Teeside’s Refurbished Trains

On my trip around Teeside, I took four trains.

There was none of the usual rubbish, that I have endured in the North like this scrapyard special at Carlisle.

All trains were refurbished Class 158 trains.

They were a lot better, with tables and clean, working toilets.

But will they get replaced with hydrogen or updated to zero-carbon trains?

Hydrogen Trains

In Fuelling The Change On Teesside Rails, I talked about the local services on Teesside being run by a fleet of hydrogen trains, based on an article in RAIL Magazine.

But the order has not been placed and it must be getting tight if trains are going to run in a few years.

There was this report in the November 2020 Edition of Modern Railways, which is entitled Tees Valley Hydrogen Hub.

This is the first paragraph.

Mott MacDonald is to create a masterplan for the development of a hydrogen transport hub in the Tees Valley. Transport Secretary Grant Shapps made the announcement as he travelled on the HydroFLEX on the 29th of September.

It appears the masterplan could be published in January and would cover several modes of transport.

Battery Electric Trains

There have been developments in the battery electric train field over the past few months.

Hitachi at Newton Aycliffe and Hyperdrive Innovation at Sunderland have partnered up to produce Hitachi’s Regional Battery Train. Three-car trains based on Hitachi’s Class 385 trains would be ideal for trundling around the North East.

The trains would need charging and what better charging system is there than Vivarail’s Fast Charge system? And they could be produced at Vivarail’s factory at Seaham just up the coast towards Sunderland.

As I indicated in £100m Station Revamp Could Double Local Train Services, where I said this about the location of chargers to power battery electric trains in the Tees and the Tyne.

There will need to be strategically-placed battery chargers around the North-East of England. These could include.

-

- Hexham

- Nunthorpe

- Redcar or Saltburn – This would also be used by TransPennine Express’s Class 802 trains, if they were to be fitted with batteries.

- Whitby

If Grand Central did the right thing and ran battery electric between London and Sunderland, there would probably be a need for a battery charger at Sunderland.

It appears that Adrian Shooter of Vivarail has just announced a One-Size-Fits-All Fast Charge system, that has been given interim approval by Network Rail.

I discuss this charger in Vivarail’s Plans For Zero-Emission Trains, which is based on a video on the Modern Railways web site.

Vivarail might just have another card or should it be train to play.

In the video, Mr. Shooter discusses using Vivarail’s technology to convert British Rail era diesel multiple units to battery electric trains.

Northern have already refurbished the Class 158 trains, so it would surely be an economical route to convert them to battery electric operation.

£100m Station Revamp Could Double Local Train Services

The title of this post, is the same as that of this article on the Northern Echo.

This is the opening paragraph.

Officials behind plans for a £100m-plus transformation of Darlington’s Bank Top Station have confirmed it will remain the only one on the East Coast Mainline without a platform specifically for the London to Scotland service.

Darlington station has made various appearances in my life, all of which have been pleasurable ones.

I went several times to ICI’s Wilton site on Teesside in the 1970s, when the route to London was worked by the iconic Class 55 locomotives or Deltics.

I wrote about one memorable trip home from Darlington in The Thunder of Three-Thousand Three-Hundred Horses.

Over the years, I also seem to have had several clients for my computing skills in the area, including the use of my data analysis software; Daisy at Cummins Engines in the town.

And lately, it’s been for football at Middlesbrough to see Ipswich play, where I’ve changed trains. Sometimes, Town even won.

The improvements planned for the station are two-fold.

Improvement Of Local Services

This paragraph from Wikipedia, sums up the local train services on the Tees Valley Line between Saltburn and Bishop Auckland via Darlington, Middlesbrough and Redcar.

Northern run their Tees Valley line trains twice hourly to Middlesbrough, Redcar and Saltburn (hourly on Sundays), whilst the Bishop Auckland branch has a service every hour (including Sundays). The company also operates two Sundays-only direct trains to/from Stockton and Hartlepool.

If ever a route needed improvement it is this one.

This paragraph from the Northern Echo article, outlines the plans for Darlington station.

The meeting was also told the overhaul, which will see new platforms, a new station building, parking and an interchange for passengers, alongside other improvements, would also double capacity on Tees Valley and Bishop Auckland lines, meaning four trains an hour on the former and two trains an hour on the latter.

I also believe that the route is a shoe-in for zero-carbon services; hydrogen or battery electric.

Hydrogen Trains On Teesside

In Fuelling The Change On Teesside Rails, I discuss using hydrogen powered trains for the lines in the area and they could certainly provide services on more than just the Tees Valley Line.

- Teesside certainly has big plans for hydrogen to fuel its chemical industry.

- Hydrogen powered transport in the area has been backed by the Government, as I wrote about in Tees Valley Wins £1.3million Project To Bring Hydrogen Vehicles To The Region.

- Plans are advancing for a depot for hydrogen-powered trains at Lackenby.

The hydrogen powered trains would probably be this Alstom Breeze.

They would appear to be in pole position to change the image of Teesside’s trains.

Battery Electric Trains On Teesside

But I suspect. that an Anglo-Japanese partnership, based in the North-East could have other ideas.

- Hitachi have a train factory at Newton Aycliffe on the Tees Valley Line.

- Hyperdrive Innovation design and produce battery packs for transport and mobile applications in Sunderland.

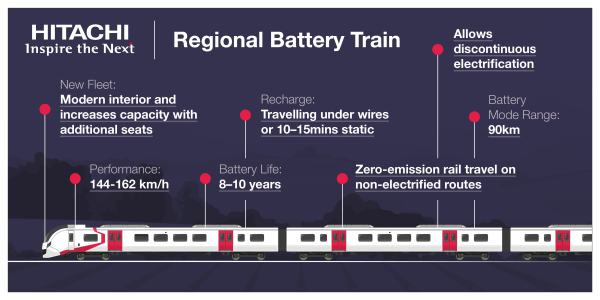

The two companies have launched the Regional Battery Train, which is described in this Hitachi infographic.

Note than 90 kilometres is 56 miles, so the train has a very useful range.

Hitachi have talked about fitting batteries to their express trains to serve places like Middlesbrough, Redcar and Sunderland with zero-carbon electric services.

But their technology can also be fitted to their Class 385 trains and I’m sure that Scotland will order some battery-equipped Class 385 trains to expand their vigorous electric train network.

Both Scotland and Teesside will need to charge their battery trains.

Example distances on Teesside include.

- Darlington and Saltburn – 28 miles

- Darlington and Whitby – 47 miles

- Darlington and Bishop Auckland – 12 miles

The last route would be possible on a full battery, but the first two would need a quick battery top-up before return.

So there will need to be strategically-placed battery chargers around the North-East of England. These could include.

- Hexham

- Nunthorpe

- Redcar or Saltburn – This would also be used by TransPennine Express’s Class 802 trains, if they were to be fitted with batteries.

- Whitby

If Grand Central did the right thing and ran battery electric between London and Sunderland, there would probably be a need for a battery charger at Sunderland.

It appears that Adrian Shooter of Vivarail has just announced a One-Size-Fits-All Fast Charge system, that has been given interim approval by Network Rail.

I discuss this charger in Vivarail’s Plans For Zero-Emission Trains, which is based on a video on the Modern Railways web site.

There is more about Vivarail’s plans in the November 2020 Print Edition of the magazine, where this is said on page 69.

‘Network Rail has granted interim approval for the fast charge system and wants it to be the UK’s standard battery charging system’ says Mr. Shooter. ‘We believe it could have worldwide implications.’

I believe that Hitachi and Hyperdrive Innovation, with a little bit of help from friends in Seaham, can build a battery-electric train network in the North-East.

The Choice Between Hydrogen And Battery Electric

Consider.

- The hydrogen trains would need a refuelling system.

- The battery electric trains would need a charging structure, which could also be used by other battery electric services to and from the North-East.

- No new electrification or other infrastructure would be needed.

- If a depot is needed for the battery electric trains, they could probably use the site at Lackenby, that has been identified as a base for the hydrogen trains.

Which train would I choose?

I think the decision will come down to politics, money and to a certain extent design, capacity and fuel.

- The Japanese have just signed a post-Brexit trade deal and France or rather the EU hasn’t.

- The best leasing deal might count for a lot.

- Vivarail have stated that batteries for a battery electric train, could be leased on a per mile basis.

- The Hitachi train will be a new one and the Alstom train will be a conversion of a thirty year old British Rail train.

- The Hitachi train may well have a higher passenger capacity, as there is no need for the large hydrogen tank.

- Some people will worry about sharing the train with a large hydrogen tank.

- The green credentials of both trains is not a deal-breaker, but will provoke discussion.

I feel that as this is a passenger train, that I’m leaning towards a battery electric train built on the route.

An Avoiding Line Through Darlington

The Northern Echo also says this about track changes at the station.

A meeting of Darlington Borough Council’s communities and local services scrutiny committee was told a bus lane-style route off the mainline at the station would enable operators to run more high-speed services.

Councillors heard that the proposed track changes would enable very fast approaches to Darlington and allow other trains to pass as East Coast Mainline passengers boarded.

Some councillors seem to be unhappy about some trains passing through the station without stopping.

Are their fears justified?

This Google Map shows Darlington station.

Note.

- The station has two long platforms and two South-facing bay platforms.

- There is plenty of space.

- There already appear to be a pair of electrified avoiding lines on the Eastern side of the station.

Wikipedia also says this about how Darlington station will be changed by High Speed Two.

The new high speed rail project in the UK, High Speed 2, is planned to run through Darlington once Phase 2b is complete and will run on the existing East Coast Main Line from York and Newcastle. Darlington Station will have two new platforms built for the HS2 trains on the Main Line, as the station is built just off the ECML to allow for freight services to pass through.

This would appear to suggest that the two current avoiding lines will be turned into high speed platforms.

Current High Speed Services At Darlington

The current high speed services at Darlington are as follows.

- LNER – two trains per hour (tph) – London Kings Cross and Edinburgh

- Cross Country – one tph – Plymouth and Edinburgh or Glasgow

- Cross Country – one tph – Southampton and Newcastle

- TransPennine Express – one tph – Liverpool and Edinburgh

- TransPennine Express – one tph – Manchester Airport and Newcastle

Northbound, this gives eight tph to Newcastle and four tph to Edinburgh

East Coast Trains

East Coast Trains‘s services are not planned to stop at Darlington.

High Speed Two Trains

Darlington is planned to be served by these High Speed Two trains.

- 1 tph – Birmingham Curzon Street and Newcastle via East Midlands Hub, York and Durham

- 1 tph – London Euston and Newcastle via Old Oak Common and York.

Both will be 200 metre High Speed Two Classic-Compatible trains

Northbound, this gives ten tph to Newcastle and four tph to Edinburgh.

As the Eastern Leg of High Speed Two has some spare capacity, I suspect there could be other services through Darlington.

Improvements To The East Coast Main Line

If you look at the East Coast Main Line between Doncaster and Newcastle, the route is a mixture of two and four-track railway.

- Between Doncaster and York, there are two tracks

- Between York and Northallerton, there are four tracks

- Between Northallerton and Darlington, there are two tracks

- North of Darlington, the route is mainly two tracks.

I have flown my virtual helicopter along much of the route and I can say this about it.

- Much of the route is through agricultural land, and where absolutely necessary extra tracks could possibly be added.

- The track is more-or-less straight for large sections of the route.

- Routes through some towns and cities, are tightly hemmed in by houses.

I also believe that the following developments will happen to the whole of the East Coast Main Line before High Speed Two opens.

- Full ERTMS in-cab digital signalling will be used on all trains on the route.

- The trains will be driven automatically, with the driver watching everything. Just like a pilot in an airliner!

- All the Hitachi Class 80x trains used by operators on the route, will be able to operate at up to 140 mph, once this signalling and some other improvements have been completed.

- All level crossings will have been removed.

- High Speed Two is being built using slab track, as I stated in HS2 Slab Track Contract Awarded. I suspect some sections of the East Coast Main Line, that are used by High Speed Two services, will be upgraded with slab track to increase performance and reduce lifetime costs.

Much of the East Coast Main Line could become a 140 mph high speed line, as against High Speed Two, which will be a 225 mph high speed line.

This will mean that all high speed trains will approach Darlington and most other stations on the route, at 140 mph.

Trains will take around a minute to decelerate from or accelerate to 140 mph and if the station stop took a minute, the trains will be up to speed again in just three minutes. In this time, the train would have travelled two-and-a-half miles.

Conclusion

I think that this will happen.

- The Tees Valley Line trains will be greatly improved by this project.

- Trains will generally run at up to 140 mph on the East Coast Main Line, under full digital control, like a slower High Speed Two.

- There will be two high speed platforms to the East of the current station, where most if not all of the High Speed Two, LNER and other fast services will stop.

- There could be up to 15 tph on the high speed lines.

With full step-free access between the high speed and the local platforms in the current station, this will be a great improvement.

Testing Begins On Midland Main Line Electrification

The title of this post, is the same as that of this article on Rail Magazine.

- From the article, it looks like the first part of mechanical testing has been completed as planned and unpowered pantograph runs have been performed at up to 110 mph.

- It does seem to me, that this thirty miles of electrification has avoided the troubles that have plagued similar projects in recent years.

Perhaps the good progress on this electrification, is making the government think again about early electrification of all of the Midland Main Line

In Hopes Rekindled Of Full Midland Main Line Electrification. I showed how battery electric Class 810 trains would be able to work the route.

This was my conclusion of that earlier post.

It appears that both the Nottingham and Sheffield services can be run using battery electric Class 810 trains.

- All four diesel engines in the Class 810 trains would need to be replaced with batteries.

- The route between Clay Cross North Junction and Sheffield station, which will be shared with High Speed Two, will need to be electrified.

- Charging facilities for the battery electric trains will need to be provided at Nottingham.

On the other hand using battery electric trains mean the two tricky sections of the Derwent Valley Mills and Leicester station and possibly others, won’t need to be electrified to enable electric trains to run on the East Midlands Railway network.

Will it be the first main line service in the world, run by battery electric trains?

There was one thing, that wasn’t available, a month ago, when I wrote that post – A charging system for battery electric trains, that could be installed at Nottingham.

In Vivarail’s Plans For Zero-Emission Trains, I report on Adrian Shooter’s plans for Vivarail, which are outlined in a video by Modern Railways.

Ar one point he says this see about Vivarail’s Fast Charge system.

The system has now been given preliminary approval to be installed as the UK’s standard charging system for any make of train.

I may have got the word’s slightly wrong, but I believe the overall message is correct.

So could we see a Hitachi Class 810 train using Vivarail’s patented Fast Charge system at Nottingham?

In Interview: Hitachi’s Nick Hughes On Driving Innovation In Rail Propulsion, Nick Hughes of Hitachi is quoted as saying.

Rail is going to become increasingly digitised and integrated into other sectors involved in smart cities, mobility-as-a-service and flexible green grid. Therefore, Hitachi Rail won’t be able to stay at the forefront of innovation by its self. This is why we are focused on building partnerships with other like-minded, innovative, clean tech companies like Hyperdrive Innovation, Perpetuum and Hitachi group companies such as Hitachi ABB.

Does Vivarail fit that philosophy? In my view, it does!

This Hitachi infographic gives the specification of their Regional Battery Train.

Note.

- The range on battery power is 90 km or 56 miles at up to 100 mph.

- Class 810 trains could be converted to battery electric trains by replacing the diesel engines with batteries.

- As the electrification has reached Kettering. there is only 55 miles between London St Pancras and Nottingham without electrification.

I could see Class 810 trains running between St. Pancras and Nottingham on delivery, provided the following projects have been completed.

- Hitachi have been able to give the Class 810 trains a range of say 60 miles on batteries.

- Hitachi have modified their trains, so they can be recharged by a Vivarail Fast Charge system in fifteen minutes.

- Vivarail have installed a Fast Charge facility at Nottingham station.

Network Rail are planning to extend the electrification from Kettering to Market Harborough, which would reduce the distance without electrification to under 50 miles. This would make running battery electric trains between London St. Pancras and Nottingham even easier.

Expanding The Network

If I am putting two and two together correctly and Hitachi have turned to Vivarail to provide a charging system or a licence for the use of the technology, I am sure, it would be possible to create a comprehensive network of battery electric trains.

Consider.

- Hitachi should be able to squeeze a sixty mile range at 90-100 mph from a battery-equipped Class 810 trains.

- Market Harborough and Derby are about 47 miles apart.

- Derby and Sheffield are about 36 miles apart

- Sheffield and Leeds are about 48 miles apart

- Corby and Leicester are about 41 miles apart.

Vivarail Fast Charge systems at Derby, Leicester and Sheffield would enable the following routes to be run using battery electric trains.

- London St. Pancras and Sheffield via Derby – Fast Charging at Derby and Sheffield

- London St. Pancras and Leeds via Derby and Sheffield – Fast Charging at Derby and Sheffield

- London St. Pancras and Sheffield via the Erewash Valley Line – Fast Charging at Ilkeston (?) and Sheffield

- London St. Pancras and Leicester via Corby – Fast Charging at Leicester

Note.

- The only extra electrification needed for the initial network would be between Kettering and Market Harborough.

- The Class 810 trains would all be identical.

- The Class 810 trains might even be built and delivered as battery electric trains

- Trains would also charge the batteries between London St. Pancras and Market Harborough, between London St. Pancras and Corby. and between Leeds and Wakefield Westgate.

The network can be extended by adding more electrification and Fast Charge systems.

Conclusion

The technologies of Hitachi and Vivarail seem complimentary and could result in a fully electric main line train network for East Midlands Railway.

Vivarail’s Plans For Zero-Emission Trains

The title of this post is the same as that of this article on the Modern Railways web site.

This is the introductory subtitle.

Vivarail Chairman Adrian Shooter talks to Modern Railways about the company’s Class 230s and its plans for battery trains.

The article is mainly a video of Mr. Shooter talking in front of various examples of Vivarail trains.

It’s probably easier to watch the video and listen on what is said.

But I have some thoughts on what he said.

Battery Range

Consider.

- Early on in the video he talks about a battery range of forty miles with four battery packs on the train.

- He also talks about switching battery supplier to Hoppecke.

- Later he says that a train with six battery packs in the train, has a hundred mile range.

That is impressive.

The number of battery packs has increased by 50 % and the range has gone up by two-and-a-half times.

If those figures are right and I’ve no reason to disbelieve them, then Hoppecke have done a good job with the batteries.

A very rough calculation indicates their size.

- The current 4 x 100 kWh takes the train 40 miles, which is 10 kWh per mile.

- So to travel a hundred miles will need 1000 kWh.

- Divide by six batteries and you get 167 kWh per battery or a 67 % increase in individual battery capacity.

If these are a new generation of batteries, what would they do for Hitachi’s Regional Battery train, which is proposed to have a range of 56 miles? They could give it a range of around 93 miles.

These ranges of distances would be very useful to manufacturers of battery trains.

Charging Battery Trains Using Vivarail’s Fast Charge System

The video did give a few more details of Vivarail’s Fast Charge system.

I was also able to take this screen capture from the video, which shows the extra rails used to pass charge to the train and the batteries.

Note.

- The rails are well-shielded. Not that they’re live unless a train is over the top and connected.

- The driver just has to stop the train in the correct place and automation does the rest.

- This image is four minutes and thirty-five seconds into the video.

My only problem with the design is that those thick copper cables used to bring electricity to the train, way be a tempting target for metal thieves.

Vivarail Now Has Permission To Charge Any Train

Mr. Shooter said this about Vivarail’s Fast Charge system.

The system has now been given preliminary approval to be installed as the UK’s standard charging system for any make of train.

I may have got the word’s slightly wrong, but I believe the overall message is correct.

In the November 2020 Edition of Modern Railways, there is a transcript of what Mr. Shooter said.

‘Network Rail has granted interim approval for the fast charge system and wants it to be the UK’s standard battery charging system’ says Mr. Shooter. ‘We believe it could have worldwide implications.’

I hope Mr. Shooter knows some affordable lawyers, as in my experience, those working in IPR are not cheap.

A Prototype Class 230 Train That Can Use 25 KVAC Is Under Construction

Mr. Shooter also announced that a version of the train with a third can in the middle, with a pantograph on the roof and a 35 KVAC transformer is under construction.

This will enable batteries to be charged from existing electrification.

I can already think of a few routes, where this train could be used.

- Bedford and Bletchley – It would replace a diesel-electric Class 230 train.

- Poulton-le-Fylde and Fleetwood

- Oxenholme and Windermere

- Glasgow Central and East Kilbride

- Glasgow Queen Street and Anniesland

- Chester and Crewe – It would replace a battery Class 230 train

- West Ealing and Greenford

- Slough and Windsor Central

- Henley and Twyford

- Maidenhead and Marlow

This could be the standard train in many places.

The November 2020 Edition of Modern Railways, also has more details on this project.

- The centre vehicle is under construction at their factory at Seaham in County Durham.

- Mr. Shooter is quoted as saying. ‘We’ve identified 60 lines on partially electrified tracks’

Vivarail plans to demonstrate the concept on the Northumberland Line to Blyth and Ashington next spring.

West Highland Opportunity

This is a section of the print article, that is not mentioned in the video.

This is the introductory paragraph.

While Mr. Shooter highlights several opportunities south of the border to deploy the 25kV/battery Class 230, he is particularly interested in deployment of Vivarail trains in Scotland.

And this is the last paragraph, describing a possible deployment on the West Highland Line.

Top of the list is the West Highland Line.

Here a 25kV/battery Class 230 would operate under electric power from Glasgow Queen Street to Craigendoran Junction, switching there to battery power. The batteries could be topped up on the way using Vivarail’s fast charge system, with Mr, Shooter suggesting this could take place at Crianlarich, Oban and Fort William. On the West Highland the 60 mph top speed of the Class 230 is not prohibitive as the top speed on the route does not exceed this.

If this sounds familiar, I made a similar proposal in Hitachi Plans To Run ScotRail Class 385 EMUs Beyond The Wires, in a section, which is entitled Electric Trains On The West Highland Line Between Glasgow And Mallaig/Oban. I start with this sentence.

This might be considered as difficult as putting a London bus on the Moon.

But that was done by the Daily Sport newspaper, so perhaps my reasoning is the same as Vivarail’s.

My conclusion of the section was as follows.

What would battery-electric trains to Oban and Mallaig do for tourism in the area?

Hitachi would have one of the most scenic and iconic test tracks in the world!

These statements would surely, apply to a Vivarail train or a battery electric Class 385 train.

Pop-Up Metro

Mr. Shooter shows a battery train, which is going to the United States to trial a concept called a Pop-up Metro.

- In the US, there are hundreds of lightly used freight lines serving towns and cities

- Temporal separation would mean that freight and passenger trains used the lines at different times of the day.

- Battery powered Vivarail trains could provide a Metro service.

He also talked about his US partner and 50 % shareholder in Vivarail, leasing trains for a year, to see if the concept was viable in a given area. He indicated, the cost could be less than a consultant’s report.

Could the Pop-up Metro concept work in the UK?

In these possible Beeching Reversal projects, there could be scope for using the concept.

- Project Wareham – Complete The Link

- Shepton Mallet (Mendip Vale)

- Increased Service Provision Bodmin General-Bodmin Parkway

- Primrose Line

- Cirencester Community Railway

- South Yorkshire Joint Railway

- Upper Wensleydale Railway

- Restoration Of A Daily Train Service On The Keighley & Worth Valley Railway

- The Aston Rowant Extension Of The Chinnor Railway

Note.

- Some of these are on heritage railway infrastructure. Does a Class 230 train count a heritage unit?

- The Aston Rowant Extension is Chiltern territory, so Mr. Shooter could know it well!

- In the Wikipedia entry for the Class 230 train, there is a useful Cost Comparison.

I should say, that I like the concept of a Pop-up Metro.

- The trains have proved they are up to the job.

- A package of one or two trains and a containerised charging system could surely be created.

- Installation of the battery charger in many platforms would not be a major engineering project costing millions.

- On a heritage railway, the enthusiasts could probably do it from their own resources.

But the best point to me, is that a system could probably be leased for a year on a Try-Before-You-Buy basis for less than the cost of a consultant’s report.

Go for it!

Conversion Of Diesel Multiple Units To Battery Electric Multiple Units

This was the bombshell in the tail of the video.

There a lot of diesel multiple units in the UK and Mr. Shooter and Vivarail have developed a plan to convert some of them to battery electric operation.

The trains he is proposing to convert are diesel multiple units, that use a Voith transmission, which I list in How Many Diesel Multiple Units In The UK Have Voith Hydraulic Transmissions?.

Consider.

- There are 815 trains on my list.

- All have a Voith hydraulic transmission, with most having similar type numbers starting with T211.

- Some are 75 mph trundlers and others are full-on 100 mph expresses.

- All have one engine and transmission per car.

They fit into distinct groups.

Sprinters

Sprinters are a group of trains that were produced by British Rail.

The earliest were built in 1984 and all were built in the last century.

- There are 314 trains in total.

- All have a Cummins engine of 213 kW, with one engine per car.

- They have a Voith T211r transmission, which drives two axles per car.

- They have an operating speed of 75 mph.

The trains may be elderly, but like some well-known actresses, they scrub up well with a little TLC.

The pictures show an immaculate refurbished Class 150 train, that I travelled on in Devon.

With a battery electric transmission, they would make a superb rural route and branch line train.

Express Sprinters

Express Sprinters are a group of trains that were produced by British Rail.

- The earliest were built in 1990 and all were built in the last century.

- There are 202 trains in total.

- All have a Cummins engine of between 260 and 300 kW, with one engine per car.

- They have a Voith T211r transmission, which drives two axles per car.

- They have an operating speed of 90 mph.

These pictures show a Class 159 train on a visit to the Swanage Railway, where it was shuttling in visitors.

With a battery electric transmission, that gave a range of say 80 miles at 90 mph, they would be low cost competition for Hitachi’s Regional Battery Train on secondary routes.

Scotrail have forty Class 158 trains, which run on the following routes.

- Glasgow Queen Street and Anniesland – 5.5 miles

- Fife Circle Line – 61 miles round trip

- Stonehaven and Inverurie – 66 miles round trip.

- Borders Railway – 70 miles round trip.

- Edinburgh and Arbroath – 76 miles

- Inverness and Kyle of Lochalsh – 82.5 miles

- Inverness and Aberdeen – 108 miles – Inter7City route.

- Inverness and Wick – 174 miles

- Inverness and Edinburgh – 175 miles – Inter7City route.

Note.

- The routes are shown in order of length.

- Anything over a hundred miles would need intermediate charging.

- Some routes would need charging at both ends.

- Glasgow Queen Street and Anniesland would probably not need a Class 158, but is very suitable for a battery electric train.

- The three longest routes from Inverness are probably too long for battery electric power, but two are run by Inter7City trains.

- A battery electric train on the Inverness and Kyle of Lochalsh route, would surely be a tourist asset.

With an eighty mile range, ScotRail could find a battery-equipped Class 158 train very useful.

Networkers

Networkers are a group of trains that were produced by British Rail.

- The earliest were built in 1990 and all were built in the last century.

- There are 96 trains in total.

- All have a Perkins engine of 261 kW, with one engine per car.

- They have a Voith T211r transmission, which drives two axles per car.

- They have an operating speed of 75 or 90 mph.

These pictures show ac selection of Class 165 and Class 166 trains.

As with the Express Sprinters, with a battery electric transmission, that gave a range of say 80 miles at 90 mph, they would be low cost competition for Hitachi’s Regional Battery Train on secondary routes.

The Networkers are used by Great Western Railway and Chiltern Railways.

- Great Western Railway do run a few long routes with their Networkers, but these routes would probably be too long for battery operation.

- Local routes around Bristol, Exeter and Plymouth and some short branch lines could be possibilities for battery operation.

- Great Western Railway have also leased tri-mode Class 769 trains for the Reading and Gatwick route.

- Chiltern Railways don’t run their Networkers on the longer routes to Birmingham.

- But they do run them on the shorter routes to Aylesbury (39 miles), Aylesbury Vale Parkway (41 miles), Banbury (69 miles), Gerrards Cross (19 miles), High Wycombe (28 miles), Oxford (66 miles) and Stratford-upon-Avon (104 miles).

- Some of these Chiltern routes must surely be possibilities for battery operation. Especially, as all the stations in the list, don’t appear to be the most difficult to add a Fast Charge facility.

With an eighty mile range, battery-equipped Networkers could be very useful.

Turbostars

Turbostars are a group of trains that were produced at Derby.

- The earliest were built in the last few years of the the last century.

- There are 177 trains in total.

- All have an MTU engine of 315 kW, with one engine per car.

- They have a Voith T211 transmission, which drives two axles per car.

- They have an operating speed of 100 mph.

These pictures show a selection of Turbostar trains.

As with the Express Sprinters and the Networkers, with a battery electric transmission, that gave a range of say 80 miles at 100 mph, they would be low cost competition for Hitachi’s Regional Battery Train on secondary routes.

The post; DfT and Arriva CrossCountry Sign Agreement is partly based on this article on Railway News, which has the same name.

This is a paragraph from the original article.

One element of this new contract is a focus on reducing the environmental impact of the operator’s diesel fleet. For instance, Arriva CrossCountry will do a trial of using electrical shore supplies on its Bombardier Turbostar fleet when these trains are in depots for cleaning. Trains are cleaned both in the winter and at night, which means that the interior lighting and heating systems have to be powered. By using electricity to power these systems instead of the trains’ diesel engines, there will be a reduction in both emissions and noise pollution, which is doubly important when the depots are near built-up areas.

If Turbostars were to have their power unit and transmission updated to battery electric, there would be less need to provide shore supplies to where the trains were to be cleaned.

How Would Sprinters, Express Sprinters, Networkers And Turbostars Be Converted To Battery Electric Power?

The layout of the transmission in all these trains is very similar.

That is not surprising, as they are effectively different interpretations of the same theme over four decades.

- A diesel engine provides the power.

- On the back of the diesel engine, a hydraulic transmission is mounted.

- The transmission performs a similar function to an automatic gearbox in a car. Trains like cars perform better in the right gear.

- The transmission is connected to the final drive in one or more of the bogies using a cardan shaft. The propeller shaft in many rear-wheel-drive vehicles, is a cardan shaft.

In the video at about 5 mins 50 seconds, Mr. Shooter outlines how the train will be converted to battery electric drive.

- The diesel engine, hydraulic transmission, radiator, fuel tank and all the other diesel-related gubbins will be removed.

- A 280 kW electric traction motor will be installed, which will be connected to the cardan shaft.

- Batteries will be installed. Possibly, they will fit, where the diesel engine was originally located.

I wouldn’t be surprised if the weight of the battery was similar to that of all the equipment that has been removed, as this would mean the train’s handling wouldn’t change.

- Acceleration will be faster, as it is in electrically-powered road vehicles.

- The traction motor can work in reverse to slow the train and the energy regenerated by braking can be stored in the batteries.

- Mr. Shooter doesn’t say if his battery electric trains use regenerative braking in the video, but it is possible and a common procedure, as it saves energy.

An intelligent control system will control everything according to the driver’s needs and wishes.

This extract from the print edition, gives Mr. Shooter’s advantages of this diesel to battery electric conversion.

‘Unlike cars, trains have a planned duty cycle so you can easily plan for when the batteries should be charged’ says. Mr. Shooter. ‘Our analysis shows the fuel cost would be halved and the maintenance cost would be halved compared to a DMU. And to allay concerns about battery life we would offer to lease batteries on a cost per mile. You get the financial payback within five years, with the greenness free of charge!’ Mr. Shooter reports early work by Vivarail suggests a converted battery train on the Far North line might need fast charge stations at four locations.

Where In The World Is This?

The print edition of the interview poses an interesting question.

Mr. Shooter says the opportunities are significant, and reports Vivarail is in discussions with an overseas customer about a bid for battery trains for a new 500 mile line which would incorporate 12 fast charge points at stations. He also said customers are suggesting the use of solar parks or even tidal power to feed the static batteries at the fast charge stations, rather than power coming from the local supply.

Imagine two large cities about 500 miles apart, with a string of small towns between them.

- The small towns might be on a scenic river or coastline.

- Commuters drive to both cities.

- People from the two cities visit the area to relax.

- There might even be a lightly used freight line or a dismantled railway alignment running between the cities.

- Perhaps, the road network is overloaded and a green alternative is needed.

Given, Vivarail is part-owned, by an American entrepreneur, I would expect, the proposed line is somewhere in North America. But I also think there would be possibilities in Australia, around the coast of the Baltic Sea and India and South East Asia.

Cpnclusion

This is the conclusion of the print article in Modern Railways.

While electrification will be the key component in decarbonising traction emissions, battery technology will have a role to play, and Vivarail is at the forefront of this development.

I wholeheartedly agree.

Vivarail Targets Overseas Markets

The title of this post, is the same as that of this article on Rail Magazine.

This is an extract from the article.

Shooter told RAIL: “We are at the moment putting together a bid for an operator – not in this country – where the routes would be up to 500 miles long, to be provided totally with battery trains using this device.

“This bid we are putting together contemplates trains that are running for several hours – 60 to 70 miles between charging stations, but possibly going twice that far in emergency if the charging station should go down.”

By this device I suspect they mean their Fast Charge device, which is described in this press release from Vivarail.

This extract describes how it works.

The concept is simple – at the terminus 4 short sections of 3rd and 4th rail are installed and connected to the electronic control unit and the battery bank. Whilst the train is in service the battery bank trickle charges itself from the national grid – the benefit of this is that there is a continuous low-level draw such as an EMU would use rather than a one-off huge demand for power.

The train pulls into the station as normal and the shoegear connects with the sections of charging rail. The driver need do nothing other than stop in the correct place as per normal and the rail is not live until the train is in place.

That’s it!

That sounds simple to me.

Where Would This Possible Order Be From?

I have ridden in a Vivarail battery train, as I wrote in Battery Class 230 Train Demonstration At Bo’ness And Kinneil Railway.

I have also ridden the diesel variant, as I wrote in A First Ride In A Revenue-Earning Class 230 Train.

I very much feel, I can list a few of the good qualities of the trains.

Big Windows

The big windows give a good view, so I wonder if the trains would work well on a railway noted for its scenery.

Quietness

I have ridden in two battery trains.

The other was Bombardier’s Class 379 BEMU, that I wrote about in Is The Battery Electric Multiple Unit (BEMU) A Big Innovation In Train Design?.

Both were extremely quiet.

No Infrastructure Required

Except for the charging stations, no infrastructure is required.

Sturdy Engineering

Although the trains were only originally built for the London Underground, they are sturdily-built trains, as they used to share tracks with full-size trains.

I suspect, they are certified to share tracks with freight trains, as they do on the Marston Vale Line.

A Range Of Interiors And Customer Facilities

Although the trains tend to use the old London Underground seat frames, they have a range of interiors, which seem to be well-designed and comfortable.

I have been on Class 230 trains, with tables, a single toilet, onboard Wi-Fi, and electrical charging points.

Zero-Carbon

The trains are probably as near to zero-carbon, as any! Especially, if all the Fast Charge stations are powered by renewable electricity.

Remote Servicing

The trains have been designed for remote servicing.

Conclusion

All of these qualities lead me to think, that an ideal line in the UK could be the Far North Line, between Inverness and Wick and Thurso.

Although the train ticks a lot of boxes, it could well be too slow, It is also only a 160 mile route and not five-hundred

But there must be quite a few long, scenic lines in countries, where a passenger service needs to be added to a freight line, that perhaps serves a remote mining town.

Sweden and Norway are surely possibilities, but Finland is ruled out because it is Russian gauge.

Could the trains end up in parts of Africa, Canada and the United States?

Who knows?

CrossCountry’s Bournemouth And Manchester Piccadilly Service

Whilst I was at Basingstoke station yesterday one of CrossCountry‘s services between Bournemouth and Manchester Piccadilly came through, so I took these pictures.

It was a long formation of Class 220 trains.

Could This Service Be Replaced By Hitachi Regional Battery Trains?

This Hitachi infographic gives the specification of the Hitachi Regional Battery Train.

I feel that in most condition, the range on battery power can be up to 56 miles.

I can break the Bournemouth and Manchester Piccadilly route into a series of legs.

- Bournemouth and Basingstoke – 60 miles – 750 VDC third-rail electrification

- Basingstoke and Reading – 15.5 miles – No electrification

- Reading and Didcot North Junction – 18 miles – 25 KVAC overhead electrification

- Didcot North Junction and Oxford – 10 miles – No electrification

- Oxford and Banbury – 22 miles – No electrification

- Banbury and Leamington Spa – 20 miles – No electrification

- Leamington Spa and Coventry – 10 miles – No electrification

- Coventry and Manchester Piccadilly – 101 miles – 25 KVAC overhead electrification

Note.

- 63 % of the route is electrified.

- The short 15.5 mile gap in the electrification between Basingstoke and Reading should be an easy route for running on battery power.

- But the 62 mile gap between Didcot North Junction and Coventry might well be too far.

The train would also need to be able to work with both types of UK electrification.

If some way could be found to bridge the 62 mile gap reliably, Hitachi’s Regional Battery Trains could work CrossCountry’s service between Bournemouth and Manchester Piccadilly.

Bridging The Gap

These methods could possibly be used to bridge the gap.

A Larger Battery On The Train

If you look at images of MTU’s Hybrid PowerPack, they appear to show a basic engine module with extra battery modules connected to it.

Will Hitachi and their battery-partner; Hyperdrive Innovation use a similar approach, where extra batteries can be plugged in as required?

This modular approach must offer advantages.

- Battery size can be tailored to routes.

- Batteries can be changed quickly.

The train’s software would know what batteries were fitted and could manage them efficiently.

I wouldn’t be surprised to see Hitachi’s Regional Battery Train able to handle a gap only six miles longer than the specification.

Battery And Train Development

As Hitachi’s Regional Battery Train develops, the following should happen.

- Useable battery capacity will increase.

- The train will use less electricity.

- Actions like regenerative braking will improve and recover more electricity.

- Driving and train operating strategies will improve.

These and other factors will improve the range of the train on batteries.

A Charging Station At Banbury Station

If some form of Fast Charge system were to be installed at Banbury station, this would enable a train stopping at Banbury to take on enough power to reliably reach Oxford or Coventry depending, on their final destination.

This method may add a few minutes to the trip, but it should work well.

Electrification Of A Section Of The Chiltern Main Line

This could be an elegant solution.

I have just flown my helicopter between Bicester North and Warwick Parkway stations and these are my observations.

- The Chiltern Main Line appears to be fairly straight and has received a top class Network Rail makeover in the last couple of decades.

- There are a couple of tunnels, but most of the bridges are new.

- Network Rail have done a lot of work on this route to create a hundred mph main line.

- It might be possible to increase the operating speed, by a few mph.

- The signalling also appears modern.

My untrained eye, says that it won’t be too challenging to electrify between say Bicester North station or Aynho Junction in the South and Leamington Spa or Warwick Parkway stations in the North. I would think, that the degree of difficulty would be about the same, as the recently electrified section of the Midland Main Line between Bedford and Corby stations.

The thirty-eight miles of electrification between Bicester North and Warwick Parkway stations would mean.

- The electrification is only eight-and-a-half miles longer than Bedford and Corby.

- There could be journey time savings.

- As all trains stop at two stations out of Banbury, Leamington Spa, Warwick and Warwick Parkway, all pantograph actions could be performed in stations, if that was thought to be preferable.

- Trains would be able to leave the electrification with full batteries.

- The electrification may enable some freight trains to be hauled between Didcot and Coventry or Birmingham using battery electric locomotives.

Distances of relevance from the ends of the electrification include.

- London Marylebone and Bicester North stations – 55 miles

- London Marylebone and Aynho junction – 64 miles

- Didcot North and Aynho junctions – 28 miles

- Leamington Spa and Coventry stations – 10 miles

- Leamington Spa and Birmingham Snow Hill stations – 23 miles

- Leamington Spa and Stratford-upon-Avon stations – 15 miles

- Warwick Parkway and Birmingham New Street stations – 20 miles

- Warwick Parkway and Birmingham Snow Hill stations – 20 miles

- Warwick Parkway and Kidderminster – 40 miles

- Warwick Parkway and Stratford-upon-Avon stations – 12 miles

These figures mean that the following services would be possible using Hitachi’s Regional Battery Train.

- Chiltern Railways – London Marylebone and Birmingham Moor Street

- Chiltern Railways – London Marylebone and Birmingham Snow Hill

- Chiltern Railways – London Marylebone and Kidderminster

- Chiltern Railways – London Marylebone and Stratford-upon-Avon

- CrossCountry – Bournemouth and Manchester Piccadilly

- CrossCountry – Southampton Central and Newcastle

- Midlands Connect – Oxford and Birmingham More Street – See Birmingham Airport Connectivity.

Other services like Leicester and Oxford via Coventry may also be possible.

As I see it, the great advantage of this electrification on the Chiltern Main Line is that is decarbonises two routes with the same thirty-eight miles of electrification.

Conclusion

CrossCountry’s Bournemouth And Manchester Piccadilly service could be run very efficiently with Hitachi’s proposed Regional Battery Train.

My preferred method to cross the electrification gap between Didcot North junction and Coventry station would be to electrify a section of the Chiltern Main Line.

- The electrification would be less than forty miles.

- I doubt it would be a challenging project.

- It would also allow Hitachi’s proposed trains to work Chiltern Main Line routes between London Marylebone and Birmingham.

I am fairly certain, that all passenger services through Banbury would be fully electric.

Converting Class 456 Trains Into Two-Car Battery Electric Trains

Mark Hopwood is the interim Managing Director of South Western Railway and in Special Train Offers A Strong Case For Reopening Fawley Line, I quote him as saying the following about the trains for the Fawley Branch Line.

However, SWR’s Mark Hopwood favours a much bolder plan. “We’d have to take a decision, once we knew the line was going ahead. But my personal belief is that we should be looking for a modern environmentally-friendly train that can use third-rail electricity between Southampton and Totton and maybe operate on batteries down the branch line.”

Pressed on whether that would mean Vivarail-converted former-London Underground stock, Hopwood ads. “It could be. Or it could be a conversion of our own Class 456, which will be replaced by new rolling stock very shortly. But I don’t think this is the time to use old diesels.

Mark Hopwood is so right about using old diesels.

- Where possible new and refurbished trains should be zero-carbon.

- Diesel is to be banned by 2035 in Scotland and 2040 in England and Wales.

- Diesel trains and hydrogen trains for that matter need to refuelled.

- Get the diagrams right and battery electric trains can be charged on existing electrification or automatic Fast Charging systems, when they turn back at terminal stations.

- Electric trains attract passengers.

- Battery electric trains are mouse-quiet!

Who would use anything else other than electric trains with a battery option for sections without electrification?

The Class 456 Train

These pictures show some of the twenty-four Class 456 trains, that are in South Western Railway’s fleet.

This is the specification of a Class 456 train.

- Two cars

- Operating speed – 75 mph.

- Capacity – 152 seats – Although the plate on the train says 113!

- Built 1990-1991

- Ability to work in pairs.

Most trains seem to be used to lengthen trains from eight to ten cars, as some of the pictures shows. As these 4+4+2 formations will be replaced with new 10-car Class 701 trains or pairs of five-car Class 701 trains, the trains will be looking for a new role.

Does this explain Mark Hopwood’s statement?

It should be noted that the Class 456 trains are members of the Mark 3 family, and bare a strong resemblance to the Class 321 train, which are shown in these pictures.

Note that I have included the side view, as it shows the amount of space under these trains.

Some Class 321 trains are being converted to Class 600 hydrogen trains, by Alstom at Widnes. Others have been given a life-extending Renatus upgrade.

Are The Driver Cars Of Class 456 and Class 321 Trains Identical?

The trains may look similar, but does the similarity go deeper?

Could Alstom Use Class 600 Hydrogen Train Technology To Create A Class 456 Train With a Battery Capability?

Consider.

- Alstom are positioning themselves as Train Upgrade Specialists in the UK. They have already signed a near billion pound deal to upgrade and maintain Avanti West Coast’s fleet of Class 390 trains.

- Alstom are creating the Class 600 hydrogen train from withdrawn Class 321 trains.

- A hydrogen-powered train is basically a battery electric train with a hydrogen tank and fuel cell to charge the batteries.

- The Class 600 train doesn’t appear to be making fast progress and is still without an order.

- One possible hydrogen route must surely be London Waterloo and Exeter, so I suspect Alstom are talking to South Western Railway.

- The Class 456 trains are owned by Porterbrook, who would probably like to extend the useful life of the trains.

Could it be that the battery core and AC traction package of Alstom’s hydrogen system for the Class 600 train can turn old British Rail-era electric multiple units into battery electric multiple units with a useful range?

It is certainly a possibility and one that is also within the capability of other companies in the UK.

Could The Class 456 Trains Receive a Class 321 Renatus Interior And Traction Package?

As Class 321 and Class 456 trains were built around the same time, the two trains must share components.

These pictures show the current interior of a Class 456 train.

This is excellent for a two-car electric multiple unit, built thirty years ago! Although, the refurbishment is more recent from 2014-15.

- Note the wheelchair space and the copious rubbish bins.

- I also spotted a stowed wheel-chair ramp on the train. It can be seen if you look hard in the picture that shows the wheelchair space.

- Some might feel that toilets should be provided.

These pictures show the interior of a Class 321 train, that has been given the Renatus upgrade.

What is not shown is the more efficient AC traction package.

I have been told or read, that the Renatus interior will be used in the conversion of a Class 321 train to an Alstom Class 600 or Breeze hydrogen train.

On the other hand, the current Class 456 interior would probably be ideal for a branch line, where one of initial aims would be to attract passengers.

Could A Class 456 Train Have a Lightweight Traction Package?

Consider.

- The Class 456 train will access electrification that is only 750 VDC third-rail.

- Batteries work in DC.

- The new traction motors will work in AC, if they follow the practice in the Class 321 Renatus and the Class 600 train.

- Regenerative braking will charge the batteries in both trains.

- Air-conditioning and other hotel services can work in DC.

Some components needed to run from 25 KVAC like a transformer could be left out to save weight and improve acceleration.

I would suspect that a Class 456 train with batteries could use a slimmed-down traction system from the Class 600 train.

On both Class 456 and 600 trains a core system, that would power the train, might contain.

- The traction battery or batteries.

- The traction motors that both drive and brake the train,

- Third-rail electrification shoes, so that the batteries could be charged in a station, as required.

- A clever computer system, that controls the acceleration, braking and charging as required.

On the Class 600 train, there would also be the following.

- Hydrogen tanks and fuel cells to provide an independent power source to charge the batteries.

- A pantograph to access 25 KVAC overhead electrification.

- Extra electrical gear to access the electrification.

I think it would be possible to design the Class 456 train with batteries as the basic train and just add the extra hydrogen and electrical gubbins to make it a Class 600 train.

Could A Class 456 Train Be Modified To Use 25 KVAC Overhead Electrification?

As I said, there are a lot of similarities between Class 456 trains and Class 321 trains.

As the Class 321 trains are equipped to use 25 KVAC Overhead Electrification, I suspect train modification specialists could create a Class 456 train, that could use overhead electrification.

What Battery Range And Size Would Be Needed In A Class 456 Train?

These are typical branch line lengths for South Western Railway.

- Fawley Branch – 8 miles

- Wareham and Swanage – 11 miles

- Lymington Branch – 5.6 miles

- Reading and Basingstoke – 15.5 miles

I would suspect that a range of thirty miles on battery power would be sufficient for a Class 456 train with batteries.

In an article in the October 2017 Edition of Modern Railways, which is entitled Celling England By The Pound, Ian Walmsley says this in relation to trains running on the Uckfield Branch, which is not very challenging.

A modern EMU needs between 3 and 5 kWh per vehicle mile for this sort of service.

So applying that formula gives battery capacity of between 180 kWh and 300 kWh.

In Issue 864 of Rail Magazine, there is an article entitled Scotland High Among Vivarail’s Targets for Class 230 D-Trains, where this is said.

Vivarail’s two-car battery units contains four 100 kWh lithium-ion battery rafts, each weighing 1.2 tonnes.

If 200 kWh can be placed under the floor of each car of a rebuilt London Underground D78 Stock, then I think it is reasonable that up to 200 kWh can be placed under the floor of each car of the proposed train.

This picture of the Driver Car of a Class 321 train, shows that there is quite a bit of space under those trains.

Are the Class 456 trains similar? This is the best picture I have got so far.

It does appear that space is similar to that under a Class 321 train.

If we assume that the Class 456 train can have the following specification.

- Battery capacity of 200 kWh in both cars.

- Regenerative braking to battery.

- Power consumption of 4 kWh per vehicle mile.

I think we could be approaching a range of fifty miles on a route without too many energy-consuming stops.

Charging The Batteries

I like the Vivarail’s Fast Charge concept of using third-rail equipment to charge battery trains.

This press release from the company describes how they charge their battery electric Class 230 trains.

- The system is patented.

- The system uses a trickle-charged battery pack, by the side of the track to supply the power.

- The first system worked with the London Underground 3rd and 4th rail electrification standard.

As the length of rails needed to be added at charging points is about a metre, installing a charging facility in a station, will not be the largest of projects.

Under How Does It Work?, the press release says this.

The concept is simple – at the terminus 4 short sections of 3rd and 4th rail are installed and connected to the electronic control unit and the battery bank. Whilst the train is in service the battery bank trickle charges itself from the national grid – the benefit of this is that there is a continuous low-level draw such as an EMU would use rather than a one-off huge demand for power.

The train pulls into the station as normal and the shoe-gear connects with the sections of charging rail. The driver need do nothing other than stop in the correct place as per normal and the rail is not live until the train is in place.

That’s it!

As an electrical engineer, I’m certain the concept could be adapted to charge the batteries of a conventional third-rail train.

Vivarail’s press release says this about modification to the trains.

The train’s shoe-gear is made of ceramic carbon so it is able to withstand the heat generated during the fast charge process.

That wouldn’t be a major problem to solve.

Class 456 Train With Batteries And Class 600 Train Compared

The following sub-sections will compare the trains in various areas.

Lightweight Design

As I suspect that the basic structure of the Class 456 and Class 600 trains are similar, systems like toilets, air-conditioning, traction motors and seats will be chosen with saving weight in mind.

Every kilogram saved will mean faster acceleration.

Operating Speed

The current Class 321 train is a 100 mph train, whilst the current Class 456 train is only a 75 mph train.

I wonder if applying the modern traction package of the Class 321 Renatus to the Class 456 train could speed the shorter train up a bit?

Range Away From Electrification

Alstom have quoted ranges of hundreds of miles for the Class 600 train on one filling of hydrogen, but I can’t see the Class 456 train with batteries doing much more than fifty miles on a full charge.

But using a Fast Charge system, I can see the Class 456 train with batteries fully-charging in under ten minutes.

Fast Charge systems at Romsey and Salisbury stations would surely enable the Class 456 trains with batteries to run the hourly service over the thirty-eight mile route between the two stations.

Passenger Capacity

The current Class 456 trains have a capacity of 152 seats.

In Orders For Alstom Breeze Trains Still Expected, I said this.

The three-car Alstom Breeze is expected to have a similar capacity to a two-car diesel multiple unit.

But until I see one in the flesh, I won’t have a better figure.

If South Western Railway were wanting to replace a two-car diesel Class 158 train, they’d probably accept something like 180 seats.

Increasing Passenger Capacity

There are compatible trailer cars around from shortening Class 321 trains from four to three cars and there may be more from the creation of the Class 600 trains.

I suspect that these could be added to both Class 456 and Class 600 trains to increase capacity by fifty percent.

As a two-car train, the Class 456 train might be a bit small, but putting in a third car, which had perhaps slightly more dense seating and possibly a toilet and even more batteries could make the train anything the operator needed.

Suitability For London Waterloo and Exeter via Salisbury

This is South Western Railway’s big need for a zero emission train.

- It is around 170 miles

- Only 48 miles are electrified.

- It is currently worked by three-car Class 159 trains working in pairs.

- Class 159 trains are 90 mph trains.

I have believed for some time, that with fast charging, a battery electric train could handle this route.

But, I would feel that.

- Class 456 trains would be too slow and too small for this route.

- Class 600 trains would be too small for this route.

On the other hand, I believe that Hitachi’s Class 800 train with a battery electric capability or Regional Battery Train, which is described in this infographic from the company, could be ideal for the route.

The proposed 90 km or 56 mile range could even be sufficient take a train between Salisbury and Exeter with a single intermediate charge at Yeovil Junction station, where the trains wait up to ten minutes anyway.

There are other reasons for using Hitachi’s Regional Battery Train rather than Class 600 trains.

- First Group have a lot of experience of running Hitachi Class 80x trains, through their various subsidiaries.

- They could share depot facilities at Exeter.

- No specialist facilities would be needed.

- A five-car Class 801 with batteries would have a convenient 300 seats.

- I suspect they could be delivered before Alstom’s Class 600 train.

As the only new infrastructure required would be Fast Charge facilities at Salisbury and Yeovil Junction stations, I feel that Hitachi’s Regional Battery Train, should be a shoe-in for this route.

First Delivery

The Wikipedia entry for the Class 600 train, says introduction into traffic could be in 2024. Given, the speed with which Greater Anglia’s Class 321 trains were updated to the Renatus specification, we could see Class 456 trains with a battery capability and new interiors running well before 2024.

A Few Questions

These questions have occurred to me.

Could The Technology Be Used To Create A Class 321 Battery Electric Train?

I don’t see why not!

I believe a Class 321 battery electric train could be created with this specification.

- Three or four cars. Remember the Class 320 train is a three-car Class 321 train.

- 100 mph operating speed.

- Regenerative braking to the batteries.

- Renatus or operator-specified interior.

- Toilet as required.

- Electrification as required.

- Battery range of around sixty miles.

- Ability to use a Fast Charge system, that can easily be installed in a terminal platform.

Trains could be tailored to suit a particular route and/or operator.

Any Other Questions?

If you have any other questions, send them in and I’ll add them to this section.

Conclusion

It does appear that if the Class 456 trains, were to be fitted with a battery capability, that they would make a very useful two-car battery electric train, with the following specification.

- Two cars

- Operating speed – 75 mph. This might be a bit higher.

- Capacity – 152 seats

- Ability to work in pairs.

- Modern interior

- Range of 45-50 miles on batteries.

- Ability to charge batteries in ten minutes in a station.

- Ability to charge batteries on any track with 750 VDC third-rail electrification.

This is the sort of train, that could attract other operators, who don’t have any electrification, but want to electrify short branch lines.

Bristol Temple Meads Station – 28th July 2020

I took these pictures of Bristol Temple Meads station, when I visited.

Note.

- The station is Listed to the highest level of Grade 1.

- London services seem to use Platforms 15 and 16.

- There is quite a fair bit of space between the tracks.

.Do Network Rail need all the hassle of full electrification of one of Brunel’s most famous creations?

Bristol Temple Meads Station And Trains With a Battery Capability

Hitachi’s Class 800 train with a battery electric capability or Regional Battery Train, is described in this infographic from the company.

The proposed 90 km or 56 mile range would even be sufficient take a train between Chippenham and Bristol Temple Meads stations on a return trip. So this means that one of these trains could work the London Paddington and Bristol Temple Meads stations service via Bath Spa using the electrification between London Paddington and Chippenham stations.

But where could trains reach, if they were able to leave Bristol Temple Meads station with a fully-charged battery?

- Bristol Parkway – 6 miles

- Cardiff Central – 5 miles to the electrified Great Western Main Line.

- Cheltenham Spa – 41 miles

- Filton Abbey Wood – 4 miles

- Gloucester – 39 miles

- Newport – 5 miles to the electrified Great Western Main Line.

- Severn Beach – 13.5 miles

- Taunton – 45 miles

- Westbury – 28.5 miles

- Weston-super-Mare – 19 miles

Note.

- Return trips to Bristol Parkway, Filton Abbey Wood, Severn Beach and Western-super-Mare would be possible.

- The other destinations will need charging facilities.

Other local destinations could be added as the Bristol Metro develops.

This Google Map shows the station.

Note.

- The curving nature of the platforms doesn’t make 25 KVAC overhead electrification easy.

- Trains to and from London appear to use the two Eastern platforms 13 and 15.

- It might be possible to increase platform lengths to run longer trains to and from places like London.

I believe that there are three possible ways of charging the trains in Bristol Temple Meads station.

25 KVAC Overhead Electrification

This could be short length of standard 25 KVAC overhead electrification in platforms, that would be served by trains with pantographs like the Class 800 trains.

The driver would stop in the correct place in the platform and connect the pantograph, whilst waiting in the station.

Note that the Class 800 trains to and from London typically take 35-20 minutes to turn round, which is time enough for a full charge.

750 VDC Third-Rail Electrification

This could be short lengths of standard 750 VDC third-rail electrification in platforms, that would be used by standard third-rail shoes on trains.

The train would connect automatically and charging would take place, whilst waiting in the station.

A Specialist Charging Facility Like Vivarail’s Fast Charge System

Vivarail’s Fast Charge system is described in Vivarail Unveils Fast Charging System For Class 230 Battery Trains.

This extract from this Vivarail press release explains how the system works.

he concept is simple – at the terminus 4 short sections of 3rd and 4th rail are installed and connected to the electronic control unit and the battery bank. Whilst the train is in service the battery bank trickle charges itself from the national grid – the benefit of this is that there is a continuous low-level draw such as an EMU would use rather than a one-off huge demand for power.

The train pulls into the station as normal and the shoe-gear connects with the sections of charging rail. The driver need do nothing other than stop in the correct place as per normal and the rail is not live until the train is in place.

That’s it!

I believe that this system or something like it could be adapted to work with all trains with a battery capability in the UK.

I also believe that this system can be designed so that it is ultra-safe and doesn’t disrupt, the visual impact of the station.

Conclusion

Bristol Temple Meads station could be converted into a station, where a high proportion of trains ran solely on electricity.

VDE Study Finds Battery Trains 35% Cheaper Than Hydrogen

The title of this post, is the same as that of this article on the International Railway Journal.

This is the introductory paragraph.

A study of the cost-effectiveness of battery electric multiple units (BEMU) and hydrogen electric multiple units (HEMU) as alternatives to diesel found that BEMUs could be up to €59m (35%) less expensive to buy and operate compared with their hydrogen fuel cell equivalents.

It also says that they are more expensive than the diesels they replace over thirty years.

As it is a professional German study, we should take note of what is said.

How Would This Apply To The UK?

There will be differences between the UK and Continental Europe, which will affect costs!

- Our small loading gauge seems to be making the design of hydrogen-powered trains difficult.

- Passenger capacity in a UK train, will probably be reduced when compared to the diesel equivalent.

- Our hydrogen technology is world-class.

- More affordable batteries would benefit both types of trains.

- I believe that companies like Vivarail, will come up with very fast and efficient chargers for battery trains using our third-rail technology, which may not be suitable outside the UK.

On balance though, I suspect that the cost difference worldwide, will be similar.

Conclusion

Companies, developers and engineers will fight a keen battle for supremacy.

There will be some suprising winners and some big losers.

Could Hitachi’s Class 800 Trains Work The Cornish Main Line On Battery Power?

The distance between Plymouth and Penzance stations along the Cornish Main Line is just seventy-nine miles and thirty-eight chains. I’ll call it 79.5 miles.

Hitachi’s proposed train is described in this infographic.

The range on battery power of 90 km or 56 miles, will not be quite enough to get all the way between Plymouth and Penzance!

But note the phrase – Allows Discontinuous Electrification; at the top of the infographic.

Will Electrification Be Needed?

Obviously or the train could perhaps wait at Truro for ten minutes to charge the batteries.

But how customer-unfriendly and disruptive to good operating practice is that?

Could Bigger Batteries Be Fitted?

This obviously is a possibility, but surely an operator would prefer all of their trains to have the same battery range and updating them all for a longer distance might not be an economic proposition.

Could Intelligent Discontinuous Third-Rail Electrification Be Used?

Third-rail electrification, is hated by the Health & Safety Taliban, as it occasionally kills people trespassing or falling on the railway. But in the UK, we have around 1,500 miles of third-rail electrified line, that generally operates to a high level of safety.

Can my modern successors make third-rail electrification absolutely safe in new installations?

Third-Rail And Discontinuous Electrification Installations!

To connect to overhead electrification, the driver or an automatic system on the train, must raise the pantograph. It doesn’t often go wrong, but when it does, it can bring down the wires. This section on panotograph weaknesses from Wikipedia give more details.

With third-rail, the connection and disconnection is automatic, with far less to go wrong.

These pictures show a gap in the third-rail electrification at the Blackfriars station, which was rebuilt in 2012, so it must meet all modern regulations.

Note the gap in the third-rail, which carries the current.

- The third-rail shoes on the train disconnect and connect automatically, as the train passes through.

- The only rails with voltage are between the tracks for safety.

- The high-tech shields appear to be real tree wood painted yellow.

As an Electrical Engineer, I actually suspect, that this gap in the conductor rail, is to isolate the North and South London electricity supplies from each other,, so that a catastrophic failure on one side doesn’t affect both halves of Thameslink.

Third-Rail Electrification In Stations

Most rail passengers in the UK, understand third-rail electrification, if they’ve ever used trains in the South of London or Merseyside.

Electrifying stations using third-rail equipment could enable battery trains to go further.

- Stopping trains could top-up their batteries.

- Passing trains, that were low on power could make a pit-stop.

- All trains would connect automatically to the third-rail, when in the station.

The safety level would be raised by making sure that the third-rail was electrically-dead unless a train was over the top.

I am by training a Control Engineer and one of my first jobs in a dangerous factory as a fifteen-year-old, was designing and building safety systems, that cut power to guillotines, when the operator put their hands somewhere they shouldn’t! I remember endlessly testing the system with an old broom, which survived unscathed.

I believe that only switching on the electrification, when a train completes the circuit, is a fairly simple operation for modern control switchgear. I can imagine an intelligent switch constantly monitoring the resistance and only switching on power, when the resistance in the circuit looks like a train.

Third-Rail Electrification In Discrete Locations

Overhead electrification can receive complaints in scenic locations, but third-rail electrification can be invisible in tunnels and over bridges and viaducts.

The Cornish Main Line has four tunnels, two bridges, which include the Royal Albert Bridge, and no less than thirty-two viaducts.

How many of these could be used to hide electrification?

- Any electrified sections could be intelligently controlled to increase safety.

- Power for the electrification could come from local renewable sources, using techniques like Riding Sunbeams.

I can see engineers developing several techniques for discrete electrification.

Third-Rail And Charging Battery Trains

I like the Vivarail’s Fast Charge concept of using third-rail equipment to charge battery trains.

This press release from the company describes how they charge their battery electric Class 230 trains.

- The system is patented.