Union Pacific Railroad Makes Largest Investment In Wabtec’s FLXdrive Battery-Electric Locomotive

The title of this post, is the same as that of this press release from Union Pacific.

This is the first three paragraphs.

Union Pacific Railroad (NYSE: UNP) today announced the purchase of 10 FLXdrive battery-electric locomotives from Wabtec Corporation (NYSE: WAB). The order, which marks the largest investment in battery technology by a North American railroad, will upgrade Union Pacific’s rail yard infrastructure and support its commitment to significantly reduce greenhouse gas emissions.

“As an industry leader, Union Pacific is pioneering a major application of battery power in its rail yards,” said Rafael Santana, President and CEO for Wabtec. “Battery power is an ideal solution to reduce the environmental impact and costs of yard operations. Using the FLXdrive in the rail yard can significantly improve local air quality, as well as reduce noise by up to 70% for neighboring communities.”

The approximately 2.5-MWh locomotives are each powered solely by 7,000 battery cells, providing Union Pacific a zero-emission solution for its yard operations. The 10 FLXdrives will enable the railroad to eliminate 4,000 tons of carbon annually from its rail yards, the equivalent of removing 800 cars from the highway. The new locomotives will be manufactured in the United States with the first units being delivered to Union Pacific in late 2023.

It would appear that the major use will be in their rail yards.

There is also this second press release from Union Pacific, which is entitled Union Pacific Railroad To Assemble World’s Largest Carrier-Owned Battery-Electric Locomotive Fleet.

This is the first paragraph.

Union Pacific Railroad (NYSE: UNP) today announced plans to purchase 20 battery-electric locomotives for testing in yard operations. The combined purchases and upgrades to yard infrastructure are expected to exceed $100 million, representing the largest investment in battery-electric technology by a U.S. Class I railroad. The locomotives will be acquired from Progress Rail, a Caterpillar company, and Wabtec Corporation (NYSE:WAB), two companies at the forefront of locomotive innovation, and will be the world’s largest carrier-owned battery-electric locomotive fleet in freight service.

The press release also says that Union Pacific will be netzero by 2050.

Conclusion

All of this action in the United States and Australia with battery-electric locomotives, from two manufacturers; Progress Rail and Wabtec, leads me to the conclusion, that proposals to create battery-electric locomotives from Class 66 or Class 68 locomotives in the UK, will soon be being discussed by the owners of the locomotives and Wabtec and Stadler.

The Future Of The Class 68 Locomotives

This post has been brought on by the comments to two posts I have written today.

- Direct Rail Services Disposes Of Heritage Locomotives

- Suppliers Sought For New Bi-Mode Locomotives For TransPennine Express And Great Western Railway

Both Direct Rail Services and TransPennine Express are major users of Class 68 locomotives, with each having a fleet of fourteen locomotives.

In addition, Chiltern Railways has a smaller fleet of six locomotives.

- Direct Rail Services use their locomotives for various passenger and freight duties, including the important one of moving nuclear material around the country.

- TransPennine Express use their locomotives on their passenger services across the North of England.

- Chiltern Railways use their locomotives on their passenger services between London and Birmingham and sometimes Oxford.

The design was a bespoke one by Stadler for Direct Rail Services and the first one entered service in 2014.

The picture shows one of TransPennine’s Class 68 locomotives at Scarborough. As the picture shows, they are a smart and purposeful-looking locomotive, that wouldn’t look out of place in the right livery on the front of the Royal Train.

It has some good features.

- It is a 100 mph locomotive.

- It seems to be well-liked by operators.

- It can haul both passenger and freight trains.

- It can act as a Thunderbird or rescue locomotive.

But they have three problems; emissions, noise and diesel.

This is from Wikipedia.

The locomotive’s propulsion system is compliant with Stage III A of the European emission standards, but not the more stringent Stage III B requirements.

But noise is a another problem and this has caused council action in Scarborough.

More important than emissions or noise, is the fact, that the locomotive is diesel-powered, so the fleet will probably have to be retired from the railway, at a time, when there is still useful life left in the locomotives.

The Class 68 locomotive is a member of the Stadler Eurolight family, of which there are three versions.

All follow similar design principles, differing mainly in dimensions, with Spain, Taiwan and the UK ordering upwards of twenty-thirty locomotives.

The UKLight branch of the family has two other members.

The Class 88 locomotive is an electro-diesel version of the Class 68 locomotive and the development of the design is described in this extract from the Class 88 locomotive’s Wikipedia entry.

Amid the fulfillment of DRS’ order for the Class 68, Stadler’s team proposed the development of a dual-mode locomotive that could be alternatively powered by an onboard diesel engine or via electricity supplied from overhead lines (OHLE). Having been impressed by the concept, DRS opted to place an order for ten Class 88s during September 2013. Having been developed alongside the Class 68, considerable similarities are shared between the two locomotives, amounting to roughly 70 percent of all components being shared.

According to Wikipedia, the type had a smooth entry into service.

The Class 93 locomotive will be the next development of the UKLight branch of the family, when it is delivered in 2023.

It will be a tri-mode locomotive, that will be capable of being powered by 25 KVAC overhead electrification, an onboard diesel engine and batteries.

It will be a 110 mph locomotive.

It can haul both passenger and freight trains.

Rail Operations Group have ordered 30 locomotives.

This is the first paragraph of the section in Wikipedia called Specification.

The Class 93 locomotive has been developed to satisfy a requirement for a fast freight locomotive that uses electric power while under the wires, but is also capable of self-powered operations. Accordingly, it is capable of running on diesel engines, from overhead wires, or from its onboard batteries. These batteries, which occupy the space used for the braking resistors in the Class 88, are charged via the onboard transformer or regenerative braking; when the batteries are fully charged, the locomotive only has its friction brakes available. The diesel engine is a six-cylinder Caterpillar C32 turbocharged power unit, rated at 900 kW, conforming with the EU97/68 stage V emission standard. The batteries units are made of Lithium Titanate Oxide and use a liquid cooling solution, enabling rapid charge and discharge.

It is a truly agnostic locomotive, that can take its power from anywhere.

The last paragraph of the specification compares the locomotive to the Class 66 locomotive.

In comparison with the Class 66, the Class 93 can outperform it in various metrics. In addition to a higher top speed, the locomotive possesses greater acceleration and far lower operating costs, consuming only a third of the fuel of a Class 66 along with lower track access charges due to its lower weight. ROG has postulated that it presents a superior business case, particularly for intermodal rail freight operations, while also being better suited for mixed-traffic operations as well. Each locomotive has a reported rough cost of £4 million.

It is no ordinary locomotive and it will change rail freight operations in the UK.

I have a feeling that the Class 93 locomotive could be a lower-carbon replacement for the Class 68 locomotive.

But I also believe that what Stadler have learned in the development of the Class 93 locomotive can be applied to the Class 68 locomotive to convert them into zero-carbon locomotives.

It may be just a matter of throwing out the diesel engine and the related gubbins and replacing them with a large battery. This process seems to have worked with Wabtec’s conversion of diesel locomotives to FLXdrive battery-electric locomotives.

Direct Rail Services Disposes Of Heritage Locomotives

The title of this post, is the same as that of this article on Rail Magazine.

This is the first paragraph.

Direct Rail Services, the rail arm of Nuclear Transport Solutions (NTS), has announced details of its much-anticipated plan to sell off some of its heritage fleet of locomotives and coaching stock.

The main job of Direct Rail Services is to move nuclear fuel and other cargoes around the country in support of the UK’s nuclear industry. For this purpose, they have a substantial fleet of over fifty modern Class 66, Class 68 and Class 88 locomotives, which seem to have taken over from the heritage fleet, which are now starting to be passed on to other operators.

Direct Rail Services also tend to be the odd-job men and innovators of the traction business.

- They have provided modern motive power for both regular, charter and replacement passenger services.

- They haul freight trains for supermarkets and others.

- They sub-lease Class 68 locomotives to other operators.

- Both the Class 68 and Class 88 locomotives are 100 mph-capable, which must widen their markets.

- They have supplied locomotives for Thunderbird duties.

- They are happy to specify a new locomotive and bring it into service, as they did with the Class 68 and Class 88.

According to Wikipedia, they have issued a tender for a further ten new-build diesel-electric locomotives.

Will these be an existing design or another new design?

This is a section of the Wikipedia entry for the Class 88 locomotive.

Akin to the Class 68, the Class 88 can achieve a maximum speed of 100 mph (160 km/h), sufficient for regular passenger operations, while operating under OHLE, it has a power output of 4,000 kW (5,400 hp). Under diesel power, provided by its 12-cylinder Caterpillar C27, it has a maximum power output of 708 kW (949 hp); however, the maximum tractive effort is available in either mode. The locomotive’s engine, which is compliant with the current EU Stage IIIB emission restrictions, has limited available power as a result of the customer’s choice to give the Class 88 comparable power to a traditional Class 20.

It almost looks like a design for all purposes.

- It can pull a passenger train at 100 mph.

- With the right rolling stock, it must be able to pull a freight train at 100 mph.

- A 100 mph freight capability must be very useful on double-track electrified main lines like the East and West Coast Main Lines, where it would increase capacity.

- It probably has enough power to drag a freight train out of the depot on to an electrified main line.

- The locomotive would appear to be able to do anything that one of Direct Rail Services’s Class 20 locomotives can do, which would surely enable it to pick-up a nuclear flask from a remote power station.

- But it would also be able to transport the flask back to Cumbria using electric power, where it is available.

- In ’88’ Makes Sizewell Debut, I describe how a Class 88 locomotive moved a flask from Sizewell to Crewe.

- It is compliant with the latest emission regulations.

- It can use regenerative braking, where the electrification can handle it.

I wonder, if Direct Rail Services are going to add a locomotive to their fleet, that is capable of bringing the longest and heaviest freight trains out of the Port of Felixstowe.

- The Felixstowe Branch is a fairly flat track.

- The only moderately severe gradients ae either side of the Spring Road Viaduct.

- Some electrification could be added.

- A 100 mph freight capability would help in increasing the capacity of the Great Eastern Main Line to and from London.

The right locomotive might be able to haul smaller freight trains between Felixstowe and Peterborough.

Conclusion

There has been no news about the extra ten locomotives that Direct Rail Services will order.

The company has form in designing the right locomotive for the job they will do.

I think, that when the order is placed, it could add another type of locomotive to Direct Rail Services’s fleet.

Could Class 66 Locomotives Be Converted Into Battery-Electric Locomotives?

This picture shows a Freightliner Class 66 locomotive passing through Stratford with a multimodal freight train.

These are a few thoughts on converting some of the four hundred and eighty Class 66 locomotives into battery-electric locomotives.

An Estimate Of Performance Of A Battery Electric Class 66 Locomotive

In Iron Ore Miner Orders Heavy-Haul Battery Locomotive, I said this about a UK-sized locomotive based on Wabtec’s FLXdrive battery-electric technology.

I could envisage Wabtec designing a UK-sized battery-electric locomotive with these characteristics.

- 2.5 MW power output, which is similar to a Class 66 locomotive.

- A battery size of perhaps 1.8 MWh based on Wabtec’s FLXdrive technology.

- A pantograph to charge the batteries and also power the locomotive where electrification exists.

- 75 mph operating speed.

- Ability to work in tandem with a Class 66 locomotive.

All technology is under Wabtec’s control.

This locomotive could have a range of at least fifty miles on battery power, doing the sort of duties that Class 66 locomotives do!

So it would be able to take a multimodal container train out of the Port of Felixstowe to the electrification at Ipswich.

The Class 66 Locomotive Is Diesel-Electric

The Class 66 locomotive is a diesel-electric locomotive, where the diesel engine drives an alternator, which generates electricity, which then powers the six traction motors, which are arranged, so that there is one on each of the six axles.

This should make conversion easier, as the heavy lump of the engine and the alternator would be replaced with a large number of lithium-ion batteries.

Wabtec Has A Modular Battery System

This article on Railway Age gives a lot of detail and several pictures of the modular FLXdrive battery system.

- Each module is a 4.9 kWh battery, that weighs 72.6 Kg.

- Batteries are arranged into strings, which feed the traction motors.

- There is a sophisticated control system, which ensures that a module failure doesn’t disable the locomotive.

- The battery system is air-cooled.

I would expect that Wabtec could arrange a number of modules in the stripped out body of a Class 66 locomotive.

The FLXdrive Battery System Handles Regenerative Barking

The Railway Age article says this.

Battery charging while the FLXdrive is operating occurs through regenerative dynamic braking.

This will certainly improve efficiency.

Could A Pantograph Be Fitted To A Class 66 Locomotive?

This picture of a Class 66 locomotive was taken at Peterborough.

Note the 25 KVAC overhead electrification and the gap between the wires and the roof of the locomotive.

I don’t think it would the toughest job to design a pantograph for a Class 66 locomotive.

What Would Be The Use Of A Battery Electric Class 66 Locomotive With A Fifty Mile Range?

I believe that a surprising number of duties currently handled by Class 66 locomotives could be performed by a battery-electric Class 66 locomotive.

- The locomotives would effectively be electric locomotives with a last fifty mile capability.

- The number of possible duties will increase as electrification increases.

- They would be ideal to support track maintenance activities.

- They would be a zero-carbon locomotive with a low noise footprint.

As I said earlier, they should be able to haul a heavy intermodal train out of the Port of Felixstowe.

Would A Battery-Electric And A Diesel-Electric Class 66 Locomotive Working As A Pair Be Able to Handle The Heaviest Trains?

As the Americans and Canadians have shown with more than one locomotive, where one is a battery-electric locomotive can reduce the carbon-emissions, the same rules must apply in the UK.

Conclusion

I am not a lover of the smelly, noisy and polluting diesel Class 66 locomotives, but it does look it could be possible to convert some into battery-electric locomotives.

I wouldn’t be surprised to see Wabtec convert some Class 66 locomotives into battery-electric locomotives.

I also believe, that conversion of Class 66 locomotives to battery-electric operation could be the most affordable way to help decarbonise rail freight.

Iron Ore Miner Orders Heavy-Haul Battery Locomotive

The title of this post, is the same as that of this article on Railway Gazette.

This is the first two paragraphs.

Mining company Roy Hill has ordered a Wabtec FLXdrive battery-electric heavy-haul freight locomotive. This will replace one the four ES44ACi diesel-electric locos used to haul its 2 700 m long iron ore trains, and is expected to reduce fuel costs and emissions by ‘double digit’ percentages while also cutting maintenance costs.

The locomotive is scheduled to be delivered in 2023. It will have a capacity of 7 MWh, an upgrade from the 2·4 MWh prototype which Wabtec and BNSF tested in revenue service in California earlier this year.

Note.

- It will have a 7 MWh battery.

- 2700 metres is 1.6 miles.

It looks to me, that the three diesel locomotives and one battery locomotive are arranged as a massive hybrid locomotive and I suspect that with sophisticated control systems, those double digit cuts in fuel costs and emissions would be possible.

A couple of years ago, I took this picture near Shenfield.

This double-headed train has a Class 90 electric locomotive and a Class 66 diesel locomotive at the front of a long freight train.

- The Class 90 locomotive has an TDM system for multiple working.

- The Class 66 locomotive has an AAR system for multiple working.

So does this mean that the two locomotives can’t work together, which if it does begs the question of what is happening.

- Had the Class 66 locomotive failed and Class 90 was acting as a Thunderbird?

- Was the Class 66 locomotive being moved from one depot to another for maintenance or repair?

- Was it an experiment to see if the two locomotives could work together?

I sometimes think that I didn’t see this unusual formation, but then the camera doesn’t lie.

But could we learn from what Wabtec are doing for Roy Hill in Australia?

The Class 93 Locomotive

Rail Operations Group have already ordered thirty Class 93 tri-mode locomotives from Stadler, which have following power ratings.

- Electric – 4000 kW

- Diesel – 900 kW

- Hybrid – 1300 kW

If this locomotive is capable of hauling the heaviest intermodal freight trains out of Felixstowe, Southampton and other ports and freight terminals, it could contribute to substantial reductions in the diesel fuel used and emissions.

As an example, I will use a freight train between Felixstowe North Terminal and Trafford Park Euro Terminal.

- It is a route of 280 miles.

- I will ignore that it goes along the North London Line through North London and along the Castlefield Corridor through Manchester Piccadilly station.

- There is fifteen miles without electrification at the Felixstowe end.

- There is under three miles without electrification at the Manchester end.

On this service , it could be as much as 94 % of diesel and emissions are saved, if the Class 93 locomotive can haul a heavy freight train out of Felixstowe. A few miles of strategically-placed electrification at the Ipswich end would help, if required.

It must also be born in mind, that the Class 93 locomotive is a 110 mph locomotive on electric power and could probably do the following.

- Run at 100 mph on the busy Great Eastern Main Line.

- Run at faster speeds on the West Coast Main Line.

- Fit in well with the 100 mph passenger trains, that run on both routes.

So not only does it save diesel and carbon emissions, but it will save time and make the freight train easier to timetable on a route with lots of 100 mph passenger trains.

The Class 93 locomotive looks like it could be a game-changer for long-distance intermodal freight, especially, if there were short sections of strategically-placed electrification, added to the electrified network.

Emissions could also be reduced further by using some for of sustainable fuel.

The picture shows a Class 66 locomotive, which is powered by Hydrotreated Vegetable Oil or HVO.

I can see that all diesel-powered trains and locomotives will be powered by sustainable fuels by the end of this decade.

A Wabtec Battery-Electric Locomotive

Wabtec is building a battery-electric locomotive for Roy Hill in Australia.

This article on Railway Age talks about Wabtec’s FLXdrive battery locomotives and describes some features of the locomotive for Roy Hill in Australia.

It mentions pantographs and overhead wires to charge the batteries.

- Wabtec’s prototype battery locomotive has a power output of 3.24 MW and a battery size of 2.4 MWh

- The Roy Hill battery locomotive has a power output of 3.24 MW and a battery size of 7 MWh

I could envisage Wabtec designing a UK-sized battery-electric locomotive with these characteristics.

- 2.5 MW power output, which is similar to a Class 66 locomotive.

- A battery size of perhaps 1.8 MWh based on Wabtec’s FLXdrive technology.

- A pantograph to charge the batteries and also power the locomotive where electrification exists.

- 75 mph operating speed.

- Ability to work in tandem with a Class 66 locomotive.

All technology is under Wabtec’s control.

This locomotive could have a range of at least fifty miles on battery power.

I think this locomotive could handle these routes.

- Peterborough and Doncaster via the Great Northern and Great Eastern Joint Line via Lincoln, with some form of charging at halfway.

- Felixstowe and Nuneaton, with some extra electrification at some point between Peterborough and Leicester.

- Oxford and Birmingham, with possibly some extra electrification in the middle.

One option for charging electrification, would surely be to electrify passing loops.

I think a battery-electric locomtive based on Wabtec’s FLXdrive technology could be a very useful locomotive.

Could Wabtec’s Battery-Electric Locomotive Pair-Up With A Class 66 Locomotive?

Roy Hill will use their locomotive to form a consist of three diesel locomotives and one battery locomotive to obtain double-digit savings of fuel and emissions, when hauling iron-ore trains that are 1.6 miles long on a route of 214 miles.

We don’t have massive iron-ore trains like this, but we do move huge quantities of segregates and stone around the country in trains generally hauled by Class 66 locomotives.

So could a Class 66 or another suitable locomotive be paired-up with a battery-electric locomotive to make savings of fuel and emissions?

I would suggest that if it works in Australia, the technology will probably work in the UK.

The biggest problem for Wabtec is that the heavy end of the market may well be a good one for hydrogen-powered locomotives. But Wabtec are going down that route too!

Conclusion

I am convinced that the two decarbonisation routes I have outlined here are viable for the UK.

But I also feel that locomotive manufacturers will produce hydrogen-powered locomotives.

Other companies like Alstom, Siemens and Talgo will also offer innovative solutions.

Let The Diving Under Begin!

The page on the Network Rail web site is entitled Network Rail Completes Major Signalling Work Near Peterborough Ready For Freight Trains To Begin Diving Under East Coast Main Line This Winter.

The Network Rail web page gives details of the innovative techniques used to build and insert the dive-under.

This Network Rail picture shows the dive-under going under the East Coast Main Line from the North East.

It certainly looks to be strongly constructed.

Freight Trains Through The Werrington Dive-Under

I have just counted the number of freight trains that would have used the route had it been open last Friday between 0600 and 2400.

It was twenty-seven trains or almost one train per hour (tph) in each direction.

- How long will it be before the residents of Lincoln and the other towns and cities on the route start protesting about the noisy, smelly and polluting Class 66 locomotives, that haul most of these freight trains?

- The long trains will also annoy drivers and residents at the many level crossings on the route.

Operators may not be able to do much about the train length, but they can start looking for some more environmentally-friendly locomotives, which could be hydrogen-powered.

At least there is funding for a lower-emission dual-dual-fuel locomotive, that I wrote about in Freightliner Secures Government Funding For Dual-Fuel Project.

Wabtec Breathes New Life Into Older Locomotives

This title of this post, is the same as that of this article on Railway Gazette.

This is the introductory paragraph.

This month Wabtec completed the 1 000th locomotive it has remanufactured for customers in the Americas under a programme launched in 2015. Norfolk Southern has taken delivery of 500 of the locos, with other customers including Canadian Pacific, BNSF, Union Pacific and Brazilian operator Rumo.

This second paragraph gives Wabtec’s aims of the remanufacturing.

Wabtec said locomotive modernisation is a key element of its sustainability efforts, with revitalised locos offering fuel efficiency improvements of up to 25%, reliability increases of more than 40%, up to a 55% increase in haulage capability and reductions in maintenance, repair, and overhaul costs of up to 20%.

This ongoing program, which although it only offers a 25 % reduction in carbon emissions, shows the size of the diesel locomotive market in North America.

- A lot of these locomotives were built by GE Transportation Systems, which is now owned by Wabtec.

- It is obviously, a market that is commercially rewarding.

In Freightliner Secures Government Funding For Dual-Fuel Project, I talked about s UK project to decarbonise one of our North American-built Class 66 locomotives.

I do wonder how long it will be before Cummins or one of the other big diesel engine manufacturers like Caterpillar offers a hydrogen conversion for these big beasts.

The numbers shown in the article, show it could be a very large and profitable market.

In the future, a lot of decarbonisation will be driven by commercial interests.

Powered By HVO

I took these pictures yesterday at Peterborough.

Note the locomotive is named Benjamin Gimbert GC.

DB Cargo have issued a press release on these trials of HVO.

Wikipedia also give more details of HVO.

Will Zero-Carbon Freight Trains Be Powered By Battery, Electric Or Hydrogen Locomotives?

These are a few initial thoughts.

We Will Not Have A One-Size-Fits-All Solution

If you consider the various freight and other duties, where diesel locomotives are used, you get a long list.

- Light freight, where perhaps a Class 66 locomotive moves a few wagons full of stone to support track maintenance.

- Intermodal freight, where a Class 66 locomotive moves a long train of containers across the country.

- Stone trains, where a Class 59 or Class 70 locomotive moves a very heavy train of aggregate across the country.

- Empty stock movements, where a diesel locomotive moves an electrical multiple unit.

- Supporting Network Rail with trains like the New Measurement Train, which is hauled by two diesel Class 43 power cars.

- Passenger trains at up to and over 100 mph.

I can see a need for several types of zero-carbon locomotive.

- A light freight locomotive.

- A medium freight locomotive, that is capable of hauling many intermodal trains across the country and would also be capable of hauling passenger services.

- A heavy freight locomotive, capable of hauling the heaviest freight trains.

- A Class 43 power car replacement, which would probably be a conversion of the existing power cars. Everybody loves InterCity 125s and there are over a hundred power cars in regular service on railways in the UK.

There are probably others.

The UK Hydrogen Network Is Growing

Regularly, there are news items about companies in the UK, who will be providing green hydrogen to fuel cars, vans, buses, trucks and trains.

Hydrogen is becoming a fuel with a much higher availability.

The UK Electricity Network Is Growing And Getting More Resilient

We are seeing more wind and solar farms and energy storage being added to the UK electricity network.

The ability to support large numbers of battery-electric buses, cars, trucks and trains in a reliable manner, is getting more resilient and much more comprehensive.

There Will Be More Railway Electrification

This will happen and installation will be more innovative. But predicting where electrification will be installed, will be very difficult.

Hydrogen Fuel Cells Now Have Rivals

Hydrogen fuel cells are normally used to convert hydrogen gas to electricity.

But over the last few years, alternative technology has evolved, which may offer better methods of generating electricity from hydrogen.

- Rolls Royce have developed a beer keg-sized 2.5 MW generator, that could run on hydrogen, which I wrote about in Our Sustainability Journey.

- Honeywell are possibly going the same route, which I wrote about in Honeywell Introduces Power Source For Hybrid-Electric Aircraft.

- JCB have converted diesel engines to run on hydrogen, which I wrote about in JCB Finds Cheap Way To Run Digger Using Hydrogen.

- Caterpiller, Cummins and Rolls-Royce mtu are showing signs of taking a similar route to JCB.

Fuel cells will not be having it all their own way.

Batteries Are Improving Their Energy Density

This is inevitable. and you are starting to see improvements in the fabrication of the battery packs to get more kWh into the space available.

In Wrightbus Presents Their First Battery-Electric Bus, I said this about the Forsee batteries used in the new buses from Wrightbus.

The Forsee brochure for the ZEN SLIM batteries gives an energy density of 166 Wh per Kg. This means that the weight of the 454 kWh battery is around 3.7 tonnes.

A one-tonne battery would have a capacity of 166 kWh.

- It is the highest value I’ve so far found.

- Technology is likely to improve.

- Other battery manufacturers will be striving to match it.

For these reasons, in the rest of this post, I will use this figure.

Some Example Locomotives

In this section, I shall look at some possible locomotives.

Conversion Of A Class 43 Power Car

There are two Class 43 power cars in each InterCity 125 train.

- The diesel engine is rated at 1678 kW.

- The transmission is fully electric.

- These days, they generally don’t haul more than five or six intermediate Mark 3 coaches.

I would see that the biggest problem in converting to battery power being providing the means to charge the batteries.

I suspect that these power cars would be converted to hydrogen, if they are converted to zero-carbon.

- I would estimate that there is space for hydrogen tanks and a small gas-turbine generator in the back of the power car.

- Much of the existing transmission could be retained.

- A zero-carbon power car would certainly fit their main use in Scotland and the South-West of England.

- I doubt hydrogen refuelling would be a problem.

They may even attract other operators to use the locomotives.

A Battery-Electric Locomotive Based on A Stadler Class 88 Locomotive

I am using this Class 88 locomotive as a starting point, as the locomotive is powerful, reliable and was built specifically for UK railways. There are also ten already in service in the UK.

In Thoughts On A Battery Electric Class 88 Locomotive On TransPennine Routes, I started the article like this.

In Issue 864 of Rail Magazine, there is an article, which is entitled Johnson Targets A Bi-Mode Future.

As someone, who has examined the mathematics of battery-powered trains for several years, I wonder if the Age of the Hybrid Battery/Electric Locomotive is closer than we think.

A Battery/Electric Class 88 Locomotive

After reading Dual Mode Delight (RM Issue 863), it would appear that a Class 88 locomotive is a powerful and reliable locomotive.

-

- It is a Bo-Bo locomotive with a weight of 86.1 tonnes and an axle load of 21.5 tonnes.

- It has a rating on electricity of 4,000 kW.

- It is a genuine 100 mph locomotive when working from 25 KVAC overhead electrification.

- The locomotive has regenerative braking, when working using electrification.

- It would appear the weight of the diesel engine is around seven tonnes

- The closely-related Class 68 locomotive has a 5,600 litre fuel tank and full of diesel would weight nearly five tonnes.

The locomotive would appear to be carrying between 7 and 12 tonnes of diesel-related gubbins.

Suppose that the diesel-related gubbins of the Class 88 locomotive were to be replaced with a ten tonne battery.

Using the Forsee figures, that I quoted earlier, this battery would hold 1660 kWh.

At the power level of the 700 kW of the Caterpillar C27 diesel engine in the Class 88 locomotive, that would give more than two hours power.

It looks to me, that a battery-electric Class 88 locomotive could be a very useful locomotive.

It might even be able to haul freight trains in and out of the Port of Felixstowe, which would be a big advantage in decarbonising the port.

Certainly, methods to charge battery trains on the move, are being developed like the system from Hitachi ABB Power Grids, that put up short sections of 25 KVAC overhead electrification, which would be driven by a containerised power system.

These systems and others like them, may enable some battery-electric freight trains to work routes like.

- Felixstowe and Ipswich.

- Ipswich and Peterborough

- Peterborough and Nuneaton.

- Peterborough and Doncaster via Lincoln

- Birmingham and Oxford

None of these routes are fully-electrified.

But because of the power limit imposed by the batteries, these locomotives will need to be recharged at points on the route.

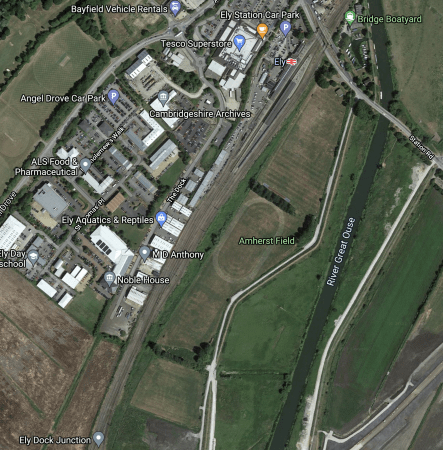

This Google Map shows the Ipswich and Peterborough route crossing the Fen Line at Ely station.

Note.

- Ely Dock junction in the South-West corner, where the line from Ipswich and Bury St. Edmunds joins the lines through Ely.

- Ely station towards the North-East corner of the map.

- Passenger trains run through the station.

But freight trains can take a route on the Eastern side of the station, which is not electrified.

At Ely station, a loop like this can be electrified using the existing electrification power supply, but at other places, systems like that from Hitachi ABB Power Grids can be used to electrify the loop or an appropriate section of the route.

These short sections of electrification will allow the train to progress on either electric or battery power.

A Hydrogen-Electric Locomotive Based on A Stadler Class 88 Locomotive

In The Mathematics Of A Hydrogen-Powered Freight Locomotive, I looked at creating a hydrogen-powered locomotive from a Class 68 locomotive.

I decided it was totally feasible to use readily available technology from companies like Rolls-Royce and Cummins to create a powerful hydrogen-powered locomotive.

The Class 68 locomotive is the diesel-only cousin of the electro-diesel Class 88 locomotive and they share a lot of components including the body-shell, the bogies and the traction system.

I suspect Stadler could create a Class 88 locomotive with these characteristics.

- 4 MW using electric power

- At least 2.5 MW using hydrogen power.

- Hydrogen power could come from Rolls-Royce’s 2.5 MW generator based on a small gas-turbine engine.

- 100 mph on both electricity and hydrogen.

- It would have power output on hydrogen roughly equal to a Class 66 locomotive on diesel.

- It would have a range comparable to a Class 68 locomotive on diesel.

This locomotive would be a zero-carbon Class 66 locomotive replacement for all duties.

A Larger And More Powerful Hydrogen-Electric Locomotive

I feel that for the largest intermodal and stone trains, that a larger hydrogen-electric locomotive will be needed.

With the way Wabtec are going in the United States, I wouldn’t be surprised to see a suitable locomotive cross the pond.

Conclusion

In the title of this post, I asked if freight locomotives of the future would be battery, electric or hydrogen.

I am sure of one thing, which is that all freight locomotives must be able to use electrification and if possible, that means both 25 KVAC overhead and 750 VDC third rail. Electrification will only increase in the future, making it necessary for most if not all locomotives in the future to be able to use it.

I feel there will be both battery-electric and hydrogen-electric locomotives, with the battery-electric locomotives towards the less powerful end.

Hydrogen-electric will certainly dominate at the heavy end.