GWR Buys Vehicles Outright In HST Fleet Expansion

The title of this post is the same as that of this article on Railway Gazette.

This is the introductory paragraph.

Despite concerns over future passenger numbers, the Department for Transport has given permission for Great Western Railway to procure three more shortened HST diesel trainsets, branded as the Castle Class by the franchisee.

These pictures show some of the Castle Class trains.

They must be profitable and/or popular with passengers.

If I have a problem with these trains, it is with the Class 43 diesel power cars.

- Each train has two power cars.

- It would appear that there are about 150 of the Class 43 power cars in regular service.

- Each is powered by a modern MTU 16V4000 R41R diesel engine, that is rated at 1678 kW.

- The engines are generally less than a dozen years old.

- They will be emitting a lot of carbon dioxide.

As the trains are now only half as long as they used to be, I would suspect, that the engines won’t be working as hard, as they can.

Hopefully, this will mean less emissions.

The article says this about use of the fleet.

With its fleet now increasing to 14, GWR expects to use 12 each day on services across the west of England. Currently the fleet is deployed on the Cardiff – Bristol – Penzance corridor, but the company is still evaluating how the additional sets will be used.

It also says, that they are acquiring rolling stock from other sources. Some of which will be cannibalised for spares.

Are First Rail Holdings Cutting Carbon Emissions?

First Rail Holdings, who are GWR’s parent, have announced in recent months three innovative and lower-carbon fleets from Hitachi, for their subsidiary companies.

- The Class 807 trains for Avanti West Coast will not have any diesel engines.

- The Class 805 trains for Avanti West Coast will initially have diesel engines, but these may be changedin a few years for battery power packs.

- The Class 803 trains for East Coast Trains will not have any diesel engines.

Hitachi have also announced a collaboration with Hyperdrive Innovation to provide battery packs to replace diesel engines, that could be used on Class 800 and Class 802 trains.

First Rail Holdings have these Class 800/802 fleets.

- GWR – 36 x five-car Class 800 trains

- GWR – 21 x nine-car Class 800 trains

- GWR – 22 x five-car Class 802 trains

- GWR – 14 x nine-car Class 802 trains

- TransPennine Express – 19 x five-car Class 802 trains

- Hull Trains – 5 x five-car Class 802 trains

Note.

- That is a total of 117 trains.

- As five-car trains have three diesel engines and nine-car trains have five diesel engines, that is a total of 357 engines.

- In Could Battery-Electric Hitachi Trains Work Hull Trains’s Services?, I showed that Hull Trains could run their services with a Fast Charging system in Hull station.

- In Could Battery-Electric Hitachi Trains Work TransPennine Express’s Services?, I concluded that Class 802 trains equipped with batteries could handle all their routes without diesel and some strategically-placed charging stations.

In the Wikipedia entry for the Class 800 train, there is a section called Powertrain, where this is said.

According to Modern Railways magazine, the limited space available for the GUs has made them prone to overheating. It claims that, on one day in summer 2018, “half the diagrammed units were out of action as engines shut down through overheating.

So would replacing some diesel engines with battery packs, also reduce this problem, in addition to cutting carbon emissions?

It does appear to me, that First Rail Holdings could be cutting carbon emissions in their large fleet of Hitachi Class 800 and Class 802 trains.

The Class 43 power cars could become a marketing nightmare for the company?

Could Class 43 Power Cars Be Decarbonised?

Consider.

- Class 43 power cars are forty-five years old.

- They have been rebuilt with new MTU engines in the last dozen years or so.

- I suspect MTU and GWR know everything there is to know about the traction system of a Class 43 power car.

- There is bags of space in the rear section of the power car.

- MTU are part of Rolls-Royce, who because of the downturn in aviation aren’t performing very well!

But perhaps more importantly, the power cars are iconic, so anybody, who decarbonises these fabulous beasts, gets the right sort of high-class publicity.

I would also feel, if you could decarbonise these power cars, the hundreds of diesel locomotives around the world powered by similar diesel engines could be a useful market.

What methods could be used?

Biodiesel

Running the trains on biodiesel would be a simple solution.

- It could be used short-term or long-term.

- MTU has probably run the engines on biodiesel to see how they perform.

- Biodiesel could also be used in GWR’s smaller diesel multiple units, like Class 150, 158, 165 and 166 trains.

Some environmentalists think biodiesel is cheating as it isn’t zero-carbon.

But it’s my view, that for a lot of applications it is a good interim solution, especially, as companies like Altalto, will be making biodiesel and aviation biofuel from household and industrial waste, which would otherwise be incinerated or go to landfill.

The Addition Of Batteries

This page on the Hitachi Rail Ltd web site shows this image of the V-Train 2.

This is the introduction to the research program, which was based on a High Speed Train, fotmed of two Class 43 power cars and four Mark 3 carriages.

The V-Train 2 was a demonstration train designed in order to demonstrate our skills and expertise while bidding for the Intercity Express Programme project.

The page is claiming, that a 20 % fuel saving could be possible.

This paragraph talks about performance.

The V-Train 2 looked to power the train away from the platform using batteries – which would in turn be topped up by regenerative braking when a train slowed down to stop at a station. Acceleration would be quicker and diesel saved for the cruising part of the journey.

A similar arrangement to that Hitachi produced in 2005 could be ideal.

- Technology has moved on significantly in the intervening years.

- The performance would be adequate for a train that just trundles around the West Country at 90 mph.

- The space in the rear of the power car could hold a lot of batteries.

- The power car would be quiet and emission-free in stations.

- There would be nothing to stop the diesel engine running on biodiesel.

This might be the sort of project, that Hitachi’s partner in the Regional Battery Train; Hyperdrive Innovation. would probably be capable of undertaking.

MTU Hybrid PowerPack

I wouldn’t be surprised to find, that MTU have a drop-in solution for the current 6V4000 R41R diesel engine, that includes a significant amount of batteries.

This must be a serious possibility.

Rolls-Royce’s 2.5 MW Generator

In Our Sustainability Journey, I talk about rail applications of Rolls-Royce’s 2.5 MW generator, that has been developed to provide power for electric flight.

In the post, I discuss fitting the generator into a Class 43 power car and running it on aviation biofuel.

I conclude the section with this.

It should also be noted, that more-efficient and less-polluting MTU engines were fitted in Class 43s from 2005, so as MTU is now part of Rolls-Royce, I suspect that Rolls-Royce have access to all the drawings and engineers notes, if not the engineers themselves

But it would be more about publicity for future sales around the world, with headlines like.

Iconic UK Diesel Passenger Trains To Receive Green Roll-Royce Jet Power!

COVID-19 has given Rolls-Royce’s aviation business a real hammering, so perhaps they can open up a new revenue stream by replacing the engines of diesel locomotives,

I find this an intriguing possibility. Especially, if it were to be fitted with a battery pack.

Answering My Original Question

In answering my original question, I feel that there could be several ways to reduce the carbon footprint of a Class 43 power car.

It should also be noted that other operators are users of Class 43 power cars.

- ScotRail – 56

- CrossCountry – 12

- East Midlands Railway – 39

- Network Rail – 3

Note.

- ScotRail’s use of the power cars, is very similar to that of GWR.

- CrossCountry’s routes would need a lot of reorganisation to be run by say Hitachi’s Regional Battery Train.

- East Midlands Railway are replacing their Inter-City 125s with new Class 810 trains.

The picture shows the power car of Network Rail’s New Measurement Train.

These may well be the most difficult to decarbonise, as I suspect they need to run at 125 mph on some routes, which do not have electrification and there are no 125 mph self-powered locomotives. After the Stonehaven crash, there may be more tests to do and a second train may be needed by Network Rail.

Why Are GWR Increasing Their Castle Class Fleet?

These are possible reasons.

GWR Want To Increase Services

This is the obvious explanation, as more services will need more trains.

GWR Want To Update The Fleet

There may be something that they need to do to all the fleet, so having a few extra trains would enable them to update the trains without cutting services.

GWR Want To Partially Or Fully Decarbonise The Power Cars

As with updating the fleet, extra power cars would help, as they could be modified first and then given a thorough testing before entering passenger service.

GWR Have Been Made An Offer They Can’t Refuse

Suppose Rolls-Royce, MTU or another locomotive power plant manufacturer has a novel idea, they want to test.

Over the years, train operating companies have often tested modified trains and locomotives for manufacturers.

So has a manufacturer, asked GWR to test something in main line service?

Are Other Train Operators Thinking Of Using Introducing More Short-Formed InterCity 125 Trains?

This question has to be asked, as I feel there could be routes, that would be suitable for a net-zero carbon version of a train, like a GWR Castle or a ScotRail Inter7City.

Northern Trains

Northern Trains is now run by the Department for Transport and has surely the most suitable route in the UK for a shorted-formed InterCity 125 train – Leeds and Carlisle via the Settle and Carlisle Line.

Northern Trains may have other routes.

Transport for Wales Rail Services

Transport for Wales Rail Services already run services between Cardiff Central and Holyhead using diesel locomotive hauled services and long distance services between South Wales and Manchester using diesel multiple units.

Would an iconic lower-carbon train be a better way of providing some services and attract more visitors to the Principality?

Conclusion

GWR must have a plan, but there are few clues to what it is.

The fact that the trains have been purchased rather than leased could be significant and suggests to me that because there is no leasing company involved to consult, GWR are going to do major experimental modifications to the trains.

They may be being paid, by someone like an established or new locomotive engine manufacturer.

It could also be part of a large government innovation and decarbonisation project.

My hunch says that as First Rail Holdings appear to be going for a lower-carbon fleet, that it is about decarbonising the Class 43 power cars.

The plan would be something like this.

- Update the three new trains to the new specification.

- Give them a good testing, before certifying them for service.

- Check them out in passenger service.

- Update all the trains.

The three extra trains would give flexibility and mean that there would always be enough trains for a full service.

Which Methods Could Be Used To Reduce The Carbon Footprint Of The Class 43 Power Cars?

These must be the front runners.

- A Hitachi/Hyperdrive Innovation specialist battery pack.

- An MTU Hybrid PowerPack.

- A Rolls-Royce MTU solution based on the Rolls-Royce 2.5 MW generator with batteries.

All would appear to be viable solutions.

Rolls-Royce Commences Series Production Of Hybrid-Ready MTU PowerPacks For Irish Rail

The title of this post, is the same as that of this article on CleanTechnica.

This is the introductory paragraph.

Rolls-Royce is to supply its very first series production MTU PowerPacks which are prepared for future use as hybrid traction units: Iarnród Éireann Irish Rail, the national railway operator of the Republic of Ireland, has ordered 41 of these MTU Hybrid-ready PowerPacks. Fitted with MTU 6H 1800 R86 engines, the PowerPacks comply with the EU Stage V emissions directives and each delivers 375 kW from the diesel engine as well as 150 kW from the electrical machine.

Later the aim would be to add batteries to the PowerPacks to make the trains fully hybrid.

I do think Rolls-Royce MTU might have a game-changer here.

- You take a modern fleet of diesel multiple units like a British Class 170 trains or an Irish Class 22000 trains,

- For starters you replace the old diesel engine, with a modern one that meets all the latest environmental regulations.

- It surely helps both sales and engineering, when the old diesel engine was supplied by MTU.

- Later you fit appropriately sized batteries to the PowerPack to create full hybrids with regenerative braking.

In Iarnród Éireann Orders Stage V MTU PowerPacks, I said this about fuel consumption and emissions.

The aim is to achieve a reduction of over thirty percent in both fuel consumption and carbon dioxide emissions.

I would suspect that with savings like that, the case for conversion might be an easy sell.

Converting Class 456 Trains Into Two-Car Battery Electric Trains

Mark Hopwood is the interim Managing Director of South Western Railway and in Special Train Offers A Strong Case For Reopening Fawley Line, I quote him as saying the following about the trains for the Fawley Branch Line.

However, SWR’s Mark Hopwood favours a much bolder plan. “We’d have to take a decision, once we knew the line was going ahead. But my personal belief is that we should be looking for a modern environmentally-friendly train that can use third-rail electricity between Southampton and Totton and maybe operate on batteries down the branch line.”

Pressed on whether that would mean Vivarail-converted former-London Underground stock, Hopwood ads. “It could be. Or it could be a conversion of our own Class 456, which will be replaced by new rolling stock very shortly. But I don’t think this is the time to use old diesels.

Mark Hopwood is so right about using old diesels.

- Where possible new and refurbished trains should be zero-carbon.

- Diesel is to be banned by 2035 in Scotland and 2040 in England and Wales.

- Diesel trains and hydrogen trains for that matter need to refuelled.

- Get the diagrams right and battery electric trains can be charged on existing electrification or automatic Fast Charging systems, when they turn back at terminal stations.

- Electric trains attract passengers.

- Battery electric trains are mouse-quiet!

Who would use anything else other than electric trains with a battery option for sections without electrification?

The Class 456 Train

These pictures show some of the twenty-four Class 456 trains, that are in South Western Railway’s fleet.

This is the specification of a Class 456 train.

- Two cars

- Operating speed – 75 mph.

- Capacity – 152 seats – Although the plate on the train says 113!

- Built 1990-1991

- Ability to work in pairs.

Most trains seem to be used to lengthen trains from eight to ten cars, as some of the pictures shows. As these 4+4+2 formations will be replaced with new 10-car Class 701 trains or pairs of five-car Class 701 trains, the trains will be looking for a new role.

Does this explain Mark Hopwood’s statement?

It should be noted that the Class 456 trains are members of the Mark 3 family, and bare a strong resemblance to the Class 321 train, which are shown in these pictures.

Note that I have included the side view, as it shows the amount of space under these trains.

Some Class 321 trains are being converted to Class 600 hydrogen trains, by Alstom at Widnes. Others have been given a life-extending Renatus upgrade.

Are The Driver Cars Of Class 456 and Class 321 Trains Identical?

The trains may look similar, but does the similarity go deeper?

Could Alstom Use Class 600 Hydrogen Train Technology To Create A Class 456 Train With a Battery Capability?

Consider.

- Alstom are positioning themselves as Train Upgrade Specialists in the UK. They have already signed a near billion pound deal to upgrade and maintain Avanti West Coast’s fleet of Class 390 trains.

- Alstom are creating the Class 600 hydrogen train from withdrawn Class 321 trains.

- A hydrogen-powered train is basically a battery electric train with a hydrogen tank and fuel cell to charge the batteries.

- The Class 600 train doesn’t appear to be making fast progress and is still without an order.

- One possible hydrogen route must surely be London Waterloo and Exeter, so I suspect Alstom are talking to South Western Railway.

- The Class 456 trains are owned by Porterbrook, who would probably like to extend the useful life of the trains.

Could it be that the battery core and AC traction package of Alstom’s hydrogen system for the Class 600 train can turn old British Rail-era electric multiple units into battery electric multiple units with a useful range?

It is certainly a possibility and one that is also within the capability of other companies in the UK.

Could The Class 456 Trains Receive a Class 321 Renatus Interior And Traction Package?

As Class 321 and Class 456 trains were built around the same time, the two trains must share components.

These pictures show the current interior of a Class 456 train.

This is excellent for a two-car electric multiple unit, built thirty years ago! Although, the refurbishment is more recent from 2014-15.

- Note the wheelchair space and the copious rubbish bins.

- I also spotted a stowed wheel-chair ramp on the train. It can be seen if you look hard in the picture that shows the wheelchair space.

- Some might feel that toilets should be provided.

These pictures show the interior of a Class 321 train, that has been given the Renatus upgrade.

What is not shown is the more efficient AC traction package.

I have been told or read, that the Renatus interior will be used in the conversion of a Class 321 train to an Alstom Class 600 or Breeze hydrogen train.

On the other hand, the current Class 456 interior would probably be ideal for a branch line, where one of initial aims would be to attract passengers.

Could A Class 456 Train Have a Lightweight Traction Package?

Consider.

- The Class 456 train will access electrification that is only 750 VDC third-rail.

- Batteries work in DC.

- The new traction motors will work in AC, if they follow the practice in the Class 321 Renatus and the Class 600 train.

- Regenerative braking will charge the batteries in both trains.

- Air-conditioning and other hotel services can work in DC.

Some components needed to run from 25 KVAC like a transformer could be left out to save weight and improve acceleration.

I would suspect that a Class 456 train with batteries could use a slimmed-down traction system from the Class 600 train.

On both Class 456 and 600 trains a core system, that would power the train, might contain.

- The traction battery or batteries.

- The traction motors that both drive and brake the train,

- Third-rail electrification shoes, so that the batteries could be charged in a station, as required.

- A clever computer system, that controls the acceleration, braking and charging as required.

On the Class 600 train, there would also be the following.

- Hydrogen tanks and fuel cells to provide an independent power source to charge the batteries.

- A pantograph to access 25 KVAC overhead electrification.

- Extra electrical gear to access the electrification.

I think it would be possible to design the Class 456 train with batteries as the basic train and just add the extra hydrogen and electrical gubbins to make it a Class 600 train.

Could A Class 456 Train Be Modified To Use 25 KVAC Overhead Electrification?

As I said, there are a lot of similarities between Class 456 trains and Class 321 trains.

As the Class 321 trains are equipped to use 25 KVAC Overhead Electrification, I suspect train modification specialists could create a Class 456 train, that could use overhead electrification.

What Battery Range And Size Would Be Needed In A Class 456 Train?

These are typical branch line lengths for South Western Railway.

- Fawley Branch – 8 miles

- Wareham and Swanage – 11 miles

- Lymington Branch – 5.6 miles

- Reading and Basingstoke – 15.5 miles

I would suspect that a range of thirty miles on battery power would be sufficient for a Class 456 train with batteries.

In an article in the October 2017 Edition of Modern Railways, which is entitled Celling England By The Pound, Ian Walmsley says this in relation to trains running on the Uckfield Branch, which is not very challenging.

A modern EMU needs between 3 and 5 kWh per vehicle mile for this sort of service.

So applying that formula gives battery capacity of between 180 kWh and 300 kWh.

In Issue 864 of Rail Magazine, there is an article entitled Scotland High Among Vivarail’s Targets for Class 230 D-Trains, where this is said.

Vivarail’s two-car battery units contains four 100 kWh lithium-ion battery rafts, each weighing 1.2 tonnes.

If 200 kWh can be placed under the floor of each car of a rebuilt London Underground D78 Stock, then I think it is reasonable that up to 200 kWh can be placed under the floor of each car of the proposed train.

This picture of the Driver Car of a Class 321 train, shows that there is quite a bit of space under those trains.

Are the Class 456 trains similar? This is the best picture I have got so far.

It does appear that space is similar to that under a Class 321 train.

If we assume that the Class 456 train can have the following specification.

- Battery capacity of 200 kWh in both cars.

- Regenerative braking to battery.

- Power consumption of 4 kWh per vehicle mile.

I think we could be approaching a range of fifty miles on a route without too many energy-consuming stops.

Charging The Batteries

I like the Vivarail’s Fast Charge concept of using third-rail equipment to charge battery trains.

This press release from the company describes how they charge their battery electric Class 230 trains.

- The system is patented.

- The system uses a trickle-charged battery pack, by the side of the track to supply the power.

- The first system worked with the London Underground 3rd and 4th rail electrification standard.

As the length of rails needed to be added at charging points is about a metre, installing a charging facility in a station, will not be the largest of projects.

Under How Does It Work?, the press release says this.

The concept is simple – at the terminus 4 short sections of 3rd and 4th rail are installed and connected to the electronic control unit and the battery bank. Whilst the train is in service the battery bank trickle charges itself from the national grid – the benefit of this is that there is a continuous low-level draw such as an EMU would use rather than a one-off huge demand for power.

The train pulls into the station as normal and the shoe-gear connects with the sections of charging rail. The driver need do nothing other than stop in the correct place as per normal and the rail is not live until the train is in place.

That’s it!

As an electrical engineer, I’m certain the concept could be adapted to charge the batteries of a conventional third-rail train.

Vivarail’s press release says this about modification to the trains.

The train’s shoe-gear is made of ceramic carbon so it is able to withstand the heat generated during the fast charge process.

That wouldn’t be a major problem to solve.

Class 456 Train With Batteries And Class 600 Train Compared

The following sub-sections will compare the trains in various areas.

Lightweight Design

As I suspect that the basic structure of the Class 456 and Class 600 trains are similar, systems like toilets, air-conditioning, traction motors and seats will be chosen with saving weight in mind.

Every kilogram saved will mean faster acceleration.

Operating Speed

The current Class 321 train is a 100 mph train, whilst the current Class 456 train is only a 75 mph train.

I wonder if applying the modern traction package of the Class 321 Renatus to the Class 456 train could speed the shorter train up a bit?

Range Away From Electrification

Alstom have quoted ranges of hundreds of miles for the Class 600 train on one filling of hydrogen, but I can’t see the Class 456 train with batteries doing much more than fifty miles on a full charge.

But using a Fast Charge system, I can see the Class 456 train with batteries fully-charging in under ten minutes.

Fast Charge systems at Romsey and Salisbury stations would surely enable the Class 456 trains with batteries to run the hourly service over the thirty-eight mile route between the two stations.

Passenger Capacity

The current Class 456 trains have a capacity of 152 seats.

In Orders For Alstom Breeze Trains Still Expected, I said this.

The three-car Alstom Breeze is expected to have a similar capacity to a two-car diesel multiple unit.

But until I see one in the flesh, I won’t have a better figure.

If South Western Railway were wanting to replace a two-car diesel Class 158 train, they’d probably accept something like 180 seats.

Increasing Passenger Capacity

There are compatible trailer cars around from shortening Class 321 trains from four to three cars and there may be more from the creation of the Class 600 trains.

I suspect that these could be added to both Class 456 and Class 600 trains to increase capacity by fifty percent.

As a two-car train, the Class 456 train might be a bit small, but putting in a third car, which had perhaps slightly more dense seating and possibly a toilet and even more batteries could make the train anything the operator needed.

Suitability For London Waterloo and Exeter via Salisbury

This is South Western Railway’s big need for a zero emission train.

- It is around 170 miles

- Only 48 miles are electrified.

- It is currently worked by three-car Class 159 trains working in pairs.

- Class 159 trains are 90 mph trains.

I have believed for some time, that with fast charging, a battery electric train could handle this route.

But, I would feel that.

- Class 456 trains would be too slow and too small for this route.

- Class 600 trains would be too small for this route.

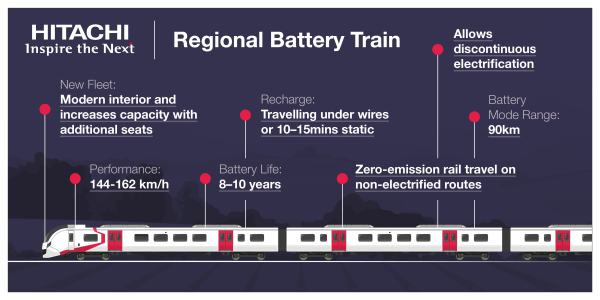

On the other hand, I believe that Hitachi’s Class 800 train with a battery electric capability or Regional Battery Train, which is described in this infographic from the company, could be ideal for the route.

The proposed 90 km or 56 mile range could even be sufficient take a train between Salisbury and Exeter with a single intermediate charge at Yeovil Junction station, where the trains wait up to ten minutes anyway.

There are other reasons for using Hitachi’s Regional Battery Train rather than Class 600 trains.

- First Group have a lot of experience of running Hitachi Class 80x trains, through their various subsidiaries.

- They could share depot facilities at Exeter.

- No specialist facilities would be needed.

- A five-car Class 801 with batteries would have a convenient 300 seats.

- I suspect they could be delivered before Alstom’s Class 600 train.

As the only new infrastructure required would be Fast Charge facilities at Salisbury and Yeovil Junction stations, I feel that Hitachi’s Regional Battery Train, should be a shoe-in for this route.

First Delivery

The Wikipedia entry for the Class 600 train, says introduction into traffic could be in 2024. Given, the speed with which Greater Anglia’s Class 321 trains were updated to the Renatus specification, we could see Class 456 trains with a battery capability and new interiors running well before 2024.

A Few Questions

These questions have occurred to me.

Could The Technology Be Used To Create A Class 321 Battery Electric Train?

I don’t see why not!

I believe a Class 321 battery electric train could be created with this specification.

- Three or four cars. Remember the Class 320 train is a three-car Class 321 train.

- 100 mph operating speed.

- Regenerative braking to the batteries.

- Renatus or operator-specified interior.

- Toilet as required.

- Electrification as required.

- Battery range of around sixty miles.

- Ability to use a Fast Charge system, that can easily be installed in a terminal platform.

Trains could be tailored to suit a particular route and/or operator.

Any Other Questions?

If you have any other questions, send them in and I’ll add them to this section.

Conclusion

It does appear that if the Class 456 trains, were to be fitted with a battery capability, that they would make a very useful two-car battery electric train, with the following specification.

- Two cars

- Operating speed – 75 mph. This might be a bit higher.

- Capacity – 152 seats

- Ability to work in pairs.

- Modern interior

- Range of 45-50 miles on batteries.

- Ability to charge batteries in ten minutes in a station.

- Ability to charge batteries on any track with 750 VDC third-rail electrification.

This is the sort of train, that could attract other operators, who don’t have any electrification, but want to electrify short branch lines.

BNSF And Wabtec Prepare To Test Battery-Electric Locomotive

The title of this post, is the same as that of this article on Railway Gazette.

Some points from the article.

- It is a 4,400 hp or 3.3 MW locomotive.

- The battery is formed from 20,000 cells.

- The locomotive uses regenerative braking.

- Testing will be on a 560 km route in California.

But what I find interesting, is that the locomotive is designed to work commonly with a diesel locomotive and this is discussed in detail.

I have this feeling, that running two different locomotives as a pair might be more efficient and I wrote Could A Battery- Or Hydrogen-Powered Freight Locomotive Borrow A Feature Of A Steam Locomotive?, where I examined the concept.

In the article, they say that when a train hauled by a diesel and a battery locomotive, slows, the batteries are recharged. This would seem to make the combination more efficient.

I’ll be interested to see the results of the tests performed by BNSF and Wabtec.

The Big Metro Fleet Upgrade That Could Make It ‘Easy’ To Finally Extend Train Services To New Areas

The title of this post, is the same as that of this article on the Newcastle Chronicle.

This is the first paragraph.

Every train in Metro’s new fleet will be capable of running via an on-board battery, reducing the chance of major shutdowns and making it much cheaper to extend the network.

The fact that it is technically possible, is not a surprise as Stadler’s Class 777 trains for Merseyrail will be using battery power to extend routes. I would be very surprised if the new Tyne and Wear Metro trains and those for Merseyrail, didn’t have a lot of design in common.

But what is surprising, is that the Tyne and Wear Metro’s whole fleet will be fitted with batteries. This must be the first time in the UK, that a whole fleet of trains has been said to have batteries.

The Merseyrail trains will also have a dual voltage capability and will be able to be modified for running on 25 KVAC overhead electrification, as well as 750 VDC third-rail electrification.

Will the Tyne and Wear trains be able to use 25 KVAC electrification? It could be useful in some places on the network and I’m sure, if there was a financial case for a service using existing 25 KVAC electrification, then some trains would be modified accordingly.

A Quick Comparison

This is a quick comparison between Merseyrail’s Class 777 trains and the Tyne and Wear Metro’s new trains.

- Cars – 777 – 4 – T&W – 5

- Operating Speed – 777 – 75 mph – T&W – 50 mph

- Capacity – 484 – T&W – 600

- Capacity Per Car – 121 – T&W – 125

- In Service – 2022 (?) – T&W – 2024

They are not that different and it looks like the Tyne and Wear trains will be built after the Merseyrail trains.

Battery Running

The article says this about running on battery power.

He said the 16km off-wire running would allow for a new loop extending out from South Hylton, through Washington, connecting back to Pelaw.

He added that it would be “easy” to create new connections between existing Metro lines – potentially allowing for a new route through Silverlink and the Cobalt business park in North Tyneside, or a link-up from South Shields towards Sunderland.

Battery power would also solve the problem of running Metro trains on Network Rail lines, which is currently impossible because they operate at different voltages.

Mr Blagburn said: “You could remove the electrification from the complex parts of the route, say over historic structures or through tunnels.

Note.

- The range of sixteen kilometres or ten miles could be very useful.

- The trains appear to be designed to run on Network Rail tracks, as the current trains already do.

- The current trains use the Karlsruhe model to effectively work as tram-trains on shared tracks.

I actually believe that the new Tyne and Wear trains could be modified to run on both 25 KVAC and 750 VDC overhead electrification, as Stadler’s Class 399 tram-trains do in Sheffield.

Conclusion

These trains are using all Stadler’s experience of trains and tram-trains from all over the world.

- They will normally operate using 750 VDC overhead electrification.

- But Stadler have the technology to enable the trains for 25 KVAC overhead electrification, if required.

- They have a range of ten miles on batteries.

- Are the batteries charged by using the energy created by the regenerative braking?

These are not bog-standard trains!

But then neither are the trains built for Greater Anglia by Stadler!

Thirsty High-Rollers … Mining’s Heavy Haulers Prime Candidates For Hydrogen Conversion

The title of this post, is the same as that of this article on ecogeneration.

You understand, what the author means about mining’s heavy haulers, when you open the article.

This paragraph describes their carbon emissions.

One large scale dump truck, depending on the haul road it is using, will use between 100 and 140 litres of diesel per 100km. These vehicles operate all day every day except for maintenance down time. That’s between 260kg and 360kg of CO2 per 100km per truck.

Large open pit mines have tens of these vehicles operating continuously, so the numbers build up very quickly.

The author then goes on to say why, that converting these vehicles to green hydrogen makes a lot of sense.

The dump trucks are already diesel/electric, which means that the diesel generator can be replaced with a hydrogen fuel cell and a battery.

Mining giant; Anglo-American will be introducing a prototype hydrogen-powered dump truck at a platinum mine in South Africa this year.

These paragraphs describe the transmission.

The vehicle, which is called a fuel cell electric vehicle (FCEV) haul truck, will be powered by a hydrogen fuel cell module paired with Williams Advanced Engineering’s scalable high-power modular lithium-ion battery system. Williams provides batteries for FIA’s E-Formula motorsport.

This arrangement will replace the existing vehicle’s diesel engine, delivering in excess of 1MWh of energy storage. The battery system will be capable of recovering energy through regenerative braking as the haul truck travels downhill.

Note that the truck has more energy storage than is proposed for a four-car battery-electric train, like the Class 756 train, which has only 600 kWh.

The author finishes with this concluding paragraph.

With the major mining companies focusing on making significant strides in decarbonisation by 2030 expect there to be more announcements such as this focusing this “low hanging fruit” for the mining industry’s to materially reduce its carbon foot print.

Reading this, I can’t help feeling that replacement of a Class 66 locomotive with a zero-carbon hydrogen-battery-electric hybrid unit could be possible.

First Order For Mireo Plus B Battery EMUs

The title of this post is the same as that of this article on Railway Gazette.

This is the introductory paragraph.

The Land of Baden-Württemberg’s rolling stock body SFBW has ordered 20 battery-equipped Mireo Plus B electric multiple-units from Siemens Mobility, which will then be responsible for their availability over a 29½-year operating life.

The Siemens Mireo Plus B Battery EMUs appear to have the following specification.

- Ability to use overhead electrification.

- Ability to use battery power for a range of eighty kilometres.

- Two underfloor lithium-ion battery packs.

- Batteries handle regenerative braking.

- 160 kph operating speed.

Delivery is by December 2023.

Batteries Come Of Age In Railway Construction

The title of this post is the same as that of this article on Rail Engineer.

It is very much a must-read article on the subject of constructing and repairing railways in a zero-carbon manner.

These are some extra comments of mine!

Smaller And Lighter First

This is a paragraph from the article.

Smaller and lighter equipment is getting the treatment first – the batteries and motors can be smaller. Volvo Construction Equipment has already supplied its first electric compact loader, to a customer in Germany.

Volvo seems to be busy creating electric loaders.

Size Appears To Be No Limit

This extract shows how a large dump truck can go electric.

If a 25-tonne excavator is not big enough, how about a Komatsu HD605-7 off-highway truck, which weighs 51 tonnes unladen and has a payload of 63 tonnes? Kuhn Switzerland, working with Lithium Storage and the Swiss Federal Office of Energy (SFOE), has converted this 111-tonne gross vehicle weight monster into an electric vehicle.

Out came the 23-litre, 778hp (578kW) diesel engine and in went a synchronous electric motor rated at 789hp (588kW) electric motors. An additional 120kW motor is fitted just to power the hydraulic systems. The battery was a challenge – the four large packs have a combined rating of 700kWh and weigh 4.5 tonnes.

Do you get much bigger than 111 tonne, nearly 600 kW and a 700 kWh battery pack?

Regenerative Braking

The article also says that in some applications, vehicles go up and down a route and can charge the batteries using regenerative braking on the downhill run. In one application batteries only need charging every three days.

Rail Application Of Off-Road Equipment

The article says this.

While an eDumper may be too large to use on the railway, it does show what can now be done. Between JCB’s mini-excavator and eMining’s dump truck, there is room to battery-power almost any item used on the railway today.

I would suspect that there are a lot of companies, including giants like Caterpillar, JCB, Komatsu. Volvo and others working to produce electric versions of their successful products.

What About The Workers

The article says this.

These new machines are only the tip of the ‘electric’ iceberg. As pressure mounts to cut carbon emissions and to protect workers from harmful fumes, there will be more to come.

Health and safety will lead to a big push towards electric, as electric vehicles are pollution, carbon and fume-free, with a substantial noise reduction.

Hydrogen Will Have A Part To Play

This statement is from the Wikipedia entry for ITM Power.

In March 2015 JCB made a strategic investment of £4.9M in ITM Power.

Why would a construction equipment company invest in a company, that makes equipment that generates hydrogen to power vehicles?

- It is known, that the Bamford heir has purchased Wrightbus and intend to make hydrogen-powered buses for the world.

- JCB have built their own diesel engines, so are they building their own hydrogen engine?

- JCB make tractors and I believe a hydrogen-powered tractor may be more than a niche market.

- Is it possible to build a hydrogen-powered JCB?

Buy any of these products and you get a gas station in the price.

To deliver hydrogen, all you need to do is connect it to the water and electricity mains and switch on.

If you’re using it to power rail or site construction equipment, the gas station could be on wheels, so it can be moved from site to site.

Conclusion

This is the writer’s conclusion.

It seems that ‘battery is the new diesel’. It will be fascinating to see how this sector develops over the next few years.

I don’t disagree, but would add, that I feel that JCB are the elephant in this room!

Will High Speed Two’s Classic-Compatible Trains Have Battery Operation?

I believe it is very likely, that High Speed Two’s new classic-compatible trains will have battery capabilities.

- Batteries would handle energy generated by regenerative braking.

- Batteries would give a train recovery capability in case of overhead catenary failure.

- Batteries would be used for depot movements.

- Batteries would probably improve the energy efficiency of the trains.

Effectively, the batteries would power the train and would be topped-up by the electrification and the regenerative braking.

But would they be able to give the trains a route extension capability on lines without electrification?

Consider.

- Battery technology is getting better with energy capacity per kilogram increasing.

- Batteries will be full, when the train leaves the electrification.

- These trains will be as light as possible.

- Trains will not be running at speeds in excess of perhaps 100 mph without electrification.

- Fast charging can be provided at station stops.

I think, that trains could be able to do at least 40 to 50 miles on a full charge.

Fast Charging Technology

The most promising fast-charging technology is Vivarail’s system of using a length of conventional third-rail connected to a bank of batteries. When the train connects with the third-rail, electricity flows to the batteries on the train.

There are also others working on systems that use short lengths of overhead electrification.

Both systems can be totally automatic and safe.

Example Routes

These are three possible example routes.

Aberdeen And Edinburgh

These are the distances between stops on the route between Aberdeen and Edinburgh.

- Aberdeen and Stonehaven – 12 miles

- Stonehaven and Montrose – 24 miles

- Montrose and Arbroath – 14 miles

- Arbroath and Dundee – 17 miles

- Dundee and Leuchars – 8 miles

- Leuchars and Kirkaldy – 25 miles

- Kirkcaldy and Inverkeithing – 13 miles

- Inverkeithing and Edinburgh – 13 miles

It is a total of 130 miles without electrification.

The route is also generally flat and mainly along the coast.

Inverness And Edinburgh

These are the distances between stops on the route between Inverness and Strirling.

- Inverness and Aciemore- 35 miles

- Aviemore and Kingussie – 12 miles

- Kingussie and Pitlochry – 43 miles

- Pitlochry and Perth – 30 miles

- Perth and Gleneagles – 15 miles

- Gleneagles and Stirling – 17 miles

It is a total of 152 miles without electrification.

As there are some steep gradients, there may be a need for some electrification in certain sections of the route.

Holyhead And Crewe

These are the distances between stops on the route between Holyhead and Crewe

- Holyhead and Bangor – 25 miles.

- Bangor and Llandudno Junction – 16 miles

- Llandudno Junction and Colwyn Bay – 4 miles

- Colwyn Bay and Rhyl – 10 miles

- Rhyl and Prestatyn – 4 miles

- Prestatyn and Flint – 14 miles

- Flint and Chester – 13 miles

- Chester and Crewe – 21 miles

It is a total of 105 miles without electrification.

The route is also generally flat and mainly along the coast.

A Stepping-Stone Approach

I believe there is a design of fast charger, that in say a three minute stop can charge the battery sufficient to get to the next station. The electrification might continue for perhaps a couple of hundred metres from the station on the tracks where the trains are accelerating.

A train making a stop at a station would do the following.

- As it approaches the stop, the train’s kinetic energy is turned into electricity by the regenerative braking.

- This energy is stored in the batteries.

- In the station, the batteries are charged from the fast charger or electrification.

- Whilst stopped, the batteries provide the power for the train’s systems.

- Accelerating away would use the batteries or electrification if it is installed.

The train’s computer would monitor the batteries and control the various power systems and sources to run the train in the most efficient manner.

This sequence would be repeated at each stop as the train progressed to its destination.

Extra Electrification

In the section on the challenging Edinburgh and Inverness route, I said that some gradients would probably need to be electrified to maintain progress.

But there are other sections, where electrification has been suggested.

- Stirling and Perth

- Crewe and Chester

So could we be seeing a mixture of electrification and charging stations on routes to allow electric trains to serve routes, where full electrification is impossible for practical, scenic, heritage or cost reasons?

The South Wales Metro is to use discontinuous electrification to save the cost of rebuilding innumerable bridges.

Conclusion

I believe that engineers can design high speed trains, that will be able to run on existing lines using battery power to serve the remoter parts of Great Britain.