Backing Up The Wind With The Keadby Power Stations

I went to Cleethorpes from Doncaster by train yesterday. You pass the Keadby site, where there are two large gas–fired power stations of 734 MW and 710 MW. A third one ; Keadby 3 of 910 MW complete with carbon capture and storage should join them by 2027.

So that will be nearly 2.5 GW of reliable electricity.

I find it interesting that one of our first gas-fired power stations with carbon capture will be in Lincolnshire, which is famous for growing plants of all shapes, types and sizes. So will we be seeing lots of greenhouses on the flat lands I saw yesterday, growing plants in an atmosphere they like, so that we can generate our carbon dioxide and eat it.

The next power station at Keadby is called the Keadby Next Generation power station, which is intended to be complete by 2030. It is a bit of a puzzle in that it will run on up to 1800 MW of hydrogen and only produce up to 910 MW of electricity.

Note.

- The hydrogen will come from SSE’s hydrogen store at Aldbrough and Centrica’s store at Rough.

- Surely, the amount of hydrogen and electricity should balance.

When I worked in ICI’s hydrogen plant in the 1960s, ICI had no use for the hydrogen, so they sent it to their power station, blended it with coal gas and used it to make steam for other processes.

Could Keadby Next Generation power station be providing zero-carbon steam for the chemical and other processes on Humberside?

Adding the 910 MW of electricity to Keadby’s gas-fired total of 2.5 GW gives 3.4 GW of electricity from Keadby to back up the wind farms.

3.4 GW at Keadby is what I call backup!

It also should be noted, that one of the reasons for building the Mersey Tidal Barrage is to provide backup for all the wind farms in Liverpool Bay.

Conclusion

I believe that SSE could be supplying zero-carbon steam in addition to electricity from the Keadby Hydrogen power station.

UK Government Sets 8-Hour Minimum For LDES Cap-And-Floor Sheme

The title of this post, is the sa,e as that of this article on Energy Storage News.

This is the sub-heading.

The UK government has published a Technical Decision Document confirming crucial aspects of its long duration electricity storage (LDES) cap-and-floor scheme, which includes increasing the minimum duration required from six hours to eight

These paragraphs give full details.

The document, released by regulator Ofgem on 11 March, details the final overarching rules and requirements for the scheme as well as how it will be implemented, though significant detail still remains to be worked out.

The scheme will provide a cap-and-floor revenue protection for 20-25 years that will allow all capital costs to be recoverable, and is effectively a subsidy for LDES projects that may not be commercially viable without it. Most energy storage projects being deployed in the UK today are lithium-ion battery energy storage systems (BESS) of somewhere between 1-hour and 3-hour in duration (very occasionally higher).

One of the most significant new details of the scheme is that, following industry feedback, the minimum duration for projects to qualify has been increased from six hours to eight hours of continuous rated power.

The ‘continuous rated power’ aspect prevents shorter duration projects from bidding in a smaller section of their MW capacity in order to act like an 8-hour system.

Another interesting detail pointed out by several commentators is that the cap is a ‘soft’ one, meaning it will allow extra revenue to be shared between developers and consumers. Exact details on the ratio are yet to be determined.

As a Graduate Control Engineer from Liverpool University in the 1960s, I hope that the move from a six to eight hours minimum duration is feasible.

I wasn’t dealing with power systems, but with multi-vessel chemical plants.

These are my thoughts.

The biggest project, I was dealing with a few years later in the 1970s, was the modeling of all the the reservoirs and pipelines by the Water Resoures Board.

As the supply side of the water industry hasn’t had too many issues with the volume of water supplied, I feel that the main modelers must have done a reasonable job.

Six To Eight Hours Of Continuous Operation

The article says this about uprating from six to eight hours of continuous operations.

All the systems that have been proposed for cap-and-floor operation, seem to have some form of physical storage.

- Energy Dome appears to have tents of carbon dioxide.

- Energy Vault uses stacks of heavy weights.

- Form Energy has tanks of rust.

- Gravitricity has huge weights in disued mine shafts.

- Highview Power has large tanks of liquid air.

- Pumped storage hydro has two lakes, that hold water.

- Rheenergise has two large tanks, of a water-based slurry.

So to go from six to eight hours will hopefully just need some more storage.

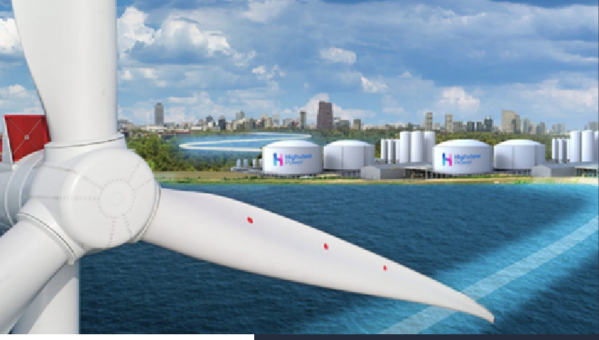

Highview Power appears to use similar gas tanks to those used to store natural gas or hydrogen.

This image clipped from Highview’s web site, shows large tanks for liquified gas storage.

With tanks like these, which can hold GW-equivalents of liquid air, Highview could be building batteries with storage to rival the smaller pumped storage hydroelectric power stations. They are already talking of 200 MW/2.5 GWh systems, which would have a 12.5 hour continuous rating and would probably need two to three tanks.

Coire Glas Pumped Storage

I’ll use Coire Glas pumped storage hydro electric power station as an example.

As currently planned SSE’s Cioire Glas pumped storage hydroelectric power station is 1.5 GW/30 GWh, so it has a a 20 hour continuous rating.

In The UK’s Pumped Storage Hydroelectricity, I gave a rough estimate of the pumped storage hydroelectricity systems in operation or planed as nearly 11 GW/224GWh.

The Soft Cap

The article says this about a soft cap.

Another interesting detail pointed out by several commentators is that the cap is a ‘soft’ one, meaning it will allow extra revenue to be shared between developers and consumers. Exact details on the ratio are yet to be determined.

I seem to remember that when I was modeling a larger multi-vessel chemical plant at ICI, I was using sharing between vessels, to get the system to operate on a PACE-231R analog computer.

So I suspect a soft cap is possible.

AI Could Make New Runways Obsolete

The title of this post, is the same as that of this article on Jewish News.

This is the sub-heading.

As Heathrow’s controversial third runway gets the green light and Gatwick looks on track for a second one, an Israeli tech innovation could reduce the need for such costly expansions.

These paragraphs add some detail.

IntellAct is a cutting-edge AI company that helps airports maximise efficiency, cut delays and save billions of pounds. By optimising ground operations and reducing aircraft turnaround times, it could spare airports the need for new runways entirely.

“The aviation industry is bleeding from a thousand cuts,” says Udi Segall, IntellAct’s founder and CEO. “Constant delays – with an average of 15.5 minutes per flight — add up to billions in costs. We saw a financial opportunity in how airlines manage their activities, and that’s where IntellAct comes in.”

IntellAct leverages big data and machine learning to provide airlines, airports and ground handling teams with real-time visibility into service performance bottlenecks and the ability to address them in a way that can yield significant operational improvements and a dramatic reduction in flight delays.

It’s an interesting thought.

I am reminded of a story from the 1960s, from ICI.

They had a polypropylene plant, that was notoriously inefficient, so a guy called Humphrey Bowen (?) used a discrete simulation program called HOCUS to create a board game of the chemical plant. This game was then played one Sunday, with beer and sandwiches between the various teams of production workers. It became heated at one point, but they did learn a lot about the behaviour of the plant and improved its efficiency.

I think it is true to say, that in the early 1970s, I worked with a bunch of interesting people at ICI Plastics.

These days, use might be made of a digital twin.

Ministers Will Relax Rules To Build Small Nuclear Reactors

The title of this post is the same as that of this article in The Times.

This is the sub-heading.

Britain’s five nuclear power stations, which generate about 6GW in total, powering 13 million homes, are all nearing the end of their lives

These first three paragraphs indicate the reasons why, the government wants to relax the rules.

Ministers are preparing to relax planning rules to make it easier to build mini nuclear power plants in more parts of the country in order to hit green energy targets and boost the industry.

They are also examining whether it is possible to streamline the process for approving the safety of new nuclear power plants as a way to reduce construction delays.

At present rules state that only the government may designate sites for potential nuclear power stations, of which there are eight, severely limiting where they can be built.

The article includes a vote and surprisingly to me, the vote embedded in the article, shows 92 % in favour of relaxing the rules and only 8 % against.

I must admit these figures surprise me, as I’d have thought more would have been against.

Certain Words Frighten The Public

It is because nuclear is one of those words, that I felt that the vote in favour would have been much lower.

Regular readers of this blog will know, that in the 1960s,, I worked for ICI doing itinerant computing and instrumentation tasks, in my first job after leaving Liverpool University with a degree in Control Engineering.

I can now classify the experience as a superb apprenticeship, where I learned a lot that has been useful to me in later life.

For a time, I was working on nuclear magnefic resonance or NMR scans. ICI Mond Division in Runcorn had one of the best installations for analysing chemicals using this technique, which is described in this Wikipedia entry, which starts with these sentences.

Nuclear magnetic resonance (NMR) is a physical phenomenon in which nuclei in a strong constant magnetic field are disturbed by a weak oscillating magnetic field (in the near field) and respond by producing an electromagnetic signal with a frequency characteristic of the magnetic field at the nucleus. This process occurs near resonance, when the oscillation frequency matches the intrinsic frequency of the nuclei, which depends on the strength of the static magnetic field, the chemical environment, and the magnetic properties of the isotope involved; in practical applications with static magnetic fields up to ca. 20 tesla, the frequency is similar to VHF and UHF television broadcasts (60–1000 MHz).

One day, the Senior Scientist, who ran the machine came in to work and announced that the property of nuclear magnetic resonance would be replacing X-rays, as the technology had just been used to give a three-dimensional image of something like the tail of a mouse.

Now fifty-five years later, many if not most of us have had MRi scans.

The Wikipedia entry for Magnetic Resonance Imaging or MRi, explains, what happened to the dreaded N-word.

MRI was originally called NMRI (nuclear magnetic resonance imaging), but “nuclear” was dropped to avoid negative associations.

Perhaps, it would be easier to build nuclear power stations, if the level of science teaching in the UK was better.

The Three Paragraphs In Detail

Earlier, I copied three paragraphs from The Times, into this post.

I shall now look at each in detail.

Paragraph 1

Ministers are preparing to relax planning rules to make it easier to build mini nuclear power plants in more parts of the country in order to hit green energy targets and boost the industry.

I was in Suffolk, when the planning of Sizewell B was undertaken.

There appeared to be little strong opposition, but the general feeling was what there was from second home owners, who were worried that the value of their holiday home would decline.

Employment and commerce created by Sizewell B was certainly good for the area in lots of ways.

At the time, my late wife; C was practicing as a family barrister in chambers in Ipswich. She believed that the building of Sizewell B had had a good effect on the area, as it had injected work and money, which had created the finance to allow a couple to end a marriage, that had long since died. She stated a couple of times, that Sizewell B was good for her practice.

Paragraph 2

They are also examining whether it is possible to streamline the process for approving the safety of new nuclear power plants as a way to reduce construction delays.

My worry about streamlining the process for approving safety, is that we approve nuclear power stations so rarely, do we have the qualified personnel to replace elapsed time with people. I would suggest that we don’t.

But we could have.

- We have some excellent universities, where Nuclear Engineering can be studied.

- How many personnel leave the Royal Navy each year, who could be trained as nuclear safety inspectors?

- If say Rolls-Royce and/or Hitachi are building several small modular nuclear reactors a year in the UK, then nuclear engineering will become fashionable, as electronics was for my generation of engineers and it will attract the brightest students.

Perhaps an established university, with access to the needed skills should be funded to set up a Nuclear Safety Institute

Paragraph 3

At present rules state that only the government may designate sites for potential nuclear power stations, of which there are eight, severely limiting where they can be built.

I can envisage new small modular nuclear reactors being built in the UK, where there is a need for lots of electricity to support developments like.

- Offshore wind farms

- Data centres

- Green steelmaking

- Metal refining

- Hydrogen production.

Rolls-Royce have said that their small reactors will be around 470 MW, so I could imagine power stations of this size being placed on disused coal-fired power station sites to boost power in an area. I have already suggested building some on Drax in The Future Of Drax Power Station.

In some locations, the choice could be between a small modular nuclear reactor and some form of energy storage.

Powering Germany

But there is one controversial area, where we can take advantage.

- The Germans are very short of electricity because of their reliance on coal and Russian gas that needs to be replaced.

- The 1.4 GW NeuConnect interconnector is being built by European and Japanese money between the Isle of Grain and Wilhelmshaven.

- The AquaVentus hydrogen system could be extended to Humberside to link with UK hydrogen production and storage.

- A couple of small modular nuclear reactors could be built on Humberside to back up hydrogen production, when the wind isn’t blowing.

But Rolls-Royce and other companies have been putting small nuclear reactors close to the sea bed safely for decades, so why no design an offshore reactor that can be placed at a safe distance offshore?

We would need to solve the Putin and friends problem first, but I can see the UK exporting a lot of electricity and hydrogen produced by nuclear energy.

US DOE Offers US$1.76 billion Loan To Hydrostor For A-CAES California Project

The title of this post, is the same as that of this article on Energy Storage News.

These three paragraphs give more detail.

The US Department of Energy’s (DOE) Loan Programs Office (LPO) has made a conditional commitment for a loan to long-duration energy storage (LDES) developer and operator Hydrostor of up to US$1.76 billion.

If finalised, the loan would be used to help fund the Willow Rock Energy Storage Centre, a 500MW/4,000MWh, 8-hour advanced compressed air energy storage system (A-CAES) in Eastern Kern County, California, led by Hydrostor subsidiary GEM A-CAES.

Compressed air energy storage (CAES) charges by pressurising air and funnelling it into a storage medium, often a salt cavern, and discharges it by releasing the compressed air through a heating system, which expands air before it is sent through a turbine generator.

Note.

- Both the Canadian Hydrostor and the British Highview Power use air in their batteries, with the Canadians using compressed air, often in salt caverns and the British using liquid air in tanks.

- Highview Power’s first large scale battery will be 200MW/2.5GWh, which is about half the size of Hydrostor’s, which will be 500MW/4.0GWh.

- Having mathematically-modeled large tanks full of chemicals in the 1970s for ICI, I wouldn’t be surprised, if the Highview Power battery is more easily scalable.

This could be an interesting technological shootout.

Complicating matters could be Trump’s policies to big batteries.

This article on Utility Dive, which is entitled Potential Trump Policies Pose Risks For US Storage Sector, With Musk Impact Uncertain.

Analysts Say Gives A Reasoned.

Higher battery material tariffs and phased-down IRA tax credits threaten a 15% drop in U.S. storage deployment through 2035 in a “worst-case” scenario,

BNEF analysts said.

Automated Wheel Shape Monitor To Detect Wear

The title of this post, is the same as that of this article on Railway Gazzette.

These three paragraphs describe the monitor.

Central Japan Railway has developed a device that allows the shape of wheels to be measured while trains are passing over it at up to 80 km/h.

Following a series of field tests, the equipment is being introduced on JR Central’s Tokyo – Shin Osaka Shinkansen route in the 2025 financial year, ending in March 2026. Similar devices will then be installed for JR Central’s electric rolling stock running on 1 067 mm gauge conventional routes.

The Automatic Wheel Shape Measurement Device is intended to ensure that wheels are reprofiled at the optimal time based on the wear condition of the wheels. Until now reprofiling has been used at regular intervals or after a train has run a specified distance.

I like this monitor and I hope it is a success.

In the early 1970s, I was working for a section in ICI, that developed innovative instruments for chemical plants.

One of the instruments that the section developed, measured the size of a plastic-film bubble using a television camera and then used the result to control the size and the pressure of the bubble.

We need more clever instruments to measure the size of moving objects.

British Gas Partners With Strata And Daikin To Launch Eco-Tech Low Bill Homes

The title of this post, is the same as that of this press release from Centrica.

This is the sub-heading.

British Gas is set to supercharge sustainable living across the UK with the launch of Low Carbon Homes – a ground-breaking pilot in partnership with Strata and heat pump manufacturer, Daikin.

These are the first four paragraphs, which fill out a bit of detail.

In anticipation of The Future Homes Standard, customers will move into new build homes which have been fitted with a full range of the latest low-carbon technology at no extra cost to the housebuilder or owner. The homes will be equipped with a 6-8 kWh Daikin air source heat pump, 4 kWh solar panels, 5 kWh battery storage, Hive electric vehicle charger and thermostat. These items will be integrated into Hive’s award-winning app, providing customers with one-stop visibility and control of their energy usage.

The first trial phase will launch at a Strata’s “Breathe” development site in Kiveton, Rotherham. As a thank you for participating in the pilot, British Gas is giving homeowners access to a fixed rate tailored British Gas tariff. Participants in the trial will also have access to a dedicated British Gas energy manager to help them optimise the technology and keep bills as low as possible, while still meeting their desired comfort levels.

Each home will be fitted with a Hive hub, which connects to the WIFI network and acts as the home’s operating system, integrating all the sustainable technology. The customers energy and heat schedules and budget will be optimised by the Hive Hub for further savings.

When the customer connects to Hive’s app they will be able to control and maximise efficiency by setting schedules and spending budgets and allowing the Hub to help them reduce their bills.

Note.

- As a Control Engineer, this to me is a good start.

- I suspect that a 6-8 kWh Daikin air source heat pump, 4 kWh solar panels and 5 kWh battery storage will keep the average house warm.

- I would expect that the three companies have optimised the ratios between the sizes of the components to give the best performance.

It is amazing to think that it was in the early seventies, that in the two sections, where I worked at ICI, engineers had just started controlling and optimising flows, pressures and temperatures in complex chemical plants.

If you’d asked any of us, when our houses heating systems would be as fully controlled, we’d have given twenty years at most.

What kept the world so long?

I have a few thoughts.

Could The Housing Have Gas For Cooking??

Yes! Centrica owns a big share with Hyundai, Kia and others of a start-up company called HiiROC.

- This is the HiiROC web site.

- HiiROC can take any hydocarbon gas and split it into green hydrogen and carbon black.

- Green hydrogen is obviously useful and the carbon black can be used for making tyres for vehicles, anodes for lithium-ion batteries and in agriculture for soil improvement.

- Waste off-gas from a chemical plant can be split into green hydrogen and carbon black.

- Biomethane from a sewage plant can be split into hydrogen and carbon black. Could a sewage plant on an estate be used to create biomethane for cooking and feeding to the HiiROC plant? Yes!

- Could green hydrogen produced on the estate be used to drive vehicles like cars, vans and ride-on-mowers. Yes! If the manufacturer of the vehicle allows it!

- How convenient would it be to have Hydrogen-at-Home?

How Much Does A British Gas Hive Save On My Energy Bill?

I asked Google and I got this answer from Home Hive.

£119. A smaller carbon footprint and a smaller bill – our award-winning smart thermostat could cut your energy bills by up to £170 a year. Join Hive Plus to boost your thermostat’s savings – and get exclusive access to £60 bill credit with any fixed British Gas dual fuel tariff.

At present, I have no intention of changing my energy supplier, but come the summer or if my health or energy circumstances change, I might see what is available.

Will British Gas Develop A Hive For a Smaller Dwelling?

I suspect in ten years, if I’m still of this world, I shall be living in the following circumstances.

- Alone.

- In a two bedroom house, cottage or flat.

- Some form of probably electric central heating or perhaps even hydrogen.

- No car.

- A short walk to the bus stop and/or train station.

- Communal gardens to sit in.

- An Ocado style delivery for food, groceries and other essentials.

- A local gluten-free cafe.

- Full Wi-Fi

Perhaps, British Gas and others will develop a community for people like me?

Did I Come Across A HiiRoc-Style Process In the 1960s?

The home page of the HiiROC web site has a title of Thermal Plasma Electrolysis with this sub-heading.

A Transformational New Process For Affordable Clean Hydrogen.

This is the first paragraph.

Leading with our proprietary plasma technology, HiiROC has developed a new process for producing affordable clean hydrogen: Thermal Plasma Electrolysis

The further I read it starts to appear familiar.

It was a long time ago in 1968, but I shared an office at ICI Mond Division with a guy called Peter, who was helping to try to get a similar process working.

ICI were using a bought-in process to try to make acetylene.

I seem to remember that ethylene was burnt in a aerosphere with little oxygen.

Was it then quenched with naphtha?

Acetylene was then supposed to be released, but all the plant did was produce lots of soot, which it spread all over Runcorn.

Peter’s job was to measure the acetylene in the burner off gas. The section I worked in had developed, a very clever instrument that could measure levels of one chemical in another by infra-red comparison to very low levels.

In this plant, it was measuring acetylene in burner off-gas.

They did it successfully, but it was a disaster, as the gas on the output of the burner was straying into explosive limits.

The plant was was immediately shut down and dismantled.

The Versatile Substance That Is Carbon Black

I suspect very few of us think much about carbon black.

In an over fifty-year working life, I have only come across carbon black indirectly and no-one has actually shown me any carbon black.

This is the first sentence of the Wikipedia entry for carbon black.

Carbon black (with subtypes acetylene black, channel black, furnace black, lamp black and thermal black) is a material produced by the incomplete combustion of coal tar, vegetable matter, or petroleum products, including fuel oil, fluid catalytic cracking tar, and ethylene cracking in a limited supply of air.

It doesn’t sound the most appetising of substances and the next sentence reinforces that view.

Carbon black is a form of paracrystalline carbon that has a high surface-area-to-volume ratio, albeit lower than that of activated carbon. It is dissimilar to soot in its much higher surface-area-to-volume ratio and significantly lower (negligible and non-bioavailable) polycyclic aromatic hydrocarbon (PAH) content.

The text is illustrated with what looks like a small pile of soot.

I first came across carbon black, in my first job after leaving Liverpool University at ICI Mond Division at Runcorn.

For a time, I shared an office with Peter, who was part of a number of engineers, who were trying to get a new plant, that had been purchased from BASF to make commercial quantities of acetylene. All the plant seemed to make was large quantities of soot, which it then proceeded to spread all over the town of Runcorn.

If I remember correctly, the process worked by burning ethylene in a limited supply of air and then quenching it with naphtha. The similarities between the BASF process and the method for producing carbon black lead me to believe, that ICI’s process was probably producing a lot of carbon black.

Peter was working on an instrument that measured the quantity of acetylene in the off-gas from the burners and he succeeded, but unfortunately proved that the plant was going into explosive limits. For this reason, ICI shut their process, although BASF persevered.

Ethylene is a hydrocarbon which has the formula C2H4 or two carbon and four hydrogen atoms. So if you can get them to stop tightly holding hands with no oxygen around, the hydrogen will pair off as H2 and the carbon will exist as a lot of single C atoms or carbon black.

BASF and ICI were trying to produce acetylene or C2H2, where there is a powerful triple bond between the two carbon atoms. All that energy in the acetylene makes it useful for activities like welding.

Common Uses Of Carbon Black

The Wikipedia entry for carbon black, has this summary of its uses.

The most common use (70%) of carbon black is as a pigment and reinforcing phase in automobile tires. Carbon black also helps conduct heat away from the tread and belt area of the tire, reducing thermal damage and increasing tire life. Its low cost makes it a common addition to cathodes and anodes and is considered a safe replacement to lithium metal in lithium-ion batteries. About 20% of world production goes into belts, hoses, and other non-tire rubber goods. The remaining 10% use of carbon black comes from pigment in inks, coatings, and plastics, as well as being used as a conductive additive in lithium-ion batteries.

The entry then gives a list of other uses, some of which are still being developed.

Global Production Of Carbon Black

This paragraph is from the Wikipedia entry for carbon black.

Total production was around 8,100,000 metric tons (8,900,000 short tons) in 2006. Global consumption of carbon black, estimated at 13.2 million metric tons, valued at US$13.7 billion, in 2015, is expected to reach 13.9 million metric tons, valued at US$14.4 billion in 2016.

So we have the useful paradox, that we don’t want to emit more carbon dioxide, but extra carbon black could probably be usefully used.

Conclusion

Using the HiiROC process to extract hydrogen could even give us a biproduct ; carbon black, that has uses.

Hydrogen Energy Explained

The title of this post, is the same as this story on Centrica.

This is the sub-heading.

Hydrogen is a clean alternative to natural gas, when it’s burnt it doesn’t produce carbon dioxide, which is a harmful greenhouse gas. It has the potential to play a significant role in achieving net-zero and decarbonising various sectors.

The story is a good introduction to hydrogen.

In the 1960s, when I first worked in a hydrogen electrolyser at ICI in Runcorn, I would have found a document like this one from Centrica invaluable.