Level Boarding Included In Rail Innovation Funding Competition

The title of this post, is the same as that of this article in Railway Gazette.

This is the introductory paragraph.

Innovate UK has opened the latest calls for grant funding proposals under the First of a Kind programme, which supports the demonstration of innovative technologies to give them a better chance at being deployed by railway companies.

What annoys me about boarding trains (and some buses for that matter!), is how variable it is.

- Trains in East Anglia, Merseyside and Switzerland are particularly good, but then they have the common Stadler factor.

- Will the Newcastle Metro and the Glasgow Subway be as good?

- Some European countries, including Germany, could do much better!

- Once at Leipzig, I helped four hefty Germans lift a guy and his wheel-chair out of the bottom-deck of a double-deck train.

- In London, the Docklands Light Railway, the Elizabeth Line and some parts of the Overground are acceptable, but there is need for improvement.

- Southeastern, including the HighSpeed is particularly dodgy and I need help at some stations like Clapham Junction and Lewisham.

- Bank has a notorious platform on the Central Line.

- Perhaps the worst in London are some stations on theBakerloo Line, where it shares with the Watford DC Line.

All passengers on buses and trains deserve the best access that designers and bus and train manufacturers can devise.

In one incident, a slight, elderly Indian lady in a sari, was having difficulty getting down from an Overground train on the Watford DC Line at Willesden Junction station.

I was the only person on the platform, so I called out. “Can You Jump?”

Which she did and landed safely on her feet! I caught her and it was smiles all round!

I suspect she’d done that before.

So is one idea to give all passengers, lessons in jumping on and off buses and trains?

Seriously though, could Lego devise a large-scale engineering version of their product, that could be used to create steps and humps, which could be glued together for strength.

Alternatively, 3D printing could be used to create gap-fillers.

I think this challenge from Innovate UK will bring forward some good solutions.

Rolls-Royce Completes Next Step On Its Journey To Decarbonising Business Aviation

The title of this post, is the same as that of this press release from Rolls-Royce.

This is the sub-heading.

Rolls-Royce today announces the successful completion of a series of tests with 100% Sustainable Aviation Fuel (SAF) on its latest generation of business aviation engines, the Pearl 15 and the Pearl 10X. The Pearl 15, the first member of the Pearl engine family, powers Bombardier’s Global 5500 and 6500 aircraft, while the Pearl 10X will power Dassault’s ultra-long-range flagship aircraft, the Falcon 10X.

These are the websites for the three aircraft, with number of passengers, typical cruise speed and range.

- Bombardier Global 5500 – 16 pax – Mach 0.85 – 5900 nm

- Bombardier Global 6500 – 17 pax – Mach 0.85 – 6600 nm

- Dassault Falcon 10X – 19 pax – Mach 0.925 – 7500 nm

This screenshot from the Dassault Falcon 10X web site shows the range from London.

Note that Buenos Aires, the Falkland Islands, Seattle, Seoul and Tokyo are all within range.

I have a few thoughts and observations.

Jet A-1 And 100% SAF

This paragraph from the press release describes how Rolls-Royce are testing the compatibility of Jet A-1 and 100% SAF.

As well as proving compatibility with 100% SAF another target of the test campaign was to run a back-to-back engine test with both Jet A-1 and SAF on the same Pearl 10X engine. The aim was to confirm further improvements in the environmental footprint when switching to SAF. The results from this first back-to-back engine emission test under standard certification conditions provides important correlations for the evaluation of future SAF within our environmental strategy.

Compatibility and back-to-back running is surely very important, as it could be many years before all airports can supply 100 % SAF for visiting jet aircraft.

The Fuels Used In The Tests And The Benefits

These two paragraphs from the press release describes the fuels used and the benefits..

The HEFA (Hydro-processed Esters and Fatty Acids) SAF was produced from waste-based sustainable feedstocks such as used cooking oils and waste fat. This fuel has the potential to significantly reduce net CO2 lifecycle emissions by about 80% compared to conventional jet fuel.

The back-to-back tests conducted with conventional fossil-based fuel and subsequently SAF also confirmed a cleaner combustion of the sustainable fuel, with significantly lower levels of non-volatile particulate matter (nvPM). In combination with the low NOx combustor technology of the Pearl 10X and its additive manufactured combustor tiles a reduction of all emissions was achieved.

Note.

- An eighty percent reduction in lifecycle emissions is not to be sneezed at.

- Cleaner combustion and low NOx emissions are very much bonuses.

- Additive manufacture is better known as 3D-printing and I’m not surprised that Rolls-Royce have embraced the technology.

As an engineer and retired light aircraft pilot, I suspect the tests have met Rolls-Royce’s objectives.

Moving To 100 % SAF

This is the final paragraph of the press release.

The tests demonstrated once again that Rolls-Royce’s current engine portfolio for large civil and business jet applications can operate with 100% SAF, laying the groundwork for moving this type of fuel towards certification. At present, SAF is only certified for blends of up to 50% with conventional jet fuel. By the end of 2023 Rolls-Royce will have proven that all its in-production Trent and business aviation engines are compatible with 100% SAF.

It must be a good selling point for aircraft equipped with Rolls-Royce engines, that the buyer knows that the aircraft can run on 100% SAF.

100 % SAF As An Airline Marketing Tool

It will be interesting to see how airlines use 100% SAF to sell tickets.

As an example, I can see routes like London and Scotland becoming very competitive.

- Avanti West Coast, LNER and Lumo already run all-electric trains to Edinburgh and Glasgow.

- The technology exists to decarbonise trains to Aberdeen and Inverness..

- Other open access operators could well move in to a lucrative market.

- The only way, that the airlines will be able to compete on emissions, would be to move to 100 % SAF.

There must be hundreds of routes like London and Scotland around the world.

100 % SAF And Business Jets

In A Class 319 Train, But Not As We Know It!, I told this tale.

I am reminded of a tale, that I heard from a former GEC manager.

He was involved in selling one of GEC’s Air Traffic Control radars to a Middle Eastern country.

The only working installation of the radar was at Prestwick in Scotland, so he arranged that the dignitaries and the sales team would be flown to Prestwick in GEC’s HS 125 business jet.

As they disembarked at Prestwick and walked to the terminal, the pilot called the GEC Manager over.

The pilot told him “The Scottish Highlands at this time of the year, are one of the most beautiful places in the world! Would you and your guests like a low-level tour on the way back? I can arrange it, if you say so!”

Despite knowing GEC’s draconian attitude to cost control he said yes.

The sale was clinched!

I also remember an article in Flight International about how JCB sold diggers.

- Dealers in a country like Greece would put together a party of prospective customers.

- The customers would then be flown to East Midlands Airport in JCB’s business jet, which is close to the JCB factory at Rocester.

- After a sales demonstration and a tour of the factory they would be flown home.

I once met a lady who had been one of JCB’s cabin staff and she told me it was a very successful sales technique.

I suspect that a business jet running on 100 % SAF would be an even better sales aid.

There are also increasing protests from the greens about business jets, which are seen as producing pollution and are only the toys of the rich and powerful.

Surely, if they were running on 100 % SAF, this would make business jets more acceptable.

100 % SAF And Niche Airlines

In the web site for the Falcon 10X, there is a section called Mission Flexibility, where this is said.

As large as it is, the Falcon 10X can still access typical airports serving business aviation as well as others with challenging approaches. The Falcon 10X will be London City-capable so that it can fly you straight into the heart of global finance. When you’re ready for rest and relaxation, the 10X can whisk you to out-of-the-way corners of the world.

British Airways used to run a service between London City Airport and New York.

- The route used 32-seat Airbus A-318 airliners.

- The flight stopped at Shannon for refuelling.

- It was business class only.

I suspect someone will think about running a similar London City Airport and New York service using a Falcon 10X.

- It has nineteen seats.

- It could do it in one hop.

- It could run on 100 % SAF.

- British Airways must have all the passenger data from the discontinued service.

- A Falcon 10X flies higher than a Boeing 767, Boeing 787 or an Airbus A350.

I have a feeling that flight time would be comparable or better to a flight between Heathrow and New York.

Conclusion

Rolls-Royce would appear to have the right strategy.

If I was going to New York in business class, I’d use it.

An Art Installation In Front Of Moorgate Station

Today, a new sculpture was installed in front of the new entrance to Moorgate station.

I took a few pictures.

Note.

- The sculpture, which is in bronze and entitled Manifold (Major Third) 5:4, is by Conrad Shawcross, who I talked about briefly in Job Done – I’ve Now Had My First Covid-19 Vaccination.

- Conrad is the guy in red t-shirt, who can be seen in several images.

- I’ve never seen a large sculpture installed before and everything went smoothly!

I have some thoughts.

More On The Sculpture

This page on Art On The Underground is entitled Manifold (Major Third) 5:4, where this description is given.

Manifold (Major Third) 5:4 by British artist Conrad Shawcross RA will be found outside the western entrance to the Elizabeth line station at Liverpool Street later this year. The artwork is a vast bronze sculpture representing a chord falling into silence extrapolated from observations of a Victorian pendulum-driven drawing machine known as a harmonograph, which was instrumental in the birth of the science of synaesthesia. This sculpture is the physical incarnation of the mathematics within a chord.

Note that I am of Conrad’s father’s generation and had a large Meccano set, like many of that generation. I must have built four or five Meccanographs, which were a harmonograph, built out of Meccano.

Bronze

The sculpture is in bronze, which is mainly an alloy of copper and tin.

My uncle; Leslie was an artist, who had won a scholarship to the Slade before the Great War, although he earned his living as an engineer. I do have two of his drawings, of my mother and his wife.

But he was also a capable sculptor, and sculpted and cast a bronze of a Hanoverian horse, which would probably be, the family possession, that C and myself would have loved to have owned. It is now owned by his granddaughter, who was also one of our bridesmaids, when we got married in 1968.

I also have another link to bronze. My father was a letterpress printer and his largest customers was a company called Enfield Rolling Mills, who rolled copper and other non-ferrous metals including bronze into various shapes.

I don’t know whether they invented the process. but sometime around 1960,Enfield Rolling Mills started to continuous cast bronze. I seem to remember that their bronze tubes were used in the original UK nuclear power stations.

Because of my father’s long-established friendship with the owner of Enfield Rolling Mills, I used to earn money there for my studies.

3D Printing

Bronze, other metals and even concrete can now be 3D printed.

I suspect we’ll see 3D printed sculptures appearing with greater regularity.

Other Materials

These pictures show Conrad Shawcross’s sculpture outside the Crick Institute.

It appears to be made out of weathered steel, which is often seen used in railway bridges and other structures.

In Denmark Hill Station – 4th September 2021, I talk about how the roof at Denmark Hill station is made out of steel covered with solar panels.

Could outdoor sculptures be made with steel covered in solar panels?

Concretene Cements Its Future With £8m Funding

The title of this post, is the same as that of this article in The Times.

This is a precis. which explains what Concretene have done.

Concretene combines graphene with concrete to form a “stronger, more sustainable and more cost-effective alternative” to the world’s most-used building material.

The eight million funding is mainly to be used for more tests.

Is Concrete The New Wonder Material?

I once lived in a concrete apartment and although it is now fifty years old, it still looks the same, as it did the day it was built.

Cromwell Tower in The Barbican may have been built to a high specification, but we don’t hear cancer, cladding, damp, fire or mould problems about the City of London’s flagship housing estate.

In the last few years, concrete has been able to be 3D-printed, so it can now be produced in different shapes.

All these wall and roof panels on the Elizabeth Line were made by 3D-printing of concrete.

The technique also seems to be being used on High Speed Two.

These innovative uses of concrete have led to research into the manufacture and use of concrete.

These posts are must-reads.

- Carbon-Neutral Concrete Prototype Wins €100k Architecture Prize For UK Scientists

- UK Cleantech Consortium Awarded Funding For Energy Storage Technology Integrated With Floating Wind

- New HS2 Pilot Project Swaps Steel For Retired Wind Turbine Blades To Reinforce Concrete

- Earth Friendly Concrete

- HS2 Utilising UK-First Pioneering 3D Concrete Printing On Project

- Carbon Capture From Cement Manufacturing Nears Market Readiness

- Mineral Carbonation International Win COP26 Clean Energy Pitch Battle

The number of these posts show how much research is going into cutting the massive amount of carbon dioxide emitted by the concrete industry.

I also feel that some could work together.

Earth Friendly Concrete is a replacement for normal concrete, so perhaps it could be enhanced with graphene, to create an Earth Friendly Concretene.

Carbon-Neutral Concrete Prototype Wins €100k Architecture Prize For UK Scientists

The title of this post, is the same as that of this article on the Architect’s Journal.

Under a picture of two white-coated scientists with their protective boots on concrete samples, the story and their invention is outlined.

A pair of PhD students at Imperial College London have won a global architecture prize for devising a groundbreaking method of creating carbon-neutral concrete

Material scientists Sam Draper and Barney Shanks landed the €100,000 2022 Obel Award with their ‘simple way’ to capture carbon from industrial production processes and create an end product that can eliminate the CO₂ footprint of concrete.

The prototype technology, dubbed Seratech, takes industrial CO₂ emissions directly from flues and produces a carbon-negative cement replacement material (silica). According to the scientists, when this is used in combination with Portland cement, the carbon capture associated with producing the silica means the concrete products can be zero carbon.

One of the products, we will need in the world is concrete and if we can make it in a carbon-neutral manner, then that will surely reduce worldwide carbon emissions.

The Technology Explained

This page on the Seratech website is entitled Our Technology.

It gives this description of the technology.

Seratech has developed a process that consumes olivine and waste CO₂ from flue gases and produces two products which both have significant value in construction.

Silica is produced which can be used as a supplementary cementitious material (SCM) in concrete meaning the amount of Portland cement in the concrete can be reduced by up to 40%. As the silica comes from a process that captures CO₂ it is “carbon negative” and the concrete can become carbon neutral.

Magnesium carbonate is produced that can be used to make a range of zero carbon construction materials and consumer products, including alternatives to building blocks and plasterboard.

The aim is for humanity to be able to continue building robust cities and infrastructure, but without the climate cost of traditional cement mixes and with the Seratech technology this goal is achievable!

Note that olivine in Europe is generally mined in Norway.

Replacement Of Steel By Concrete

Could we also replace steel in some applications with concrete?

In UK Cleantech Consortium Awarded Funding For Energy Storage Technology Integrated With Floating Wind, I talked about some of ground-breaking methods used by a company called RCAM Technologies to create infrastructure using 3D printing of concrete.

If Imperial’s concrete, which is called Seratech can be 3D printed, I can see lots of applications for the technology.

So you could kill two sources of large carbon emissions with one technology.

Conclusion

I have said on this blog before, that we will have to keep or even build more gas-fired power stations, as they can be an efficient source of pure carbon dioxide, that will be needed as a feedstock to create an increasing number of agricultural and building products.

UK Cleantech Consortium Awarded Funding For Energy Storage Technology Integrated With Floating Wind

The title of this post, is the same as that of this page on the UK Government’s Catapult Offshore Renewable Energy Web Site.

This is the introductory paragraph.

STORE, a UK-based cleantech consortium led by RCAM Technologies Limited, has been awarded £150,000 of funding to develop an advanced subsea energy storage technology manufactured using 3D printed concrete that could help offshore wind farms produce a steady and predictable energy output to the electricity grid.

This paragraph talks of the concept of Marine Pumped Hydro.

STORE is assessing the feasibility of integrating Marine Pumped Hydro (MPH) technology, which stores energy using hollow concrete spheres fitted with a hydraulic turbine and pump, with floating offshore wind plants in UK waters. In addition, the project advances the design of MPH systems and plans a prototype demonstration in the UK.

Note.

- The hollow concrete spheres are 3D-printed in concrete using the technology of RCAM Technologies.

- Spheres are structurally very strong.

- 3D printing of concrete is now mainstream technology and has been extensively used on the Elizabeth Line as I wrote about in The Story Behind The Concrete Panels On The Elizabeth Line.

- There is a visualisation on the Catapult web page, which shows several floating turbines, a floating sub station and several concrete hemispheres sitting on the seabed.

- The energy storage medium is sea water and air, which must be environmentally-friendly.

The technology is described in detail on this page of the STORE consortium web site.

- The spheres are fifteen metres across.

- The spheres can be installed at depths between 150 and 2000 metres.

- The system has a round-trip efficiency is up to 70%, which is similar to pumped storage hydro.

- The design life is 50 to 80 years.

I think that this system has possibilities.

This last paragraph in the Catapult web page gives a look into the future.

As well as improving the reliability and predictability of energy to the electricity grid, the project will support the cross sector transfer of UK offshore expertise and port infrastructure for use in renewable energy and create high-value UK jobs in engineering, construction, and operations and maintenance. This energy storage solution is ideally suited to coupling with floating wind plants and for powering offshore oil and gas assets from renewable energy. The 3D printed concrete also facilitates localized manufacturing and enables low cost fabrication of new and complex shapes that were previously not practical.

I also feel that if the concrete sphere energy storage can be made to successfully work, then the technology can surely be fitted to any offshore wind farm, by just adding the right number of spheres and connecting them to the offshore sub station.

The STORE Consortium

The STORE consortium has a web site, which has a heading of Innovative Subsea Energy Storage.

It describes the technology in this paragraph.

STORE is advancing a subsea energy storage technology called Marine Pumped Hydro (MPH). MPH uses large hollow concrete spheres on the seafloor to store mechanical energy in the form of pressure. MPH charges when seawater is pumped out of the spheres and releases energy to the grid when high-pressure water flows back into the spheres through a turbine. MPH features a patent-pending multi-sphere pod to increase the amount of energy stored and uses efficient 3D concrete printing to reduce manufacturing costs.

It sounds like an engineer with children, has been playing with them and their plastic toys in a bath and has had an Archimedes moment.

The project and its funding is described in this paragraph.

STORE was awarded £150,000 from the Department for Business, Energy & Industrial Strategy Longer Duration Energy Storage Demonstration (LODES) competition. Phase 1 will deliver a Feasibility Study focused on the design and analyses for the UK. Phase 2, if awarded, will design, manufacture, and operate a prototype system at TRL 6.

Note that TRL 6 is Technology Readiness Level 6 and is fully defined on this NASA web page, as having a fully functional prototype or representational model.

There is also an interesting link to the ScotWind N3 wind farm. that I wrote about in ScotWind N3 Offshore Wind Farm.

- This is an unusual floating wind farm with a floating substation.

- Technip and Loch Kishorn port are involved in both the wind farm and STORE.

- Loch Kishorn has a history of building immense concrete structures.

I wouldn’t be surprised if this wind farm would be the location of the prototype system.

Conclusion

This is a brilliant concept.

- It is the ideal energy storage system for offshore wind, as it can turn a wind farm with a variable output into one with a much more constant output.

- It can be retrofitted to existing offshore wind farms.

- It will work with both fixed and floating wind farms.

- The concrete storage spheres can be fully assembled with all their electrical gubbins on shore and towed out, before sinking in the required position.

It also looks like the Department for Business, Energy & Industrial Strategy have got involved and helped with the funding. Someone there seems to know a good idea, when they see it!

RCAM Technologies

Wouldn’t it be a good idea to have a wind turbine with built-in energy storage?

This article on Power Engineering, is entitled Five Long-Duration Energy Storage Projects Get Funding In New York.

One of the projects, from RCAM Technologies is described like this.

To develop a 3D concrete-printed marine pumped hydroelectric storage system that integrates directly with offshore wind development in support of grid resiliency and reduced reliance on fossil fuel plants to meet periods of peak electric demand.

That sounds like an offshore wind turbine with built-in energy storage, that is 3D-printed in concrete.

The RCAM Technologies web site is all about 3D-printed concrete.

- It looks like they can build taller wind farm towers, than you can make with steel.

- It appears offshore wind turbine tower with integrated foundations can be built on-site.

- Material can be 100 % locally-sourced.

- The next step could be to build some form of pumped storage into the tower.

- They are experimenting with storing energy as pressure in 3D-printed concrete spheres. The New York grant will help fund this.

- High Speed Two is using 3D-printing of concrete, as I wrote about in HS2 Utilising UK-First Pioneering 3D Concrete Printing On Project.

The company has offices in Colorado, California and Edinburgh.

Conclusion

This technology could be on the right track. Read their web site.

The Story Behind The Concrete Panels On The Elizabeth Line

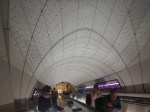

These are a selection of the pictures I took yesterday inside Elizabeth Line stations.

Note.

- The walls and ceilings appear to be covered in light grey panels with holes.

- The material appears to look like concrete.

- Every one is a totally different shape, so how were they manufactured?

This article on Ian Visits is entitled How Crossrail Is Using 3D-Printing To Build Its Stations.

This is the two opening paragraphs.

When you start to use the new Elizabeth line stations, among its many achievements will be the first large scale use of 3D-printing in concrete.

The use of 3D printing has made possible one of the more distinctive features of the future Elizabeth line stations — the curved concrete panels that will line the inside of the passenger tunnels and some stations, and sinuously glide around corners in a way never seen before in a tube station.

There will be a total of something like 36,000 of these panels and although printing each in concrete is possible, Crossrail would probably have been delivered in the 2040s or 2050s.

The contractors used an innovative process called FreeFAB, which had been invented by an Australian architect.

- The process creates a wax mould for each panel using 3D printing.

- This mould is then used to create the actual panel.

- After each panel is cast, the wax is melted off and recycled.

- The panels are made in a factory in Doncaster.

We will see a lot more of this technique used in the construction industry.

Skyrora Creates Europe’s Largest 3D Printer In ‘Game-Changer’ For Cutting Rocket Building Time

The title of this post, is the same as that of this article on CityAM.

The title is a good summary of a must-read article.

HS2 Utilising UK-First Pioneering 3D Concrete Printing On Project

The title of this post, is the same as that of this article on Rail Technology Magazine.

3D-Printing of concrete has been around for some time and it has been used extensively on Crossrail.

But High Speed Two are printing the heavy components on site, to avoid the problems of transport.