Are The Office Of Rail And Road (Or Their Lawyers) Too Risk Averse?

An article in the April 2022 Edition of Modern Railways is entitled Uckfield Third Rail Is NR Priority.

This is the first two paragraphs.

Electrification of the line between Hurst Green and Uckfield in East Sussex and the remodelling of East Croydon are the top Network Rail investment priorities south of the river, according to Southern Region Managing Director John Halsall. He told Modern Railways that third rail is now the preferred option for the Uckfield Line, as it would allow the route to use the pool of third-rail EMUs in the area. This is in preference to the plan involving overhead electrification and use of dual-voltage units put forward by then-Network Rail director Chris Gibb in his 2017 report (p66, September 2017 issue).

NR has put forward options for mitigating the safety risk involved with the third-rail system, including switching off the power in station areas when no trains are present and section isolation systems to protect track workers. ‘The Office of Rail and Road hasn’t yet confirmed third rail would be acceptable, but we are working out ways in which it could be’ Mr Halsall told Modern Railways. He added that bi-mode trains with batteries were not a feasible option on this line, as the 10-car trains in use on the route would not be able to draw sufficient charge between London and Hurst Green to power the train over the 25 miles on to Uckfield.

As an Electrical Engineer, who’s first real job in industry at fifteen was installing safety guards on guillotines nearly sixty years ago, I don’t believe that an acceptable solution can’t be devised.

But as at Kirkby on Merseyside, the Office Of Rail And Road, do seem to be stubbornly against any further third-rail installations in the UK.

I wonder what, the Office Of Rail And Road would say, if Transport for London wanted to extend an Underground Line for a few miles to serve a new housing development? On previous experience, I suspect Nanny would say no!

But is it more than just third-rail, where the Office Of Rail And Road is refusing to allow some technologies on the railway?

Battery-Electric Trains

I first rode in a viable battery-electric train in February 2015, but we still haven’t seen any other battery-electric trains in service on UK railways running under battery power.

Does the Office Of Rail And Road, believe that battery-electric trains are unsafe, with the lithium-ion batteries likely to catch fire at any time?

Hydrogen-Powered Trains

The hydrogen-powered Alstom Coradia iLint has been in service in Germany since September 2018.

But progress towards a viable hydrogen train has been very slow in the UK, with the only exception being demonstrations at COP26.

Are The Office Of Rail And Road still frightened of the Hindenburg?

Although hydrogen-powered buses have been allowed.

A Tale From Lockheed

When Metier Management Systems were sold to Lockheed, I worked for the American company for a couple of years.

I met some of their directors and they told some good American lawyer jokes, such was their disgust for the more money-grabbing of the American legal profession.

At the time, Flight International published details of an innovative landing aid for aircraft, that had been developed by Lockheed. It was a suitcase-sized landing light, that could be quickly setup up on a rough landing strip, so that aircraft, like a Hercules, with an outstanding rough field performance could land safely.

I read somewhere that a Flying Doctor service or similar had acquired some of these landing aids, so they could provide a better service to their clients.

But Lockheed’s lawyers were horrified, that they would get sued, if someone was seriously injured or even died, whilst the aid was being used.

Apparently, in the end, the aids were marked Not For Use In The USA.

Conclusion

I do wonder, if third-rail electrification, battery-electric trains and hydrogen-powered trains have come up against a wall created by over-cautious lawyers.

Siemens Mobility and Deutsche Bahn Present New Hydrogen Train

The title of this post, is the same as that of this article on Global Railway Review.

This is the sub-title.

Deutsche Bahn and Siemens Mobility have presented the newly developed Mireo Plus H and a newly designed mobile hydrogen storage trailer.

It seems that Deutsche Bahn and Siemens Mobility have put together a well-thought out plan to use hydrogen on a lot of unelectrified lines.

The Germans have given the project, the catchy name of H2goesRail.

How does that translate into German?

Battery And Hydrogen Trains For ScotRail ‘Could Make Scotland A Global Leader’ In Zero-Emission Transport

The title of this post is the same as that of this article in the Scotsman.

This is the first paragraph.

New fleets of cutting-edge trains expected to include battery and hydrogen power are to be ordered for ScotRail which the rail industry believes will put Scotland at the forefront of zero-emission transport.

Other points from the article.

- Talgo appear to have passed the story to Scotland on Sunday.

- Three routes are mentioned; Borders Railway, Fife Circle and Glasgow-East Kilbride.

- The new trains could help phase out diesel trains by 2035, which is Scottish Government policy.

- The Inter7City trains might be replaced by 2030.

- Talgo hopes to win an order for its factory in Fife.

Talgo’s Managing Director is quoted as saying, they are starting testing of a hydrogen and electric train with a range of 311 miles.

Consider.

- I wrote about this train in Talgo To Begin Fuel Cell Loco Trials.

- Talgo’s hydrogen and electric train would be ideal for Scotland’s railways of which only forty percent are electrified.

- A four or five-car high specification hydrogen and electric train would be ideal for the Inter7City routes, if it were built specifically for the routes.

- The range would cover all of Scotland.

- Hydrogen hubs are being planned all over Scotland.

- Scotland have 26 Inter7City trainsets.

This could be a rather nice order to fund the factory and test all the trains close to the factory.

Is there a better place to show off your new train to a prospective buyer than the Highlands of Scotland?

In A Class 319 Train, But Not As We Know It!, I told this tale.

I am reminded of a tale, that I heard from a former GEC manager.

He was involved in selling one of GEC’s Air Traffic Control radars to a Middle Eastern country.

The only working installation of the radar was at Prestwick in Scotland, so he arranged that the dignitaries and the sales team would be flown to Prestwick in GEC’s HS 125 business jet.

As they disembarked at Prestwick and walked to the terminal, the pilot called the GEC Manager over.

The pilot told him “The Scottish Highlands at this time of the year, are one of the most beautiful places in the world! Would you and your guests like a low-level tour on the way back? I can arrange it, if you say so!”

Despite knowing GEC’s draconian attitude to cost control he said yes.

The sale was clinched!

I’m sure that Talgo will exploit the scenery and the local produce.

Talgo’s Hydrogen Trains

This page on the Talgo web site, is entitled Talgo’s Hydrogen Train Will Be Ready In 2023.

This paragraph gives an overview of Talgo’s hydrogen power system.

This system is configured as a modular solution that can be installed on all types of trains, as well as in upgrades from diesel to hydrogen. However, it has been specifically designed for the Vittal platform for Commuter and Regional trains, which Talgo has presented in the bidding process for various tenders in Spain and other countries.

And these two paragraphs describe Talgo’s hydrogen trains in more detail.

This innovative system uses hydrogen batteries that provide the energy for the train’s electric motors. It is powered by renewable energy sources, such as solar photovoltaic or wind, which produce hydrogen that is stored and then used to power fuel cell-based propulsion systems, such as the one designed by Talgo. The system is complemented by batteries that increase the speed of the train when it starts, taking advantage of the braking system to recharge it.

Unlike the extended battery systems in the automotive industry, hydrogen (H2) technology is the logical answer to the needs of heavy transport and, in particular, of those railway lines that do not have catenary electrification systems, and which today depend on trains powered by diesel engines. The hydrogen system designed by Talgo enables conventional network lines to be “electrified” without the need for costly and lengthy adaptation operations, and without the use of fossil fuels.

What do they mean by hydrogen batteries? Looking at the German and the Spanish on the page, I think Talgo means hydrogen fuel cells.

The Rebuilding Of Ukraine

It should be noted that Talgo have sold trains in the past to Russia, which has a gauge of 1.520 metres, which lies between Iberian gauge of 1.668 metres and our standard gauge of 1.435 metres.

- Talgo have also sold trains to Germany, who use standard gauge.

- Talgo have built Strizh trains for Russia, that are both standard gauge and Russian gauge for running between Berlin and Moscow.

- According to the BBC and The Times, Ukraine’s railways have been an important lifeline during the Russian invasion, but pictures show they are in need of modernisation and more electrification.

- The Strizh trains or a development would surely be ideal for running between Kviv and Berlin, Budapest, Prague and Warsaw.

- There would also appear to be a need for a hydrogen and electric regional train to reconnect the country back together.

- Other countries using Russian gauge include Mongolia, Kazakhstan, Kyrgyzstan, Tajikistan, Turkmenistan, Uzbekistan, Armenia, Azerbaijan, Georgia, Belarus, Moldova, Estonia, Latvia, Lithuania, and Finland.

So are Talgo positioning themselves to take part in the modernisation of Ukraine’s railways, once the war is over?

- Development and testing is done in Spain and Scotland.

- Manufacturing could be done in Spain and Scotland.

- Delivery from Scotland could either be by ship or if they were dual-gauge trains, they could be hauled through the Channel Tunnel and then through Germany and Poland.

As Talgo has the technology, I can certainly see them exploiting the Russian gauge market once Vlad the Mad has gone.

Norfolk Wind Farms Offer ‘Significant Benefit’ For Local Economy

The title of this post, is the same as that of this article on the BBC.

This is a comprehensive article, which looks at the benefits of the huge Norfolk Boreas and Norfolk Vanguard wind farms will have to the economy of Norfolk.

The last section is devoted to Norfolk Nimby; Raymond Pearce.

This is the section.

Following the re-approval of the decision by the government, Mr Pearce says he is considering a new appeal over what he calls “a very poor decision”.

He is also sceptical of claims the two new wind farms will bring the economic gains promised by Vattenfall.

“It’s renewable energy at any cost and the cost here is to the environment in Norfolk,” he says.

“I don’t blame them for being positive about it, it’s their industry but they’re not looking at it holistically.”

He says he is not against renewable energy but thinks a better plan is needed to connect the offshore windfarms and minimise the number of cables and substations onshore.

It’s his money if he appeals, but we do need more wind, solar and other zero-carbon energy to combat global warming and its effects like the encroachment of the sea around Norfolk.

I believe, that building wind farms off the coast of Essex, Suffolk and Norfolk is a good move, as in the future, if we have spare electricity, it will be easy to export energy to Europe, through existing interconnectors.

But I do agree with him, that a better plan is needed to connect the offshore windfarms and minimise the number of cables and substations onshore.

A Norfolk Powerhouse

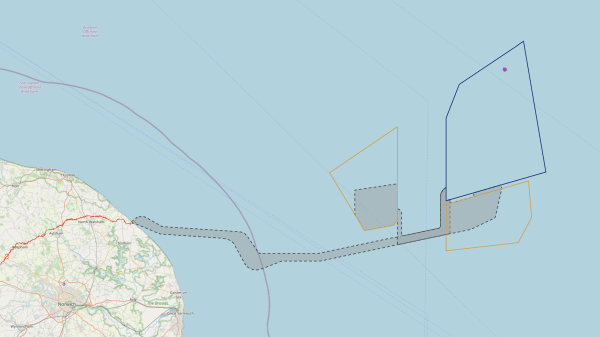

This map from Vattenfall, the developer of the two wind farms, shows the position of the farms and the route of the cable to the shore.

Note.

- The purple line appears to be the UK’s ten mile limit.

- Norfolk Boreas is outlined in blue.

- Norfolk Vanguard is outlined in orange.

- Cables will be run in the grey areas.

- Both wind farms are planned to have a capacity of 1.8 GW

Landfall will be just a few miles to the South of the Bacton gas terminal.

Bacton Gas Terminal

Bacton gas terminal is much more than a simple gas terminal.

- It is a complex of six gas terminals on four sites.

- There is a National Grid terminal, that odourises and blends the gas before distributing it into the National Transmission System via five outgoing 36-inch feeders to much of Southern England.

- There is a gas interconnector to Belgium.

- There is a gas interconnector to The Netherlands.

- There is coastal erosion in the area.

With the need to decarbonise, I can’t help feeling that the Bacton gas terminal is very much on the decline and the site will need to be repurposed in the next few years.

Blending Hydrogen With Natural Gas

If you blend a proportion of hydrogen into natural gas, this has two beneficial effects.

- Gas used in domestic and industrial situations will emit less carbon dioxide.

- In the near future we will be replacing imported natural gas with hydrogen.

The hydrogen could be produced by a giant electrolyser at Bacton powered by the electricity from the two Norfolk wind farms.

At the present time, a research project call HyDeploy is underway, which is investigating the blending of hydrogen into the natural gas supply.

- Partners include Cadent, Northern Gas Networks, the Health and Safety Executive, Keele University and ITM Power and Progessive Energy.

- A first trial at Keele University has been hailed as a success.

- It showed up to twenty percent of hydrogen by volume can be added to the gas network without the need to change any appliances or boilers.

Larger trials are now underway.

A Giant Electrolyser At Bacton

If hydrogen were to be produced at Bacton by a giant electrolyser, it could be used or distributed in one of the following ways.

- Blended with natural gas for gas customers in Southern England.

- Stored in a depleted gas field off the coast at Bacton. Both Baird and Deborah gas fields have been or are being converted to gas storage facilities, connected to Bacton.

- Distributed by truck to hydrogen filling stations and bus and truck garages.

- Greater Anglia might like a hydrogen feed to convert their Class 755 trains to hydrogen power.

- Sent by a short pipeline to the Port of Great Yarmouth and possibly the Port of Lowestoft.

- Exported to Europe, through one of the interconnectors.

Note.

- If the electrolyser were to be able to handle the 3.6 GW of the two wind farms, it would be the largest in the world.

- The size of the electrolyser could be increased over a few years to match the output of the wind farms as more turbines are installed offshore.

- There is no reason, why the electrical connection between Bacton and the landfall of the wind farm cable couldn’t be offshore.

If ITM Power were to supply the electrolyser, it would be built in the largest electrolyser factory in the World, which is in Sheffield in Yorkshire.

A Rail Connection To The Bacton Gas Terminal

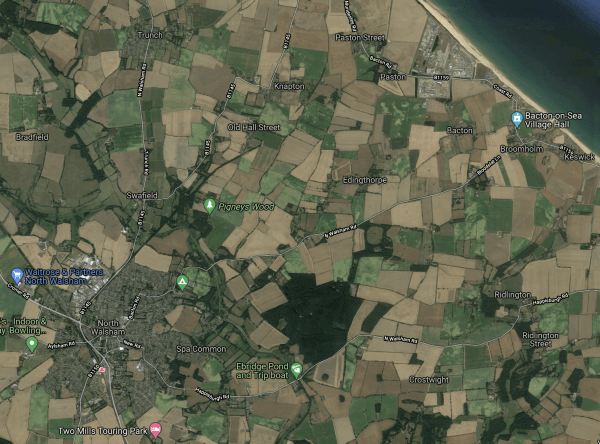

This Google Map shows the area between North Walsham and the coast.

Note.

- North Walsham is in the South-Western corner of the map.

- North Walsham station on the Bittern Line is indicated by the red icon.

- The Bacton gas terminal is the trapezoidal-shaped area on the coast, at the top of the map.

I believe it would be possible to build a small rail terminal in the area with a short pipeline connection to Bacton, so that hydrogen could be distributed by train.

How Much Hydrogen Could Be Created By The Norfolk Wind Farms?

In The Mathematics Of Blending Twenty Percent Of Hydrogen Into The UK Gas Grid, I said the following.

Ryze Hydrogen are building the Herne Bay electrolyser.

- It will consume 23 MW of solar and wind power.

- It will produce ten tonnes of hydrogen per day.

The electrolyser will consume 552 MWh to produce ten tonnes of hydrogen, so creating one tonne of hydrogen needs 55.2 MWh of electricity.

Each of the Norfolk wind farms, if they were working flat out would produce 43.2 GWh of electricity in a day.

Dividing the two figures gives a daily production rate of 782.6 tonnes of hydrogen per day.

But what happens if the wind doesn’t blow?

This is where the gas storage in the Baird, Deborah and other depleted gas fields comes in.In times of maximum wind, hydrogen is stored for use when the wind doesn’t blow.

Conclusion

I believe a plan like this, would be much better for Norfolk, the UK and the whole planet.

Using the existing gas network to carry the energy away from Norfolk, could mean that the electricity connection across Norfolk could be scaled back.

Talgo To Begin Fuel Cell Loco Trials

The title of this post, is the same as that of this article on Railway Gazette.

These are the first two paragraphs.

Trials are to begin shortly with the TPH2 fuel cell test locomotive developed by Talgo as part of its hydrogen traction programme. This forms part of a low-carbon research and development strategy which is being supported by a green hydrogen supply alliance and financing from the European Investment Bank.

The TPH2 loco has been produced by fitting fuel cells and traction batteries to the Travca L-9202 ‘Virgen del Buen Camino’ prototype multi-system and variable gauge locomotive which was built by Talgo in 2005.

This page on the Talgo web site describes the Travca locomotive like this.

Travca: Traction Without Borders

Travca is a locomotive that stops at nothing; not at different power supplies, track gauges nor signalling systems all of which makes Travca Talgo’s most advanced development in the field of traction.

This is the specification of the electric locomotive from the Talgo web site.

- Operating speed – Up to 250km/h (passenger version)

- Configuration – Bo-Bo

- Track gauge (mm) -1435-1668

- Length (m) – 19400

- Bodyshell width (mm) – 2950

- Unladen weight (tonnes) – 72 (passenger version)

- Number of axles – 4

- Power – 2,400 kW (25kV, 50Hz) / 2,000kW (3kV dc)

- Brakes – Regenerative, rheostatic and air brakes

Notes.

- It is a variable-gauge and variable-voltage locomotive.

- 1435 mm is standard gauge

- It is lighter and wider than a Class 90 locomotive.

It does seem to be the basis of a very useful locomotive.

This article on Railway News is entitled University Of Extremadura To Work With Talgo On Its Hydrogen Train, says this about the test train.

During the first stage of the hydrogen train project, Talgo is developing the necessary engineering for the assembly and commissioning of hydrogen traction in a test train. The train will comprise a Talgo Travca MS locomotive, which can change gauges and run under different electrification systems, and five Talgo hauled cars that will house the hydrogen fuel cell system. One of the cars will be a laboratory car.

This would appear to be an experimental train with the hydrogen power station in four of the coaches.

It also appears that Extremadura is developing a hydrogen infrastructure.

Applications In The UK

The obvious application in the UK, is as a Class 66 diesel locomotive replacement, for some of the light to medium duties.

The Class 66 locomotives have a power of 2400 kW, which could be within the range of the Talgo locomotive.

In LNER Seeks 10 More Bi-Modes, I speculated that Talgo, with all their experience of high speed trains might like to bid for the extra ten trains, that LNER requires.

They could be ideal to allow electric trains to run between London and Aberdeen and Inverness.

- The Travca locomotive running on electricity could certainly handle 140 mph between London and Edinburgh.

- The power requirements North of Edinburgh would be less, as speeds would be lower.

- Ranges on hydrogen would be under two hundred miles.

It would be a flagship service for both LNER and Talgo.

H2goesRail

The title of this post, is the same as that of this page on the Deutsche Bahn web site.

These three paragraphs introduce the H2goesRail philosopher.

Deutsche Bahn is currently developing and implementing solutions that utilize hydrogen. One such endeavor is the H2goesRail project. In partnership with Siemens Mobility, we are breaking new ground and driving forward decarbonization of the transport sector for the good of the environment. Together we are developing an innovative hydrogen system for rail transport, which will comprise a refueling station, hydrogen train, and maintenance infrastructure.

We aim to replace diesel multiple units in regional service and thus further reduce carbon emissions in rail transport. To achieve this, with H2goesRail we are developing an innovative mobile refueling station whose smart control unit will allow fast refueling of hydrogen trains.

DB Energie GmbH will ensure the supply of hydrogen for the project, from production by means of renewable-powered electrolysis all the way through to storage and provision.

There is a lot of video.

Lhyfe’s Green Hydrogen To Power Deutsche Bahn Trains

The title of this post, is the same as that of this article on Renewables Now.

This is the first paragraph.

Deutsche Bahn AG has agreed to source about 30 tonnes of green hydrogen from French producer Lhyfe from 2024 onward to power its trains as the German railway operator seeks to reach climate neutrality by 2040.

The electrolyser will be built at Tuebingen.

In Can The UK Have A Capacity To Create Five GW Of Green Hydrogen?, I said the following.

Ryze Hydrogen are building the Herne Bay electrolyser.

- It will consume 23 MW of solar and wind power.

- It will produce ten tonnes of hydrogen per day.

The electrolyser will consume 552 MWh to produce ten tonnes of hydrogen, so creating one tonne of hydrogen needs 55.2 MWh of electricity.

I suspect that in my quote above from the article on Renewables Now, that the Tuebingen electrolyser will be producing thirty tonnes of hydrogen per day or just under 11,000 tonnes per year.

In that case it would be three times the size of the Herne Bay Electrolyser.

Alstom And Liebherr Sign A Collaboration Agreement, In Order To Optimise Hydrogen Fuel Cells

The title of this post, is the same as that of this press release from Alstom.

The press release starts with these points.

-

Liebherr is developing air management technology that is particularly well suited to hydrogen fuel cells.

-

Alstom’s hydrogen strategy is part of its ambition to innovate by pioneering smarter and greener mobility solutions for all.

This paragraph then gives the basic outline of the agreement.

Alstom has signed a collaboration agreement with Liebherr – Aerospace & Transportation SAS, a France-based company specialising in the manufacture of compressors for fuel cells. This agreement is aimed at optimising hydrogen systems, including improving the reliability and durability of fuel cells, increasing their power density and reducing the cost of such solutions.

The press release gives a lot more details about Alstom’s hydrogen collaborations with other companies

Alstom seem very serious about hydrogen-powered trains.

Arcola Showcases Scottish Hydrogen Conversion

The title of this post is the same as an article in the December 2021 Edition of Modern Railways.

The article has this sib-title.

Class 614 Demonstration Runs at Bo’ness Next Year

This is a key paragraph early in the article.

The aim is to build capability within the Scottish supply chain with a view to future conversion of hydrogen fleets within Scotland. The choice of a ‘314’ to provide the donor vehicles was based solely on availability, following the withdrawal of the EMU fleet by ScotRail at the end of 2019.

I don’t think they would have been my choice of donor train, as the Class 314 trains were built over forty years ago.

But, as Merseyrail have shown, British Rail trains of that era scrub up well.

The article is worth a full read and worth the cover price of the magazine, as it has details on the conversion and tips on how you might design a hydrogen train.

- All the hydrogen tanks , fuel cells and batteries are designed to be fitted in the vehicle underframes and don’t take up space in the passenger compartment.

- There is a fuel cell raft under both driving motor vehicles.

- Each raft contains a 70 kW fuel cell from Ballard and hydrogen cylinders.

- 40 kg. of hydrogen at a pressure of 350 bar can be carried in each raft.

- Waste heat from the fuel cell is used to heat the train.

- The DC traction motors have been replaced by modern three-phase AC motors.

- The hydrogen fillers come from the automotive industry, which is surely an obvious move.

- The interior looks good in the picture and has uses seats reclaimed from Pendolino refurbishment.

The article also reveals that Arcola are working with Arup on a study to convert a Class 158 DMU to hydrogen power.

Conclusion

I wish all the engineers and suppliers well, but I feel that these two projects are both driven by Scottish politics, rather than sound engineering principles.