Visiting The Consultation For Ferrybridge Next Generation Power Station At Knottingley

Yesterday, I visited the first meeting for the consultation on Ferrybridge Next Generation Power Station, which was held in the old town hall at Knottingley.

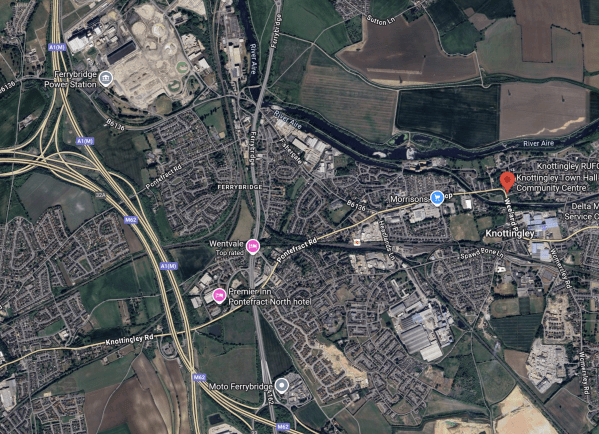

This Google Map shows the power station in relation to Knottingley.

Note.

- The meeting was held in the Knottingley Town Tall Community Centre, which is marked by the red arrow.

- I had arrived by train from Wakefield at Knottingley station and I was lucky enough to be able to get a taxi to the Town Hall.

- Knottingley station is marked on the map about a twenty-minute walk to the West of the Town Hall.

- The Ferrybridge power station site is in the North-West corner of the map and appears to be bordered by the B6136 road.

- The A1 (M) and the M 62 motorways run North-South past the power station site.

- The A (M) motorway continues North-South to Newcastle and Scotland, and London respectively.

- The M62 motorway continues West-East to Liverpool and Manchester, and Hull respectively.

- The well-appointed Moto Ferrybridge services is accessible from both motorways.

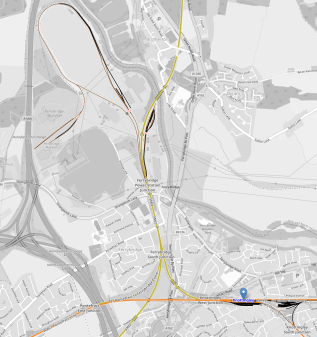

This OpenRailwayMap shows the rail lines in the area.

Note.

- The A 62 and A 1(M) motorways running down the West side of the map.

- Knottingley station is on the Pontefract Line, and is marked by a blue arrow.

- The Pontefract Line could have connections from both East and West to the Ferrybridge power station site via Ferrybridge Power Station junction.

- The loop, where the merry-go-round coal trains turned, appears to be still intact at the North of the power station site.

Will these rail lines be any use in the building and operation of the new power station?

These are my thoughts.

Fuel For The Power Station

The brochure for the consultation says this about the fuel for the Ferrybridge Next Generation Power Station.

Ferrybridge Next Generation Power Station will be designed to run on 100% hydrogen, natural gas or a

blend of natural gas and hydrogen.

The brochure has an informative section, which is entitled Natural Gas Pipeline Corridors.

Additionally, I should say, that I lived within a couple of hundred metres of a major gas pipeline in Suffolk, for over twenty years and it was the most unobtrusive of neighbours.

The brochure also says this about hydrogen safety.

As with all of our sites, appropriate measures will be

in place to ensure safe operation. Hydrogen is not

inherently more dangerous than other fuel sources.Hydrogen is flammable and must be handled with care,

just like other flammable fuels. To ignite, hydrogen

must be combined with an additional oxidising agent,

such as air or pure oxygen, in a specific concentration

and with an ignition source (a spark).

It is nearly sixty years ago now, since I worked as an Instrument Engineer, in ICI’s Castner-Kellner works at Runcorn, where hydrogen, chlorine and caustic soda were produced by the electrolysis of brine.

The plant was an unhealthy one, as it used a lot of mercury and my main task, was to design instruments to detect mercury in air and operators’ urine.

The Wikipedia entry for the Castner-Kellner process is a fascinating read and explains why it is being replaced by much better modern mercury-free processes.

I asked Google AI, if the Castner-Kellner process is still used and received this reply.

No, the Castner-Kellner process, a type of mercury cell for producing chlorine and caustic soda, is now largely obsolete due to occupational health and mercury pollution concerns, though a few plants may still operate globally. Modern chlor-alkali processes primarily use safer diaphragm cell and membrane cell technologies to produce chlorine and other chemicals from brine electrolysis.

I suspect that countries, where life is cheap, still use this process, which is very dangerous to those that work on the plant.

INEOS now own ICI in Cheshire and they still produce a large proportion of the hydrogen, chlorine and caustic soda, that the UK needs, but in a much safer way.

The question has to be asked about how hydrogen will be delivered to the Ferrybridge site.

Consider.

- SSE are developing a large hydrogen store at Aldbrough.

- Centrica are developing a large hydrogen store at Brough.

- Both of these stores could be connected to the German AquaVentus system, as the Germans are short of hydrogen storage.

- There is an East Coast Hydrogen Delivery Plan, which could probably have an extension pipeline to the Ferrybridge site.

- The East Coast Hydrogen Delivery Plan, talks of a hydrogen capacity of 4.4 GW.

I don’t feel, that this is the sort of project, that will be delivered until the mid-2030s, at the earliest.

There is also one other important development, that will require hydrogen at Ferrybridge.

I asked Google AI, if there will be hydrogen-powered coaches by 2030 and received this reply.

Yes, there will be hydrogen-powered coaches and buses by 2030, particularly in the UK and EU, with government strategies and funding promoting their deployment, especially for routes requiring high range and quick refueling where battery-electric models may be less suitable. For example, the EU’s CoacHyfied project is developing fuel cell coaches, and the UK government envisions hydrogen playing a role in its transport decarbonization by 2030, with potential to accelerate its zero-emission bus goals.

The nearest you can get to a hydrogen-powered coach in England, is to take an upmarket Wrightbus upmarket hydrogen-powered bus between Sutton station and Gatwick Airport.

- It is mouse quiet and vibration-free.

- It handles the hills with alacrity.

- I wrote about my journey in Sutton Station To Gatwick Airport By Hydrogen-Powered Bus.

That journey convinced me of the superiority in many ways of a hydrogen bus or coach over its diesel cousins.

I believe that this superiority will see large growth in hydrogen-powered long-distance coaches in the next few years.

But I also feel that some specialist transport, like horse transport, will go the hydrogen route.

As there are services at Ferrybridge, where two important motorways cross, I can envisage that the services will need to be able to refuel passing hydrogen buses, coaches trucks and other heavy vehicles, as well as the occasional car.

So would it be possible to supply hydrogen for the motorway services, by the same route as the power station?

I believe that the hydrogen could come from Saltend to the East of Hull, so I gave Google AI the phrase “Saltend zero-carbon hydrogen” and received this reply.

Saltend is home to several initiatives for producing and utilizing zero-carbon hydrogen, most notably the H2H Saltend project by Equinor, which aims to build the world’s largest hydrogen production plant with carbon capture capabilities by 2026 to supply industrial users at the Saltend Chemicals Park. Additionally, a new green hydrogen facility is planned for the park by Meld Energy with a target operation in early 2027, and a separate low-carbon hydrogen plant by ABP, HiiROC, and px Group is also being developed to meet local industrial demand. These projects collectively contribute to the broader Zero Carbon Humber initiative, which seeks to significantly reduce industrial emissions in the region.

Note.

- Saltend will certainly have enough zero-carbon hydrogen for everybody who wants it.

- Delivery dates in a couple of years are being talked about.

- Local industrial demand could be satisfield using specialised trucks, just as ICI used in the 1960s.

- As the Germans want to connect their AquaVentus system to Humberside, any excess hydrogen, could always be sold across the North Sea.

- OpenRailwayMap shows that Saltend is rail-connected.

But how do you get hydrogen between Saltend and Ferrybridge?

I am sure, that hydrogen could be delivered by truck from Saltend to Ferrybridge, but would the locals allow a stream of hydrogen trucks on the roads.

On the other hand, both Saltend and Ferrybridge are both rail-connected, so would it be possible to deliver the hydrogen by rail?

Google AI says this about railway wagons for hydrogen.

Railway wagons for hydrogen transport include liquid hydrogen tank cars (tankers) for transporting cryogenic liquid hydrogen and compressed gas tank cars for carrying hydrogen in its gaseous state or bound within carrier mediums like ammonia or methanol. Hydrogen fuel cell technology is also being developed for use on trains themselves, with a hydrogen fuel cell generator wagon providing power for main-line, non-electrified freight routes.

I believe that it will be possible to develop trains of an appropriate length to shuttle hydrogen between where it is produced and where it is used.

Such a specially-designed shuttle train would be ideal for moving hydrogen between Saltend and Ferrybridge.

- Once at Ferrybridge, the train would be connected to the local hydrogen system feeding the power station, the motorway services and any local businesses that needed hydrogen.

- The trains could be hydrogen fuel cell powered, so they could use any convenient route.

- Like hydrogen powered buses, I suspect they could be mouse quiet.

- The trains would be sized to perhaps deliver a day’s hydrogen at a time.

- There could only be minor changes needed to the rail system.

- If required, the trains could could deliver their cargo in the dead of night.

It could even be based on the contept of the TruckTrain, which I wrote about in The TruckTrain.

Consultation Opens For Ferrybridge Next Generation Power Station

The title of this post, is the same as that of this press release from SSE.

These three bullet points act as sub-headings.

- Ferrybridge Next Generation sets out plans for continuing the legacy of power generation at the site, with the potential to bring significant investment to the region.

- Statutory consultation phase launched, inviting communities and stakeholders to have their say on project proposals.

- Hydrogen-enabled project could support the security of supply and offer a clear route to decarbonisation.

These three paragraphs add more detail.

Members of the public are being invited to have their say on plans for a proposed new power station in development, Ferrybridge Next Generation Power Station.

The station is being designed so that it can run on hydrogen, as a lower-carbon alternative to natural gas. It would also be able to operate using natural gas or a blend of hydrogen and natural gas until a technically and commercially viable hydrogen supply becomes available to the site.

With a proposed capacity of up to 1.2GW, Ferrybridge Next Generation Power Station could play an important role in supporting the UK’s energy system in the short term – providing reliable flexible back-up power during periods of peak demand and balancing the system when the wind doesn’t blow or the sun doesn’t shine, while delivering a route to decarbonised power generation in the longer term.

Note.

- A 150 MW/300 MWh Battery Electric Storage System is being developed on the site, which I wrote about in SSE Renewables Announces Construction Of Second Utility-Scale Battery Storage System.

- The last Ferrybridge power station; C had a capacity of just over 2 GW.

- This will be SSE Renewable’s second hydrogen-fired power station after Keadby, which I wrote about in Consultation On Plans For Keadby Hydrogen Power Station To Begin.

- As the press releases says, Ferrybridge Hydrogen-Fired Power Station will be West Yorkshire’s backup for when the wind doesn’t blow and the sun doesn’t shine.

How similar will the two hydrogen-fired power stations be?

Will SSE Be Building Any More In The First Wave Of Hydrogen-Fired Power Station?

This is a paragraph from SSE’s press release.

The station is being designed so that it can run on hydrogen, as a lower-carbon alternative to natural gas. It would also be able to operate using natural gas or a blend of hydrogen and natural gas until a technically and commercially viable hydrogen supply becomes available to the site.

It would appear that the availability of the hydrogen fuel may be a problem.

But places like Aberdeen, Bradford, Brighton, Humberside and Merseyside, do seem to be planning for hydrogen, so all is not lost.

Hydrogen Milestone: UK’s First Hydrogen-to-Power Trial At Brigg Energy Park

The title of this post, is the same as that of this press release from Centrica.

This is the sub-heading.

Centrica and HiiROC, supported by the Net Zero Technology Centre (NZTC), have successfully demonstrated the injection of hydrogen into a gas-fired peak power plant at Centrica’s Brigg Energy Park, North Lincolnshire. The trial that took place last Thursday (11 September) marks a UK first in using hydrogen to decarbonise peak power generation supplying power directly to the electricity grid.

These three opening paragraphs add detail.

HiiROC’s modular hydrogen production technology, using Thermal Plasma Electrolysis (TPE), produced hydrogen on site which was then blended at a 3% ratio for the purposes of a one-hour trial.

The trial marks a further step forward in Centrica’s ongoing efforts to advance innovative solutions for the decarbonisation of its portfolio of gas plants, demonstrating that existing gas infrastructure can operate on a hydrogen blend to provide reliable, low carbon electricity to UK homes and businesses. More broadly, the trial shows a viable route for delivering on decarbonisation readiness obligations for peaker generation as part of the UK’s journey to net zero.

It is also a key milestone in HiiROC’s journey, demonstrating the effectiveness and affordability of HiiROC’s TPE process, which produces hydrogen without CO2 emissions, making it compliant with the UK’s Low Carbon Hydrogen Standard (LCHS). By leveraging the existing gas network and co-locating hydrogen production where it is needed, operators can decarbonise without costly new infrastructure.

Note.

- This test was only at a low level of hydrogen.

- Brigg power station is a 240 MW power station, which is fuelled by natural gas.

A long journey starts with a single step.

Centrica And X-energy Agree To Deploy UK’s First Advanced Modular Reactors

The title of this post, is the same as that of this press release from Centrica.

This is the sub-heading.

Centrica and X-Energy, LLC, a wholly-owned subsidiary of X-Energy Reactor Company, LLC, today announced their entry into a Joint Development Agreement (JDA) to deploy X-energy’s Xe-100 Advanced Modular Reactors (“AMR”) in the United Kingdom.

These three paragraphs add more details.

The companies have identified EDF and Centrica’s Hartlepool site as the preferred first site for a planned U.K. fleet of up to 6 gigawatts.

The agreement represents the first stage in a new trans-Atlantic alliance which could ultimately mobilise at least £40 billion in economic value to bring clean, safe and affordable power to thousands of homes and industries across the country and substantive work for the domestic and global supply chain.

A 12-unit Xe-100 deployment at Hartlepool could add up to 960 megawatts (“MW”) of new capacity, enough clean power for 1.5 million homes and over £12 billion in lifetime economic value. It would be developed at a site adjacent to Hartlepool’s existing nuclear power station which is currently scheduled to cease generating electricity in 2028. Following its decommissioning, new reactors would accelerate opportunities for the site and its skilled workforce. The site is already designated for new nuclear under the Government’s National Policy Statement and a new plant would also play a critical role in generating high-temperature heat that could support Teesside’s heavy industries.

This is no toe-in-the-water project, but a bold deployment of a fleet of small modular reactors to provide the power for the North-East of England for the foreseeable future.

These are my thoughts.

The Reactor Design

The Wikipedia entry for X-energy has a section called Reactor Design, where this is said.

The Xe-100 is a proposed pebble bed high-temperature gas-cooled nuclear reactor design that is planned to be smaller, simpler and safer when compared to conventional nuclear designs. Pebble bed high temperature gas-cooled reactors were first proposed in 1944. Each reactor is planned to generate 200 MWt and approximately 76 MWe. The fuel for the Xe-100 is a spherical fuel element, or pebble, that utilizes the tristructural isotropic (TRISO) particle nuclear fuel design, with high-assay LEU (HALEU) uranium fuel enriched to 20%, to allow for longer periods between refueling. X-energy claims that TRISO fuel will make nuclear meltdowns virtually impossible.

Note.

- It is not a conventional design.

- Each reactor is only about 76 MW.

- This fits with “12-unit Xe-100 deployment at Hartlepool could add up to 960 megawatts (“MW”) of new capacity” in the Centrica press release.

- The 960 MW proposed for Hartlepool is roughly twice the size of the Rolls-Rpoyce SMR, which is 470 MW .

- Safety seems to be at the forefront of the design.

- I would assume, that the modular nature of the design, makes expansion easier.

I have no reason to believe that it is not a well-designed reactor.

Will Hartlepool Be The First Site?

No!

This page on the X-energy web site, describes their site in Texas, which appears will be a 320 MW power station providing power for Dow’s large site.

There appear to be similarities between the Texas and Hartlepool sites.

- Both are supporting industry clustered close to the power station.

- Both power stations appear to be supplying heat as well as electricity, which is common practice on large industrial sites.

- Both use a fleet of small modular reactors.

But Hartlepool will use twelve reactors, as opposed to the four in Texas.

How Will The New Power Station Compare With The Current Hartlepool Nuclear Power Station?

Consider.

- The current Hartlepool nuclear power station has two units with a total capacity of 1,185 MW.

- The proposed Hartlepool nuclear power station will have twelve units with a total capacity of 960 MW.

- My instinct as a Control Engineer gives me the feeling, that more units means higher reliability.

- I suspect that offshore wind will make up the difference between the power output of the current and proposed power stations.

As the current Hartlepool nuclear power station is effectively being replaced with a slightly smaller station new station, if they get the project management right, it could be a painless exercise.

Will This Be The First Of Several Projects?

The press release has this paragraph.

Centrica will provide initial project capital for development with the goal of initiating full-scale activities in 2026. Subject to regulatory approval, the first electricity generation would be expected in the mid-2030s. Centrica and X-energy are already in discussions with additional potential equity partners, as well as leading global engineering and construction companies, with the goal of establishing a UK-based development company to develop this first and subsequent projects.

This approach is very similar to the approach being taken by Rolls-Royce for their small modular reactors.

Will Centrica Use An X-energy Fleet Of Advanced Modular Reactors At The Grain LNG Terminal?

This press release from Centrica is entitled Investment In Grain LNG Terminal.

This is one of the key highlights of the press release.

Opportunities for efficiencies to create additional near-term value, and future development options including a combined heat and power plant, bunkering, hydrogen and ammonia.

Note.

- Bunkering would be provided for ships powered by LNG, hydrogen or ammonia.

- Heat would be needed from the combined heat and power plant to gasify the LNG.

- Power would be needed from the combined heat and power plant to generate the hydrogen and ammonia and compress and/or liquify gases.

Currently, the heat and power is provided by the 1,275 MW Grain CHP gas-fired power station, but a new nuclear power station would help to decarbonise the terminal.

Replacement Of Heysham 1 Nuclear Power Station

Heysham 1 nuclear power station is part-owned by Centrica and EdF, as is Hartlepool nuclear power station.

Heysham 1 nuclear power station is a 3,000 MW nuclear power station, which is due to be decommissioned in 2028.

I don’t see why this power station can’t be replaced in the same manner as Hartlepool nuclear power station.

Replacement Of Heysham 2 Nuclear Power Station

Heysham 2 nuclear power station is part-owned by Centrica and EdF, as is Hartlepool nuclear power station.

Heysham 2 nuclear power station is a 3,100 MW nuclear power station, which is due to be decommissioned in 2030.

I don’t see why this power station can’t be replaced in the same manner as Hartlepool nuclear power station.

Replacement Of Torness Nuclear Power Station

Torness nuclear power station is part-owned by Centrica and EdF, as is Hartlepool nuclear power station.

Torness nuclear power station is a 1,290 MW nuclear power station, which is due to be decommissioned in 2030.

I don’t see why this power station can’t be replaced in the same manner as Hartlepool nuclear power station.

But the Scottish Nationalist Party may have other ideas?

What Would Be The Size Of Centrica’s And X-energy’s Fleet Of Advanced Modular Reactors?

Suppose.

- Hartlepool, Grain CHP and Torness power stations were to be replaced by identical 960 MW ADRs.

- Heysham 1 and Heysham 2 power stations were to be replaced by identical 1,500 MW ADRs.

This would give a total fleet size of 5,880 MW.

A paragraph in Centrica’s press release says this.

The companies have identified EDF and Centrica’s Hartlepool site as the preferred first site for a planned U.K. fleet of up to 6 gigawatts.

This fleet is only 120 MW short.

Hydrogen Coaches? Setra Begins Testing Of A Technology Carrier With Cellcentric Fuel Cell Module

The title of this post, is the same as that of this article on Sustainable Bus.

This paragraph introduces the article.

Daimler Buses has started test drives of its first Setra coach equipped with a hydrogen fuel cell drive, named the technology carrier “H2 Coach.” The 13.9-meter high-decker, model S 517 HD, combines two hydrogen tanks with a total capacity of 46 kilograms and a fuel cell module capable of as many as 300 kW, developed.

Dailmler have also said this about the interim approval for the H2 Coach.

This approval allows test drives both on Daimler Buses’ internal testing grounds and on public roads. The vehicle is intended to offer a zero-emission alternative to diesel-powered coaches, with lower noise, higher range, and shorter refueling times compared with battery-electric vehicles, contributing to improved air quality in cities and holiday regions.

I’ll go along with that.

As Wrightbus and others are developing hydrogen coaches, I believe this could be the first big hydrogen application in road transport.

Which Companies Are Developing Hydrogen-Powered Coaches?

Google AI gave me this answer.

Companies actively developing or deploying hydrogen-powered coaches include Wrightbus (UK), partnering with Symbio, and Temsa and Caetanobus (Turkey). Toyota is converting used coaches with fuel cell modules, while Daimler Buses is road-testing its H2 Coach precursor. Other companies in the broader hydrogen transport space with relevant technology are Hyundai, Volvo, and Tata Motors.

As Symbio’s Wikipedia entry is in French, I am fairly certain, that Symbio is a French company in Grenoble.

This press release from Symbio is entitled Symbio And Wrightbus Unveil TThe Successful Outcome Of Their UK Government-Funded Partnership At CENEX EXPO 2024: A 300 kW Hydrogen-Powered Demonstrator Coach.

This is the sub-heading.

A partnership to develop a 300 kW, zero-emission demonstrator fuel cell coach and future 75 kW city bus applications.

These two introductory paragraphs add more details.

Symbio and Wrightbus signed a partnership to develop and demonstrate a zero-emission, hydrogen fuel cell coach designed for on-road public transportation in the UK. The joint project started in January 2024 with the delivery by Symbio to Wrightbus of four 75 kW StackPack™ fuel cell systems, forming a 300-kW power unit that Wrightbus integrated and tested into one of its single-deckers. The tests enabled the innovation teams on both sides to adjust and define the optimal settings for the vehicle’s powertrain. Having successfully completed this objective, the demonstrator is displayed for the first time at the Cenex Expo, starting Sept. 4, and will be operational and hit the road shortly.

This successful project sets the basis for future development of hydrogen-powered city buses equipped with Symbio 75 kW StackPack™ fuel cell systems, specifically designed for bus applications.

Symbio’s approach is different.

- Many drivers of my generation had a Ford XR3i hatchback.

- This sporty car had an 80 kW engine, a top speed of 115 mph and an acceleration time of 0-60 mph, of under 9 seconds.

- It was also great fun!

I do wonder if one of Symbio’s 75 kW StackPack™ fuel cell systems could be developed and fitted into a small hatchback, to create an afffordable zero-carbon runabout.

Already the press release says that Wrightbus and Symbio are co-operating with each other on 75 kW city bus applications.

Lord Bamford’s company ; JCB found Hyperdrive Innovation to develop batteries for their diggers. These batteries are now used in Hitachi’s Battery Intercity Express Trains.

Now, it looks like his son’s company have found Symbio to develop the fuel-cells needed for their innovative buses and coaches. Would one or two 75kW fuel cells be idea for smaller tractors and diggers?

The Monster That Is AquaVentus Is Waking Up

I have written about AquaVentus for some time, but inh the last couple of days, ten references have been found to the project by my Google Alert.

What Is AquaVentus?

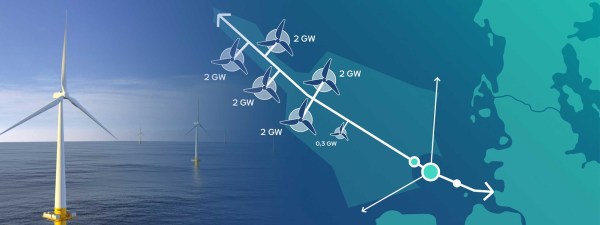

AquaVentus has a web page on the RWE web site, from where I clipped this image.

Note.

- The spine of AquaVentus is a pipeline called AquaDuctus to bring hydrogen to Germany.

- This image shows 10.3 GW of hydrogen will be generated and brought to near Wilhelmshaven in North-West Germany.

These two paragraphs introduce AquaVentus.

Hydrogen is considered the great hope of decarbonisation in all sectors that cannot be electrified, e.g. industrial manufacturing, aviation and shipping. Massive investments in the expansion of renewable energy are needed to enable carbon-neutral hydrogen production. After all, wind, solar and hydroelectric power form the basis of climate-friendly hydrogen.

In its quest for climate-friendly hydrogen production, the AquaVentus initiative has set its sights on one renewable energy generation technology: offshore wind. The initiative aims to use electricity from offshore wind farms to operate electrolysers also installed at sea on an industrial scale. Plans envisage setting up electrolysis units in the North Sea with a total capacity of 10 gigawatts, enough to produce 1 million metric tons of green hydrogen.

It is not an unambitious project.

North Sea Hydrogen Co-operation: AquaVentus And Hydrogen Scotland

The title of this section is the same as that of this page on the Hydrogen Scotland web site.

This is the introduction.

Hydrogen Scotland signed a comprehensive Memorandum of Understanding (MoU) with AquaVentus at Offshore Europe in Aberdeen. The partnership aims to unlock the North Sea’s vast potential for hydrogen production and establish Scotland as a key supplier to European markets through the development of shared infrastructure.

Both partners are committed to intensifying research activities and advocating for the rapid scale-up of a European hydrogen economy.

By joining forces, members of AquaVentus and Hydrogen Scotland can help advance the development and deployment of technologies along the entire value chain – from production through transport and storage to the use of hydrogen for decarbonising the energy system. In addition, both organisations intend to intensify their supporting activities and jointly advocate for the accelerated ramp-up of a European hydrogen economy.

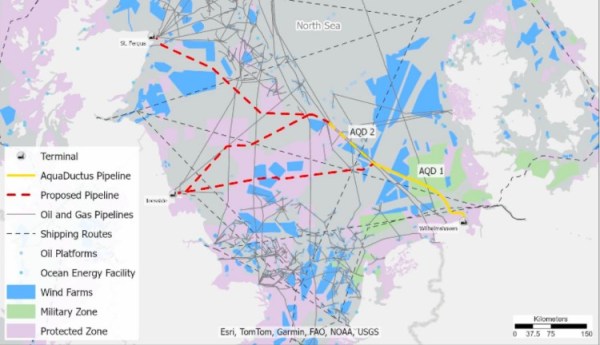

This map of the North Sea, which I downloaded from the Hydrogen Scotland web site, shows the co-operation.

Note.

- The yellow AquaDuctus pipeline connected to the German coast near Wilhelmshaven.

- There appear to be two AquaDuctus sections ; AQD 1 and AQD 2.

- There are appear to be three proposed pipelines, which are shown in a dotted red, that connect the UK to AquaDuctus.

- The Northern proposed pipeline appears to connect to the St. Fergus gas terminal on the North-East tip of Scotland.

- The two Southern proposed pipelines appear to connect to the Easington gas terminal in East Yorkshire.

- Easington gas terminal is within easy reach of the massive gas stores, which are being converted to hold hydrogen at Aldbrough and Rough.

- The blue areas are offshore wind farms.

- The blue area straddling the Southernmost proposed pipe line is the Dogger Bank wind farm, is the world’s largest offshore wind farm and could evebtually total over 6 GW.

- RWE are developing 7.2 GW of wind farms between Dogger Bank and Norfolk in UK waters, which could generate hydrogen for AquaDuctus.

This cooperation seems to be getting the hydrogen Germany needs to its industry.

These five paragraphs outline a position paper by AquaVentus.

This opportunity for German-British cooperation on hydrogen is highlighted in a position paper presented by AquaVentus alongside the signing of the MoU. This paper addresses how the requirements of German-British cooperation – as outlined, for example, in the July 2025 Kensington Treaty between the UK and Germany and the European Commission’s Common Understanding published in May 2025 – can be met.

The position paper highlights the significant potential of hydrogen production in Scotland, the necessity of imports for Germany, and references transport infrastructure already under planning. It thus lays the foundation for cross-border hydrogen trade between Germany and the United Kingdom, and for deeper European cooperation in the hydrogen sector, with three essential prerequisites:

Firstly, the networking of producers and consumers across national borders is critical for a successful market ramp-up

Secondly, beyond this synchronised production and transport infrastructure, regulatory frameworks must also be harmonised. Hybrid connection concepts (pipes & wires) that integrate both electricity and hydrogen networks provide the necessary flexibility for future energy needs, enable efficient use of renewable energy and ensure cost-effective grid expansion

Thirdly, the development from a national core network to a European Hydrogen Backbone is emphasised. Projects such as AquaDuctus can serve as a nucleus for building a pan-European hydrogen network that will shape Europe’s energy infrastructure in the long term. For the authors, strengthened cooperation with the United Kingdom is not only a sound energy policy and economic decision, but also a key contribution to European energy resilience.

Note.

I’m Getting A New Hydrogen-Ready Boiler

The pump in my current nine-year-old boiler has died and it needs to be replaced.

The plumber gave me two solutions.

- Put a new pump in the old boiler.

- Replace the boiler with the current version of the old boiler.

Note.

- The plumber said the new boiler would be hydrogen-ready.

- I seem to remember the same pump failed before.

- The pump had failed because of a water-leak into its electrics.

- Was the previous failure of the pump caused by the same water-leak?

- Fitting a heat pump in my house would probably cost more than I could afford.

- The new boiler would come with a ten-year guarantee.

As an engineer, I can see the following scenarios for heating my house and providing hot water.

1. Keeping Calm And Carrying On

This means that the current arrangements for energy continue.

- There would be no compulsory heat pumps.

- There would be no change to any of my hardware, after installing the new boiler.

- I would continue to get gas for heating and hot water delivered through the mains.

The new boiler solution should give me ten years of reasonably trouble free-running, so long as the gas was natural gas, hydrogen blend or hydrogen.

2. Keeping Calm And Carrying On But My Energy Supplier Switches My Gas To 20 % Hydrogen-Blend

This means that the current arrangements for energy continue.

- There would be no compulsory heat pumps.

- There would be no change to any of my hardware, after installing the new boiler.

- I would continue to get gas for heating and hot water delivered through the mains.

- The gas pipe into my house would have to be checked for compatibility with hydrogen-blend. But then I encountered no problems when switched from coal-gas to North Sea Gas around 1970.

The new boiler solution should give me ten years of reasonably trouble free-running, so long as the gas was natural gas, hydrogen-blend or hydrogen.

3. Keeping Calm And Carrying On But My Energy Supplier Switches My Gas To 100 % Hydrogen

This means that the current arrangements for energy continue.

- There would be no compulsory heat pumps.

- There would be no change to any of my hardware, after installing the new boiler.

- I would continue to get gas for heating and hot water delivered through the mains.

- The gas pipe into my house would have to be checked for compatibility with hydrogen.

The new boiler solution should give me ten years of reasonably trouble free-running, so long as the gas was natural gas, hydrogen blend or hydrogen.

4. Switching To Some Form Of Heat Pump

- This would mean that I would go all electric.

- My house is a concrete lump and a guy I trust, said it would be difficult to fit a heat pump.

- I am suspicious of scientific and technical solutions proposed by politicians.

I’m not saying, I’d never use a heat pump, but I will take a lot of convincing.

5. Switching To Some New Form Of Electric Heating

I have seen two companies, which use the excess heat from a data centre to heat water for central heating and/or hot water for domestic needs.

- heata is a spin out from Centrica, that provides hot water and saves you money on your utility bill.

- thermify is a startup from Wales, that replaces the gas boiler, with an electric one.

There are probably other similar systems under development.

From my knowledge of computing and electrical engineering, I believe devices like this could be new form of cost-efficient electric heating.

Because my house has three-bedrooms, I would need a thermify, for both heating and hot water, but a heata working in tandem with my gas boiler could probably keep me in hot water.

I would feel that large blocks of flats or offices could have a data centre in the basement to provide heat for the building.

I would also suspect, that there are other devices out there, that work on different principles.

My Decision

I’m fitting a new boiler, as that should give me ten years’guarantee-backed and trouble free running and future-proof me for all possible government decisions, except saying that everybody must fit a heat pump.

When, this new boiler pops its clogs, i would hope, that some clever engineers have come up with a plug-compatible electric replacement for the new boiler I am about to have fitted.

Scotland And AquaVentus Partner On North Sea Hydrogen Pipeline Plans

The title of this post, is the same as that of this article on H2-View.

These four paragraphs introduce the deal and add some detail.

Hydrogen Scotland has committed to working with the AquaDuctus consortium on cross-border infrastructure concepts to connect Scotland’s offshore wind power to hydrogen production in the North Sea.

Under a Memorandum of Understanding (MOU), the two organisations plan to combine Scotland’s offshore wind with AquaVentus’ offshore electrolysis expertise, linking export and import goals across the North Sea.

The AquaDuctus pipeline is a planned offshore hydrogen link designed to carry green hydrogen through the North Sea, using a pipes and wires hybrid approach. The German consortium plans 10GW of offshore electrolysers in the North Sea, producing around one million tonnes of green hydrogen.

The pipeline design allows offshore wind farms to deliver electricity when the grid needs it, or convert power into hydrogen via electrolysis and transport it through pipelines.

Germany is embracing hydrogen in a big way.

- I introduce AquaVentus in AquaVentus, which I suggest you read.

- AquaVentus is being developed by RWE.

- AquaVentus connects to a German hydrogen network called H2ercules to actually distribute the hydrogen.

This video shows the structure of AquaVentus.

I clipped this map from the video.

Note.

- The thick white line running North-West/South-East is the spine of AquaVentus, that will deliver hydrogen to Germany.

- There is a link to Esbjerg in Denmark, that is marked DK.

- There appears to be an undeveloped link to Norway, which goes North,

- There appears to be an undeveloped link to Peterhead in Scotland, that is marked UK.

- There appears to be a link to just North of the Humber in England, that is marked UK.

- Just North of the Humber are the two massive gas storage sites of Aldbrough owned by SSE and Rough owned by Centrica.

- Aldbrough and Rough gas storage sites are being converted into two of the largest hydrogen storage sites in the world!

- There appear to be small ships sailing up and down the East Coast of the UK. Are these small coastal tankers, that are distributing the hydrogen to where it is needed?

When it is completed, AquaVentus will be a very comprehensive hydrogen network.

I believe that offshore electrolysers could be built in the area of the Hornsea 4, Dogger Bank South and other wind farms and the hydrogen generated would be taken by AquaVentus to either Germany or the UK.

- Both countries get the hydrogen they need.

- Excess hydrogen would be stored in Aldbrough and Rough.

- British Steel at Scunthorpe gets decarbonised.

- A 1.8 GW hydrogen-fired powerstation at Keadby gets the hydrogen it needs to backup the wind farms.

Germany and the UK get security in the supply of hydrogen.

Conclusion

This should be a massive deal for Germany and the UK.

Powering The Humber Energy Revolution

The title of this post is the same as this story on the Centrica web site.

This is the sub-heading.

From the UK’s largest industrial carbon emitter to a clean energy powerhouse, the Humber is ready to be transformed.

These are the first two paragraphs, which add more detail.

We’re prepared to invest £2 billion to keep Rough open and transform it into one of the world’s largest hydrogen storage facilities. This bold move is vital for the UK’s energy security, accelerating the energy transition and unlocking thousands of green jobs. But to make this vision a reality, we need strategic support from government.

We’ve spent time in the Humber, speaking with local communities and industry leaders to understand how this region’s infrastructure shapes lives and powers the nation.

It looks to me, that Centrica have got fed up with our useless, squabbling politicians and decided to act.

There is also a video to watch.

Shell Pulls Plug On Rotterdam Biofuels Plant

The title of this post, is the same as that of this article on The Times.

This is the sub-heading.

Retreat from green energy continues as facility that was earmarked to produce sustainable aviation fuel and renewable diesel will not now be built

These first three paragraphs add some details.

Shell has scrapped construction of one of Europe’s biggest biofuels plants as it continues its retreat from green energy

The move by the FTSE 100 oil and gas group represents a further setback for efforts to cut aviation emissions.

Shell said it would not restart construction of the biofuels facility at its Rotterdam energy and chemicals plant, which was due to produce sustainable aviation fuel (SAF) and renewable diesel.

When I wrote Centrica Secures Investment Stake In Gasrec Helping Boost UK Bio-LNG Ambitions, I took a look at the use of liquified natural gas (LNG) in transport.

This paragraph from the Centrica press release about the stake, gives the thoughts of Chris O’Shea, who is Group Chief Executive, Centrica.

Chris O’Shea, Group Chief Executive, Centrica plc, said: “Demand for bio-LNG for transport is growing fast as more HGV operators make the switch – drawn by a clean, ready-to-use fuel which slashes CO2 emissions by up to 85 per cent in comparison to diesel*. This investment in Gasrec enhances our collaboration with the leading company in the sector, and puts us in a strong position to energise a vital sector of the industry on its journey to net zero.”

Chris O’Shea of Centrica appears to feel that bio-LNG is a good alternative to diesel, so have Shell come to a similar decision, about satisfying the demand for diesel?

I asked Google AI if LNG has advantages over diesel as a truck fuel and received this answer.

Yes, LNG offers advantages over diesel, including significantly lower emissions of nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter (PM), which improves local air quality. It can also be more economically efficient, with fuel costs potentially lower than diesel depending on market conditions. However, the overall greenhouse gas (GHG) benefits are mixed; while LNG has a lower carbon content, it can result in higher lifecycle GHG emissions due to energy losses in its production and transport, as well as methane slip.

Note.

- If it drops emissions by up to 85 percent for bio-LNG, surely, it would do the same for LNG.

- I also think with tight regulations, the use of LNG could improve air quality in cities like London.

- LNG would probably be a more affordable fuel than hydrogen.

It should also be noted, that several major diesel engine makers, now make families of engines, which can handle, diesel, hydrogen and natural gas.

LNG would also be a convenient stepping stone between current fuels and hydrogen, that might give a few extra years for the transition.

Could LNG Be Used In Aircraft?

Consider.

- LNG would certainly give some reduction in carbon emissions.

- Handling LNG in aircraft could have similar problems to hydrogen, so companies like Airbus might have already solved them.

- In addition, LNG doesn’t have the fearsome reputation, that hydrogen seems to have gained because of the Hindenburg.

- It would be easier to provide LNG fuel at airports all round the world.

- Airbus have said availability of hydrogen at airports, could be a problem.

Out of curiosity, I asked Google AI if LNG could be used to power an airliner and received this answer.

Yes, liquefied natural gas (LNG) can theoretically be used to power airliners, offering a potential reduction in CO2 emissions compared to conventional jet fuel, but significant challenges exist. These challenges include the need for entirely new, larger, and heavier cryogenic fuel tanks, modifications to aircraft engines and fuel systems, and the development of a new global infrastructure for LNG supply. While experimental tests have been conducted, such as on the Soviet Union’s Tupolev Tu-155 in 1989, LNG is not currently in normal service due to these practical and infrastructural hurdles.

I would prefer it was a purpose-designed Airbus, than a Soviet-era Tupolev.