Cummins To Cease New Electrolyser Activity Amid Worsening Market

The title of this post, is the same as that of this article on Renewables Now.

These are the first three paragraphs.

Cummins Inc has decided to stop new commercial activity in the electrolysers space following a strategic review of the segment launched last year, citing deteriorating market conditions and weakening customer demand.

The decision is linked to USD 458 million (EUR 388.4m) of charges for the full-year 2025 related to the electrolyser business within the company’s zero-emission technologies arm, Accelera, of which USD 415 million were non-cash charges.

The company noted that it will continue to fulfil existing customer commitments before winding down new commercial activity in the segment.

Although, I am in favour of using hydrogen as a fuel, I recognise, that traditional electrolysis is not the most efficient process.

These methods are more efficient.

HiiROC

- HiiROC use a process, that they call Thermal Plasma Electrolysis to split any hydrocarbon gas into hydrogen and carbon black.

- HiiROC originated in the University of Hull.

- Typical gases that can be used are chemical plant off-gas, biomethane and methane.

- I like the ability to use chemical plant off-gas, as some of this is particularly nasty and HiiROC may offer safe disposal.

But the big advantage is that the HiiROC process is five times more energy efficient than traditional electrolysis.

The carbon black is no useless by-product, but has several valuable uses in its own right, which are detailed in its Wikipedia entry.

These two paragraphs from Wikipedia, give a summary of the more common uses of carbon black.

The most common use (70%) of carbon black is as a reinforcing phase in automobile tires. Carbon black also helps conduct heat away from the tread and belt area of the tire, reducing thermal damage and increasing tire life. Its low cost makes it a common addition to cathodes and anodes and is considered a safe replacement to lithium metal in lithium-ion batteries. About 20% of world production goes into belts, hoses, and other non-tire rubber goods. The remaining 10% use of carbon black comes from pigment in inks, coatings, and plastics, as well as being used as a conductive additive in lithium-ion batteries.

Carbon black is added to polypropylene because it absorbs ultraviolet radiation, which otherwise causes the material to degrade. Carbon black particles are also employed in some radar absorbent materials, in photocopier and laser printer toner, and in other inks and paints. The high tinting strength and stability of carbon black has also provided use in coloring of resins and films. Carbon black has been used in various applications for electronics. A good conductor of electricity, carbon black is used as a filler mixed in plastics, elastomer, films, adhesives, and paints. It is used as an antistatic additive agent in automobile fuel caps and pipes.

It can also be used as a soil improver in agriculture.

HiiROC would appear to be five times more energy efficient than traditional electrolysis.

I would also rate the range of their investors as a particular strength.

Google AI lists these companies as investors.

HiiROC, a UK-based developer of plasma torch technology for “turquoise” hydrogen production, is backed by a consortium of industrial and strategic investors. Key investors include Centrica, Melrose Industries, Hyundai Motor Company, Kia, HydrogenOne Capital, CEMEX Ventures, Wintershall Dea, and VNG.

Note.

- CEMEX must be going to decarbonise cement making.

- Melrose describe themselves as an industry-leading aerospace technology provider.

- Will we be seeing hydrogen cars from Korean manufacturers?

- Wintershall Dea is Europe’s leading independent gas and oil company.

HiiROC has an impressive list of investors.

Bloom Energy

I wrote about Bloom Energy’s process in Westinghouse And Bloom Energy To Team Up For Pink Hydrogen.

This method also looks promising.

- Westinghouse Electric Company is an American builder of nuclear power stations.

- Bloom Energy Corporation make a solid-oxide electrolyser.

- Pink hydrogen is green hydrogen produced using nuclear power.

It uses electrolysis at a higher temperature, which speeds it up.

Desert Bloom

This is an Australian process, that I wrote about in 10GW Green Hydrogen Project Aims To Electrolyze Water Drawn From Desert Air.

Conclusion

You can understand, why Cummins are getting jumpy!

But you have to remember that when I worked in a hydrogen plant in the 1960s, the hydrogen was an unwanted by-product and it was mixed with coal gas and sent down the power station to raise steam, so that it could be used to do something useful.

New Bid To Connect Heritage Railway To Mainline

The title of this post, is the same as that of this article on the BBC.

The is the sub-heading.

A bid to connect one of the longest heritage railways in Britain with mainline services has taken a step forward.

These are the first two paragraphs.

West Somerset Railway (WSR) and Somerset Council have now submitted a business plan to the government to restore the mainline from Taunton to the final WSR stop at Bishop’s Lydeard.

The proposal suggests Bishop’s Lydeard could become a commuter and tourist hub.

There has been several attempts to connect the branch to Taunton station.

These are my thoughts.

Minehead, Bishop’s Lydeard And Hinckley Point C

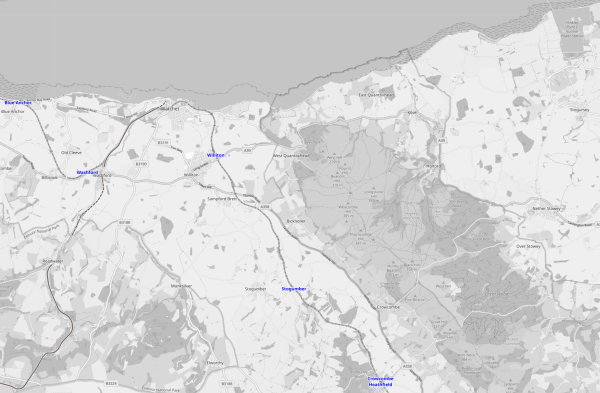

This Google Map shows the area.

Note.

- Minehead is in the North-West corner of the map.

- Hinckley Point power station is indicated by the red arrow.

- Bishop’s Lydeard is in the middle of the map.

- The M5 motorway curves diagonally between the North-East and South-West corners of the map.

- There are motorway services at Taunton Deane, which is to the South of Taunton and Cullompton, which is a few miles South-West of Wellington.

- The large town of Taunton is the junction of the London and Exeter and the Bristol and Exeter railway lines.

- The town of Wellington will be getting a new railway station.

It is a very busy area and it will only get busier, as the availability of power will only attract industry, like the battery factory pencilled in for Bridgewater.

The Major Effect Of Hinckley Point C

Hinckley Point C will generate 3.26 GW of electricity and to operate the power station will need around nine hundred workers.

I can also expect that the Hinckley Point site will get involved in other energy handling and use.

- The site would be an ideal place for a large electrolyser to produce hydrogen.

- Wind turbines in the Bristol Channel could use Hinckley’s grid connection.

- Energy could be stored on the site. It could be an ideal location for one of Highview Power’s 200 MW/3.25 GWh liquid air batteries.

- Hydrogen could be exported using coastal tankers.

- Interconnectors could take electricity to Cornwall, Devon, Wales and Ireland.

All of these activities would create needs for workers at all levels.

- A rail connection to Taunton and Bristol, will probably be needed to bring workers into Hinckley Point.

- A rail connection would be ideal for bringing construction materials, steel and other heavy goods into and out of the Hinckley Point site.

- Hydrogen could also be taken out in rail tankers.

- Nuclear waste could be taken out by train.

I think it is highly likely, that Hinckley Point will need a rail connection for efficient operation.

Sizewell C And Hydrogen

Hydrogen is so important to the philosophy of the design and construction of Sizewell C, that hydrogen has its own section on the Sizewell C web site.

Hydrogen produced by nuclear power stations like Hinckley Point C, is called pink hydrogen, but like green hydrogen it is zero-carbon and pollution-free.

Hinckley Point C And Hydrogen

I can envisage Hinckley Point C will create a lot of hydrogen both for use locally and distribution to remote users.

- Hydrogen could be delivered locally by truck, just as propane is today around the world.

- Coastal tankers could distribute the hydrogen from a jetty.

- Pipelines could connect the two nearby motorway service stations to the power station site.

Just as is happening at Sizewell, a local hydrogen network could be built.

Hydrogen Refuelling On The M5

Consider.

- In MAN Expands Its Zero-Emission Portfolio, I talked about MAN’s new hydrogen-powered hTGX truck, which has been designed with a 600 km. or 373 mile range.

- As Cullompton, which is the Southernmost of the two services on the M5 that are close to Hinckley Point C, is only 124.9 miles from Penzance, it should be possible for a truck, with a range similar to that of the MAN hTGX to do a round trip from the Southern end of the M5 to Penzance, without refuelling.

- As the total length of the M5 is only 163 miles, a hydrogen-powered truck with the range of the MAN hTGX would be able to do a delivery anywhere along the motorway and return to the hydrogen from Hinckley Point C, without refuelling.

- MAN are saying that the hTGX truck can be refuelled in less than fifteen minutes.

It looks to me, that a hydrogen electrolyser at Hinckley Point C would be ideally located to provide pink hydrogen for a zero-carbon hydrogen-powered route to and from the far South-West.

I believe that if there were a best-in-class hydrogen-refuelling facility close to Hinckley Point C, it would encourage those who regularly drove to Devon and Cornwall to look seriously at hydrogen-powered vehicles.

The Nature Of The Hinckley Point C Rail Link

Sizewell C are using a simple practical approach to connect the Sizewell C site to the nearby East Suffolk Line.

- The existing freight sidings are being expanded.

- Two Park-and-Ride sites are being created at stations in the East Suffolk Line.

- A link road will be built between the railway and the Sizewell C site.

- A fleet of hydrogen-powered double-deck buses has been ordered to take workers between the railway and the power station.

- The signalling on the East Suffolk Line is being improved.

This map from OpenRailwayMap shows the Northern end of the West Somerset Railway and its relationship to Hinckley Point C power station.

Note.

- Hinckley Point C power station is in the North-East corner of the map.

- Crowcombe & Heathfield, Stogumber, Sampford Brett, Doniford Halt, Williton, Watchet, Washford and Blue Anchor are existing or former stations on the West Somerset Railway.

- Existing stations are shown in blue.

- West of Blue Anchor are the two existing stations of Dunster and Minehead.

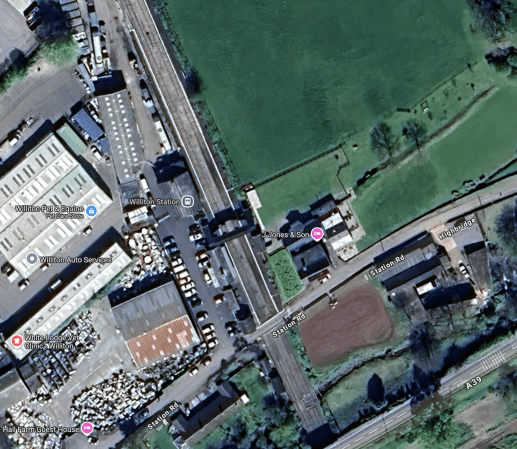

This Google Map shows Williton station, which is the nearest station to Hinckley Point C.

Note.

- The station has a footbridge, which was erected in 2011, so is probably in good condition.

- There are several Listed buildings on the site.

- Going East on the A39 should lead to Hinckley Point C.

I suspect a quality bus company could build a small fleet of buses to shuttle workers, visitors and others to Hinckley Point C.

As I’m sure, hydrogen will be in plentiful supply, I’m certain hydrogen-powered buses could be used.

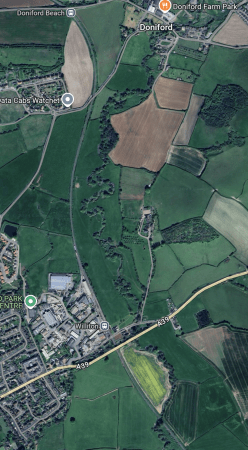

This Google Map shows a longer section of the West Somerset Line through Williton station.

Note.

- The West Somerset Line runs North-South down the map.

- Doniford Halt station is at the top of the map, where the coast road crosses the railway on a bridge.

- Williton station is in the middle of the map, where the A39 crosses the railway.

Looking at the railway, which runs mainly between fields, I wouldn’t be surprised that if Hinckley Point wanted a freight siding, they could fit one in.

Go-op

Go-op are an open access railway company, that wants to run services in Somerset.

I wrote about their successful application in Regulator Approves New Go-op Train Service Between Swindon, Taunton and Weston-super-Mare.

This is the first paragraph of their Wikipedia entry.

Go-op Cooperative Ltd.,[ branded as Go-op, is an open access train operating company, proposing to operate a service in south-west England between Taunton and Swindon, via Westbury. It aims to become the first cooperatively owned train operating company in the United Kingdom, to improve access to the public transport infrastructure through open access rail services linking main lines to smaller market towns, and by co-ordinating services with light rail, bus links and car pools.

If you read their Wikipedia entry and their web site, they seem to have ambition and be different.

According to Wikipedia, they have made no less than five different proposals, but it is the fourth that I find interesting.

In 2021, Go-op began discussions with Network Rail for services between Swindon and Bishops Lydeard (just beyond Taunton), which it hoped to begin in mid-2022. At first there could only be three services per day, due to congestion between Swindon and Westbury; a further three could be provided to Frome or Westbury, connecting with existing services to Swindon. These plans would also improve local services on the TransWilts Line, calling at Trowbridge and Melksham.

The plans for Bishops Lydeard would restore the link broken in 1971 between the national network and the preserved West Somerset Railway, which runs leisure services to Minehead.

This sounds very much like an extended and simplified version of the West Somerset Line proposal.

But it does look like two groups have looked at the infrastructure and what is needed and come to similar conclusions.

Perhaps, they have other things in common like train procurement and servicing.

Stadler Presents A World First In Berlin

The title of this section, is the same as that of this press release from Stadler.

These are the first two paragraphs.

With the RS ZERO, the rail vehicle manufacturer is presenting the successor to the successful Regio-Shuttle RS1 model. There is a choice of two modern and environmentally friendly drive technologies: Hydrogen and battery. Both will enable CO2 emission-free operation of secondary lines in the future.

Stadler today unveiled the prototype of the new RS ZERO, the innovative successor to the successful RS1 Regio-Shuttle. The Regio-Shuttle has been one of the most popular vehicles in German regional rail transport for 28 years, with around 500 RS1 vehicles currently in operation in Germany and the Czech Republic. Stadler is building on this proven technology and integrating state-of-the-art, environmentally friendly drive systems. The RS ZERO is optionally available with a hydrogen and/or battery drive and thus not only sets new standards for environmentally friendly rail transport, but also presents a world first.

These pictures from Chemnitz Trams And The Chemnitz Model, show the Regio-Shuttle RS1.

Note.

- The Regio-Shuttles can run as up to seven car trains.

- These Regio-Shuttles are electro-diesel.

- The distinctive diagonal windows.

- They can carry 170 passengers at 75 mph.

- They can run as train-trams using the Chemnitz model on compatible tram networks.

The Regio-Shuttle Wikipedia entry gives more details.

This image from the press release shows the prototype RS ZERO.

It looks very similar to my pictures from Chemnitz.

I have a few thoughts.

Comparison To A Class 150 Train

A Class 150 train can carry up to 149 seated passengers at 75 mph, which is similar to the RS ZERO.

As Stadler have built trains for Greater Anglia, Merseyrail and the Glasgow Subway, I believe that Stadler could build an RS ZERO, that would fit the UK loading gauge.

In What Train Is This?, I show the standard of interior, that can be achieved by refurbishing a Class 150 train, but unlike the RS ZERO, the train won’t be zero-carbon.

Does The RS ZERO Have A Toilet?

This is a paragraph from the press release.

The prototype of the RS ZERO presented today in Berlin is a one-car vehicle with hydrogen drive. Stadler is demonstrating the numerous design options with a multi-purpose area equipped for carrying bicycles, pushchairs and bulky luggage, lounge and comfort zones, standard and privacy seats, a wheelchair space, WC and a train office.

The train appears to be able to have what an operator might need.

What Will Be The Range Of An RS ZERO On Hydrogen?

I suspect, Stadler will provide a train, that will handle the route.

Would Stadler Be Able To Produce An RS ZERO That Could Satisfy The West Somerset/Go-op Requirement?

I obviously, can’t answer that.

But.

- The train is zero-carbon.

- It’s the right size.

- I suspect that the hydrogen fuel will be available from Hinckley Point C.

- The design has a proven track record.

- The train is not by any means vapourware!

- Stadler need a launch order.

- An experienced ROSCO would probably finance the trains.

One perk is that those involved in buying the train, could probably wangle a trip to Chemnitz to see several Regio-Shuttle RS1 trains at work.

Note that Chemnitz used to be Karl-Marx Stadt, so some of our Government will feel nostalgic.

But I do believe, this could be a very handy train to decarbonise branch and secondary lines in the UK.

UK Investment Summit Latest: Starmer Announces £1.1bn Expansion Of Stansted Airport

The title of this post, is the same as that of this article on The Times.

The Times has this sub-heading about Stansted

Analysis: Stansted Deal Prioritises Growth Over Climate

There are four paragraphs of analysis.

Over the weekend, Sir Keir Starmer made clear that his commitments to boost workers’ rights would not get in the way of his desire to bring in cash from the owners of P&O. As ministers now trumpet a deal to upgrade Stansted airport, it seems that growth and jobs also trump concerns about emissions.

Louise Haigh, the transport secretary who prompted the row with DP World by calling P&O a “rogue operator”, praised the Stansted deal as a “clear signal that Britain is open for business”. She argued that Stansted could be upgraded “while also meeting our existing environment obligations”, with the airport promising a new solar farm to generate electricity. But environmentalists will be dismayed by the prospect of more plane journeys and associated emissions.

The deal also raises fresh questions about a third runway at Heathrow after years of dithering under the Conservatives. No 10 has previously said it is “not opposed” to expansion if it can meet tests on emissions, climate change, noise pollution — and growth.

Starmer has said he will not duck decisions because they are “too difficult”. A decision on Heathrow offers a very clear test of that promise.

Is Hydrogen The Reason For The Choice Of Stansted?

I wonder if the choice of Stansted for expansion is down to the likelihood, that East Anglia will be a big centre for the generation of zero-carbon green and pink hydrogen, with gigawatts of offshore wind farms for the green and nuclear at Sizewell for the pink.

Aircraft of the future will surely need hydrogen for flying to their destinations.

Already, the massive construction of Sizewell C is going to be performed using zero-construction methods involving electricity and hydrogen, as far as is possible.

Large construction at Stansted Airport could be done in a similar manner, using perhaps a hydrogen pipeline between Sizewell and Stansted running along the A 14. This would probably be built anyway, so that East Anglia’s large numbers of heavy trucks could be converted to hydrogen.

Already the hydrogen buses to bring workers to the Sizewell C site have been ordered from Wrightbus in Ballymena.

Airbus, are planning to have their hydrogen-powered Boeing 737/A 320-size airliner in service by the mid-2030s. From visualisations released by Airbus, the Zeroe hydrogen Turbofan looks very much like a redesigned version of the current A320 neo, with two hydrogen turbofans (hopefully with RR on the side!) Converting an existing proven airliner, only means that the new parts need to be certified, so this would bring the plane into service quicker.

Airbus’s infographic shows the Zeroe hydrogen Turbofan will seat up to 200 passengers and have a range of 2,000 nautical miles or 3,700 km.

Discover the three zero-emission concept aircraft known as ZEROe in this infographic. These turbofan, turboprop, and blended-wing-body configurations are all hydrogen hybrid aircraft.

A typical A 320 neo will fly 165 passengers up to 3,500 nautical miles or 6.500 km.

A few distances from Stansted include.

- Athens – 2,400 km.

- Berlin – 905 km.

- Cairo – 3514 km.

- Copenhagen 913 km.

- Dublin – 470 km.

- Edinburgh – 509 km.

- Gander 3,800 km

- Geneva – 760 km.

- Glasgow – 540 km.

- Istanbul – 2480 km.

- Madrid – 1300 km.

- Milan – 960 km.

- Munich – 909 km.

- Palma de Mallorca – 1,400 km.

- Reykjavík – 1870 km.

- Rome – 1,442 km.

- Stockholm – 1,400 km.

- Tel-Aviv – 3,564 km.

- Tenerife North – 2944 km.

- Tenerife South – 2999 km.

- Warsaw 1,412 km.

These distances would mean, a lot of current European destinations could be reached, if the plane were filled at both airports, but a surprising number of popular places could be reached by only refuelling at Stansted.

It also appears to me, that with refuelling in Iceland and perhaps a stopover, in that delightful and different country, zero-carbon flights across the Atlantic would be possible.

If a hydrogen-powered aircraft has the 3,700 km. range that Airbus are promising, it will be an aircraft with a lot of possibilities!

Short Flights

- Amsterdam – 541 km.

- Cardiff – 253 km.

- Exeter – 284 km.

- Jersey – 344 km.

- Liverpool – 264 km.

- Newcastle – 373 km.

- Newquay – 399 km.

- Ronaldsway – 408 km.

- Southampton – 151 km.

Some of these flights would be competing with trains.

Flights Around The British Isles

One of the longest flights around the British Isles would be between Stansted and Sumburgh Airport in the Shetland Isles.

But this is only 894 kilometres, so a return trip would be possible.

I also feel that arranging hydrogen refuelling on Shetland will not be a difficult task, as the islands are likely to have copious supplies of green hydrogen.

Flights From Stansted To Europe

Applying a ten percent reserve probably means a safe one-way range of around 1,700 km.

This would mean that.

- Amsterdam – 541 km.

- Berlin – 905 km.

- Copenhagen – 913 km.

- Madrid – 1300 km.

- Milan – 960 km.

- Munich – 909 km.

- Palma de Mallorca – 1,400 km.

- Rome – 1,442 km.

- Stockholm – 1,400 km.

- Warsaw 1,412 km.

Should all be in range. of an out-and-back flight, after fully fuelling the plane at Stansted Airport.

Others like.

- Athens – 2,400 km.

- Bucharest – 2070 km.

- Cairo – 3514 km.

- Istanbul – 2480 km.

- Lisbon – 1630 km.

- Malta – 2107 km.

- Marrakech – 2350. km.

- Sofia – 2010 km.

- Tel-Aviv – 3,564 km.

- Tenerife North – 2944 km.

- Tenerife South – 2999 km.

Could be handled by refuelling at the destination.

Hopping Across The Atlantic

Consider.

- My great aunt Beatrice used to fly the Atlantic in the 1950s, although it was usually a succession of small hops between Heathrow Shannon and Gander Airports. I think she regularly used ships like the Queen Mary and Elizabeth, as she found them less stressful.

- Icelandair offer short stopovers in Reykjavik and I suspect they will offer this with hydrogen-fuelled aircraft.

- British Airways used to offer a London City Airport to New York flight via Shannon using an Airbus A 318.

I would certainly be interested to hop across from Stansted to New York in a hydrogen-powered aircraft, and I suspect others would do it for the environmental brownie points.

Legs could be.

- Stansted and Reykjavík – 1870 km.

- Reykjavík and Gander – 2568 km

- Gander and New York – 1767 km.

A stop could possibly be squeezed in at Boston.

It could be an interesting way to cross the Atlantic.

Hydrogen Production In East Anglia

I said earlier that East Anglia could produce a lot of zero-carbon green and prink hydrogen from wind and nuclear and this would be used for the following.

- Aviation out of Stansted and Southend Airports.

- Shipping out of the Port of Felixstowe, London Gateway and other smaller ports.

- Providing energy for heavy transport in East Anglia.

- Providing energy for Freeport East at Felixstowe and Harwich.

- Refuelling passing shipping.

- Supplying off-grid energy to rural properties and businesses in the East of England, which I wrote about in Developing A Rural Hydrogen Network.

Any spare hydrogen could always be sold to the Germans.

Decarbonisation Of The Railways In East Anglia

Undoubtedly, some hydrogen will be used to decarbonise some parts of East Anglia’s railways.

Many passenger trains are electrified, but some rural and cross-country services still use diesel. However, the Class 745 trains, that were built by Stadler for these services could be converted to hydrogen or battery-electric.

Similarly, locomotives that haul the freight trains out of the ports of East Anglia will be replaced with hydrogen or battery-electric locomotives.

I am fairly certain, that by 2040, all railways in East Anglia will be zero-carbon.

The East-West Rail Link

It is not known yet, whether the current government will continue to build the East West Rail Link, but it could be invaluable in connecting Stansted Airport to the West of England.

Connecting Stansted Airport To The North Of England and Scotland By Rail

If Stansted is developed as a zero-carbon airport, based on the new hydrogen-powered aircraft, travellers between say the North of England and Scotland, will surely want to travel to Stansted in a carbon-free manner.

So would it be sensible to run rail electric services between the North and Stansted?

Conclusion

Stansted could develop into the UK’s zero-carbon airport.

Sizewell C And Hydrogen

The Sizewell C web site has a page with a title of Hydrogen and SZC.

The page asks this question.

Why Does Sizewell C Want To Produce Hydrogen?

It gives this answer.

Nuclear is a great way of producing hydrogen as it generates huge amounts of reliable, low-carbon energy. Nuclear and hydrogen are also two clean technologies that can help us make big reductions in carbon emissions. While both technologies are vital on their own, at Sizewell C we have an exciting vision to bring them together.

The page is worth a read about how they will use the hydrogen, which will include.

- Providing Wrightbus hydrogen-powered buses to link the main construction site with Park-and-Ride sites on the A 12 at Darsham and Wickham Market.

- Powering vehicles and machinery on the main construction site.

- Supplying hydrogen to Freeport East.

- Refuelling hydrogen vehicles.

I have a few thoughts.

Supplying Hydrogen To Users

On my last stud farm, we had three fuel deliveries.

- Propane to heat the house.

- Red diesel to power the farm machinery.

- Road diesel to power the horse box and a couple of diesel cars, that went on the roads.

Note.

- Like most farms in East Anglia, we didn’t have mains gas.

- The local low-life of whom you never speak their name, used to regularly steal the diesel.

- We had two boilers, that ran on the propane.

- All farm vehicles and machinery will in the future use hydrogen.

- Propane and diesel would be replaced by clean hydrogen.

I believe companies like Centrica, will develop the technology so that farms and businesses could have their own hydrogen system, that would be topped-up accordingly, by road tankers, which themselves would be fuelled by hydrogen.

One set of tankers would be replaced by another zero-carbon set.

Sizewell sits on the Suffolk Coast and it appears, there will be a new road link to the A 12, which connects to Suffolk’s main road system.

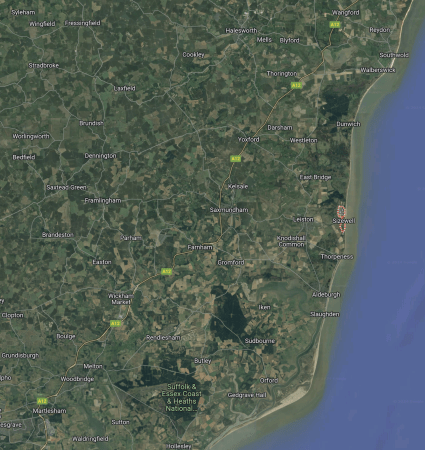

This map shows Sizewell C and East Suffolk.

Note.

- The Sizewell site is outlined in pink on the coast, about halfway up the map.

- The A 12 road and the East Suffolk Line run almost parallel to the coast between Ipswich in the South and Lowestoft and Yarmouth in the North.

Energy use in East Suffolk would be transformed and all because there will be a plentiful supply of zero-carbon hydrogen.

Hydrogen And The Arts

Suffolk has been an artistic county for hundreds of years and some works of art, like casting bronzes, firing pottery or working with glass or wrought iron need a lot of energy. Local hydrogen networks supplied by tanker, as propane is now could help to decarbonise one of the most difficult of professions.

Pink Hydrogen

This page on the National Grid web site explains the various hydrogen colours.

It describes pink hydrogen like this.

Pink hydrogen is generated through electrolysis powered by nuclear energy. Nuclear-produced hydrogen can also be referred to as purple hydrogen or red hydrogen.

In addition, the very high temperatures from nuclear reactors could be used in other hydrogen productions by producing steam for more efficient electrolysis or fossil gas-based steam methane reforming.

I also call it Barbie hydrogen.

Sizewell C would be an ideal place to create pink hydrogen.

Before Sizewell C is up and running, the electrolyser at Sizewell could be powered by Sizewell B or even offshore wind.

Teesside Private SMR Nuclear Power Station To Be Built

The title of this post, is the same as that of this article on the BBC.

This is the sub-heading.

An agreement has been reached to build a privately financed nuclear power station in Teesside.

These are the first three paragraphs.

Community Nuclear Power (CNP) has announced plans to install four small modular reactors (SMRs) in North Tees.

CNP said it aims to be up and running in ten years’ time and will supply “roughly a gigawatt of energy”.

With other similar power stations planned, hundreds of jobs are expected to be created in the north-east of England.

A CNP spokesperson said the four North Tees reactors will generate clean, always-on energy which will be used to help develop a green energy and chemical hub, also within the North Tees Group Estate, on the north bank of the River Tees near Stockton.

These are my thoughts.

The Westinghouse AP300™ SMR

This SMR has its own web page.

This is the sub-heading.

Only SMR based on Licensed, Operating & Advanced Reactor Technology

These paragraphs introduce the reactor.

The Westinghouse AP300™ Small Modular Reactor is the most advanced, proven and readily deployable SMR solution. Westinghouse proudly brings 70+ years of experience developing and implementing new nuclear technologies that enable reliable, clean, safe and economical sources of energy for generations to come.

Our AP1000® reactor is already proving itself every day around the globe. Currently, four units utilizing AP1000 technology are operating in China, setting performance records. Six more are under construction in China and one AP1000 reactor is operating at Plant Vogtle in Georgia while a second nears completion.

Our AP300 SMR leverages that operating experience, as well as tens of millions of hours on AP1000 reactor development.

Gain the benefits of the record-setting Westinghouse AP1000 PWR technology in a smaller power output to augment the backbone of your community energy system.

The AP300 SMR complements the AP1000 reactor for a cleaner energy mix, energy security, and grid flexibility and stabilization.

Westinghouse seem to have taken a very professional and scientifically correct approach and downsized something that works well.

Where Will The Reactors Be Built?

This is a paragraph from the BBC article.

Small reactors, built in a factory by the American power giant Westinghouse, will be transported to Seal Sands near Billingham, coming on stream in the early 2030s and going some way to providing part of the big rise in nuclear capacity the UK government wants to see by 2050.

This Google Map shows the mouth of the River Tees.

Note.

- The red arrow at the bottom of the map indicates the location of North Tees Group Estate.

- Follow the river to the North and a capitalised label indicating the position of Seal Sands can be seen.

This second Google Map shows the Seal Sands area in a larger scale.

There seems to be several spaces, where the reactors could be located.

Would It Be Safe To Locate A Nuclear Reactor Or Reactors In a Cluster Of Oil Refineries And/Or Chemical Plants?

Consider.

- In the 1970s, when I worked at ICI, there were companies like Westinghouse advocating nuclear steelmaking.

- We did discuss the concept a couple of times over coffee but no one, I worked with, ever looked at it officially or seriously, as far as I know.

- In addition to requiring large amounts of electricity, oil refineries and chemical plants often use a lot of steam.

- Nuclear reactors generate steam to produce electricity, so some could be diverted to oil refineries or chemical plants

- To decarbonise some processes might switch to hydrogen.

- In Westinghouse And Bloom Energy To Team Up For Pink Hydrogen, I talk about how to use a nuclear reactor to efficiently produce pink hydrogen.

It looks like for efficiency, building the various plant close together could be a good thing.

But is it safe?

I suspect the level of safety will be that of the least safe plant.

So provided all plants are designed to the highest standards, it should be OK, as nuclear plants, oil refineries and chemical plant don’t regularly explode.

The Donald C Cook Nuclear Plant

The Donald C Cook Nuclear Plant in Michigan is a 2.2 GW nuclear plant, that was built by Westinghouse and commissioned in the mid-1970s.

They were clients for Artemis, the project management system that I wrote.

Soon after the Three Mile Island accident on March 28th, 1979, I visited the Donald C Cook Nuclear Plant to see how they were coping with the aftermath of the accident.

I remember being told by the operators of the plant, who were American Electric Power, that as it was their only nuclear plant, they were going to do everything by the book and Artemis was helping them to do that.

Reading about the plant, which is now licenced to operate until 2034 for one reactor and 2037 for the other, it seems to have performed impeccably so far for nearly fifty years.

It is a credit to both Westinghouse, who built it and American Electric Power who own it.

Now that is what I call high-class engineering and I’d be happy to have a cluster of SMRs to the same standard in my back yard.

Sizewell B

I used to live a few miles from Sizewell B, which is another Westinghouse reactor.

- This is the Wikipedia entry for the power station.

- Sizewell B was based on a proven Westinghouse design.

- It seems to have performed well since it was commissioned in 1995.

It looks like it will be operating until 2055, which will make its working life similar to those of the reactors at the Donald C Cook Nuclear Plant.

Westinghouse And Hinckley Point C Compared

Consider.

- Sizewell B was built in approximately seven years.

- This compares well with the two units at the Donald C Cook Nuclear Plant, which took six and nine years respectively

- It looks like Hinckley Point C will take between twelve and fourteen years to build.

- Sizewell B and the two units at Donald C Cook Nuclear Plant seem to be looking at a sixty year operating lifetime.

- Sizewell has a rail connection and Hinckley Point does not.

- Sizewell B seems to have been signed off, when John Major was Prime Minister.

- Hinckley Pont C seems to have resulted from a government white paper when Gordon Brown was Prime Minister.

Westinghouse seem to design nuclear power stations, that can operate for a long period and can be built within a decade.

Westinghouse And Rolls-Royce

Consider.

- Rolls-Royce also have an SMR design.

- Rolls-Royce and Westinghouse are both world-class companies.

- Rolls-Royce have the advantage they are British.

- I also suspect, that both Westinghouse and Rolls-Royce will use the same subcontractors and sub-assembly manufacturers.

- The Rolls-Royce SMR has a power output of 470 MW.

- The Westinghouse SMR has a power output of 300 MW.

I suspect the choice between the two, will be like choosing between top-of-the-range British and American products.

Conclusion

I wonder why we ended up with an unproven new French design at Hinckley Point, when sitting in Suffolk was a traditional Westinghouse design, that was performing to its design specification?

But for the SMR, we need to buy the reactors, which are financially best for Britain. If Westinghouse choose to manufacture large sections in the UK, they could be the better bet, as I suspect, if SMRs are successful, we’ll be seeing exports from the UK.

Ultra Safe Nuclear, Hyundai Engineering, SK Ecoplant Sign MOU For Clean Hydrogen Production

The title of this post, is the same as that of this press release from Ultra Safe Nuclear Corporation.

These are the first two paragraphs.

Ultra Safe Nuclear Corporation, the U.S.-based global leader in the deployment of fourth-generation gas-cooled microreactors, Hyundai Engineering (Representative Director Hong Hyun-sung) and SK ecoplant (Representative Director Park Kyung-il) are teaming up to conduct research and development for carbon-free hydrogen production. The three companies signed an MOU on Thursday, April 20th for the construction of a “Hydrogen Micro Hub” at the SK ecoplant headquarters in Seoul’s Jongno-gu.

The “Hydrogen Micro Hub” is a facility that produces hydrogen by applying a high-temperature electrolysis process of solid oxide electrolysis cells (SOEC) to the electricity and high-temperature steam generated by USNC’s Micro-Modular™ Reactor (MMR®). This is a carbon-free hydrogen production method that extracts hydrogen by decomposing water with electricity generated from nuclear power.

Ultra Safe Nuclear Corporation has a web site.

- Ultra Safe Nuclear Corporation, is a U.S. corporation headquartered in Seattle.

- Canada appears to be deeply involved.

- Innovate UK appears to have dished out a grant.

- They appear to have sold five of their MMRs.

The company could be a serious competitor in the market for small modular nuclear reactors.

Suffolk: Sizewell C To Explore ‘Innovative’ Waste Heat Lido

The title of this post, is the same as that, of this article on the East Anglian Daily Times.

This is the sub-heading.

The developers of the new Sizewell C nuclear power station have expressed an interest in an “innovative” plan to use waste heat from the plant to heat a new lido.

And this is the first paragraph.

Creating the outdoor pool was one of a number of ideas contained within the Leiston masterplan – a blueprint for transforming the Suffolk town – and now the Sizewell C company has pledged to explore the proposal with the town council.

This map shows the town of Leiston and the Sizewell power stations site.

Note.

- Leiston is in the South-West corner.

- The power station site is in the North-East corner.

I have a few thoughts.

Pink Hydrogen

Pink hydrogen is zero-carbon hydrogen produced using nuclear power.

The production of hydrogen is already part of the plans for Freeport East, which I wrote about in Ryze Hydrogen’s Suffolk Freeport Hydrogen Vision Takes Shape.

In that article, I said this.

This would mean that Sizewell’s 6 MW electrolyser could be producing around a thousand tonnes of hydrogen per year or 2.6 tonnes per day.

The more efficient high temperature electrolysis can be used, using some of the waste heat from the nuclear power station. I wrote about this in Westinghouse And Bloom Energy To Team Up For Pink Hydrogen.

I also suspect that it may be more efficient to use seawater to produce the hydrogen.

Could high temperature electrolysis be used at Sizewell?

District Heating

The waste heat can also be used for district heating.

A Train Service To Ipswich

This Google Map shows the railway through Leiston, which is currently used to bring fuel to Sizewell B power station and remove waste.

Note.

- The railway starts in the North-West corner of the map.

- The green dot in that corner marks Leiston cemetery.

- The railway then goes East before turning to the South-East corner of the map.

- In that corner, there are two sidings for loading and unloading the flasks.

Surely, Leiston also needs a new railway station, with at least an hourly service to Saxmundham, Wickham Market, Woodbridge and Ipswich. And possibly even Aldeburgh!

This map from OpenRailwayMap shows the route of the Aldeburgh branch.

Note.

- The North-South yellow line is the East Suffolk Line.

- Their were three stations; Leiston, Thorpeness Halt and Aldeburgh.

- Leiston station was in the North of the town.

The intact section of the branch is shown in yellow.

There would be no need for any electrification, as Stadler, who built Greater Anglia’s Class 755 trains, are the masters of battery-powered trains and could convert these trains to battery operation. Recently, one of the smaller metro trains, that Stadler are building for Liverpool, ran for nearly 90 miles on battery power alone, which I wrote about in New Merseyrail Train Runs 135km On Battery.

An hourly train service would double the frequency of the train service between Saxmundham and Ipswich.

Does the Leiston masterplan include a train service?

And if it does, does it terminate at a new Aldeburgh station?

Conclusion

Integrating development around a nuclear power station could be a way of levelling up.

It would bring electricity, heat, a rail link and jobs to an area.

Will Rolls-Royce use these benefits to sell one of their SMRs to those living around a site?

Rolls-Royce To Develop mtu Hydrogen Electrolyser And Invest In Hoeller Electrolyser

The title of this post, is the same as that of this press release from Rolls-Royce.

These are the three main points in the press release.

- Holdings in start-up companies in northern Germany secure Rolls-Royce Power Systems access to key green hydrogen production technology.

- Electrolysis systems for several megawatts of power.

- First demonstrator in 2023 using a Hoeller stack.

This is the introductory paragraph to the deal.

Rolls-Royce is entering the hydrogen production market and acquiring a 54% majority stake in electrolysis stack specialist Hoeller Electrolyzer, whose innovative technology will form the basis of a new range of mtu electrolyzer products from its Power Systems division. Hoeller Electrolyzer, based in Wismar, Germany, is an early-stage technology company that is developing highly efficient polymer electrolyte membrane (PEM) stacks, under the brand name Prometheus, for the cost-effective production of hydrogen.

This page on the Hoeller Electrolysis web site gives details of Prometheus.

- Hoeller are planning small, medium and large electrolyser modules, the largest of which is rated at 1.4 MW.

- Load changes of between 0 and 100 % within seconds.

- Cold start capability.

- It will produce 635 Kg/day.

- They are talking of a cost of 4€/Kg.

It all sounds good to me.

This paragraph is from the press release.

Founded in 2016, Hoeller Electrolyzer has positioned itself, with Prometheus, as one of the few highly specialized expert players in the field of high-efficiency PEM electrolysis stacks. Its founder, Stefan Höller, has more than a quarter of a century’s experience of developing electrolysis technology and has already registered 14 patents connected with Prometheus. Particularly high efficiency is promised by special surface technologies for the bipolar plates which significantly reduce the use of expensive precious metals platinum and iridium as catalysts, as well as increased output pressure.

I know a small amount about electrolysis and feel that Rolls-Royce may have got themselves a high-class deal.

Rolls-Royce’s large German presence in companies like mtu, will also help to smooth any doubts about the deal.

This paragraph indicates a shared belief.

Rolls-Royce and Hoeller Electrolyzer are united by a shared belief in the opportunity of zero-carbon energy – both for power supply and the propulsion of heavy vehicles. With decades of experience and systems expertise, Rolls-Royce is going to develop a complete electrolyzer system and has a global sales and service network, which opens up the potential for significant worldwide sales.

But perhaps, this is the most significant paragraph of the press release.

Armin Fürderer, who heads up the Net Zero Solutions business unit of Power Systems, said: “We’re going to launch electrolyzers with several megawatts of power right from the start. A total output of over 100 megawatts is conceivable by combining several electrolyzers.”

A quick search of the Internet, indicates that 100 MW is the size of the world’s largest electrolysers.

Applications

I can see applications for these large electrolysers.

Rolls-Royce Power Systems

This is a sentence from the press release.

Hoeller Electrolyzer, whose innovative technology will form the basis of a new range of mtu electrolyzer products from its Power Systems division.

The Rolls-Royce Power Systems web site, has this mission statement.

The Power Systems Business Unit of Rolls-Royce is focused on creating sustainable, climate neutral solutions for drive, propulsion and power generation.

In Rolls-Royce Makes Duisburg Container Terminal Climate Neutral With MTU Hydrogen Technology, I describe one of Rolls-Royce Power Systems projects.

The title of this post, is the same as this press release from Rolls-Royce.

This is the first sentence.

Rolls-Royce will ensure a climate-neutral energy supply at the container terminal currently under construction at the Port of Duisburg, Germany.

There is also this Rolls-Royce graphic, which shows the energy sources.

It would appear batteries, combined heap and power (CHP), grid electricity, hydrogen electrolyser, hydrogen storage and renewable electricity are being brought together to create a climate-neutral energy system.

Note.

- The system uses a large hydrogen electrolyser.

- I suspect the hydrogen will be generated by off-peak electricity and local renewables.

- Hydrogen will probably power the container handling machines, ships, trucks, vehicles and other equipment in the port.

Hydrogen appears to be used as a means of storing energy and also for providing motive power.

I would suspect, the ultimate aim is that the port will not emit any carbon dioxide.

Other ports like Felixstowe and Holyhead seem to be going the hydrogen route.

Refuelling Hydrogen Buses and Charging Electric Buses

If you look at the Duisburg system, I can imagine a similar smaller system being used to refuel hydrogen buses and charge electric ones.

- The hydrogen electrolyser would be sized to create enough hydrogen for a day or so’s work.

- Hydrogen would be generated by off-peak electricity and local renewables.

- If an operator bought more buses, I’m certain that the architecture of the electrolyser would allow expansion.

- Hydrogen fuel cells would boost the electricity supply, when lots of buses needed to be charged.

- Any spare hydrogen could be sold to those who have hydrogen-powered vehicles.

- Any spare electricity could be sold back to the grid.

It should be noted that manufacturers like Wrightbus have developed a range of hydrogen and electric buses that use the same components. So will we see more mixed fleets of buses, where the best bus is assigned to each route?

I have used buses as an example, but the concept would apply to fleets of cars, trucks and vans.

Green Hydrogen

Large efficient electrolysers will surely be the key to producing large quantities of green hydrogen in the future.

It appears that about 55 MWh is needed to produce a tonne of green hydrogen using existing electrolysers.

The Hoeller electrolyser appears to be about 53 MWh, so it is more efficient.

Green Hydrogen From An Onshore Wind Farm

If you look at the average size of an onshore wind farm in the UK, a quick estimate gives a figure of 62 MW. I shouldn’t expect the figure for much of the world is very different, where you ignore the gigafarms, as these will distort the numbers.

An appropriately-sized electrolyser could be added to onshore wind farms to provide a local source of hydrogen for transport, an industrial process or a domestic gas supply for a new housing estate.

A single 5 MW wind turbine with a capacity factor of around 30 % would produce around 680 Kg of green hydrogen per day.

Green Hydrogen From An Offshore Wind Farm

There are basic methods to do this.

Put the electrolyser onshore or put the electrolyser offshore and pipe the hydrogen to the shore.

I think we will see some innovative configurations.

In ScotWind N3 Offshore Wind Farm, I described how Magnora ASA are developing the ScotWind N3 wind farm.

The floating turbines surround a concrete floater, which in the future could contain an electrolyser and tankage for hydrogen.

The ScotWind N3 wind farm is designed to be a wind farm rated at 500 MW.

I can see an electrolyser on the floater, of an optimal size to make sure all electricity is used.

Pink Hydrogen

Pink hydrogen, is zero-carbon hydrogen produced using nuclear-generated electricity.

There are industrial processes, like the making of zero-carbon chemicals, concrete and steel, that will require large quantities of zero-carbon green or pink hydrogen.

Rolls-Royce are developing the Rolls-Royce SMR, which will be a 470 MW small modular nuclear reactor.

One of these placed near to a steel works and coupled to one or more 100 MW electrolysers could provide enough zero-carbon electricity and hydrogen to produce large quantities of zero-carbon green steel.

Manufacturing

Rolls-Royce and their subsidiaries like mtu, seem to be extensive users of advanced manufacturing techniques and I would expect that they can improve Hoeller’s manufacturing.

Research And Development

The press release says this about the founder of Hoeller.

Its founder, Stefan Höller, has more than a quarter of a century’s experience of developing electrolysis technology and has already registered 14 patents connected with Prometheus.

If Rolls-Royce can develop and support Stefan Höller and his team, development could easily go to a higher level.

Conclusion

I think that Rolls-Royce have taken over a company, that will in the end, will design excellent efficient electrolysers.

Nuclear-Enabled Hydrogen – How It Helps To Reach Net Zero

The title of this post, is the same as that of this article on Power Engineering.

These are the first two paragraphs.

Nuclear enabled hydrogen is zero carbon, has low cost energy input, is large scale and offers co-location synergy and energy system connectivity.

With the revival of interest in nuclear energy, interest is growing in the potential for nuclear-enabled hydrogen, otherwise sometimes known as ‘pink’ hydrogen, to meet the anticipated demand for hydrogen at scale.

The article is certainly a must-read.

Topics covered include.

- Co-location of pink hydrogen production with industrial clusters, where heat can also be provided.

- The production of hydrogen on a large scale.

- The use of high temperature electrolysis, using steam from the nuclear plant.

I particularly like the idea of combining a small modular nuclear reactor with high temperature electrolysis to generate hydrogen for local industry like a steelworks or chemical plant.

Westinghouse And Bloom Energy To Team Up For Pink Hydrogen

The title of this post, is the same as that of this article on Hydrogen Fuel News.

This is the introductory paragraph.

Westinghouse Electric Company and Bloom Energy Corporation have announced that they have signed a letter of intent together for the production of pink hydrogen in the commercial nuclear power market.

Note.

- Westinghouse Electric Company is an American builder of nuclear power stations.

- Bloom Energy Corporation make a solid-oxide electrolyser.

- Pink hydrogen is green hydrogen produced using nuclear power.

Figures on the Bloom web site, claim that their electrolysers could be upwards of twelve percent more efficient than PEM electrolysers, as produced by companies like ITM Power.

Bloom Energy Vice President of Hydrogen Business Rick Beuttel, is quoted as saying this.

We are proud Westinghouse has turned to Bloom and our solid oxide technology to supercharge the clean hydrogen economy. Solid oxide technology is well suited for nuclear applications, efficiently harnessing steam to further improve the economics of hydrogen production. High temperature electrolysis is already garnering attention and accolades as a cost-effective and viable solution to create low-cost, clean hydrogen, which is critical to meeting aggressive decarbonization goals.

It sounds that by integrating the nuclear power station and the electrolyser, there are cost savings to be made.

Conclusion

I think this could turn out to be a significant development.

Some countries, like Iceland, Indonesia, New Zealand, Philippines and the United States, who can generate large amounts of electricity and steam from geothermal energy, Bloom’s technology must surely be a way of electrolysing hydrogen.