A Waste Of Valuable Resources Between Paddington And Heathrow

Much of my working life was spent in writing project management software.

I like to think, I was an expert at writing software to juggle resources.

I wrote my first piece of software in that field in ICI, to get my boss out of trouble, after he’d promised the department a program to allocate the department’s office space more efficiently.

Unfortunately, the student, who’d written the software, without leaving anything that worked or any decent instructions.

So I told my boss;Colin, that I’d have a go.

In my previous position at ICI in Runcorn, I’d worked out an algorithm to decode mass spectrometer traces, which started with a rough idea of what was there, which was entered by an operator and then used permutations and combinations to fit the output.

I used the algorithm in every resource scheduler, I ever wrote and it worked a treat.

So when I see a waste of resources, I get angry, as I know those who devised the system could have done a lot better.

Look at these pictures, I took of a Heathrow Express, that I took today.

It is barely ten percent full.

It has become a waste of resources; train, valuable paths in the Heathrow tunnel, and platform space at Paddington.

These are a few thoughts.

Capacity To And From Heathrow

Consider.

- Heathrow Express uses twelve-car Class 387 trains, with a capacity of 672 seats, that run at a frequency of four trains per hour (tph), which is 2,688 seats per hour.

- The Elizabeth Line uses nine-car Class 345 trains, with a capacity of 454 seats, that run at a frequency of six tph, which is 2,724 seats per hour.

- The Class 345 trains can also carry another 1046 standing passengers on each journey, which adds up to a maximum of 6276 standees per hour.

- The Piccadilly Line uses 73 Stock trains, with a capacity of 684 seats, that run at a frequency of twelve tph, which is 8,208 seats per hour.

This gives a capacity of 19,896 passengers, staff and visitors per hour, or which 13,620 get seats.

Expressed as percentages, the four modes of transport are as follows.

- Heathrow Express – 13.5 %

- Elizabeth Line – Sitting – 13.7 %

- Elizabeth Line – Standees – 33.8 %

- Piccadilly Line – 41.2 %

In Effects Of The ULEZ In West London, I said this about journeys to and from the airport.

Heathrow Airport is one of the world’s busiest airports and 76,000 people work at the airport, with many more employed nearby.

The airport handled 61.6 million passengers in 2022, which is a few short of 170,000 per day.

If you consider that those that work at the airport do two trips per day and passengers generally do one, that means there are 322,000 trips per day to or from the airport.

But as it now so easy to get to the Airport using the Elizabeth Line will more people use the new line to meet and greet and say goodbye to loved ones or business associates. Since the Elizabeth Line opened, I’ve met a couple of friends at Heathrow, who were passing through.

I wonder, if that daily journey total of 322,000 could be nearer to 350,000 or even 400,000.

If the ULEZ charge makes some passengers and staff switch from their car to using a bus or train, this probably means that public transport to and from the airport, will need to be boosted by a substantial amount.

322,000 trips per day is 13,416 per hour assuming a 24 hour day.

Consider.

- The ULEZ will drive employees and passengers to trains to Heathrow.

- A lot of would-be travellers to Heathrow have had a tough couple of years.

- Because of the Elizabeth Line more meeters and greeters will go to the airport.

- The Elizabeth Line is making it easy to get to Heathrow for a large proportion of those living in the South-East.

- There have been numerous car parking scandals at Heathrow and other airports.

- Are there enough charging points for electric cars in Heathrow’s parking?

- Parking at Heathrow is expensive.

- Taxis to the airport are very expensive.

- Passengers with large cases can use the Elizabeth Line.

- Good reports of the Elizabeth Line will push people to use it.

- The Elizabeth Line serves the City, Canary Wharf and the West End.

- The Elizabeth Line has a step-free connection with Thameslink.

- Passengers seem to travel with very large cases.

- Passengers seem to be deserting Heathrow Express, as I wrote in Elizabeth Line Takes Fliers Away From Heathrow Express.

Note.

- The train, I took back from Heathrow this morning was full with all seats taken and quite a few standees.

- And it was a Sunday morning!

- We won’t know the effect of the ULEZ until August, but I believe it will be significant.

Obviously, I’m only using rough figures, but they lead me to believe that in a few months, the Elizabeth Line will be at full capacity to and from Heathrow.

Heathrow Express’s Train Paths Should Be Re-Allocated To The Elizabeth Line

This would increase hourly passenger capacity from 19,896 to 23,208 or by seventeen percent.

Great Western Railway would get two extra platforms at Heathrow and the Class 387 trains could be reallocated.

Where Would Great Western Railway Run Trains From Two Extra Platforms?

Consider.

- Various government levelling up funding has been allocated to Wales and the West.

- I talk about the Mid-Cornwall Metro in Landmark Levelling Up Fund To Spark Transformational Change Across The UK.

- The Mid-Cornwall Metro could include direct trains between London and Newquay.

- There are also plans for a new station at Okehampton Parkway.

- Given all the wind farm development in the Celtic Sea, I can see more trains between London and Pembrokeshire.

- Cardiff and Bristol would probably welcome extra services.

I don’t think Great Western Railway will have problems finding destinations to serve from two extra platforms.

What Will Happen To The Class 387 Trains?

Currently, twelve Class 387 trains are used for Heathrow Express.

In The Future Of The Class 387 And Class 379 Trains, I said this.

The Battery-Electric Class 379 Train

I rode this prototype train in 2015.

I think it is reasonable to assume, that as battery technology has improved in the seven years since I rode this train, that converting Class 379 trains to battery-electric operation would not be a challenging project.

Creating A Battery-Electric Class 387 Train

If the Class 387 train is as internally similar to the Class 379 train as it outwardly looks, I couldn’t believe that converting them to battery-electric operation would be that difficult.

I could see a lot of the Class 379 and Class 387 trains converted to 110 mph battery-electric trains.

Would Heathrow Express Completely Disappear?

If the Elizabeth Line trains are going between Heathrow Airport and Central London, at a frequency of 10 tph or one train every six minutes, I feel there may be scope for marketing and operational reasons to create a sub-fleet of the Class 345 trains.

The trains would be identical to the Elizabeth Line’s current fleet, except for livery, seating and some internal passenger features.

- Perhaps, they could be called the Heathrow Train boldly on the outside, so even the dimmest passenger didn’t get on a Reading train instead of a Heathrow one.

- All trains would have wi-fi and 4G connectivity. These features have been promised for the Class 345 trains.

- Some coaches would be fitted with luggage spaces for the outsize cases people carry.

I could envisage the Heathrow Trains terminating at a wide number of places in addition to Abbey Wood and Shenfield. Possibilities must include Beaulieu Park, Ebbsfleet, Gravesend, Northfleet and Southend Victoria

Farewell! Mary Quant!

This is a true story I heard, when I worked for ICI.

Do you remember those horrible drip-dry shirts, that men used to wear in the 1960s?

I suspect I took some to University, as my mother felt I could wash them.

Did you know that Mary Quant was partly responsible for their demise?

Mathematics tell us, that a pair of tights need a lot more nylon, than a pair of stockings.

As Mary Quant got a lot more ladies wearing tights to go with mini-skirts, there was a shortage of nylon.

ICI, who made much of the UK’s nylon, decided unilaterally to divert nylon from men’s shirts to ladies’ hosiery.

Bye bye! Nylon shirts!

RIP Dame Mary

Centrica Business Solutions Begins Work On 20MW Hydrogen-Ready Peaker In Redditch

The title of this post, is the same as that as this news item from Centrica Business Systems.

This is the sub-heading.

Centrica Business Solutions has started work on a 20MW hydrogen-ready gas-fired peaking plant in Worcestershire, as it continues to expand its portfolio of energy assets.

These three paragraphs outline the project.

Centrica has purchased a previously decommissioned power plant in Redditch, and is set to install eight UK assembled containerised engines to burn natural gas.

Expected to be fully operational later this year, the peaking power plant will run only when there is high or peak demand for electricity, or when generation from renewables is low. The Redditch project will have the capacity to power the equivalent of 2,000 homes for a full day when required, helping to maintain stability and reliability on the grid.

The engines will also be capable of burning a blend of natural gas and hydrogen, futureproofing the site and helping the UK transition towards a decarbonised energy system.

- The original power station had Rolls-Royce generators.

- Cummins and Rolls-Royce mtu and possibly other companies can probably supply the dual fuel generators.

- Cummins have received UK Government funding to develop hydrogen-powered internal combustion engines.

- This press release from Cummins, which is entitled Dawn Of A New Chapter From Darlington, gives more details on Cummins’ plans for the Darlington factory and hydrogen.

Given that Cummins manufactured sixty-six thousand engines in Darlington in 2021 and it is stated that these containerised engines will be assembled in the UK, I feel, that these engines may be from Cummins.

Centrica’s Plans

This paragraph in the Centrica Business Systems news item, outlines their plans.

The Redditch peaking plant is part of Centrica’s plans to deliver around 1GW of flexible energy assets, that includes the redevelopment of several legacy-owned power stations, including the transformation of the former Brigg Power Station in Lincolnshire into a battery storage asset and the first plant in the UK to be part fuelled by hydrogen.

As Redditch power station is only 20 MW, Centrica could be thinking of around fifty assets of a similar size.

Brigg Power Station

The Wikipedia entry for Brigg Power station gives these details of the station.

- The station was built in 1993.

- It is a combined cycle gas turbine power station.

- The primary fuel is natural gas, but it can also run on diesel.

- It has a nameplate capacity of 240 MW.

Brigg power station is also to be used as a test site for hydrogen firing.

This news item from Centrica is entitled Centrica And HiiROC To Inject Hydrogen At Brigg Gas-Fired Power Station In UK First Project.

These paragraphs from the news item explains the process.

The 49MW gas fired plant at Brigg is designed to meet demand during peak times or when generation from renewables is low, typically operating for less than three hours a day. Mixing hydrogen in with natural gas reduces the overall carbon intensity.

It’s anticipated that during the trial, getting underway in Q3 2023, no more than three per cent of the gas mix could be hydrogen, increasing to 20% incrementally after the project. Longer term, the vision is to move towards 100% hydrogen and to deploy similar technology across all gas-fired peaking plant.

HiiROC’s proprietary technology converts biomethane, flare gas or natural gas into clean hydrogen and carbon black, through an innovative Thermal Plasma Electrolysis process. This results in a low carbon, or potentially negative carbon, ‘emerald hydrogen’.

Because the byproduct comes in the form of a valuable, solid, pure carbon it can be easily captured and used in applications ranging from tyres, rubbers and toners, and in new use cases like building materials and even as a soil enhancer.

It looks to me, that HiiROC are using an updated version of a process called pyrolysis, which is fully and well-described in this Wikipedia entry. This is the first paragraph.

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements pyro “fire”, “heat”, “fever” and lysis “separating”.

Pyrolysis is more common than you think and is even used in cooking to do things like caramelise onions. This is a video of a chef giving a demonstration of caramelising onions.

On an industrial scale, pyrolysis is used to make coke and charcoal.

I came across pyrolysis in my first job after graduating, when I worked at ICI Runcorn.

ICI were trying to make acetylene in a process plant they had bought from BASF. Ethylene was burned in an atmosphere, that didn’t have much oxygen and then quenched in naphtha. This should have produced acetylene , but all it produced was tonnes of black soot, that it spread all over Runcorn.

I shared an office with a guy, who was using a purpose-built instrument to measure acetylene in the off-gas from the burners.

When he discovered that the gas could be in explosive limits, ICI shut the plant down. The Germans didn’t believe this and said, that anyway it was impossible to do the measurement.

ICI gave up on the process and demolished their plant, but sadly the German plant blew up.

It does look like HiiROC have tamed the process to be able to put hydrocarbons in one end and get hydrogen and carbon black out the other.

I wonder how many old and possibly dangerous chemical processes can be reimagined using modern technology.

It certainly appears that Centrica are not holding back on innovation.

Conclusion

I’ve never run a large electricity network. Not even a simulated one.

But I’m fairly sure that having a large number of assets of different sizes, that can be optimised to the load and the fuel available, creates a more reliable and efficient network.

Heavy energy users may even have their own small efficient power station, that is powered by gases piped from the local landfill.

UK’s Largest Carbon Capture Project Will Turn 40,000 Tonnes Of CO2 Into Sodium Bicarbonate For Dialysis Machines, Pharmaceutical Tablets And Baking Soda Every Year

The title of this post, is the same as that of this article in the Daily Mail.

These bullet points summarise the article.

- A facility that turns carbon dioxide into sodium bicarbonate was opened today

- Tata Chemicals Europe will remove up to 40,000 tonnes of CO2 each year

- The resulting sodium bicarbonate will be used as baking soda and in tablets

- Much of it will be used in haemodialysis to treat people with kidney disease

When I worked at ICI in Runcorn, the company had a facility at Winnington.

- In the 1960s, when I was there the main product was soda ash, which was produced by the Solvay process.

- The plant is now owned by Tata Chemicals Europe, and I suspect the new process is a replacement for the Solvay process.

- The carbon dioxide probably comes from a local 94 MW gas-fired power station on the site.

This ia a good example of Carbon Capture and Use, where a modern process is much better for the environment.

How much better could we protect the environment and the health of everyone, by improving or changing industrial processes?

Memories of the Solvay Process

I went over one of the Solvay processes a couple of times, when I worked at Runcorn.

- I can’t remember why now, but it was probably just to give the newest engineer in the department some experience.

- ICI trained me well at that time, especially in Health and Safety.

- One of the Victorian plants, I went over was built using a framework of oak beams, rather than the steel, we’d use today.

- The thing, that I remember most was the white sodium bicarbonate powder everywhere at the finishing end.

All the grades had uses from baking down to clearing up acid spills. Wikipedia details these uses.

Solvay Process Repurposed

Searching the Internet for more information on Tata Chemicals Europe’s process, I found this article on Scientific American, which is entitled Desalination Breakthrough: Saving The Sea From Salt.

The first paragraph outlines the problem.

Farid Benyahia wants to solve two environmental problems at once: excess carbon dioxide in the atmosphere and excess salt in the Persian Gulf (aka the Arabian Gulf). Oil and natural gas drive the region’s booming economies—hence the excess CO2—and desalination supplies the vast majority of drinking water, a process that creates concentrated brine waste that is usually dumped back into the gulf.

Benyahia, who is a chemical engineer at Qatar University appears to have solved the problem, by repurposing and simplifying the Solvay process.

I suggest that if you’ve got this far, that you read the Scientific American article all the way through, as it paints a horrific vision of the dangers of water desalination.

Hopefully, though Benyahia has the solution, which turns the problem into baking soda and calcium chloride.

We Can Suck CO2 From The Air And Store It In The Ocean As Baking Soda

The title of this section is the same as that of this article on New Scientist.

I first heard about this process on Radio 5.

It concerns some work by Arup Sen Gupta at LeHigh University in Bethlehem, Pennsylvania.

He seems the sort of researcher, who does it properly and his research on capturing carbon dioxide and turning it into baking soda, that is stored in the ocean may well be an idea in the right direction.

It further supports my view that research will find new and better ways of reducing carbon dioxide levels in the atmosphere.

Researchers Use Sea Water To Produce Green Hydrogen At Almost 100% Efficiency

The title of this post, is the same as that of this article on Hydrogen Fuel News.

This paragraph gives more details.

“We have split natural seawater into oxygen and hydrogen with nearly 100 percent efficiency, to produce green hydrogen by electrolysis, using a non-precious and cheap catalyst in a commercial electrolyser,” explained Professor Shi-Zhang Qiao, project leader at the School of Chemical Engineering at the University of Adelaide.

They use what is called a Lewis acid catalyst.

In the late 1960s, I worked for ICI in Runcorn.

Most of the hydrogen they needed was produced from brine by the large Castner-Kellner process, which may have been green, but was filthy, as it used a lot of mercury.

ICI also had an older and cruder process, which produced hydrogen and oxygen, by electrolysing brine, in a simple cell.

- These cells had a metal tub, with a concrete lid.

- Two electrodes passed through the lid.

- The lids quickly degraded and cells were rebuild regularly.

- But it did produce medical grade sodium hydroxide.

Legend also had it, that the salt that collected around the lid was pure enough to use in the canteen.

In Torvex Energy, I describe a company in Stockton which is also going the sea water electrolysis route.

Having seen, its Victorian ancestor in operation, I believe that sea water electrolysis has possibilities to make hydrogen efficiently.

World’s First Offshore Wind Farm Using 16 MW Turbines Enters Construction In China

The title of this post, is the same as that of this article on the offshoreWIND.biz.

This is the sub-heading.

China Three Gorges Corporation (CTG) has started construction of the second phase of its offshore wind farm Zhangpu Liuao. The project will be both China’s and the world’s first wind farm to comprise 16 MW wind turbines.

I hope the Chinese have done all their calculations, research and testing. The dynamics of large wings are tricky and there are a lot of square law factors involved. I’d always be worried that at a particular wind speed a dangerous vibration will be setup.

How many Chinese engineers have seen videos of Galloping Gertie?

As the video says, no one was injured or killed, when the Tacoma Narrows Bridge fell into the river, but we nearly had a very similar disaster in the UK. I used to work at ICI in Runcorn and at the time, I lived in Liverpool, so every day, I went to work I crossed the Silver Jubilee Bridge twice.

One day, after a party in Cheshire, I even got so drunk, I had to stop the car on the bridge and was sick into the Mersey. It was before C and myself were married and she always claimed she nearly called the marriage off, after the incident.

But have you ever wondered, why that bridge is a through arch bridge rather than a suspension bridge as over the Forth, Hmber and Severn, which were all built around the same time?

Wikipedia has a section, which describes the Planning of the bridge.

The new bridge had to allow the passage of shipping along the Manchester Ship Canal. Many ideas were considered, including a new transporter bridge or a swing bridge. These were considered to be impractical and it was decided that the best solution was a high-level bridge upstream from the railway bridge. This would allow the least obstruction to shipping and would also be at the narrowest crossing point. The first plan for a high-level bridge was a truss bridge with three or five spans, giving an 8 yards (7 m) dual carriageway with a cycle track and footpaths. This was abandoned because it was too expensive, and because one of the piers would be too close to the wall of the ship canal. The next idea was for a suspension bridge with a span of 343 yards (314 m) between the main towers with an 8 yards (7 m) single carriageway and a 2-yard (2 m) footpath. However aerodynamic tests on models of the bridge showed that, while the bridge itself would be stable, the presence of the adjacent railway bridge would cause severe oscillation.

The finally accepted design was for a steel through arch bridge with a 10-yard (9 m) single carriageway. The design of the bridge is similar to that of Sydney Harbour Bridge but differs from it in that the side spans are continuous with the main span rather than being separate from them. This design feature was necessary to avoid the problem of oscillation due to the railway bridge. The main span measures 361 yards (330 m) and each side span is 83 yards (76 m).

But that misses out part of the story that I learned about at ICI.

I developed a very simple piece of electronics for ICI Runcorn’s noise and vibration expert. The equipment allowed the signals from two noise meters to be subtracted. This meant that if they were pointed in different directions, the noise generated by an object or piece of equipment could be determined.

The noise and vibration expert had tremendous respect from his fellow engineers, but his involvement in the design of the Runcorn bridge had elevated him to a legend.

The designers of the suspension bridge, that is detailed in the Wikipedia extract, presented their design to the ICI (Merseyside) Scientific Society.

The noise and vibration expert was at the meeting and questioned the design and said it would collapse due to oscillations caused by the presence of the railway bridge. He advised aerodynamic tests should be done on the bridge.

His back of the fag packet calculations were shown by tests to be correct and the bridge was built as a through arch bridge.

These pictures show the bridge.

They were taken from a train on the railway bridge.

Centrica Partners With Hull-Based HiiRoc For Hydrogen Fuel Switch Trial At Humber Power Plant

The title of this post, is the same as that on this article on Business Live.

This is a paragraph.

It comes as the owner of British Gas has also increased its shareholding in the three-year-old business to five per cent. Last November it was one of several investors to pump £28 million into HiiRoc alongside Melrose Industries, HydrogenOne, Cemex, Hyundai and Kia, who joined existing strategic investors Wintershall Dea and VNG.

This could be sensational.

The reason I said that was that I used to share an office at ICI Mond Division, with Peter, who was putting instruments on a plant called the Badische. It was a new process to create acetylene. If I remember correctly, the process was as follows.

Ethylene was burned and then quenched in naptha.

The trouble was that the process produced a lot of carbon, which clogged the burners, and masses of black smoke, which upset everybody in Runcorn, especially on washing day!

Someone was worried that the plant might go into explosive limits, so Peter had devised a clever infra-red instrument to read the composition of the off-gas from the burner. It was found to be in explosive limits and ICI shut it down. BASF said ICI were wrong and there was no way to measure the composition of the off-gas anyway. A few months later BASF’s plant exploded and buried itself in a hillside in Southern Germany. Upon hearing this news, ICI shut the Badische for ever. ICI were annoyed in that they had to spend £200,000 on a flameless cutter to dismantle the plant.

I do wonder, if HiiROC have tamed BASF’s beast to do something useful, like produce hydrogen and carbon black!

Hydrogen Fuel Cells Could Get A Lot Cheaper With Newly Developed Iron Catalyst

The title of this post, is the same ass that of this article on Hydrogen Fuel News.

These are the first two paragraphs.

Scientists have been looking for an alternative to precious metals such as platinum for decades, in the hopes of bringing down the cost of hydrogen fuel cells.

An alternative to a platinum catalyst that costs considerably less will help to bring down the cost of hydrogen fuel cells and of using H2 as a carbon emission-free fuel. This would make it cheaper to both produce and use H2.

Researchers at the University of Buffalo, appear to be on the road to using iron as an affordable catalyst.

This paragraph describes he structure of the catalyst.

The researchers looked to iron because of its low cost and abundance. On its own, iron does not perform as well as platinum as a catalyst, particularly because it isn’t as durable in the face of highly corrosive and oxidative environments such as those within hydrogen fuel cells. The researchers bonded four nitrogen atoms to the iron in order to overcome that barrier, followed by embedding the material within a few graphene layers “with accurate atomic control of local geometric and chemical structures,” said Wu.

Gang Wu is leading the research.

In the early 1970s, I worked with one of ICI’s catalyst experts and he said, that improvements in this area will be large in the future.

Increasingly, I see his prediction being proved right, in the varied fields, where catalysts are used.

The Massive Hydrogen Project, That Appears To Be Under The Radar

This page on the SSE Thermal web site, is entitled Aldbrough Gas Storage.

This is the introductory paragraph.

The Aldbrough Gas Storage facility, in East Yorkshire, officially opened in June 2011. The last of the nine caverns entered commercial operation in November 2012.

This page on Hydrocarbons Technology is entitled Aldbrough Underground Gas Storage Facility, Yorkshire.

It gives these details of how Aldbrough Gas Storage was constructed.

The facility was originally planned to be developed by British Gas and Intergen in 1997. British Gas planned to develop Aldbrough North as a gas storage facility while Intergen planned to develop Aldbrough South.

SSE and Statoil became owners of the two projects in 2002 and 2003. The two companies combined the projects in late 2003. Site work commenced in March 2004 and leaching of the first cavern started in March 2005.

The storage caverns were created by using directional drilling. From a central area of the site, boreholes were drilled down to the salt strata located 2km underground.

After completion of drilling, leaching was carried out by pumping seawater into the boreholes to dissolve salt and create a cavern. Natural gas was then pumped into the caverns and stored under high pressure.

Six of the nine caverns are already storing gas. As of February 2012, dewatering and preparation of the remaining three caverns is complete. Testing has been completed at two of these caverns.

The facility is operated remotely from SSE’s Hornsea storage facility. It includes an above ground gas processing plant equipped with three 20MW compressors. The gas caverns of the facility are connected to the UK’s gas transmission network through an 8km pipeline.

Note.

- The caverns are created in a bed of salt about two kilometres down.

- It consists of nine caverns with the capacity to store around 370 million cubic metres (mcm) of gas.

- Salt caverns are very strong and dry, and are ideal for storing natural gas. The technique is discussed in this section in Wikipedia.

As I worked for ICI at Runcorn in the late 1960s, I’m very familiar with the technique, as the company extracted large amounts of salt from the massive reserves below the Cheshire countryside.

This Google Map shows the location of the Aldbrough Gas Storage to the North-East of Hull.

Note.

- The red-arrow marks the site of the Aldbrough Gas Storage.

- It is marked on the map as SSE Hornsea Ltd.

- Hull is in the South-West corner of the map.

This Google Map shows the site in more detail.

It appears to be a compact site.

Atwick Gas Storage

This page on the SSE Thermal web site, is entitled Atwick Gas Storage.

This is said on the web site.

Our Atwick Gas Storage facility is located near Hornsea on the East Yorkshire coast.

It consists of nine caverns with the capacity to store around 325 million cubic metres (mcm) of gas.

The facility first entered commercial operation in 1979. It was purchased by SSE in September 2002.

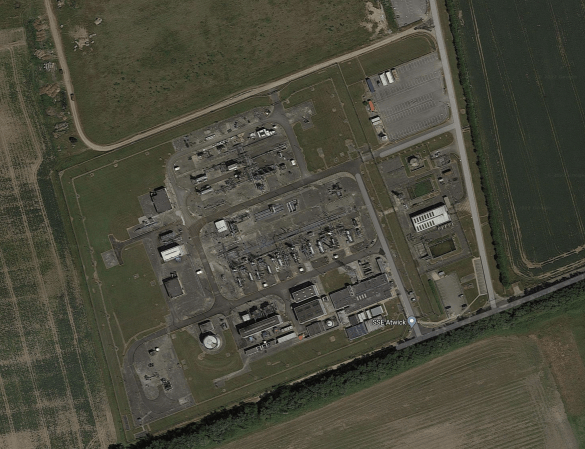

This Google Map shows the location of the Atwick Gas Storage to the North-East of Beverley.

Note.

- The red-arrow marks the site of the Atwick Gas Storage.

- It is marked on the map as SSE Atwick.

- Beverley is in the South-West corner of the map.

This Google Map shows the site in more detail.

As with the slightly larger Aldbrough Gas Storage site, it appears to be compact.

Conversion To Hydrogen Storage

It appears that SSE and Equinor have big plans for the Aldbrough Gas Storage facility.

This page on the SSE Thermal web site is entitled Plans For World-Leading Hydrogen Storage Facility At Aldbrough.

These paragraphs introduce the plans.

SSE Thermal and Equinor are developing plans for one of the world’s largest hydrogen storage facilities at their existing Aldbrough site on the East Yorkshire coast. The facility could be storing low-carbon hydrogen as early as 2028.

The existing Aldbrough Gas Storage facility, which was commissioned in 2011, is co-owned by SSE Thermal and Equinor, and consists of nine underground salt caverns, each roughly the size of St. Paul’s Cathedral. Upgrading the site to store hydrogen would involve converting the existing caverns or creating new purpose-built caverns to store the low-carbon fuel.

With an initial expected capacity of at least 320GWh, Aldbrough Hydrogen Storage would be significantly larger than any hydrogen storage facility in operation in the world today. The Aldbrough site is ideally located to store the low-carbon hydrogen set to be produced and used in the Humber region.

Hydrogen storage will be vital in creating a large-scale hydrogen economy in the UK and balancing the overall energy system by providing back up where large proportions of energy are produced from renewable power. As increasing amounts of hydrogen are produced both from offshore wind power, known as ‘green hydrogen’, and from natural gas with carbon capture and storage, known as ‘blue hydrogen’, facilities such as Aldbrough will provide storage for low-carbon energy.

I have a few thoughts.

Will Both Aldbrough and Atwick Gas Storage Facilities Be Used?

As the page only talks of nine caverns and both Aldbrough and Atwick facilities each have nine caverns, I suspect that at least initially only Aldbrough will be used.

But in the future, demand for the facility could mean all caverns were used and new ones might even be created.

Where Will The Hydrogen Come From?

These paragraphs from the SSE Thermal web page give an outline.

Equinor has announced its intention to develop 1.8GW of ‘blue hydrogen’ production in the region starting with its 0.6GW H2H Saltend project which will supply low-carbon hydrogen to local industry and power from the mid-2020s. This will be followed by a 1.2GW production facility to supply the Keadby Hydrogen Power Station, proposed by SSE Thermal and Equinor as the world’s first 100% hydrogen-fired power station, before the end of the decade.

SSE Thermal and Equinor’s partnership in the Humber marks the UK’s first end-to-end hydrogen proposal, connecting production, storage and demand projects in the region. While the Aldbrough facility would initially store the hydrogen produced for the Keadby Hydrogen Power Station, the benefit of this large-scale hydrogen storage extends well beyond power generation. The facility would enable growing hydrogen ambitions across the region, unlocking the potential for green hydrogen, and supplying an expanding offtaker market including heat, industry and transport from the late 2020s onwards.

Aldbrough Hydrogen Storage, and the partners’ other hydrogen projects in the region, are in the development stage and final investment decisions will depend on the progress of the necessary business models and associated infrastructure.

The Aldbrough Hydrogen Storage project is the latest being developed in a long-standing partnership between SSE Thermal and Equinor in the UK, which includes the joint venture to build the Dogger Bank Offshore Wind Farm, the largest offshore wind farm in the world.

It does seem to be, a bit of an inefficient route to create blue hydrogen, which will require carbon dioxide to be captured and stored or used.

Various scenarios suggest themselves.

- The East Riding of Yorkshire and Lincolnshire are agricultural counties, so could some carbon dioxide be going to help greenhouse plants and crops, grow big and strong.

- Carbon dioxide is used as a major ingredient of meat substitutes like Quorn.

- Companies like Mineral Carbonation International are using carbon dioxide to make building products like blocks and plasterboard.

I do suspect that there are teams of scientists in the civilised world researching wacky ideas for the use of carbon dioxide.

Where Does The Dogger Bank Wind Farm Fit?

The Dogger Bank wind farm will be the largest offshore wind farm in the world.

- It will consist of at least three phases; A, B and C, each of which will be 1.2 GW.

- Phase A and B will have a cable to Creyke Beck substation in Yorkshire.

- Phase C will have a cable to Teesside.

Creyke Beck is almost within walking distance of SSE Hornsea.

Could a large electrolyser be placed in the area, to store wind-power from Dogger Bank A/B as hydrogen in the Hydrogen Storage Facility At Aldbrough?

Conclusion

SSE and Equinor may have a very cunning plan and we will know more in the next few years.

Torvex Energy

Hydrogen And Chlorine Production At ICI Mond Division in The 1960s.

In my time in the late 1960s, when I worked For ICI Mond Division, I spent time in the Castner-Kellner works trying fairly unsuccessfully to develop an analyser to detect mercury-in-air in the Castner-Kellner process, that created chlorine and hydrogen from brine.

The process is not a nice one as it uses a mercury cathode and Wikipedia says this about safety.

The mercury cell process continues in use to this day. Current-day mercury cell plant operations are criticized for environmental release of mercury leading in some cases to severe mercury poisoning (as occurred in Japan). Due to these concerns, mercury cell plants are being phased out, and a sustained effort is being made to reduce mercury emissions from existing plants.

ICI felt that a mercury-in-air analyser would help to make the plant safer.

But ICI did have an alternative way to produce the chlorine they needed for selling as a gas or liquid or using as a base chemical for products like disinfectants, bleaches and dry cleaning fluids, without the use of mercury.

It was only a small plant and I was taken there once.

As with the Castner-Kellner process, it used a series of electrolyser cells.

- These were smaller and had a tub, with a concrete lid.

- The anode and cathode and the pipes collecting the hydrogen and the chlorine went through the lid.

- They were rebuilt regularly.

- As with the Castner-Kellner process, brine is electrolysed.

- The process was old and probably dated from before the Castner-Kellner process.

But of course as there was no mercury, the hydrogen and chlorine were pure and could be used for certain types of manufacture like pharmaceuticals.

Torvex Energy

This article on Hydrogen Fuel News is entitled Stockton R&D Firm Unveils New Hydrogen From Seawater Production Process.

These are some points from the article.

- Torvex Energy, a Stockton research and development company, recently unveiled a new technique for producing hydrogen from seawater.

- This unique method of producing hydrogen from seawater does not result in oxygen gas emissions.

- As such, it is clearly quite different from more traditional water electrolysis methods used for producing green H2.

- The team behind the production method call it an environmentally friendly technique.

- There is no desalination process.

- The firm has patents pending on this unique form of electrochemical process.

- It worked with the Material Processing Institute to establish proof of concept for this purpose.

I originally felt that Torvex Energy may have updated the ancient ICI process, that I saw over forty years ago, but when I asked the company, they said it was different.

It now appears that they haven’t, which means they must have found a totally new process.

There is certainly an ongoing patent application with a number of gb1900680.8.

How Efficient Is The Torvex Energy Process?

This will be key and there is nothing on their web site or on the Internet to indicate, if the Torvex Energy process is more or less efficient than traditional electrolysis.

Offshore Hydrogen Production

The main application for the Torvex Energy process must surely be in the production of hydrogen offshore.

- A fleet of floating wind turbines could surround a mother platform with a Torvex Energy process.

- The hydrogen could then be sent ashore in a pipeline.

- If there to be a handy depleted gas field, this possibly could be used to store the gas.

Depending on the efficiency of the Torvex Energy process, this could be a more cost-effective way to bring energy ashore, as gas pipelines can be more affordable, than HVDC electrical links. Especially, if the pipeline already exists.

Conclusion

Torvex Energy would have appeared to have made a major breakthrough in the production of hydrogen.