Replacement Of Heysham 2 Nuclear Power Station

Heysham 2 nuclear power station is part-owned by Centrica and EdF, as is Hartlepool nuclear power station.

Heysham 2 nuclear power station is a 3,100 MW nuclear power station, which is due to be decommissioned in 2030.

I don’t see why this power station can’t be replaced in the same manner as Hartlepool nuclear power station.

Replacement Of Torness Nuclear Power Station

Torness nuclear power station is part-owned by Centrica and EdF, as is Hartlepool nuclear power station.

Torness nuclear power station is a 1,290 MW nuclear power station, which is due to be decommissioned in 2030.

I don’t see why this power station can’t be replaced in the same manner as Hartlepool nuclear power station.

But the Scottish Nationalist Party may have other ideas?

What Would Be The Size Of Centrica’s And X-energy’s Fleet Of Advanced Modular Reactors?

Suppose.

- Hartlepool, Grain CHP and Torness power stations were to be replaced by identical 960 MW ADRs.

- Heysham 1 and Heysham 2 power stations were to be replaced by identical 1,500 MW ADRs.

This would give a total fleet size of 5,880 MW.

A paragraph in Centrica’s press release says this.

The companies have identified EDF and Centrica’s Hartlepool site as the preferred first site for a planned U.K. fleet of up to 6 gigawatts.

This fleet is only 120 MW short.

Centrica Enters Into Long Term Natural Gas Sale & Purchase Agreement

The title of this post, is the same as this press release from Centrica.

This is the sub-heading,

Centrica plc today confirmed that its trading arm, Centrica Energy, has entered into a natural gas sale and purchase agreement with US-based Devon Energy Corporation.

This first paragraph adds a few more details.

Under the agreement, Devon Energy will supply 50,000 (MMBtu) per day of natural gas over a 10‑year term starting in 2028. This is equivalent to five LNG cargoes per year. The volumes will be indexed to European gas hub price (TTF). This sale and purchase agreement supports Centrica’s objective of managing market price risk in its LNG portfolio by aligning feed gas pricing with European gas prices whilst providing Devon Energy with international price exposure.

At a first look, it looks a lot of gas.

In Investment In Grain LNG, I talk about Centrica’s purchase of the Grain LNG Terminal from National Grid. But the Grain LNG Terminal comes with several things that Centrica might need for gas from Devon.

- A large amount of gas storage.

- The ability to convert liquid natural gas (LNG) into gas suitable for consumers.

- Space to build more storage if required.

- The ability to store LNG for other companies.

- Two jetties for delivering the LNG to the Grain LNG Terminal.

- The ability to load tankers with LNG, so that it can be sold on to third parties like say the Germans or the Poles.

Centrica also say this about their use of the Grain LNG Terminal in this press release, that describes the purchase of the terminal.

Aligned with Centrica’s strategy of investing in regulated and contracted assets supporting the energy transition, delivering predictable long-term, inflation-linked cash flows, with 100% of capacity contracted until 2029, >70% until 2038 and >50% until 2045.

Centrica have obviously modelled their gas supply and delivery and I believe they have come up with a simple strategy, that will work.

How Will Centrica Use The Gas From The Grain LNG Terminal?

The Wikipedia entry for the Grain LNG Terminal says this about the terminal delivering gas into the gas grid.

The terminal can handle up to 15 million tonnes per annum of LNG, has a storage capacity for one million cubic metres of LNG, and is able to regasify up to 645 GWh per day (58 million cubic metres per day) for delivery into the high pressure gas National Transmission System (NTS).

Note.

- This will be one of the major uses of the gas.

- I wouldn’t be surprised if these capacities will be increased significantly, so that more gas can be stored and processed.

In Investment in Grain LNG, I outlined how I believe that hydrogen and ammonia will be produced for the bunkering of ships on one of busiest sea lanes in Europe, if not the world.

Some LNG will be used to create these zero-carbon fuels.

Some modern ships, also run on natural gas, so I asked Google AI about their operation and received this answer.

Ships can run on natural gas, specifically liquefied natural gas (LNG), by using it as a fuel source in specially designed engines. LNG is natural gas that has been cooled to a liquid state at -162°C, making it easier to store and transport. This liquid form is then used to power the ship’s engines, either directly or by burning the boil-off gas (BOG) that naturally occurs when LNG warms up.

This means that some LNG could be used to directly fuel these ships.

What Is The Gas Capacity Of The Grain LNG Terminal?

I asked Google AI this question and received this answer.

The Grain LNG Terminal, the largest LNG import terminal in Europe, has a storage capacity of 1,000,000 cubic meters (m³) and an annual throughput capacity of 15 million tonnes of LNG. This is equivalent to about 20% of the UK’s total gas demand. The terminal also has the capacity to deliver 25% of the UK’s daily gas demand.

As the space is there, I wouldn’t be surprised to see Centrica increase the capacity of the terminal, as in cold weather, emergency gas for Germany can be delivered quicker from Kent than the United States.

Could The Grain LNG Terminal Accept Gas Deliveries From The United States?

I’m certain that it already does.

Could The Grain LNG Terminal Accept Gas Deliveries From The UK?

If we start extracting gas again from under the seas around the UK, could the Grain LNG Terminal be used to store it?

Yes, but it would have to be liquified first.

It would be more energy efficient to process the extracted gas, so it could be used directly and gasify enough gas at Grain LNG Terminal from storage to make up any shortfall.

Conclusion

Centrica have done some very deep joined up thinking, by doing a long term gas deal and the Grain LNG Terminal purchase so that they have the gas to supply and somewhere to keep it, until it is needed.

Investment in Grain LNG

The title of this post, is the same as that of this press release from Centrica.

This sub-heading outlines the deal.

Centrica plc (the “Company”, “Centrica”) is pleased to announce the acquisition of the Isle of Grain liquified natural gas terminal (“Grain LNG”) in partnership1 with Energy Capital Partners LLP (“ECP”) from National Grid group (“National Grid”) for an enterprise value of £1.5 billion. After taking into account approximately £1.1 billion of new non-recourse project finance debt, Centrica’s 50% share of the equity investment is approximately £200 million.

The press release lists these key points.

- Grain LNG delivers vital energy security for the UK, providing critical LNG import/export, regasification and rapid response gas storage capacity to balance the energy system.

- Aligned with Centrica’s strategy of investing in regulated and contracted assets supporting the energy transition, delivering predictable long-term, inflation-linked cash flows, with 100% of capacity contracted until 2029, >70% until 2038 and >50% until 2045.

- Opportunities for efficiencies to create additional near-term value, and future development options including a combined heat and power plant, bunkering, hydrogen and ammonia.

- Highly efficient funding structure, with Centrica’s equity investment of approximately £200 million alongside non-recourse project financing.

- Strong life of asset returns aligned with Centrica’s financial framework, with an expected unlevered IRR2 of around 9% and an equity IRR2 of around 14%+

Underpins delivery of £1.6 billion end-2028 EBITDA target3 – Centrica’s share of EBITDA expected to be approximately £100 million per annum and cash distributions expected to be around £20 million on average per annum for 2026-2028, representing an attractive yield on Centrica’s equity investment - Partnership with ECP (part of Bridgepoint Group plc), one of the largest private owners of natural gas generation and infrastructure assets in the U.S. with direct experience in supporting grid reliability.

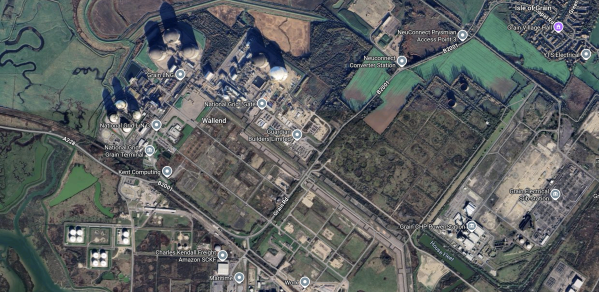

This Google Map shows the various energy assets on the Isle of Grain.

Note.

- It appears that works for the 1, 400 MW NeuConnect interconnector to Wilhelmshaven in Germany, are taking place in the North-East corner of the map.

- Grain CHP powerstation is a 1,275MW CCGT power station, which is owned by German company; Uniper, that is in the South-East corner of the map, which can also supply up to 340MW of heat energy recovered from the steam condensation to run the vapourisers in the nearby liquefied natural gas terminal.

- The Grain LNG terminal is at the Western side of the map.

- In the Thames Estuary to the East of the Isle of Grain, I estimate that there are about 1,500 MW of wind turbines.

I find it interesting that two of the assets are German owned.

I have some thoughts.

It Is A Large Site With Space For Expansion

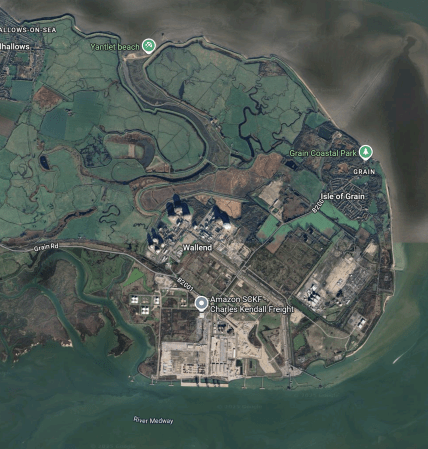

This Google Map shows the whole of the Isle of Grain.

Note.

- The Grain LNG terminal is around the label Wallend.

- The River Medway runs East-West at the bottom of the map.

- Gas tankers deliver and take on gas at jetties on the North Bank of the Medway.

There could be space to expand the terminal, if the RSPB would allow it.

As an example, I asked Google AI, if peregrine falcons nest on chemical plants and got this reply.

Yes, peregrine falcons do nest on chemical plants. They have adapted to using various urban and industrial structures, including chemical plants, for nesting. This is particularly true in areas where natural cliff habitats are scarce.

Peregrine falcons are known for their adaptability, and their population has seen a resurgence in recent decades, partly due to their ability to utilize man-made structures. These structures often mimic their natural cliffside nesting

Cliffs do seem scarce on the Isle of Grain. I also asked Google AI, if peregrine falcons ate small rodents, as several chemical and other plants, where I’ve worked, had a rodent problem. One plant had a cat problem, as there had been so many rats. This was the reply.

Yes, peregrine falcons do eat small rodents, though they primarily consume birds. While their diet mainly consists of other birds like pigeons, doves, and waterfowl, they will also hunt and eat small mammals, including rodents such as mice, rats, and voles. They are opportunistic hunters and will take advantage of readily available prey, including insects, amphibians, and even fish.

I’m sure if Centrica wanted to expand, they’d employ the best experts.

Who Are ECP?

One of the key points of the press release is that this deal is a partnership with ECP (part of Bridgepoint Group plc), one of the largest private owners of natural gas generation and infrastructure assets in the U.S. with direct experience in supporting grid reliability.

The Wikipedia entry for ECP or Energy Capital Partners has this first section.

Energy Capital Partners Management, LP (ECP) is an American investment firm headquartered in Summit, New Jersey. It focuses on investments in the energy sector. The firm has additional offices in New York City, Houston, San Diego, Fort Lauderdale and Seoul.

In August 2024, ECP merged with Bridgepoint Group to form a private assets investment platform.

The Wikipedia entry for the Bridgepoint Group has this first paragraph.

Bridgepoint Group plc is a British private investment company listed on the London Stock Exchange and is a constituent of the FTSE 250 Index.

The company had started as part of NatWest.

Are The Germans Going To Take Away Some Of Our Electricity?

Consider.

- Germany has a big need to replace Russian gas and indigenous coal, and to decarbonise.

- Neuconnect is a 1.4 GW interconnector between the Isle of Grain and Wilhelmshaven in Germany. It is scheduled to be completed in 2028.

- The Grain CHP powerstation is a 1,275MW CCGT power station, which is owned by German company; Uniper, could almost keep NeuConnect working at full power on its own.

- I said earlier, in the Thames Estuary to the East of the Isle of Grain, I estimate that there are about 1,500 MW of wind turbines. One of which is part German-owned.

The Germans are also building a large electrolyser at Wilhelshaven, which is described by Google AI like this.

The Wilhelmshaven Green Energy Hub will initially feature a 500MW electrolyzer, with plans to potentially expand to 1GW, according to Energy Monitor. The hub, a joint project between Tree Energy Solutions (TES) and EWE, aims to produce green hydrogen using renewable energy sources like offshore wind. The 500MW electrolyzer is scheduled to be operational by 2028.

I wouldn’t be surprised to see that the Wilhelmshaven electrolyser were to be powered by British-generated electricity flowing down NeuConnect.

Centrica Says Their Future Development Options Include A Combined Heat And Power Plant

This objective was set in one of the key points.

This is the first paragraph of the Wikipedia entry for the Grain LNG Terminal.

Grain LNG Terminal is a Liquefied Natural Gas (LNG) terminal on the Isle of Grain, 37 miles (60 km) east of London. It has facilities for the offloading and reloading of LNG from ships at two jetties on the River Medway; for storing and blending LNG; for truck loading; and regasifying and blending natural gas to meet UK specifications. The terminal can handle up to 15 million tonnes per annum of LNG, has a storage capacity for one million cubic metres of LNG, and is able to regasify up to 645 GWh per day (58 million cubic metres per day) for delivery into the high pressure gas National Transmission System (NTS). The facility is owned and operated by National Grid Grain LNG Ltd, a wholly owned subsidiary of National Grid.

Note.

- This paragraph was written before the Centrica takeover.

- The terminal also converts liquid natural gas into gas to be distributed around the UK.

The heat needed to convert the liquid natural gas to gas is provided by the Grain CHP power station.

- Currently 340 MW of heat is provided.

- If the Grain LNG terminal is expanded, it will probably need more heat.

I can see Centrica building a combined heat and power (CHP) power station, that can be expanded to meet the current and future needs of gasification at the Grain LNG terminal.

I wouldn’t be surprised to see the CHP power station fitted with carbon capture, as Kent is surely one county, where carbon dioxide can be used in food production, so we can generate our carbon dioxide and eat it.

Centrica Says Their Future Development Options Include Hydrogen

This objective was set in one of the key points.

Consider.

- Centrica are an investor in HiiROC, who have a unique method of generating affordable zero-carbon hydrogen called thermal plasma electrolysis, which uses a fifth of the electricity, that traditional electrolysis does.

- HiiROC can use natural gas as a feedstock. Centrica won’t be short of that at Grain.

- There is space to build a large HiiROC system at the Isle of Grain site.

- The hydrogen could be taken away by tanker ships.

Like the electricity , which will use the 450 mile NeuConnect interconnector, the hydrogen could even be exported to Wilhelmshaven in Germany by pipeline.

Wilhelmshaven is being setup to be a major German hub to both generate, import and distribute hydrogen.

I asked Google AI, how much hydrogen a GWh would produce and received this answer.

A GWh of electricity can produce approximately 20-22 tonnes of hydrogen through electrolysis, depending on the efficiency of the electrolyzer. Modern commercial electrolyzers operate at an efficiency of roughly 70-80%, meaning they require about 50-55 kWh of electricity to produce 1 kg of hydrogen. A GWh (1 gigawatt-hour) is equal to 1,000,000 kWh, and 1 tonne of hydrogen contains roughly 33.33 MWh of energy.

As it is claimed on the web that HiiROC is five times more efficient than traditional electrolysis, it could need around 10-11 kWh to produce one kg. of hydrogen.

1 GWh would produce between 90-100 tonnes of hydrogen.

Centrica Says Their Future Development Options Include Ammonia

This objective was set in one of the key points.

I asked Google AI if ammonia can be produced from hydrogen and received this answer.

Yes, ammonia (NH3) can be produced from hydrogen (H2) through a process called the Haber-Bosch process. This process involves combining hydrogen with nitrogen (N2) from the air, under high temperature and pressure, in the presence of a catalyst.

Ammonia has a large number of uses, including making fertiliser and the powering of large ships.

I asked Google AI, if there are small Haber-Bosch processes to make ammonia from hydrogen and nitrogen and received this answer.

Yes, there are efforts to develop smaller-scale Haber-Bosch processes for ammonia production. While the traditional Haber-Bosch process is typically associated with large industrial plants, research and development are exploring ways to adapt it for smaller, distributed production, particularly for localized fertilizer or fuel applications.

I wondered if Centrica are involved in the efforts to develop smaller-scale Haber-Bosch processes for ammonia production.

Google AI gave me this quick answer.

Centrica is involved in research related to the Haber-Bosch process, particularly in the context of transitioning to a low-carbon energy future. They are exploring how to adapt the Haber-Bosch process, which is crucial for fertilizer production but also a significant source of CO2 emissions, to utilize renewable energy sources. This includes investigating the use of green hydrogen produced from water electrolysis and renewable electricity. Centrica is also involved in research related to using ammonia as a fuel, including potentially for power generation

That looks to be a very positive answer. Especially, as local low-carbon fertiliser production could be a very powerful concept.

Centrica Says Their Future Development Options Include Bunkering

This objective was set in one of the key points.

Bunkering is the process of refuelling ships.

I didn’t know much about bunkering, when I started to read Centrica’s press release, but the Wikipedia entry, was a good way to get some information.

This section in the Wikipedia entry is entitled Two Types Of Bunkering, where this is said.

The two most common types of bunkering procedure at sea are “ship to ship bunkering” (STSB), in which one ship acts as a terminal, while the other moors. The second type is “stern line bunkering” (SLB), which is the easiest method of transferring oil but can be risky during bad weather.

Over the years, I have found, that two zero-carbon fuels are under development, for powering ships; hydrogen and ammonia. Others are developing ships powered by naturalo gas.

I asked Google AI if hydrogen can power ships and received this answer.

Yes, hydrogen can power ships. It can be used as a fuel for fuel cells, which generate electricity to power the ship’s propulsion and other systems, or it can be burned in modified combustion engines. Hydrogen offers a zero-emission solution for shipping, with water vapor being the only byproduct when used in fuel cells.

Google AI also told me this.

The world’s first hydrogen-powered cruise ship, the “Viking Libra”, is currently under construction and is scheduled for delivery in late 2026. This innovative vessel, a collaboration between Viking Cruises and Italian shipbuilder Fincantieri, will utilize hydrogen for both propulsion and electricity generation, aiming for zero-emission operation.

I also asked Google AI if ammonia can power ships and received this answer.

Yes, ammonia can be used to power ships and is considered a promising alternative fuel for the maritime industry. Several companies and organizations are actively developing ammonia-powered ship designs and technologies. While challenges remain, particularly around safety and infrastructure, ammonia is seen as a key potential fuel for decarbonizing shipping.

Finally, I asked I asked Google AI if natural gas can power ships and received this answer.

Yes, ships can be powered by natural gas, specifically in the form of liquefied natural gas (LNG). LNG is increasingly used as a marine fuel, offering environmental benefits over traditional fuels like diesel.

It would seem to be a case of you pays your money and makes a choice between one of four technologies; ammonia, hydrogen fuel-cell, hydrogen-ICE and LNG.

I looks to me, that if Centrica provide bunkering services for ships, they have the means to cover most of the market by providing hydrogen and ammonia, in addition to natural gas.

Although, I don’t know much about bunkering, I do feel that the two current methods, that work for oil, could be made to work for these fuels.

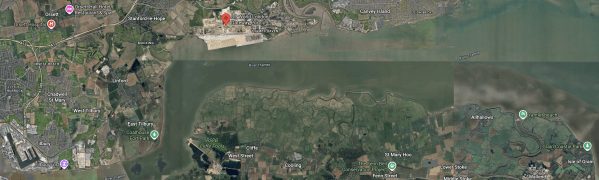

This Google Map shows the Thames Estuary.

Note.

- The Port of Tilbury is in the South-West corner of the map.

- London Gateway is indicated by the red arrow.

- The Isle of Grain is in the South-East corner of the map.

- Other ports between Tilbury and the Isle of Grain include Barking, Dagenham, Dartford, Erith, Greenwich, Northfleet, Purfleet, Silvertown and Thurrock.

There was never a more true phrase than – “Location, Location and Location”. And the Isle of Grain would appear to be in the right place to send out a bunkering tanker to a passing ship, that was calling at a port in London or just passing through the Strait of Dover.

This Google Map shows the Thames between London Gateway and the Isle of Grain.

Note.

- London Gateway is indicated by the red arrow.

- The Isle of Grain is in the South-East corner of the map.

It seems to me, that a refuelling philosophy could easily be worked out.

How Large is The Bunkering Market?

I asked Google AI this question and received this answer.

The world bunker fuel market is a multi-billion dollar industry, with the market size valued at USD 150.93 billion in 2023. It is projected to reach USD 242.29 billion by 2032, growing at a CAGR of 5.4% according to SkyQuest Technology. In terms of volume, the global bunker demand was estimated at 233.1 million metric tons in 2023 according to the IMO.

The market is not small!

Why Firms Are Racing To Produce Green Ammonia

The title of this post, is the same as that of this article on the BBC.

This is the sub-heading.

In the 19th Century, Europeans realised what the Inca had known long before. Bird droppings, or guano, made a fantastic fertiliser.

These are the first three paragraphs.

And so sprang up a gigantic industry dedicated to the harvesting of guano from Latin American bird colonies, where there were huge piles of the stuff.

It was so rich in ammonia, the key ingredient, that a mere whiff could induce coughing and sneezing. Not exactly a pleasant cargo to ferry across the world.

As demand for fertiliser rose in the early 1900s, someone began to think, “Perhaps there’s another way?” That someone was Fritz Haber, a German chemist who, along with Carl Bosch, developed the Haber-Bosch process for synthesising ammonia.

This Wikipedia entry describes the Haber-Bosch process.

This is the first paragraph.

The Haber process, also called the Haber–Bosch process, is the main industrial procedure for the production of ammonia. The German chemists Fritz Haber and Carl Bosch developed it in the first decade of the 20th century. The process converts atmospheric nitrogen (N2) to ammonia (NH3) by a reaction with hydrogen (H2) using an iron metal catalyst under high temperatures and pressures. This reaction is slightly exothermic (i.e. it releases energy), meaning that the reaction is favoured at lower temperatures and higher pressures. It decreases entropy, complicating the process. Hydrogen is produced via steam reforming, followed by an iterative closed cycle to react hydrogen with nitrogen to produce ammonia.

These companies are mentioned in the BBC article.

Starfire Energy

This is their web site.

Their home page has a title of Modular, Variable-Rate Ammonia (NH3) Production and this description of their technology.

We are scaling up technologies to make and use carbon-free ammonia fuel. Rapid Ramp is a variable-rate ammonia production process engineered into a modular plant design. Prometheus Fire is a lower temperature, high flow ammonia cracking process that allows ammonia to be used like natural gas, but with no CO2 emissions.

According to the co-founder of the company, Starfire’s process can use intermittent power, like wind and solar.

Could a farmer make their own fertiliser with a containerised system and say a 5MW wind turbine or a small solar farm?

Atmonia

This is their web site.

This description of their process is on their home page.

Atmonia is developing a nitrogen electrolyser with our patented catalyst. The technology uses only air, water and electricity for direct ammonia production. This enables zero carbon ammonia production, when applying renewable electricity.

Could a farmer make their own fertiliser with a containerised system and say a 5MW wind turbine or a small solar farm?

Jupiter Ionics

This is their web site.

Their home page has an endless video and this statement.

We’re commercialising carbon-neutral, electrochemical technology for sustainable agriculture, ammonia-fuelled transport and renewable energy exports.

These three paragraphs in the BBC article, say more about the process used by Jupiter Ionics.

Jupiter Ionics is currently planning to build an ammonia production module on the megawatt scale, which could produce a tonne per day.

Jupiter Ionics’ technology differs from Starfire Energy and Atmonia’s in that it uses lithium as a mediator to break apart nitrogen molecules, which naturally exist as strongly bonded pairs of nitrogen atoms, to form lithium nitride. This then reacts with hydrogen to make the ammonia.

Within the next 12-18 months, Jupiter Ionics aims to scale up its equipment so that it can produce a kilogram of ammonia per day. A grape farmer in the state of Victoria who has solar panels on his land is hoping to trial the system, says Prof MacFarlane.

It appears that Starfire Energy, Atmonia and Jupiter have containerised systems, that can take air, water and electricity and can create sizeable quantities of ammonia for fertiliser or a fuel.

This page on the Ammonia Energy Association web site is entitled Amogy: Ammonia-Powered Tractor, where this is said, alongside a picture of a standard John Deere tractor.

Earlier this month, Amogy demonstrated a new ammonia-powered tractor in Stony Brook, New York. A 100 kW ammonia-to-power system was successfully integrated into a John Deere mid-size standard tractor, which can operate on liquid ammonia fuel for a period of several hours. The tractor conversion demonstration was made possible by significant seed funding secured in late 2021.

The unique system is comprised of a standard liquid-storage tank and highly efficient ammonia-cracking modules integrated into a hybrid fuel cell system, which can provide consistent primary power for several hours per refueling. Therefore, the pioneering vehicle maintains the functionality and duration requirements operators rely on to support farming tasks, which has never been offered with other alternative energy solutions. The ammonia-powered tractor was driven for separate periods, with a refueling session in between. Refueling a tractor with liquid ammonia is fast and simple, similar to gas or diesel refueling.

This is Amogy’s web site.

I can also see a problem, if every farmer of a certain size wants to make their own ammonia for both fertiliser and fuel.

The NIMBYs will have a field day, but at least the countryside’s low-life won’t be nicking your diesel.

Nitricity

The BBC article also talks about Nitricity.

As Josh McEnaney, president and chief executive of Nitricity in the US, explains, spreading ammonia on fields results in greenhouse gas emissions that could be avoided if we took a more direct approach to applying nitrogen, the crucial element that promotes plant growth, to the soil.

His company is developing a system that uses solar-powered plasma cells to fix nitrogen from the air. This is then used to make nitric acid, which can be applied to the soil. Early experiments with tomato plants yielded success and the company is now trialling its technology with suppliers for the US fast food chain Chipotle.

“We don’t require any hydrogen production,” says Dr McEnaney. “We go straight for the fertiliser.”

This is the Nitricity web site.

Two Experts Give Their Views

The BBC article finishes with the views of two experts.

Bill David at the University of Oxford points out that, around the world, there is already lots of infrastructure designed to store and transport ammonia.

He praises large projects for manufacturing ammonia using renewable energy, such as the one in Uzbekistan that will reportedly spew out 454,000 tonnes of ammonia per year with the help of 2.4 gigawatts of wind energy.

While ammonia can be used as a fuel, it can also be cracked to release hydrogen, which may itself be burned as a fuel, points out Lindsey Motlow, senior research associate at Darcy Partners, a technology firm that works with the oil and gas industry.

“We’re seeing real progress in [the] development of ammonia cracking technology,” she says.

Conclusion

According to the BBC article, two percent of the carbon dioxide emitted on the planet comes from the creation of fertiliser.

So it looks like we can either fry or starve, if we don’t address the problem of zero-carbon fertiliser.

But the downside could be every farm having its own wind turbine.

The BBC article and the related web sites are a must-read.

Centrica Energy, Bord Gáis Energy And Mitsubishi Power Announce Development Of Europe’s First Ammonia Fired Power Generation Facility

The title of this post, is the same as that of this press release from Centrica.

This is the sub-heading.

Centrica plc and Mitsubishi Power Europe Limited “Mitsubishi Power Europe” have signed a Memorandum of Understanding (MOU) to explore the development, construction, and operation of Europe’s first-ever ammonia-fired power generation facility at Bord Gáis Energy’s Whitegate Combined Cycle Gas Turbine (CCGT) power station in Cork, Ireland.

These four paragraphs outline the project.

The project is being led by Centrica through its Bord Gáis Energy and Centrica Energy businesses and Mitsubishi Power Europe and would become Europe’s inaugural ammonia-fired power generation facility and one of only two such facilities in the world.

The utilisation of low carbon ammonia as a clean and sustainable fuel source for power generation has the potential to provide security of supply while reducing greenhouse gas emissions. Low carbon ammonia has a higher volumetric density than hydrogen, enabling the utilisation of low carbon hydrogen in a form which is easy to transport and store, resulting in a fuel that can be combusted with no carbon emissions at point of use. Its use as a fuel is a promising long-term energy solution for the transition to a low-carbon energy value chain.

Bord Gáis Energy’s facility at Whitegate CCGT power station would serve as a global demonstration site for ammonia-fired power generation technology, providing insight into the feasibility and scalability of low carbon ammonia as a green fuel and shaping the future of power generation worldwide, with low carbon ammonia being sourced through Centrica Energy’s global trading network.

Following the signing of the MOU, the project team is being established to commence project feasibility assessments. Upon the successful outcome of this assessment, extensive local stakeholder engagement will commence.

Note.

- No mention of the size of the new power station is given in the press release.

- Whitegate power station is a 445 MW combined cycle gas turbine (CCGT), that was built in 2010.

- It can meet ten percent of Ireland’s electricity demand.

I have a few thoughts.

Will The Existing Power Station Be Converted To Ammonia Or Will A New Ammonia-Fired Power Station Be Built Alongside?

Consider.

- If the second station doesn’t work, there’s no reduction in power.

- If a replacement station doesn’t work, ten percent of Ireland will be in the dark.

- Ireland will be needing more power in the next few years.

- A second power station can be appropriately-sized.

- Japanese don’t like to lose face!

Prudence probably says that building a second station alongside is the least risky route.

Wind Power In Ireland

This Wikipedia entry is entitled Wind Power In Ireland.

This is the first paragraph.

As of 2021 the island of Ireland has 5,585 megawatt and the Republic of Ireland has 4,309 MW of installed wind power nameplate capacity, the third highest per capita in the world. In 2020 wind turbines generated 36.3% of Ireland’s electrical demand, one of the highest wind power penetrations in the world.

There is also one 500 MW interconnector between the islands of Great Britain and Ireland, with another similar-sized one under construction.

As the wind doesn’t blow all the time, the island of Ireland will need some low-carbon backup.

Why Ammonia?

This paragraph from the press release gives several reasons.

The utilisation of low carbon ammonia as a clean and sustainable fuel source for power generation has the potential to provide security of supply while reducing greenhouse gas emissions. Low carbon ammonia has a higher volumetric density than hydrogen, enabling the utilisation of low carbon hydrogen in a form which is easy to transport and store, resulting in a fuel that can be combusted with no carbon emissions at point of use. Its use as a fuel is a promising long-term energy solution for the transition to a low-carbon energy value chain.

There may also be secondary issues here.

If you read the Applications section in the Wikipedia entry for ammonia, you will realise, what a useful chemical ammonia is.

As Ireland has a lot of agriculture, a fertiliser plant could be located close to the power station.

If the ammonia was green ammonia, then this will help to decarbonise the island of Ireland.

Where Will The Green Ammonia Come From?

These posts deal with the production and distribution of green ammonia.

- Could West Africa Become A Green Energy Powerhouse?

- H2U Eyre Peninsula Gateway Hydrogen Project Begins Largest Green Ammonia Plant

- KEPSA Signs Large-Scale Green Energy Projects MoU In Kenya

- Namibia Is Building A Reputation For The Cheapest Green Hydrogen

- Uniper To Make Wilhelmshaven German Hub For Green Hydrogen; Green Ammonia Import Terminal

Note.

- A continent with a lot of renewable energy like Africa or Australia can create lots of green ammonia.

- As the press release says, ammonia is easier to transport and store compared to hydrogen.

- The press release says that low carbon ammonia will be sourced through Centrica Energy’s global trading network.

- Fortescue Future Industries is mentioned in several posts, as producers of green hydrogen and green ammonia.

- Centrica is big enough to stand up to Andrew “Twiggy” Forrest and Fortescue Future Industries.

As in a few years, we will have many GWs of renewable energy, could we be making green ammonia for the Irish?

This news story on the UK Research and Innovation web site is entitled Designs For Green Ammonia Plant Become Reality.

This is the sub-heading.

Science and Technology Facilities Council (STFC) researchers are building a small-scale plant to generate ammonia using only renewable energy sources.

These two paragraphs outline the story.

Ammonia is a promising carbon-free fuel source of the future and so if successful, the plant has the potential to considerably advance the UK’s net zero ambitions.

It marks the second phase of the Ammonia Synthesis Plant from Intermittent Renewable Energy (ASPIRE) initiative which will be led by STFC in conjunction with the University of Bath, Johnson Matthey, and Frazer-Nash Consultancy.

The UK Research and Innovation news story has this description of the ASPIRE technology.

Current commercial ammonia synthesis is optimised for near steady production requiring constant power.

The first phase of ASPIRE however saw the design of a patented modular reactor and thermal management system that should enable operation from an intermittent renewable power supply.

The new plant will have three core elements:

- a pressure swing adsorption system which extracts nitrogen from air

- a modular electrolyser which splits hydrogen from water

- a synthesis loop that uses the modular reactor and a thermal management system to combine hydrogen and nitrogen to make ammonia

This will enable the entire production process to operate autonomously, powered by a small wind turbine and series of solar canopies with an ammonia generation rate proportional to the available renewable power.

There is even this quote from a Dr. Alan Partridge.

Thanks to the incredible work on this initiative by the team at Rutherford Appleton Laboratory as well as the University of Bath and private sector partners, we are closer than ever to producing industry-scale green ammonia for the UK and the world.

Perhaps, this technology will allow the island of Ireland to make all the green ammonia it needs.

Will Centrica Be Going Into The Green Ammonia Business?

The Centrica press release says they will be dealing in green ammonia for the benefit of Ireland. So Yes!

Conclusion

The news story on the UK Research and Innovation web site is a must-read.

As we have so much renewable energy in the UK, some company will build an ASPIRE-based green ammonia plant in the UK.

Air Liquide Paves The Way For Ammonia Conversion Into Hydrogen With New Cracking Technology

The title of this post, is the same as that of this article on Hydrogen Central.

These two paragraphs outline the story.

Air Liquide announces the construction of an industrial scale ammonia (NH3) cracking pilot plant in the port of Antwerp, Belgium. When transformed into ammonia, hydrogen can be easily transported over long distances. Using innovative technology, this plant will make it possible to convert, with an optimized carbon footprint, ammonia into hydrogen (H2).

With this cracking technology, Air Liquide will further contribute to the development of hydrogen as a key enabler of the energy transition.

I think this could be very significant, in the development of hydrogen as an industrial fuel for heavy energy users.

Hydrogen Fuel Pioneer Wins £247k Funding For Carbon Capture Tech

The title of this post, is the same as that of this article on gasworld.

This is the introductory paragraph.

UK-based waste-to-hydrogen specialist Compact Syngas Solutions (CSS) has won £246,568 from the Hydrogen BECCS (bioenergy with carbon capture and storage) Innovation Programme.

I first wrote about Compact Syngas Solutions, in Welsh Firm Wins £300K BEIS Grant To Advance Hydrogen Fuel Tech.

Compact Syngas Solutions appear to be developing a process to turn waste, that would otherwise go to landfill, into green hydrogen.

- The first stage turns the waste into syngas using gasification.

- This process produces carbon dioxide, which must be captured.

- Compact Syngas Solutions seem to have found a chemical mechanism, that uses water to capture this carbon dioxide instead of ammonia-derived amines.

The last two paragraphs of the article state Compact Syngas Solutions’s plans.

Intended to be portable, CSS plans to develop ten Micro H2 hubs complete with four gasifiers.

Capable of producing 60kg of hydrogen and capturing 3.1kg of CO2 per day, the technology could contribute to full-scale Waste-to-Syngas-Liquid-Fuel facilities, leading to a 50,100 tonne CO2 capture capacity in the UK.

I feel, that if this technology can be made to work at scale, then Compact Syngas Solutions will have a viable way to make green hydrogen.

ITM Power’s 24MW Electrolyser Sale to Yara

The title of this post, is the similar to that of this press release from ITM Power. I just added a few words.

These are the first three paragraphs.

ITM Power (AIM: ITM), the energy storage and clean fuel company, is pleased to provide details of the sale of a 24MW electrolyser to Linde Engineering contained in the Company’s Half Year Report issued yesterday. The electrolyser is to be installed at a site operated by Yara Norge AS (“Yara”) located at Herøya outside Porsgrunn, about 140 km southwest of Oslo. The site covers an area of approximately 1.5 square kilometres and is the largest industrial site in Norway. The Porsgrunn site produces 3 million tons of fertiliser per year.

The hydrogen required for ammonia production is currently produced from SMR. Yara intends to start replacing this grey hydrogen with green hydrogen produced from renewable energy and electrolysis. The 24MW system supplying 10,368 kg/day of hydrogen will account for approximately 5% of the plant’s consumption and serve as a feasibility study for future upscaling. Yara has received a grant of up to NOK 283m (£23.6m,pending ESA approval) from Enova SF, a Government funding body, to invest in green solutions for hydrogen used for industrial purposes in Norway.

The electrolyser equipment is due to be ready for shipment from ITM Power in Q4 2022 with revenue realised in the Company’s 2022/2023 financial year.

These are my thoughts.

The Size Of The Electrolyser

A 24 MW electrolyser, that produces 10,368 Kg of hydrogen/day may sound a large device.

This is an extract from the press release.

In January 2021, the Company received an order for the world’s then largest PEM electrolyser of 24MW from Linde. In October 2021, the Company, with Linde, announced the deployment of a 100MW electrolyser at Shell’s Rhineland refinery, following the start-up of an initial 10MW facility at the site.

It appears that ITM Power have built one before and one four times the size has been ordered.

What Size Of Electrolyser Would Yara Need To Fully Decarbonise Ammonia Production?

According to the press release, a 24 MW electrolyser will produce five percent of the plant’s consumption, which means that a 480 MW electrolyser will be needed, if Yara use an ITM electrolyser to produce all their hydrogen.

Will manufacture of an electrolyser of this size be a problem for ITM Power?

The press release says this about electrolyser production.

ITM Power operates from the world’s largest electrolyser factory in Sheffield with a capacity of 1GW (1,000MW) per annum, with the announced intention to build a second UK Gigafactory in Sheffield with a capacity of 1.5GW expected to be fully operational by the end of 2023. The Group’s first international facility, expected to have a capacity of 2.5GW per annum, is intended to be operational by the end of 2024, bringing total Group capacity to 5GW per annum.

It also says that the company has raised £250m to accelerate expansion.

The Delivery Date

The delivery date of the electrolyser is stated as Q4 2022.

I find this rather quick, which makes me believe that one of the reasons for the success of ITM Power is their production process.

How Much Ammonia Is Produced Worldwide?

This is an extract from this publication from the Royal Society, which is entitled Ammonia: Zero-Carbon Fertiliser, Fuel And Energy Store.

Current global ammonia production is about 176 million tonnes per year and is predominantly achieved through the steam reforming of methane to produce hydrogen to feed into ammonia synthesis via the Haber Bosch process.

Ammonia production is a highly energy intensive process consuming around 1.8% of global energy output each year (steam methane reforming accounts for over 80% of the energy required) and producing as a result about 500 million tonnes of carbon dioxide (about 1.8% of global carbon dioxide emissions)2,3,4. Ammonia synthesis is significantly the largest carbon dioxide emitting chemical industry process. Along with cement, steel and ethylene production, it is one of the ‘big four’ industrial processes where a decarbonisation plan must be developed and implemented to meet the netzero carbon emissions target by 2050.

It looks like Linde and ITM Power have a fairly simple plan to decarbonise world ammonia production. And they have started with one of the easier targets; Yara in the very environmentally-correct Norway.

I estimate that to produce 176 million tonnes of green ammonia will need over 28 GW of electrolyser capacity.

Conclusion

If Linde and ITM Power can persuade the world, that their technology is the way to go, then they’ve got it made.