Eastern Green Link 2 Moves Up A Gear Using Low Carbon Fuel For Material Handling Trucks

The title of this post is the same, as that of this press release from National Grid.

These three bullet points act as sub-headings.

- Eastern Green Link 2 (EGL2), a high voltage direct current (HVDC) 436km subsea transmission cable connecting Scotland and England, is being delivered as a joint venture by National Grid Electricity Transmission and SSEN Transmission.

- Project sustainability efforts are accelerating by adopting Hydrogenated Vegetable Oil (HVO) fuelled trucks to move materials in Yorkshire.

- The introduction of HVO fuel will deliver up to 90% reduction in direct CO2 emissions.

The use of HVO fuel is good and the carbon dioxide emission savings are to be welcomed, but there is only so much of this HVO fuel available.

If hydrogen-fueled trucks were available, then this would deliver up to 100% reduction in direct CO2 emissions.

This paragraph from the press release talks about where the HVO fuel will be used.

HVO, a low-carbon biofuel made from waste vegetable oils, will be used at the Wren Hall converter station site in North Yorkshire, where 20-tonne construction trucks will transport approximately 370,000 tonnes of quarry stone from a quarry 27 miles away. This switch from conventional diesel to HVO is expected to deliver up to a 90% reduction in direct CO2 emissions and an 80% reduction in other harmful emissions such as particulate matter.

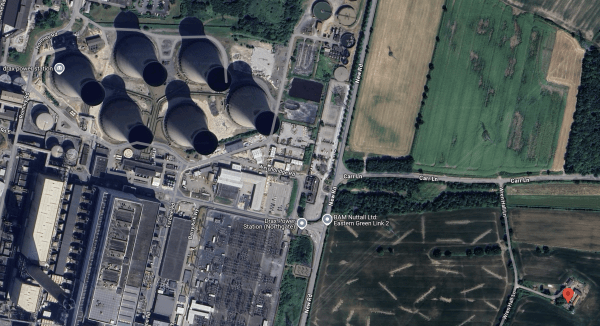

This Google Map shows the location of Wren Hall with respect to Drax power station.

Note.

- The six large cooling towers of the Drax power station are in the North-West corner of the map.

- Google Maps indicate, where they think Wren Hall is, with a red arrow.The lane running North-South to the West of the red arrow is called Wren Hall Lane.

- There is a legend saying BAM Nuttall Ltd Eastern Green Link 2 on the opposite side of the square of lanes to the red arrow.

Click the map to show it to a larger scale.

It looks to me, that if hydrogen could be provided on the Drax site, then the 370,000 tonnes of quarry stone from a quarry 27 miles away could be brought to the site by hydrogen-powered 20-tonne construction trucks.

So how could hydrogen be provided on the Drax site?

- Drax is a 2.6 GW biomass power station, so I’m sure that some electricity could be used to generate hydrogen.

- Drax is a rail-connected site, so hydrogen could be brought in by rail.

- Depending on the amount of hydrogen needed, hydrogen could surely be brought in by road.

I feel that if hydrogen-powered 20-tonne construction trucks were available, this transfer of quarry stone could be performed carbon-free.

Conclusion

This project illustrates a problem with large infrastructure projects all over the UK.

Moving the large amounts of stone, concrete, sand and rubble into and out of construction sites generates a lot of carbon dioxide and pollution from the 20-tonne trucks employed.

If I were to be given Ed Miliband’s job of Secretary of State for Energy Security and Net Zero, one of my first actions, would be to say that all new 20 tonne construction and cement trucks would have to be zero carbon.

I suspect, that zero-carbon with trucks this size, will mean hydrogen, as the weight of the battery would destroy the mathematics of the truck.

This would obviously reduce carbon emissions, but more importantly, what would it do for the health of those working on large construction sites?

In MAN Expands Its Zero-Emission Portfolio, I show MAN’s heavy hydrogen trucks.

This is an articulated heavy hydrogen truck.

I’m sure that MAN could build a hydrogen-powered 20-tonne construction truck.

In Cummins Agrees To Integrate Its Hydrogen ICE Technology Into Terex® Advance Trucks, I talk about the solution to the cement truck problem.

This is a side view of the top-of-the-range monster.

Note.

- Front is to the right.

- I suspect the driver doesn’t have to get out of the cab to discharge the concrete.

- The engine is at the rear with vertical exhausts.

- All axles are driven.

You’d certainly notice one of these if they were to be used in the City of London.

And this is the baby of the range.

Three axles is normal for the UK. so I wonder if this machine will ever make it across the pond.

This last paragraph in the original article describes the X15H hydrogen internal combustion engine.

The X15H was showcased at the Advanced Clean Transportation (ACT) Expo in May (2023), along with its hydrogen ICE-powered concept truck. The X15H features a 700-bar pressure 80kg capacity hydrogen storage system and a range of more than 500 miles, with up to 500 horsepower.

Could one of these trucks really deliver ready-mix concrete from London to Manchester and return?

The trucks would appear to be available, so let’s get a few over and try them out.

Incidentally, if someone had told me ten years ago, there would be rear-wheel drive trucks like Volkswagen Beetles, I’d have said they were wrong in no uncertain terms.

The Wren Hall substation would appear to be an ideal trial project for hydrogen-powered construction trucks and cement trucks.

Wrightbus To Build 1,000 Zero-Emission Buses

The title of this post, is the same as that of this article on The Times.

This is the sub-heading.

Northern Ireland company to ramp up production by 40% and recruit hundreds more employees as it also develops the UK’’s first long-distance hydrogen coach

These are the first two paragraphs, which add more detail.

Wrightbus, the Northern Ireland bus manufacturer, could be supplying as many as 1,000 zero-emission vehicles to depots around the UK as it increases production by 40 per cent over a two-year period and takes on hundreds more workers.

The company, best known for the redesigned 21st century take on the Routemaster ordered by the former mayor of London Boris Johnson, also announced it is to spend £5 million developing the UK’s first long-distance hydrogen coach capable of travelling 1,000km (621 miles) on a single recharging of its fuel cells.

These two paragraphs describe their production and employment plans.

Jean-Marc Gales, the former senior Peugeot director who is Wrightbus’s chief executive, said production at its Northern Ireland plant would go from 1,000 vehicles last year to 1,200 this year and 1,400 in 2026.

Over the same period the company’s workforce will grow from 1,500 to 2,500.

Peter Kyle, the secretary of state for science, innovation and technology, said this.

The level of innovation at Wrightbus and their quality standards have been recognised.

That is surely rare praise for a private company from a Labour Minster.

I first wrote about Wrightbus’s new hydrogen coach in early March, when I wrote Wrightbus Goes Back To The Future As It Relaunches The Contour Coach, which was based on this Wrightbus press release, which has the same title.

I said this in my post.

Wrightbus is entering the coach market for the first time in more than 30 years with the launch of two new vehicles in the next 18 months.

The first vehicle to hit the market is the Contour, a low-emission 55-seater coach that was launched at a customer showcase event today (March 5).

It’s a case of back to the future for Wrightbus, which last produced a Contour coach in 1987 before retiring the vehicle.

The second vehicle, a zero-emission hydrogen coach – which is under development in Ballymena, Northern Ireland – will be added to the Wrightbus coach range within the next 18 months to help drive decarbonisation of the sector.

The low emission Contour has a lead time of just six months from order, which is considerably faster than the current one-to-two-year average wait customers have come to expect from the sector. Featuring a Cummins Euro 6 400BHP X11 engine and a ZF automatic gearbox, the modern-day Contour has been built with comfort in mind, with up to 55 reclining seats – each with its own USB port – alongside other modern safety features. Competitively priced and available with or without PSVAR compliance, there is also the option of the vehicle being ‘pre-prepared’, protecting the vehicle’s ‘second life’ and flexibility.

The coach has a range of bespoke options for customers to choose from and is designed to maximise luggage space and functionality.

The low emission Contour coach was to have been built in China.

But events have moved on fast in the last month, with Trump and China trading insults on tariffs almost daily.

From today’s article in The Times and a press release from the Government, which is entitled Science Secretary Hails Wrightbus As Company Pledges £25 million To Bolster UK’s Green Transport Revolution And Drive Growth, it appears that the Chinese coach has been dropped.

Could the plan now be something like this?

- The low emission Contour coach will either be dropped, built in Ballymena or perhaps even built on JCB’s site in Texas.

- It might possibly be advantageous to build the coach in the United States to balance the tariffs and target the North American market.

- I would feel, that North America could be a lucrative market for the larger thousand kilometre coach.

- With the low emission Contour coach, Cummins get a chance to show the United States their excellent hydrogen technology.

- Trump can claim, that he’s brought jobs back to the United States.

- If Wrightbus and/or JCB build the low emission Contour coach, they could probably create a better product and get it to market earlier.

I suspect we’ll learn more of Wrightbus’s plans in the next few weeks.

A Busy Saturday Lunchtime At Victoria Coach Station

I went to Victoria Coach station at lunchtime today and took these pictures.

These are my thoughts.

Where Are The British Coaches?

The nearest I saw were the smart coaches of the Oxford Tube, which were built by Plaxtons on a Volvo chassis.

The National Express coaches were made by Caetano in Spain.

I can certainly understand, why Wrightbus’s first product of a new era of British coach-building is an affordable Chinese-built coach, that is fitted with a Cummins engine, that possibly can be converted to hydrogen, as is the case, with some Cummins diesel engines.

As the coach will have a delivery time of six months, I think we’ll see them on the road fairly soon.

There Were Several Three Axle Coaches

In fact, I didn’t know they were very common.

- I suspect that three axles is better for the weight.

- But then you don’t see too many coaches in Central London unless you go to Victoria.

Wrightbus are saying that their hydrogen coach will have three axles.

The Wrightbus Effect

This article on Route One, says of the new Wrightbus Contour coach.

- It will be released this year.

- It will be an affordable product and Chinese-built.

- It will be a 55-seat diesel coach.

- It will have a Cummins engine.

In Wrightbus StreetDeck Ultroliner Next-Gen To Get Cummins Power, I describe how Wrightbus’s new Cummins-powered double-deck bus will be able to be converted to hydrogen-power. I suspect the same option will be available with the Contour diesel coaches.

The article on Route One, says this about the availability of the new coaches.

The Contour’s “competitive price” and lead time of six months promises an edge over some current industry norms, the business says.

That fits with what my finance company found forty years ago, when it was leasing coaches. If there were more coaches, you could lease more.

It looks to me, that the Cummins-powered, Chinese-built Wrightbus Contour coach will be affordable, available and convertible to zero-carbon hydrogen power.

If the quality and reliability of the coaches are high, then these coaches should sell and more coach operators will be wanting to run services from Victoria coach station, with their new affordable Wrightbus Contour coaches.

After what I saw on Saturday, will Victoria coach station have the space to accommodate them?

Coaches To Attractions

I saw coaches to Harry Potter, Legoland and other attractions.

Will this be an area that develops, if there were to be a greater availability of coaches, which Wrightbus, appears to be offering?

FLiXBUS

This is the first paragraph of the Wikipedia entry for FLiXBUS.

FlixBus (styled FLiXBUS) is a German brand that offers low-cost intercity coach services in Europe, North America, South America, and Asia. It is owned by Flix SE , which also operates FlixTrain, FlixCar, Kâmil Koç, and Greyhound Lines. FlixBus operates buses or, in many cases, just handles marketing, pricing, and customer service for a commission, on behalf of bus operators. In 2023, FlixBus had revenues of €2 billion and carried 81 million passengers of which 55 million were in Europe, 14 million were in Turkey, and 12 million were in North America.

They certainly seem to be an ambitious low-cost company, who serve a lot of places in the UK.

As they are a German company and Wrightbus have sold scores of zero-carbon buses to Germany could Wrightbus and FLiXBUS have been talking about affordable, quality coaches?

Wrightbus Goes Back To The Future As It Relaunches The Contour Coach

The title of this post, is the same as that of this press release from Wrightbus.

This is the detail of the press release.

Wrightbus is entering the coach market for the first time in more than 30 years with the launch of two new vehicles in the next 18 months.

The first vehicle to hit the market is the Contour, a low-emission 55-seater coach that was launched at a customer showcase event today (March 5).

It’s a case of back to the future for Wrightbus, which last produced a Contour coach in 1987 before retiring the vehicle.

The second vehicle, a zero-emission hydrogen coach – which is under development in Ballymena, Northern Ireland – will be added to the Wrightbus coach range within the next 18 months to help drive decarbonisation of the sector.

The low emission Contour has a lead time of just six months from order, which is considerably faster than the current one-to-two-year average wait customers have come to expect from the sector. Featuring a Cummins Euro 6 400BHP X11 engine and a ZF automatic gearbox, the modern-day Contour has been built with comfort in mind, with up to 55 reclining seats – each with its own USB port – alongside other modern safety features. Competitively priced and available with or without PSVAR compliance, there is also the option of the vehicle being ‘pre-prepared’, protecting the vehicle’s ‘second life’ and flexibility.

The coach has a range of bespoke options for customers to choose from and is designed to maximise luggage space and functionality.

It will be supported by a full Wrightbus warranty, alongside an unparalleled service and maintenance package from AllServiceOne, the Wrightbus repair and maintenance arm.

With the largest fleet of mobile technicians throughout the UK and Northern Ireland, AllServiceOne is the ultimate one-stop-shop for fleet support and service.

Wrightbus CEO, Jean-Marc Gales, said bringing the Contour to market was a pivotal move.

“The coach market has changed over the last few years and it’s the right time for a new player to come to the market.

We have long spoken about broadening our portfolio to offer customers an even greater range of Wrightbus vehicles.

Our first entry into the coach sector after an absence of more than three decades is another significant step in our expansion plans,” said Mr Gales.

“We know there are gaps in the market and the demand for coaches is growing.

This partnership allows us to bring high-quality low-emission vehicles to market almost immediately.

Throughout the process of readying the vehicle for our UK market, we have worked alongside our partner closely to ensure the Contour meets the exacting Wrightbus high quality standards that customers have come to expect.

Our AllServiceOne technicians have embarked on an extensive training programme and have a full working knowledge of the coach to ensure excellent fleet support. “At the same time as the launch of the Contour, our world-leading engineers are continuing to develop our own zero-emission hydrogen coach from our factory in Northern Ireland. We expect the hydrogen coach to be ready for launch in the next 18 months, which is a hugely exciting prospect.” The hydrogen coach concept was first revealed in 2024 as a prototype vehicle.

When launched, it will be a tri-axle hydrogen fuel cell electric coach capable of a 1,000km range, putting it on a par with traditional diesel-fuelled coaches.

These are my thoughts.

The Coach Has A Cummins Engine

Cummins will probably build the engines in their UK factory in Darlington.

Thirty years ago, I did a small data analysis consultancy for Cummins in Darlington and I was impressed by the operation and the company’s attitude.

One of their policies was that if the customer wants a special engine, then the company, is prepared to give the customer what they need.

So you can be sure, that the Cummins X11 engine to be supplied for the Contour coach, will be exactly what Wrightbus want.

The Cummins X15 Engine Is Convertible To A X15 Hydrogen Engine

Some of Cummins diesel engines are convertible to hydrogenfuel, by changing the cylinder head and the fuel system.

This can be done with a Cummins X15 engine and I wouldn’t be surprised if the X11 engine fitted to the Contour coach can be converted to hydrogen.

So an operator can buy a diesel coach and if they need, they could convert it to hydrogen.

USB Ports

This is stated in the press release.

Contour has been built with comfort in mind, with up to 55 reclining seats – each with its own USB port.

When I rode recently in a Irizar coach, there were no USB ports.

There Is A Promised Delivery Time Of Six Months

In the 1990s, I used to part-own a finance company, that leased vehicles.

One of the vehicles we used to loan money for was upmarket coaches like the Wrightbus Contour.

- They were a relatively large loan of about £50,000.

- The borrower was often very reputable with a good credit history.

- The repossession rate was very low.

The press release says, that a two-year delivery time is normal for coaches and, I can remember that we could have financed more coaches, if they had been available.

So it would appear to me, that if Wrightbus can deliver a new coach in six months, they will sell a lot of coaches and I believe from past experience, that finance will be available from trusted sources.

The Hydrogen Coach Will Be A Hydrogen Fuel Cell Electric Tri-Axle Coach

This is stated in the press release.

When launched, it will be a tri-axle hydrogen fuel cell electric coach capable of a 1,000km range, putting it on a par with traditional diesel-fuelled coaches.

I suspect to get the 1,000 km range of the diesel coach and to protect the hydrogen tank, means some extra weight and an extra axle.

But I wouldn’t be surprised to see a reduced range hydrogen coach without the third axle.

Wrightbus Are The Company Who Launched Ballard Hydrogen Fuel Cells In London

I wrote London’s Hydrogen Buses in July 2013 and all Wrightbus buses hydrogen buses have used hydrogen full cells from Ballard Power Systems in Canada.

But there could be a complication in that Cummins make fuel cells in Germany and we are approaching Trumpian Tariff War Territory.

On the other hand in Australian Volgren Rolls Out First Hydrogen Bus Based On Wrightbus Chassis Technology, it shows how Wrightbus are prepared to licence their technology to reputable companies.

So any country, like Australia, Brazil, Canada, India, Mexico, Singapore or the United States, who can build coaches, can licence Wrightbus’s designs and fit the appropriate components to make a complete coach.

Note.

- Wrightbus is owned by the Bamford family, who own JCB.

- Wrightbus have licenced designs to Australia, Hong Kong and Singapore in the past.

- JCB have large manufacturing facilities in India.

I’m certain that the Bamfords and their advisors can work it out!

Scotch Whisky Is In A Unique Position

Scotland has so much zero-carbon energy now, let alone in a few years, that Scotch whisky would not be the most difficult of industries to make completely zero-carbon, which could marketing-wise completely trump any tariffs, that Trummkopf might impose.

- Already some small distilleries are using hydrogen to distill the whisky.

- Some glass bottles are already made using hydrogen instead of natural gas to make zero-carbon malt whiskies.

- I’m sure Cummins in Darlington, JCB in Rocester and Ricardo in Sussex will be pleased to help make farm machinery, mechanical handling and road transport zero carbon.

- Soft fruit like raspberries are already used to absorb the carbon dioxide from the distillation process in some areas of Scotland. I’m sure dealing with more quality raspberries would not be a problem.

- A large electrolyser is planned for Kintore in the North of Scotland. Think of the good publicity for say Centrica or SSE, if they built the world’s largest hydrogen plant to help make zero-carbon whisky.

These are some more thoughts.

Taste Is Everything

As only the method of providing heat and electricity will have been changed, I can’t see there will be any change to the taste.

It’s Already Happening

This page on the Annandale Distillery web site is entitled Annandale Distillery Pioneers Zero-Carbon Whisky Production with EXERGY 3 Project.

The Kintore Electrolyser

These figures summarise the Kintore Electrolyser.

- Total Electrolyser Capacity – 3 GW

- First Phase – 500 MW

- Hydrogen – 200 kTonnes per year

Explore the Kintore Hydrogen web site.

Marketing Advantage

Scotland, is probably, the only country, where the main ingredients for whisky come together in abundance ; barley, energy, tradition and water.

It also is all produced in a single country in many different brands and types, which could all be produced in a zero-carbon manner.

Conclusion

Let’s give Trump a beating and the planet a kiss.

H2Rescue Truck Smashes World Record With 1,806 Miles On A Single Hydrogen Fill!

The title of this post, is the same as that of this article on Hydrogen Fuel News.

This is the sub-heading.

H2Rescue Truck Sets New World Record in Hydrogen Transportation

These first two paragraphs add more detail.

A groundbreaking milestone in hydrogen-powered transportation has been achieved by the H2Rescue truck, a prototype heavy-duty vehicle capable of addressing energy challenges during disaster relief. Built by Accelera (a division of Cummins), with support from the U.S. Department of Energy (DOE) and other federal agencies, the truck recently achieved a Guinness World Record by traveling an astonishing 1,806 miles on a single fill of hydrogen fuel.

What makes this feat remarkable is the environmental implications of the technology. While a traditional internal combustion engine would have emitted 664 pounds of carbon dioxide (CO2) over the same distance, the hydrogen-fueled H2Rescue truck produced zero CO2 emissions. Hydrogen-powered vehicles like this one exemplify cutting-edge innovation in decarbonizing transportation.

This last paragraph describes the use of the vehicle in emergencies.

More than just a long-distance performer, the H2Rescue truck is an essential tool during emergencies. It can provide 25 kilowatts of power for critical relief operations, such as lighting, medical equipment, and communication systems, for up to 72 hours without refueling. This capability could make a significant difference in disaster zones, where reliable energy sources are often scarce.

Cummins are certainly serious about the innovative use of hydrogen.

Wrightbus StreetDeck Ultroliner Next-Gen To Get Cummins Power

The title of this post, is the same as that of this article on Route One.

These three paragraphs give more details.

Wrightbus will utilise Cummins power in its StreetDeck Ultroliner diesel double-decker for the first time in a next-generation variant of that model.

Those vehicles will be powered by the six-cylinder B6.7 engine rated at 250bhp or 300bhp, driving through the Voith DIWA.8 seven-speed automatic gearbox. Such an approach will further reduce emissions, and the new model will be Ultra-Low Emission Bus accredited by Zemo Partnership, the manufacturer says.

The existing StreetDeck Ultroliner, which is powered by the Daimler OM 934 four-cylinder engine, will continue to be available. The first Cummins-powered examples are to be supplied to Isle of Man operator Bus Vannin.

As a hydrogen version of the the Cummins six-cylinder B6.7 engine is available, at some point in the future, these buses will be convertible to zero-emission hydrogen power.

Wrightbus have already set up a division called New Power to do the conversion of existing buses, as I reported in Wrightbus Launches NewPower In Bicester.

Iarnród Éireann Looks At Diesel Loco Replacement Options

The title of this post, is the same as that of this article on Railway Gazette.

These three paragraphs introduce the article.

The Stadler Class 99 electro-diesel locomotive for UK operator GB Railfreight was receiving close scrutiny from Iarnród Éireann at InnoTrans in Berlin, with the Irish national operator confirming to Railway Gazette International that it had discussed with the manufacturer how the type might be adapted for operation in Ireland.

Iarnród Éireann Chief Executive Jim Meade told Railway Gazette International ‘we will eventually need to replace our aging diesel fleet with dual-mode locomotives because our freight strategy will take us down that direction after we complete our electrification programme.

‘The replacement for the class 071s and 201s eventually will have to be a bi-mode electric with some form of HVO [renewable diesel fuel] traction in the long term; even the Class 201s are beyond mid-life already.

The Class 99 locomotive is a version of the Stadler Eurodual locomotive, which is described in this Stadler data sheet.

The Wikipedia entry for the Stadler Euro Dual is also informative and lists a dozen different versions of the locomotive, that have been sold to various countries and operators.

This paragraph summarises how the design can handle different gauges and electrical voltages.

The Euro Dual was designed from the onset as a highly modular platform, allowing it to be offered to customers in various different configurations, covering various gauges and voltage systems.

I doubt Stadler would have great difficulty producing an Irish gauge locomotive capable of running on whatever electrification, the Irish erect.

Will The Irish Class 99 Have Enough Power?

The power of the various diesel locomotives are as follows.

- Current Irish Class 071 – 1.68 MW

- Current Irish Class 201 – 2.4 MW

- UK Class 66 – 2.4 MW

- UK Class 99 – 1.79 MW

It would appear that the Class 99 is less powerful than the Irish Class 201 and the UK Class 66, but the Wikipedia entry for the Class 99 says this.

The chief executive of GBRf, John Smith, reports that the Class 99, despite having a less powerful diesel engine than the Class 66, will outperform the Class 66 at low speeds. The greater tractive effort means that the Class 99 on diesel power can deliver more power at the rail than the 66.

But as the Class 99 has 6.17 MW in electric mode, the solution must be to electrify the difficult sections.

I have just looked at the Felixstowe Branch Line, which will be very much Class 99 territory. I am fairly sure, that with some short lengths of electrification on the single-track sections, any performance problems with the Class 99 on the branch could be solved.

Could The Irish Class 99 Use Hydrogen As Secondary Power?

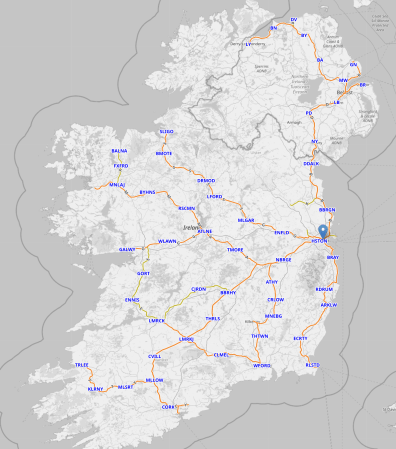

This OpenRailwayMap shows all the railways on the island of Ireland.

Note.

- All railways on the island of Ireland have an Irish gauge of 1.6 m.

- Only the DART in Dublin is electrified with 1,500 VDC overhead.

- There are 2,733 km. of track.

- New lines are still being added and old ones have been reopened in recent years.

- There will surely be pressure for the Irish to decarbonise their railways, both North and South of the Northern Irish border.

- There are no rail connections to another country, except for the link between Northern Ireland and the Republic of Ireland, which is between two similar systems.

- It is unlikely, that there will ever be a rail link between the Irish gauge railways on the island of Ireland and the standard gauge railways of Europe.

Effectively, the island of Ireland has an isolated network of tracks on which they could build a zero-carbon railway system.

- Signalling could be an off-the-shelf digital system.

- Zero-carbon traction power could be trains powered by either electricity and/or hydrogen.

- Both electricity and hydrogen would need substantial amounts of new rolling stock.

- Electricity would require electrification at €1,000,000 per single track kilometer, which could be around €5.5 billion for the electrification alone.

- Electrification would also need many bridges, stations and tunnels to be modified or rebuilt.

- Hydrogen would need a refuelling infrastructure and could go anywhere that diesel can.

- Hydrogen locomotives and trains, would be one-to-one replacements for diesel locomotives and trains.

It would appear that because of their geographic isolation, hydrogen could be an ideal zero-carbon fuel for the railways of Ireland.

In Do Cummins And Stadler Have a Cunning Plan?, I speculated that the electro-diesel Class 99 locomotive could be converted into an electro-hydrogen Class 99 locomotive, as Cummins are building diesel engines that can be converted into hydrogen ones.

Ireland with its unusual network could change to a zero-carbon railway in the following way.

- Purchase a fleet of diesel locomotives and trains that can run on Hydrotreated Vegetable Oil (HVO) and be convertible to hydrogen.

- A version of the Class 99 with or without the electrical gubbins would satisfy the locomotive replacement.

- A version of the tri-mode Stadler FLIRT like a Class 745 train, would satisfy the train replacement.

- All new trains and locomotives would replace the current stock and run on HVO.

- The hydrogen infrastructure would be built.

- The new trains and locomotives would be gradually converted to run on green hydrogen.

Within a few years, the island of Ireland would have a zero-carbon railway.

Advantages Of A Fully-Hydrogen Railway

These are a few advantages.

- One fuel for all trains.

- All trains and locomotives would be one manufacturer.

- No expensive electrification.

- Hydrogen trains and locomotives have a long range.

- No infrastructure modification for gauge clearance.

- Ireland has plenty of onshore and offshore wind for hydrogen.

- Standard fuelling systems are being developed.

- There would be no disruption as the trains changed to HVO and little disruption as they changed to hydrogen.

I believe that there would be a large increase in train usage both from locals and visitors, which can only be good for the Irish economy.

Managing The Project

This could be one of those rare projects that flows well.

- The changeover to hydrogen could involve very little rail infrastructure work.

- The hydrogen filling stations could be more-or-less independent of the rail infrastructure.

- Trains and locomotives could go into service, when they are accepted and the staff have been trained.

- Trains and locomotives would only be converted to hydrogen, as routes are made hydrogen-capable.

- There should be no gauging problems with the new trains and locomotives.

- There is only one train manufacturer.

Hopefully, it will all be delivered on time and on budget.

Innotrans 2024: Rolls-Royce Shows mtu Solutions For On-Track Energy Transition And Celebrates 100 years Of Rail Engine Business

The title of this post, is the same as that of this press release from Rolls-Royce.

These four bullet points, act as sub-headings.

- All mtu engine series for locomotives and railcars approved for sustainable fuels

- DB, RDC Autozug Sylt, Trenitalia and České dráhy use or test HVO

- Rolls-Royce celebrates 100 years of success with mtu rail drives

- More than 250 rail customers worldwide value the performance, compact design and low exhaust emissions of mtu systems

These are the first two paragraphs.

Rolls-Royce will be presenting its mtu-brand propulsion and service solutions at the international rail exhibition Innotrans in Berlin from September 24 to 27, 2024 in Hall 18, Booth 500. The company will be celebrating an anniversary at the same time: for 100 years, mtu products have been powering trains, including mainline and multi-purpose locomotives, high-speed trains and local transport railcars. On display will be sustainable propulsion solutions such as the mtu Series 4000 and 1600 engines for locomotives and the underfloor drive systems mtu PowerPacks for railcars, all of which are now released for sustainable fuels such as HVO. Rolls-Royce will also be presenting its repower and reman solutions.

100 years ago, Karl Maybach laid the foundation for the rail drive systems of today’s mtu brand with the world’s first high-speed diesel engine for railcars, the Maybach G 4a. Maybach also developed the GO 5 engine for the “Fliegender Hamburger” express train.

These are my thoughts.

Chiltern Railways Could Go Carbon-Neutral By Using HVO

In Vegetable Oil Fuelling Chiltern Railways Trains In UK First, I described how Chiltern Railways are running their Class 68 locomotives on HVO.

This move by Rolls-Royce mtu will allow all Chiltern’s Class 168 trains to be run on sustainable HVO, as they have Rolls-Royce mtu diesel engines.

Chiltern Railways Class 168 train fleet is as follows.

- 10 x 4-car

- 9 x 3-car

- 9 x 2-car

This will still leave Chiltern Railways Class 165 train fleet to be converted to sustainable fuel.

- 28 x 2-car

- 11 x 3-car

Note.

- There are 75 of these trains in service with Chiltern Railways and Great Western Railway.

- They are fitted with Perkins engines.

- Perkins engines are now owned by Caterpillar, who built the engines for the Class 68 locomotives.

As Caterpillar have the sustainable diesel technology, could they convert the Class 165 trains to HVO?

Cummins And HVO

Although this post is mainly about Rolls-Royce mtu, it would be convenient to put in this section about Cummins and how their diesel engines run on HVO.

The UK train fleet contains the following trains with Cummins engines.

- 10 x Class 175 train x 2-car

- 16 x Class 175 trains x 3-car

- 14 x Class 180 trains x 5-car

- 34 x Class 220 trains x 4-car

- 23 x Class 221 trains x 5-car

- 4 x Class 221 trains x 4-car

- 4 x Class 222 trains x 7-car

- 23 x Class 222 trains x 5-car

Cummins says this about their engines and HVO.

Cummins approves use of HVO fuel in all high-horsepower engines

(19L-95L), including the QSK19, K19, QSK23, QST30, QSK38, K38, QSK45,

QSK50, K50, QSK60, QSK78, QSK95, V903 and ACE for all industrial

markets. No engine modifications are required; engines currently in the

field can be used with HVO at any percentage.

It would appear that all trains with Cummins engines can be converted to run on HVO.

CAF And HVO

Class 195, 196 and 197 trains all have Rolls-Royce mtu diesel engines, so they will be able to run on HVO.

Hitachi And HVO

Class 800, 1801, 802, 805 and 810 trains all have Rolls-Royce mtu diesel engines, so they will be able to run on HVO.

Conclusion

If all diesel engines are to be converted to HVO, there is going to be a lot of HVO needed in the UK.

But many train fleets will be carbon-neutral.

Cummins Debuts Integrated HELM Drivetrain At IAA

The title of this post, is the same as that of this article on truckinginfo.com.

This is the sub-heading under a rather informative image.

Cummins’ integrated drivetrain offers fleets three powertrain options: advanced diesel, diesel-hybrid and zero-carbon hydrogen.

These are the first two paragraphs.

Cummins pulled the curtain back on a new integrated drivetrain concept at the IAA Transport Show in Hannover, Germany, on September 17. According to Jennifer Rumsey, Cummins chair and CEO, the newly designed drivetrain is based on the OE’s HELM engine platform. It is also intended to highlight Cummins’ broader product portfolio and continued commitment to providing flexible, sustainable power solutions.

The Cummins HELM engine platform is a fuel-agnostic series of engine versions that are derived from a common base.

The article could be called the Jennifer and Jane Show, after the two people, who provided most of the words.

When I was dealing with large American corporations in the last century, one lady would have been a rarity, but two at the top indicates how Cummins has turned itself into a sustainable company for the twenty-first century.

The Cummins Integrated Drivetrain Concept

The Cummins Integrated Drivetrain Concept is shown in a Cummins image in the trucking.info.com article.

- Up-front is a 15-litre internal combustion engine, which can be diesel, natural-gas or hydrogen-fueled.

- As Cummins manufacture fuel cells, I suspect that the motive power can be one or more hydrogen fuel cells.

- It looks like along each side of the truck are tanks for the hydrogen fuel cells.

- Between the tanks is a powerful electric motor, that drives the rear axle.

- The electric rear axle could incorporate batteries for regenerative braking and traction efficiency.

A vehicle of any size between a Fiat 500 and a 44-tonne articulated truck could use this integrated drivetrain concept, with components sized accordingly.

This is a paragraph from the trucking.info.com article.

Rumsey emphasized that Cummins’ acquisition of Meritor, Siemens Commercial Vehicles and Jacobs Vehicle Systems in recent years means Cummins can now offer full powertrain capability.

Don’t develop your own, if you can buy the best!

Siemens electric motors and Cummins diesel engines are used in London’s New Routemaster buses.

Could The Cummins Integrated Drivetrain Concept Be Used For A Small Car?

I don’t see why not?

Just watch the Koreans, who are going large on hydrogen.