How To Take A Ride On A New Docklands Light Railway Train

This article on the BBC is entitled After Delays, New Trains Finally Arrive On The DLR.

This is the sub-heading.

The first of 54 new trains for the Docklands Light Railway (DLR) is now in service, featuring “the latest technology”, according to Transport for London (TfL)

These two paragraphs add more details.

The new carriages are air-conditioned, have mobile device charging points and dedicated spaces for wheelchair users.

They will replace the oldest trains in the DLR fleet, some of which have been in service for more than three decades, with “modern, high-capacity trains designed to meet the needs of a growing city”, said TfL.

I travelled to West Ham station this morning and took these pictures on a journey to Woolwich Arsenal.

Note.

- The Docklands Light Railway and the Jubilee Line are on the same level and connected by the bridge in West Ham station.

- The old DLR trains have red bodywork and the new trains have light blue bodywork.

- The first train through was a test train.

- The last row of pictures show the comparative length of the two trains at Woolwich Arsenal station.

These are some more detailed thoughts.

The Length Of The New Trains

The original cars are 28 metres long.

- Running as a 2-car train, the trains are 56 metres long.

- Running as a 3-car train, the trains are 84 metres long.

- The new 5-car trains are 86.7 metres long.

I asked Google AI how many seats were in a DLR train and received this answer.

A DLR (Docklands Light Railway) train’s seat count varies by the specific rolling stock, but newer trains have a higher capacity; for example, the new B23 rolling stock is a 5-coach unit replacing older, coupled 3-car trains and offers a total capacity of 790 passengers, with 156 seats. Older trains typically consist of two cars and have 70 seats per car for a total of 140 seats.

Newer B23 Rolling Stock:

Each 5-coach train has 156 seats.

It can carry a total of 790 passengers.

Older Trains:

These trains generally consist of two cars coupled together.

Each car has 70 seats, making for a total of 140 seats in a typical two-car train.

Older, single-unit trains may have had fewer seats, as a current 3-car train had about 680 passengers in total capacity.

West Ham Was A Good Place To Start A First Ride

Consider.

- At the present time, there aren’t many trains running on the DLR.

- There may only be a couple of trains running between Stratford International and Woolwich Arsenal.

- West Ham is an island platform, so the train goes by on both sides, which also makes it easy to get on a single train.

- West Ham is a well-connected station.

I did have to wait about thirty minutes for the train to arrive.

Rolls-Royce To lead EU’s New Clean Aviation project UNIFIED To Transform And Decarbonise Aviation

The title of this post the same as that of this press release from Rolls-Royce.

These two opening paragraphs add a few details.

Rolls-Royce has been selected by the European Union’s Clean Aviation programme to lead one of 12 groundbreaking new projects aiming to decarbonise aviation. These initiatives, which include new aircraft concepts and innovative propulsion technologies, will receive funding of about €945 million.

The Clean Aviation Joint Undertaking (CAJU) is the European Union’s leading research and innovation programme for transforming aviation towards a sustainable and climate neutral future.

I asked Google AI about the European Union’s Clean Aviation programme and received this reply.

The European Union’s Clean Aviation programme, part of the Horizon Europe research initiative, is a public-private partnership aimed at developing disruptive, climate-neutral aviation technologies, including hydrogen-powered, hybrid-electric, and ultra-efficient aircraft, to achieve net-zero emissions by 2050. Launched in 2022, it has a budget of €4.1 billion (€1.7 billion from the EU, €2.4 billion from private partners) and focuses on technologies that will be integrated into a new generation of short- to medium-range aircraft with a target entry into service by 2035. Key goals include a 30% reduction in CO2 emissions and energy efficiency compared to 2020 standards for new aircraft by 2030, with a long-term objective of climate-neutral aviation by 2050.

Note.

- Only someone like Trump would think that the key goals in the last sentence were not worthwhile.

- €4.1 billion in the right place could be a very good start.

- There is a Clean Aviation web site.

The press release says this about the UNIFIED project.

UNIFIED – Ultra Novel and Innovative Fully Integrated Engine Demonstrations

The UNIFIED consortium is led by Rolls-Royce and contains key industrial, academic and research partners across France, Germany, the Netherlands, Norway, Spain and the United Kingdom. Subject to successful completion of grant preparation, the project will enable ground testing of an UltraFan® technology demonstrator at a short to medium range thrust class for future narrowbody aircraft and also enable the preparation of key activities towards future flight test of the UltraFan architecture.

I am not surprised Ultrafan is mentioned.

The Wikipedia entry for the Rolls-Royce Trent has a section about the UltraFan, which starts with these two paragraphs.

The UltraFan is a geared turbofan with a variable pitch fan system that promises at least 25% efficiency improvement. The UltraFan aims for a 15:1 bypass ratio and 70:1 overall pressure ratio.

The Ultrafan keeps the Advance core, but also contains a geared turbofan architecture with variable-pitch fan blades. The fan varies pitch to optimise for each flight phase, eliminating the need for a thrust reverser. Rolls-Royce planned to use carbon composite fan blades instead of its usual hollow titanium blades. The combination was expected to reduce weight by 340 kg (750 lb) per engine.

Note.

- 25 % is a very good efficiency improvement.

- No thrust reverser.

- A saving of 340 kg. in weight per engine.

It should also be noted that October 2028, will see the hundredth anniversary of Henry Royce sketching the R-type engine in the sand on the beach in Sussex.

The R-type was the engine that won the Schneider Trophy outright and enabled Rolls-Royce’s engineers to design the unrivalled Merlin engine that powered Hurricanes, Spitfires, Mosquitos, Mustangs and Lancasters in World War Two.

Should New Stations Be Shown On Google Maps With Opening Dates?

I recently posted a comment on The Times recently, where I suggested a guy was opening one of his coffee shops in a town, that was getting a new railway station.

Another, who commented, suggested that I look at Google Maps to see their relative positions.

The coffee shop was shown, but the station wasn’t.

Surely, once the position of the station is known, it should be marked on Google Maps with an opening date, as this could help people take important decisions about their life.

Blyth Bebside station on the new Northumberland Line between Newcastle and Ashington is already shown with the familiar logo, despite not opening until the 19th of October.

The other two unopened stations on the line, which are Northumberland Park and Bedlington, are going to open next year, are also shown with familiar logos, but no opening date.

Someone in Network Rail, needs to be given the responsibility to make sure that details like this are correct.

In the case of Blyth Bebside station, I can see two different captions indicating the station on Google Maps.

- Before October 19th 2025 – Blyth Bebside – Opens 19th Octopber 2025.

- After October 19th 2025 – Blyth Bebside – Opened 19th Octopber 2025.

Detailed labeling may even help deliveries during construction.

Is Last Energy The Artemis Of Energy?

In Raft Of US-UK Nuclear Deals Ahead Of Trump Visit, I quoted from this article on World Nuclear News.

The article also contains, these two paragraphs, with talk about an MoU between Last Energy and DP World.

An MoU has also been signed between US-based micro-nuclear technology developer Last Energy and DP World, a global leader in logistics and trade, to establish the world’s first port-centric micro nuclear power plant at London Gateway. A proposed PWR-20 microreactor – to begin operations in 2030 – would supply London Gateway with 20 MWe of electricity to power the logistics hub, with additional capacity exported to the grid.

“The initiative represents a GBP80 million (USD109 million), subsidy-free investment for the development of Last Energy’s first unit, unlocking clean power supply for DP World’s ongoing GBP1 billion expansion of London Gateway,” Last Energy said. “The partnership is closely aligned with both UK and US ambitions to increase nuclear capacity and strengthen long-term energy security.”

Note.

- Last Energy are proposing a micro-reactor of just 20 MW.

- DP World own and/or operate sixty ports in over forty countries, so should know their energy requirements well.

- It appears that DP World are investing £80 million in Last Energy’s first unit.

- Thurrock Storage is a 300 MW/600 MWh battery close to London Gateway and the Port of Tilbury.

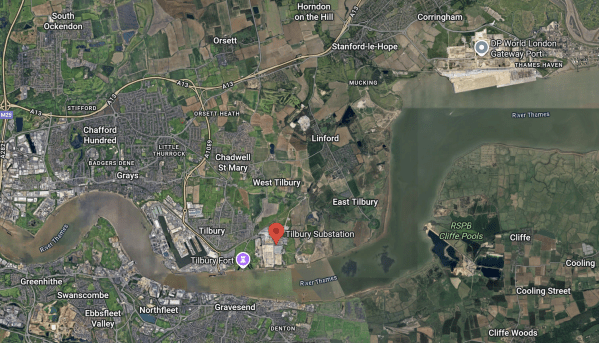

This Google Map shows London Gateway and the Port of Tilbury.

Note.

- DP World London Gateway is in the North-East corner of the map.

- The A13 road runs across the North-West corner of the map and links the area to London and the M25.

- Thurrock Storage is next to the Tilbury substation, which is marked by the red arrow.

- The Port of Tilbury is to the West of the substation.

I wonder if DP World London Gateway have had power supply problems.

The Design Of The First Artemis Project Management Software System

Before Artemis, project management was usually done on a large mainframe computer like an IBM-360-50, that I’d used extensively for solving simultaneous differential equations in a previous job at ICI.

Mainframe computers worked on complex problems, but to put it mildly, they were slow and needed a team to operate them and a big air-conditioned room to keep them happy.

When the four of us decided to create Artemis, our vision was something simpler.

- A processor – something like a PDP-11, which I judged would be big-enough for the computing.

- A visual display unit.

- A printer.

- A standard-size desk to hold the hardware.

- Ability to run from a 13-amp socket.

When it came to writing the software, I took few risks.

- Much of the data decoding software, I’d developed when I left ICI to write a program to solve up to a thousand simultaneous differential equations.

- The scheduling software was generic and I’d first used it for different purposes in two programs at ICI.

- The aggregation software had been devised, whilst I was a consultant at Lloyds Bank over several bottles of wine with their Chief Management Accountant, who was a wizard with numbers. I suspect, but can’t prove it, that if the idiots that programmed the Horizon system for the Post Office had used that algorithm, the problems there would have been much smaller.

- I also spent a lot of time reading old papers from the 1950s in IBM’s library on the South Bank, looking for better algorithms.

- I also made sure, I chose the best hardware and I believe HP did us proud.

- I used HP’s operating system and proprietary database to cut down, what could go wrong.

- Almost all of the first system was written by one person – me!

But we also put the right features into how we supported, delivered and trained users of the system.

I certainly, think we made few mistakes in the design of that first system.

Have Last Energy Used A Similar Cut Back Approach?

Reading their web site, I think they have.

They have obviously chosen, the 20 MW unit size with care.

But from worldwide experience with wind turbines, linking smaller power sources together, is not as difficult as it once was.

These are some of the statements on their web site’s introductory screens.

- Fully Modular, Factory Made

- A Scalable Solution

- <24 Month Delivery

- 100+ Supply Chain Partners

- 300+ Pressurised Water Reactors Operating Globally

- 0.3 acre – Plant Footprint Fits Within A Football Field

But a chain is only as strong as its weakest link.

It should be noted, that I have been over several nuclear power stations.

Three were a tour to show me how Artemis was being used to track and sign off, the problems identified after the Three Mile Island incident.

The other was a trip over Sizewell A, a couple of years before it was decommissioned.

Comparing these experiences with some of the chemical plants, that I’ve worked on, I would prefer to be close to a nuclear power plant.

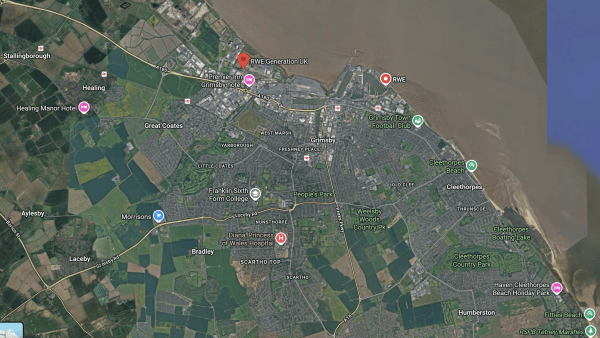

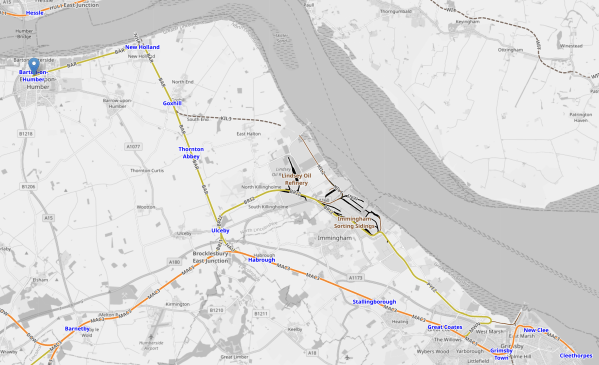

Consultation Opens For Ferrybridge Next Generation Power Station

The title of this post, is the same as that of this press release from SSE.

These three bullet points act as sub-headings.

- Ferrybridge Next Generation sets out plans for continuing the legacy of power generation at the site, with the potential to bring significant investment to the region.

- Statutory consultation phase launched, inviting communities and stakeholders to have their say on project proposals.

- Hydrogen-enabled project could support the security of supply and offer a clear route to decarbonisation.

These three paragraphs add more detail.

Members of the public are being invited to have their say on plans for a proposed new power station in development, Ferrybridge Next Generation Power Station.

The station is being designed so that it can run on hydrogen, as a lower-carbon alternative to natural gas. It would also be able to operate using natural gas or a blend of hydrogen and natural gas until a technically and commercially viable hydrogen supply becomes available to the site.

With a proposed capacity of up to 1.2GW, Ferrybridge Next Generation Power Station could play an important role in supporting the UK’s energy system in the short term – providing reliable flexible back-up power during periods of peak demand and balancing the system when the wind doesn’t blow or the sun doesn’t shine, while delivering a route to decarbonised power generation in the longer term.

Note.

- A 150 MW/300 MWh Battery Electric Storage System is being developed on the site, which I wrote about in SSE Renewables Announces Construction Of Second Utility-Scale Battery Storage System.

- The last Ferrybridge power station; C had a capacity of just over 2 GW.

- This will be SSE Renewable’s second hydrogen-fired power station after Keadby, which I wrote about in Consultation On Plans For Keadby Hydrogen Power Station To Begin.

- As the press releases says, Ferrybridge Hydrogen-Fired Power Station will be West Yorkshire’s backup for when the wind doesn’t blow and the sun doesn’t shine.

How similar will the two hydrogen-fired power stations be?

Will SSE Be Building Any More In The First Wave Of Hydrogen-Fired Power Station?

This is a paragraph from SSE’s press release.

The station is being designed so that it can run on hydrogen, as a lower-carbon alternative to natural gas. It would also be able to operate using natural gas or a blend of hydrogen and natural gas until a technically and commercially viable hydrogen supply becomes available to the site.

It would appear that the availability of the hydrogen fuel may be a problem.

But places like Aberdeen, Bradford, Brighton, Humberside and Merseyside, do seem to be planning for hydrogen, so all is not lost.

Centrica And X-energy Agree To Deploy UK’s First Advanced Modular Reactors

The title of this post, is the same as that of this press release from Centrica.

This is the sub-heading.

Centrica and X-Energy, LLC, a wholly-owned subsidiary of X-Energy Reactor Company, LLC, today announced their entry into a Joint Development Agreement (JDA) to deploy X-energy’s Xe-100 Advanced Modular Reactors (“AMR”) in the United Kingdom.

These three paragraphs add more details.

The companies have identified EDF and Centrica’s Hartlepool site as the preferred first site for a planned U.K. fleet of up to 6 gigawatts.

The agreement represents the first stage in a new trans-Atlantic alliance which could ultimately mobilise at least £40 billion in economic value to bring clean, safe and affordable power to thousands of homes and industries across the country and substantive work for the domestic and global supply chain.

A 12-unit Xe-100 deployment at Hartlepool could add up to 960 megawatts (“MW”) of new capacity, enough clean power for 1.5 million homes and over £12 billion in lifetime economic value. It would be developed at a site adjacent to Hartlepool’s existing nuclear power station which is currently scheduled to cease generating electricity in 2028. Following its decommissioning, new reactors would accelerate opportunities for the site and its skilled workforce. The site is already designated for new nuclear under the Government’s National Policy Statement and a new plant would also play a critical role in generating high-temperature heat that could support Teesside’s heavy industries.

This is no toe-in-the-water project, but a bold deployment of a fleet of small modular reactors to provide the power for the North-East of England for the foreseeable future.

These are my thoughts.

The Reactor Design

The Wikipedia entry for X-energy has a section called Reactor Design, where this is said.

The Xe-100 is a proposed pebble bed high-temperature gas-cooled nuclear reactor design that is planned to be smaller, simpler and safer when compared to conventional nuclear designs. Pebble bed high temperature gas-cooled reactors were first proposed in 1944. Each reactor is planned to generate 200 MWt and approximately 76 MWe. The fuel for the Xe-100 is a spherical fuel element, or pebble, that utilizes the tristructural isotropic (TRISO) particle nuclear fuel design, with high-assay LEU (HALEU) uranium fuel enriched to 20%, to allow for longer periods between refueling. X-energy claims that TRISO fuel will make nuclear meltdowns virtually impossible.

Note.

- It is not a conventional design.

- Each reactor is only about 76 MW.

- This fits with “12-unit Xe-100 deployment at Hartlepool could add up to 960 megawatts (“MW”) of new capacity” in the Centrica press release.

- The 960 MW proposed for Hartlepool is roughly twice the size of the Rolls-Rpoyce SMR, which is 470 MW .

- Safety seems to be at the forefront of the design.

- I would assume, that the modular nature of the design, makes expansion easier.

I have no reason to believe that it is not a well-designed reactor.

Will Hartlepool Be The First Site?

No!

This page on the X-energy web site, describes their site in Texas, which appears will be a 320 MW power station providing power for Dow’s large site.

There appear to be similarities between the Texas and Hartlepool sites.

- Both are supporting industry clustered close to the power station.

- Both power stations appear to be supplying heat as well as electricity, which is common practice on large industrial sites.

- Both use a fleet of small modular reactors.

But Hartlepool will use twelve reactors, as opposed to the four in Texas.

How Will The New Power Station Compare With The Current Hartlepool Nuclear Power Station?

Consider.

- The current Hartlepool nuclear power station has two units with a total capacity of 1,185 MW.

- The proposed Hartlepool nuclear power station will have twelve units with a total capacity of 960 MW.

- My instinct as a Control Engineer gives me the feeling, that more units means higher reliability.

- I suspect that offshore wind will make up the difference between the power output of the current and proposed power stations.

As the current Hartlepool nuclear power station is effectively being replaced with a slightly smaller station new station, if they get the project management right, it could be a painless exercise.

Will This Be The First Of Several Projects?

The press release has this paragraph.

Centrica will provide initial project capital for development with the goal of initiating full-scale activities in 2026. Subject to regulatory approval, the first electricity generation would be expected in the mid-2030s. Centrica and X-energy are already in discussions with additional potential equity partners, as well as leading global engineering and construction companies, with the goal of establishing a UK-based development company to develop this first and subsequent projects.

This approach is very similar to the approach being taken by Rolls-Royce for their small modular reactors.

Will Centrica Use An X-energy Fleet Of Advanced Modular Reactors At The Grain LNG Terminal?

This press release from Centrica is entitled Investment In Grain LNG Terminal.

This is one of the key highlights of the press release.

Opportunities for efficiencies to create additional near-term value, and future development options including a combined heat and power plant, bunkering, hydrogen and ammonia.

Note.

- Bunkering would be provided for ships powered by LNG, hydrogen or ammonia.

- Heat would be needed from the combined heat and power plant to gasify the LNG.

- Power would be needed from the combined heat and power plant to generate the hydrogen and ammonia and compress and/or liquify gases.

Currently, the heat and power is provided by the 1,275 MW Grain CHP gas-fired power station, but a new nuclear power station would help to decarbonise the terminal.

Replacement Of Heysham 1 Nuclear Power Station

Heysham 1 nuclear power station is part-owned by Centrica and EdF, as is Hartlepool nuclear power station.

Heysham 1 nuclear power station is a 3,000 MW nuclear power station, which is due to be decommissioned in 2028.

I don’t see why this power station can’t be replaced in the same manner as Hartlepool nuclear power station.

Replacement Of Heysham 2 Nuclear Power Station

Heysham 2 nuclear power station is part-owned by Centrica and EdF, as is Hartlepool nuclear power station.

Heysham 2 nuclear power station is a 3,100 MW nuclear power station, which is due to be decommissioned in 2030.

I don’t see why this power station can’t be replaced in the same manner as Hartlepool nuclear power station.

Replacement Of Torness Nuclear Power Station

Torness nuclear power station is part-owned by Centrica and EdF, as is Hartlepool nuclear power station.

Torness nuclear power station is a 1,290 MW nuclear power station, which is due to be decommissioned in 2030.

I don’t see why this power station can’t be replaced in the same manner as Hartlepool nuclear power station.

But the Scottish Nationalist Party may have other ideas?

What Would Be The Size Of Centrica’s And X-energy’s Fleet Of Advanced Modular Reactors?

Suppose.

- Hartlepool, Grain CHP and Torness power stations were to be replaced by identical 960 MW ADRs.

- Heysham 1 and Heysham 2 power stations were to be replaced by identical 1,500 MW ADRs.

This would give a total fleet size of 5,880 MW.

A paragraph in Centrica’s press release says this.

The companies have identified EDF and Centrica’s Hartlepool site as the preferred first site for a planned U.K. fleet of up to 6 gigawatts.

This fleet is only 120 MW short.

Rolls-Royce mtu Series 4000 engines To Power New Catalina Express Ferry In California

The title of this post, is the same as that of this press release from Rolls-Royce.

These two bullet points act as sub-headings.

High-capacity ferry to feature four EPA Tier 4-certified engines, delivering over 7463 kW (10,000 bhp)

Cutting-edge propulsion system will integrate SCR and DPF once certified by the EPA, USCG, and CARB to meet commercial harbour craft regulations

These three paragraphs from the press release, describe the ferry and its operation.

Rolls-Royce has been selected by Catalina Express of San Pedro, CA (USA) to supply the marine propulsion system for its new high-capacity ferry. The 500-passenger vessel, which will be the largest in the Catalina Express fleet upon completion, will be powered by four mtu 12V4000 M65L engines, delivering a combined output of over 7463 kW (10,000 bhp).

The new ferry is part of the Port of Los Angeles’ $31 million LA MER project, which is funded by the California Air Resources Board (CARB). Via the project, Catalina Express received a $15 million grant, matching it with $15 million of its own investment. The goal of the LA MER project is to test ways to reduce emissions as the Port works toward becoming a zero-emission port.

The new 42-meter ferry, which will be able to reach speeds up to 37 knots, will replace three older Catalina Express vessels maintaining capacity and increasing environmental performance. The vessel will serve as a next-generation leader of the fleet, showcasing the company’s commitment to sustainable operations.

The Wikipedia entry for Catalina Express has this first paragraph.

Catalina Express is an American passenger ferry service that operates scheduled trips between Santa Catalina Island and mainland California. The company began service in 1981 with a single sixty-passenger vessel. As of 2016, the Catalina Express fleet includes eight high-speed vessels that can make the roughly 30-mile (48 km) crossing in about an hour.

There appears to be strong commitment of the California Air Resources Board and Catalina Express to air quality and zero emissions.

In Liberty Lines Commissions First High-Speed Ferry With mtu Hybrid System From Rolls-Royce, I wrote about another high-speed ferry, that will be powered by a Rolls-Royce mtu hybrid system.

The European ferry will be able take 281 passengers at 34.5 mph, and also use battery-power in port.

I can see larger, faster and more advanced ferries being developed, with lower-emission power systems, that will take over some of the shorter sea routes.

Busiest UK Airports Raise Kiss-and-Fly Fees, Says RAC

The title of this post, is the same as that of this article on the BBC.

This is the sub-heading.

More than half of Britain’s busiest airports have raised “kiss-and-fly” fees for cars dropping off passengers close to terminals, according to research from the RAC.

These two paragraphs add details.

The motoring group found 11 out of 20 UK airports had put up prices since last July, with Gatwick, Bristol, Leeds Bradford and Southampton joining Stansted in charging the top rate of £7 to park for a matter of minutes.

In contrast, at nine of the 10 busiest airports in the European Union there are no drop-off fees.

I don’t drive and these days I can’t walk very far, but I travel around the UK and Europe without any difficulty.

Here are a few tips.

Use James Cameron’s Packing Method

James Cameron was one of BBC’s most famous and much-travelled journalists and his life is documented in this Wikipedia entry.

The Wikipedia entry says nothing about his packing method, which my late wife and myself used after hearing him describe it in one of his excellent documentaries.

Sort everything you think you’ll need into two piles. Each pile contains half the shirts, trousers, swimwear, underwear etc. that you think you’ll need.

Pack each pile in a separate case and leave one case behind.

As to money he said, work out the most you’ll need and double it. These days with credit cards, that is probably not so relevant.

Choose An Airport With Good Step-Free Public Transport

I’m lucky in London, in that I can get a bus within a hundred metres of my house, that takes me to Moorgate, Bank or London Bridge stations, which give me direct access to City, Gatwick, Heathrow, Luton, Southend or Stansted Airports.

Step-free access to some airports in the UK is abysmal.

Use A Train From A Station With a Properly Designed Drop-Off Area

These pictures show the taxi rank and drop off area at Leicester station.

The building would appear to have a Grade II Listed taxi rank and free twenty-minute car park.

How many other stations have well-designed facilities like these?

According to this article on the BBC, Preston station has an innovative solution.

If you spot any others, let me know!

Service Your Car Near The Airport

For three or so years, we had a car, where there was a main dealer a couple of stops on the Piccadilly Line from Heathrow.

So we dropped the car in, walked a short distance to the Underground and started our holiday with a tube ride.

It just needs a bit of research.

I don’t drive anymore after a stroke, but if I did, my car would be serviced by a garage, I could get to on public transport.

UK Among Tri-Axle Zero-Emission Wrightbus StreetDeck Prospects

The title of this post, is the same as that of this article on routeone.

This is the sub-heading.

Orders for new product ‘already lined up’ in Europe and the Far East, the manufacturer has said

These are the first two paragraphs.

Wrightbus sees UK sales opportunity for its new tri-axle zero-emission StreetDeck double-deck bus platform in addition to core Far Eastern markets for that class of vehicle, it says.

That was noted by CEO Jean-Marc Gales (pictured) when debuting prototype examples of the 6×2 bus that it says are “simultaneously” coming off production lines in Northern Ireland and Malaysia. The manufacturer adds that orders are “already lined up” for the product in Europe and the Far East.

I seem to remember that London’s electric trolleybuses used to have three axles.

So I asked Google AI if London’s trolleybuses did have three axles and got this reply.

Yes, London’s trolleybuses were predominantly three-axle vehicles. To accommodate their length and the power of their electric motors, most London trolleybuses, designed to replace trams, were built with three axles. This design allowed them to be larger and carry more passengers, similar to the trams they replaced.

So my memory was correct.

Where I live in De Beauvoir Town, the main North-South bus route is the 141 between London Bridge and Palmers Green.

- They are ten-year-old diesel hybrid buses.

- The route is busy and the buses are far too small.

- During my childhood, the route was the 641 trolleybus, which I used regularly.

- Southgate Road, where the trolleybuses ran is wider than most roads in London.

It would be ironic, if our inadequate 141 buses were to be replaced by new three-axle buses following some of the design rules of trolleybuses.

Is A Three-Axle Bus Better At Climbing Hills Than A Two-Axle?

In the UK, Bradford, Brighton and Sheffield are cities with hills.

If a three-axle bus is better at climbing hills, then this could be a big selling point.

The Chinese Won’t Be Pleased

This is said in the article.

The manufacturer adds that orders are “already lined up” for the product in Europe and the Far East

The Chinese won’t like Wrightbus stealing their markets.