Centrica Secures Investment Stake In Gasrec Helping Boost UK Bio-LNG Ambitions

The title of this post, is the same as that of this press release from Centrica.

This is the sub-heading.

Centrica has secured a minority stake in Gasrec, the UK’s largest dual provider of bio-LNG (bio-Liquified Natural Gas) and bio-CNG (bio-Compressed Natural Gas) to the road transport sector,

These first two paragraphs give more details.

Gasrec says the investment will drive the next phase of its infrastructure ambitions, with plans to open a UK wide network of open-access refuelling stations supplying renewable bio-LNG for the decarbonisation of heavy goods vehicles.

Centrica is taking a 16% stake and becomes one of three major shareholders in Gasrec, alongside global integrated energy company bp and private family office 44 North.

I have some thoughts.

Does Running A Truck On bio-LNG or bio-CNG. Reduce Carbon Emissions?

This paragraph from the press release, gives the thoughts of Chris O’Shea, who is Group Chief Executive, Centrica.

Chris O’Shea, Group Chief Executive, Centrica plc, said: “Demand for bio-LNG for transport is growing fast as more HGV operators make the switch – drawn by a clean, ready-to-use fuel which slashes CO2 emissions by up to 85 per cent in comparison to diesel*. This investment in Gasrec enhances our collaboration with the leading company in the sector, and puts us in a strong position to energise a vital sector of the industry on its journey to net zero.”

As Centrica is a public company, with shareholders, who would take a dim view of Mr. O’Shea telling porkies, I suspect we can assume that the following is true.

Drawn by a clean, ready-to-use fuel which slashes CO2 emissions by up to 85 per cent in comparison to diesel.

The asterisk in the full quote, refers to this note.

Low Carbon Vehicle Partnership, Innovate UK and Office for Low Emission Vehicles, Low Emission Freight & Logistics Trial (LEFT), Key Findings, November 2020. Using specific feedstocks CO2 reductions of 200% are achievable.

Centrica could be being conservative with their claims.

Decarbonising Buses, Locomotives And Trucks

Despite what Elon Musk, would have us believe, electric trucks will not dominate the future of freight transport.

An electric truck would be the vehicle equivalent of asking Usain Bolt to run a hundred metres with a large refrigerator on his back.

Trucks are going to need a fuel without a weight penalty and with a long range.

I asked Google for information about Cummins diesel, natural gas and hydrogen engines and received this AI Overview.

Cummins offers engines powered by diesel, natural gas, and hydrogen. While diesel engines are well-established, Cummins is also developing both natural gas and hydrogen engines, particularly focusing on hydrogen as a pathway to zero-carbon solutions for various applications. Cummins utilizes a fuel-agnostic platform, meaning a common base engine can be adapted for different fuel types, including diesel, natural gas, and hydrogen.

Recently, GB Railfreight purchased thirty Class 99 locomotives from Stadler.

- They can use electrification, where it exists.

- Where electrification doesn’t exist, they can use an onboard Cummins diesel engine, which is built in Darlington.

- In electric-mode, they have 6.2 MW of power, and are the most powerful locomotives ever to run on UK railways.

- In diesel-mode, they have 1.8 MW of power, which is more than enough to haul a large container train in and out of Felixstowe.

I had thought that at some future date, Cummins would convert these locomotives to electro-hydrogen.

But now that Gasrec is providing bio-LNG and bio-CNG, GB Railfreight, have the option of converting both hydrogen and biomethane.

Similar logic can be applied to Wrightbus’s Streetdeck Ultroliner, one version of which is fitted with a Cummins engine, that can be converted to electric, hydrogen or natural gas, which of course includes biomethane. This page on the Wrightbus web site describes the bus.

Wrightbus are also going back into coach manufacture, as I wrote about in Wrightbus Goes Back To The Future As It Relaunches The Contour Coach. As with the Streetdeck Ultroliner, Cummins seem to be providing one of the power units.

It seems to me, that the zero- and low-carbon revolution in transport will generate a need for the availability of biomethane, hydrogen and natural gas fuel for transport all over the country.

Gasrec with around twenty biomethane fuelling points around the country, seem well-placed to supply the biomethane in bio-LNG or bio-CNG form.

Could Gasrec Deliver Hydrogen?

Various bus companies in the UK, have had difficulty getting the fuel for their hydrogen buses.

I believe that delivering hydrogen would be very similar to delivering LNG and if Gasrec can deliver LNG successfully and safely, they probably have the technology to do the same for hydrogen.

Centrica Seem To Be Assembling An Interesting Consortium

These are some deals, that I have reported on this blog, that involve Centrica.

- Centrica, along with Hyundai, Kia, Siemens and others have backed Hull-based hydrogen start-up; HiiROC, who can produce affordable hydrogen from any hydrocarbon gas including natural gas, where it is needed.

- Centrica have invested in Sizewell C. Will they be using their share of the electricity to make affordable pink hydrogen using HiiROC?

- In Centrica And Ryze Agree To Develop Hydrogen Pathway, I talked about how Centrica and Ryse were aiming to bring hydrogen to the masses.

- In Recurrent Energy’s Middle Road Project Sold To Centrica, I talked about a Centrica investment in solar power.

- In Aberdeen’s Exceed Secures Centrica Rough Contract, I talked about how Centrica were redeveloping the Rough gas storage site for hydrogen.

- In Lhyfe And Centrica To Develop Offshore Renewable Green Hydrogen In The UK, I talked about developing offshore hydrogen.

- In Centrica Announces Hydrogen Ready Combined Heat And Power Partnership With 2G, the title says it all.

- In Centrica Signs UK Biomethane Agreement With Yorkshire Water And SGN Commercial Services, Centrica appear to be sourcing biomethane from Yorkshire Water.

- In Centrica Invests In Renewable Energy Storage Capabilities To Boost UK’s Energy Security And Accelerate Transition To Net Zero, I talk about Centrica, Goldman Sachs and others, investment in liquid-air energy storage company; Highview Power.

- In British Gas Owner Mulls Mini-Nuke Challenge To Rolls-Royce, I talk about rumours that Centrica might invest in SMRs.

Note.

- A lot of these deals are are about hydrogen production.

- Some of these deals are about biomethane production.

- None of these deals talk about getting hydrogen and biomethane to customers.

It appears to me, that Gasrec have a model that works to get hydrogen, methane and biomethane from production and storage to the end customers.

Developing A Rural Hydrogen Network

In Developing A Rural Hydrogen Network, I talked about supplying all those millions of off-gas grid properties with hydrogen for heating, agricultural and industrial purposes, in the countryside of the UK.

Gasrec have the technology to decarbonise the countryside.

Conclusion

Gasrec would appear to be a very useful partner for Centrica.

I’ve Just Glimpsed The Future Of Train Travel Across The North Of England And I Like It

Yesterday, I had an appointment at Liverpool Lime Street station at four o’clock, so as I hadn’t seen the works for the TransPennine Upgrade for some time, I decided to go the long way round with a change of train from LNER to TransPennine Express at Leeds.

These sections document my day.

London King’s Cross To Leeds In An InterCity 225

I took these pictures on the journey.

Note.

- The 31 InterCity 225 trains were built around 1990.

- They have a capacity of 535 seats, whereas the newer Hitachi Class 801 trains have a capacity of 611 seats. Both trains are nine cars with both First and Standard seats.

- There is more of a step-up and step-down when entering or leaving the trains, compared to the best of today’s trains.

- They are now being phased out in favour of ten new CAF tri-mode Class 897 trains, which should be entering service in 2027.

- No details are available of the seating capacity of these trains, but they could be between 650 and 700, so they could maximise capacity on any LNER route.

Yesterday, the InterCity 225 performed well, although the windows at the seat where I sat, were rather dirty.

Changing Trains At Leeds Station

I changed to TransPennine Exzpress at Leeds station.

- At least, Leeds station, is one of the few in the UK, with a ticket office behind the barrier. Reading station please note this.

- But, I did have to walk across the bridge from one side of the station to the other.

In the end, I caught the TransPennine Express with about thirty seconds to spare.

Between Leeds And Huddersfield Stations

I took these pictures between Leeds and Huddersfield stations.

Note.

- Dewsbury and Huddersfield stations is about eight miles and takes about eight minutes.

- It is virtually a continuous building site, where extra tracks are being inserted.

- Three stations are being rebuilt.

- Overhead electrification is being installed. But except for approaching Huddersfield, there’s not much to be seen.

- OpenRailwayMap gives the maximum speed between Dewsbury and Huddersfield stations as between 60-75 mph.

The ride on my Class 803 train was very quiet and smooth. Was it on battery power or was I sitting in a coach without a diesel engine underneath?

Huddersfield Station

I took these pictures at Huddersfield station.

Note.

- Huddersfield station is Grade I Listed.

- There is a pub in each wing.

- I had a beer in the West Wing.

- There are currently three main through platforms and three bay platforms.

- Extensive works, which will be part of the TransPennine Upgrade, will include electrification, a new roof, a new footbridge, and two extra through platforms.

Huddersfield station will be the jewel in the Costa del Yorkshire.

The Platforms At Huddersfield Station

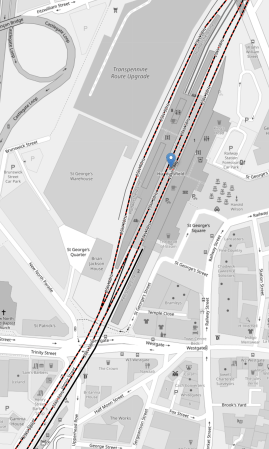

This OpenRailwayMap shows the platforms in Huddersfield station.

Note.

- The red and black tracks are being electrified.

- Of the current platforms, Platforms 1, 4 and 8 will be electrified.

- The two bay platforms; 5 and 6, will be converted into through platforms.

- Platform 2 is the bay platform in the South-West corner of the map, that is used by the shuttle train from Sheffield.

I am sure extra platforms could be electrified as required, as there must be a good electrical connection at Huddersfield station.

A Tram-Train Service Between Huddersfield And Sheffield Stations

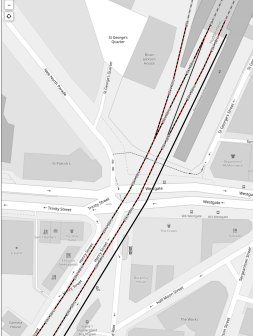

This OpenRailwayMap shows platform 2 at Huddersfield station.

Note.

- Platform 2 is the black track at the right of the two through tracks, that are being electrified.

- Platform 2 is a bay platform close to the Head of Steam pub.

- I estimate that the platform is about 90 metres long.

- I suspect Platform 2 could be lengthened if required.

- Sheffield’s Class 399 tram/trains are 37.2 metres long, so a pair should fit in Platform 2.

- The Class 398 tram/trains can run on battery power and climb hills in South Wales.

- Platform 2 at Huddersfield station could be electrified to charge the tram/trains.

- There could be a significant height difference between Huddersfield and Sheffield stations of about 40 metres, which could be used to charge tram/trains on the way down.

- I feel with some track improvements, that a four trains per hour (tph) service could be run.

The service would call at Meadowhall, Chapeltown, Elsecar, Wombwell, Barnsley, Dodworth, Silkstone Common, Penistone, Denby Dale, Shepley, Stocksmoor, Brockholes, Honley, Berry Brow and Lockwood

The Pair Of Cranes In Huddersfield Station

These can’t be missed in the pictures. But why two massive cranes?

With an old roof to be taken down and a new roof and a footbridge to be lifted into place, I believe Network Rail have decided to bring in two of largest mobile cranes available in the UK, so that all the lifting doesn’t delay the project.

Between Huddersfield And Stalybridge Stations

I took these pictures between Huddersfield and Stalybridge stations.

Note.

- The Class 802 train was running freely along a well-laid track.

- There are four stations between Huddersfield and Stalybridge; Slaithwaite, Marsden, Greenfield and Mossley(Manchester).

- The stations were in reasonable condition, but some needed new footbridges and a bit of refurbishment.

- There was virtually no signs of any foundations for electrification.

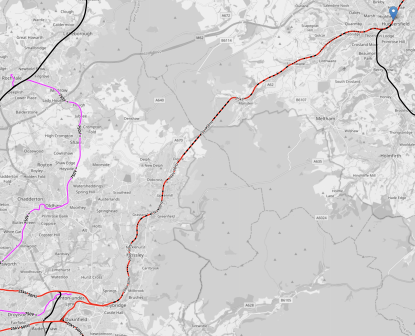

This map shows the route.

Note.

- The pink tracks are the Manchester Metrolink.

- The red tracks are electrified at 25 KVAC overhead.

- The red and black tracks are being electrified.

- Huddersfield is indicated by the blue arrow in the North-East corner of the map.

- Stalybridge station is in the South-West corner of the map.

- The pink track in the South-West corner of the map is the Manchester Metrolink branch to Ashton-under-Lyme.

- The route between Huddersfield and Stalybridge is shown as it will will be fully electrified.

- Huddersfield and Stalybridge is 18 miles.

- There are three short tunnels between Huddersfield and Stalybridge.

I wonder, if it would be more affordable to not put up wires between Huddersfield and Stalybridge and use battery-electric passenger trains and hydrogen freight locomotives?

Stalybridge Station

I took these pictures at Stalybridge station.

The station is fully-electrified and has direct services to Huddersfield, Hull, Leeds, Liverpool, Manchester Piccadilly, Manchester Victoria, Newcastlle, Wigan and York.

Will Liverpool Lime Street And Newcastle Be Fully Electrified?

Consider.

- Liverpool Lime Street and Newcastle stations is 180.8 miles.

- Newcastle and Church Fenton stations is 91.4 miles and is fully-electrified.

- Liverpool Lime Street and Stalybridge stations is 39.4 miles and is fully-electrified.

This means that the gap between Church Fenton and Stalybridge stations is just fifty miles.

Real Time Trains indicate that the current Class 802 trains on the route run on diesel between Stalybridge and York stations, which is 60.8 miles.

- Changing power in Stalybridge and York stations means if anything goes wrong passengers can be easily rescued.

- From what I saw on Thursday, it looks like electrification will be completed between Neville Hill depot and Huddersfield.

I wouldn’t be surprised, if they just electrified to the West of Stalybridge and the East of Huddersfield.

That would mean that the 18 miles between Stalybridge and Huddersfield would be run on batteries.

- But it would also avoid electrifying three tunnels.

- How much disruption would be saved, by not electrifying the tunnels?

- Freight trains would use something like a bi-mode Class 99 locomotive, but it would only need a range of 18 miles on diesel.

I can also see improvised bi-mode locomotives being used like this combination of a Class 66 and Class 90 locomotives.

It was certainly doing its job, when I saw the combination at Shenfield.

Centrica Really Can’t Lose At Sizewell

The title of this post, is the same as that of this article in The Times.

This is the sub-heading.

Centrica’s £1.3 billion investment in Sizewell C guarantees substantial returns, even with cost overruns.

These two-and-a-half paragraphs explain the funding.

Now we know what Ed Miliband means by his “golden age of nuclear” — golden for the companies putting their money into Sizewell C. Yes, reactor projects have a habit of blowing up private investors. But maybe not this one. It looks more like an exercise in transferring risk to consumers and the taxpayer.

Sure, nobody builds a £38 billion nuke on a Suffolk flood plain without a frisson of danger. But the energy secretary and his Treasury chums have done their bit to make things as safe as possible for the companies putting in equity alongside the government’s 44.9 per cent stake: Canada’s La Caisse with 20 per cent, British Gas-owner Centrica (15 per cent), France’s EDF (12.5 per cent) and Amber Infrastructure (7.6 per cent).

For starters, nearly all the debt for the 3.2 gigawatt plant, three-quarters funded by loans, is coming from the state-backed National Wealth Fund. It’s bunging in up to £36.6 billion, with £5 billion more guaranteed by a French export credit agency.

It looks to me that between them the British and French governments are providing £41.5 billion of loans to build the £38 billion nuke.

These are my thoughts.

Hydrogen And Sizewell C

This page on the Sizewell C web site is entitled Hydrogen And Sizewell C.

Under a heading of Hydrogen Buses, this is said.

At Sizewell C, we are exploring how we can produce and use hydrogen in several ways. We are working with Wrightbus on a pilot scheme which, if successful, could see thousands of workers transported to and from site on hydrogen double decker buses. You can read more about the pilot scheme in our press release

Firstly, it could help lower emissions during construction of the power station. Secondly, once Sizewell C is operational, we hope to use some of the heat it generates (alongside electricity) to make hydrogen more efficiently.

This would appear to be a more general statement about hydrogen and that the following is planned.

- Hydrogen-powered buses will be used to bring workers to the site. A press release on the Sizewell C web site, talks about up to 150 buses. That would probably be enough buses for all of Suffolk.

- Hydrogen-powered construction equipment will be used in the building of the power station.

- It also talks about using the excess heat from the power station to make hydrogen more efficiently. I talk about this process in Westinghouse And Bloom Energy To Team Up For Pink Hydrogen.

This is a substantial investment in hydrogen.

Centrica And Electricity From Sizewell C

The article in The Times, also says this.

Even so, there’s a fair bit of protection for the likes of Centrica, which has also agreed a 20-year offtake deal for its share of Sizewell’s electricity. The price of that is not yet known.

Nothing is said in the article about the size of Centrica’s electricity offtake.

- If they get 15 % of Sizewell C, that would by 480 MW.

- If they get 15 % of Sizewell B + C, that would by 660 MW.

If they use their share to generate hydrogen, Suffolk would have a massive hydrogen hub.

To power the buses and construction of Sizewell C, Sizewell B could be used to provide electricity to create the hydrogen.

How Would The Hydrogen Be Produced?

Centrica, along with other companies, who include Hyundai and Kia, are backers of a company in Hull called HiiROC, who use a process called Thermal Plasma Electrolysis to generate hydrogen.

On their web site, they have this sub-heading.

A Transformational New Process For Affordable Clean Hydrogen

The web site also describes the process as scalable from small modular units up to industrial scale. It also says this about the costs of the system: As cheap as SMR without needing CCUS; a fraction of the energy/cost of water electrolysis.

If HiiROC have achieved their objective of scalability, then Centrica could grow their electrolyser to meet demand.

How Would The Hydrogen Be Distributed?

Consider.

- Currently, the Sizewell site has both road and rail access.

- I can still see in my mind from the 1960s, ICI’s specialist articulated Foden trucks lined up in the yard at Runcorn, taking on their cargoes of hydrogen for delivery all over the country.

- As that factory is still producing hydrogen and I can’t remember any accidents in the last sixty years, I am fairly sure that a range of suitable hydrogen trucks could be developed to deliver hydrogen by road.

- The road network to the Siewell site is being updated to ensure smooth delivery of workers and materials.

- The rail access to the Sizewell site is also being improved, for the delivery of bulk materials.

I believe there will be no problems delivering hydrogen from the Sizewell site.

I also believe that there could be scope for a special-purpose self-propelled hydrogen tanker train, which could both distribute and supply the hydrogen to the vehicles, locomotives and equipment that will be using it.

Where Will The Hydrogen Be Used?

I have lived a large part of my life in Suffolk and know the county well.

In my childhood, there was quite a lot of heavy industry, but now that has all gone and employment is based on agriculture, the Port of Felixstowe and service industries.

I can see hydrogen being used in the following industries.

Transport

Buses and heavy trucks would be powered by hydrogen.

The ports in the East of England support a large number of heavy trucks.

Large Construction Projects

Sizewell C is not the only large construction project in the East of England, that is aiming to use low-carbon construction involving hydrogen. In Gallagher Group Host Hydrogen Fuel Trial At Hermitage Quarry, I talked about a hydrogen fuel trial for the Lower Thames Crossing, that involved JCB and Ryse Hydrogen.

Hydrogen for the Lower Thames Crossing could be delivered from Sizewell by truck, down the A12.

Rail

We may not ever see hydrogen-powered passenger trains in this country, but I do believe that we could see hydrogen-powered freight locomotives.

Consider.

- The latest electro-diesel Class 99 locomotives from Stadler have a Cummins diesel engine.

- The diesel engine is used, when there is no electrification.

- Cummins have developed the technology, that allows them to convert their latest diesel engines to hydrogen or natural gas power, by changing the cylinder head and the fuel system.

- Access to the Port of Felixstowe and London Gateway needs a locomotive with a self-powered capability for the last few miles of the route.

A Class 99 locomotive converted to hydrogen would be able to run with out emitting any carbon dioxide from Felixstowe or London Gateway to Glasgow or Edinburgh.

Ports

Ports have three main uses for hydrogen.

- To power ground-handing equipment, to create a pollution-free atmosphere for port workers.

- To fuel ships of all sizes from the humblest work-boat to the largest container ships.

- There may need to be fuel for hydrogen-powered rail locomotives in the future.

There are seven ports with excellent road and/or rail connections to the Sizewell site; Felixstowe, Great Yarmouth, Harwich, Ipswich, London Gateway, Lowestoft and Tilbury.

The proposed Freeport East is also developing their own green hydrogen hub, which is described on this page on the Freeport East web site.

Airports

Airports have two main uses for hydrogen.

- To power ground-handing equipment, to create a pollution-free atmosphere for airport workers.

- In the future, there is likely to be hydrogen-powered aircraft.

There are three airports with excellent road and/or rail connections to the Sizewell site; Norwich, Southend and Stansted.

Agriculture And The Rural Economy

Agriculture and the rural economy would be difficult to decarbonise.

Consider.

- Currently, most farms would use diesel power for tractors and agricultural equipment, which is delivered by truck.

- Many rural properties are heated by propane or fuel oil, which is delivered by truck.

- Some high-energy rural businesses like blacksmiths rely on propane, which is delivered by truck.

- Electrification could be possible for some applications, but ploughing the heavy land of Suffolk, with the added weight of a battery on the tractor, would probably be a mathematical impossibility.

- JCB are developing hydrogen-powered construction equipment and already make tractors.

- Hydrogen could be delivered by truck to farms and rural properties.

- Many boilers can be converted from propoane to run on hydrogen.

I feel, that hydrogen could be the ideal fuel to decarbonise agriculture and the rural economy.

I cover this application in detail in Developing A Rural Hydrogen Network.

Exports

Consider.

- Sizewell B and Sizewell C nuclear powerstations have a combined output of 4.4 GW.

- A rough calculation shows that there is a total of 7.2 GW of wind farms planned off the Suffolk coast.

- The East Anglian Array wind farm alone is said in Wikipedia to be planned to expand to 7.2 GW.

- The Sizewell site has a high capacity connection to the National Grid.

Nuclear plus wind should keep the lights on in the East of England.

Any excess electricity could be converted into hydrogen.

This Google Map shows the location of Sizewell B in relation to Belgium, Germany and The Netherlands.

The Sizewell site is indicated by the red arrow.

The offshore oil and gas industry has used technology like single buoy moorings and coastal tankers to collect offshore natural gas for decades.

I don’t see why coastal hydrogen tankers couldn’t export excess hydrogen to places around the North Sea, who need the fuel.

It should be born in mind, that Centrica have a good reputation in doing natural gas trading. This expertise would surely be useful in hydrogen trading.

Conclusion

I believe that a hydrogen hub developed at Sizewell makes sense and I also believe that Centrica have the skills and technology to make it work.

Inside A Class 99 – The UK’s Most Powerful Locomotive

The title of this post, is the same as the title of this YouTube video.

This locomotive and its siblings, which can run on both electrification and diesel is the future of rail freight in the UK and GB Railfreight have ordered thirty of them.

Hopefully, by the end of the year, I’ll see one of these locomotives running along the North London Line, through Highbury & Islington and Dalston Kingsland stations.

At the present time, there are 480 Class 66 diesel freight locomotives in the UK. A substantial amount of carbon emissions would be saved, if as many as possible of Class 66 locomotives as possible were replaced by Class 99 locomotives.

These Class 99 locomotives will literally turn the rail freight business upside down.

Can These Locomotives Be Converted from Diesel To Hydrogen Power?

Stadler or Cummins have not said, but Cummins are decarbonising the company.

Already, large American trucks fitted with the latest Cummins engines can be converted to hydrogen. I write about this in Cummins Debuts Integrated HELM Drivetrain At IAA.

Cummins are also supplying Wrightbus with engines for the next generation of low-emission bus, as I wrote about in Wrightbus StreetDeck Ultroliner Next-Gen To Get Cummins Power.

Did Stadler fit a Cummins diesel engine in a Class 99 locomotive, as they know that every Class 99 locomotive or similar locomotives for other markets can be converted to hydrogen?

It is strange but very heartening, that when we have an American President, who thinks that climate change is fake news, one of the United States, largest and most iconic companies is leading the charge to decarbonisation.

Arriving In Liverpool Lime Street Station – 10th May 2025

Liverpool Lime Street station has one of the more spectacular approaches of British railway stations, as these pictures show.

These sections describe the approach.

Crossing The Mersey

You cross the Mersey at Runcorn on the Ethelfreda or Britannia Bridge, which is described in this Wikipedia entry.

It was completed in 1868 and hopefully in a few years, it will be carrying High Speed Two trains between London and Liverpool.

On your right as you cross the Mersey to Liverpool is the Silver Jubilee road bridge, which is a through arch bridge that opened in 1961 to replace a historic transporter bridge. I am just a little bit too young to have seen the transporter bridge.

Further to your right, you can see the Mersey Gateway Bridge, which is a cable-stayed bridge, that opened in 2017 and is described in this Wikipedia entry.

Drax’s Biomass

As you approach Lime Street station, you pass through Edge Hill, where there are the GB Railfreight sidings, where the biomass trains for Drax power station are marshalled for their journey across the Pennines. These Drax trains seem to be one of the few freight trains in the UK, that carry advertising. Tesco trains also do, but their’s is just big letters.

In Do Cummins And Stadler Have a Cunning Plan?, I talked about the possible conversion at some date in the future of GB Railfreight’s new electro-diesel Class 99 locomotives to electro-hydrogen locomotives. These locomotives will surely be ideal for hauling Drax’s biomass trains across the Pennines.

I do believe that these Class 99 locomotives are the future of heavy freight trains in the UK. In Iarnród Éireann Looks At Diesel Loco Replacement Options, I write about speculation, that Stadler may build a version for the Irish.

Through The Edge Hill Cutting

From Edge Hill a deep cutting through the sandstone takes you into Lime Street station.

It looked good in the sun, but the first time I arrived in the city to start my studies at Liverpool University, it was chucking it down and the cutting was very dark and wet.

It was a very different welcome to that, which I got yesterday.

My Train Arrived In Platform 10

Liverpool Lime Street has two cast iron train sheds.

- The Western shed has platform 1 to 5 and generally handles trains from the East.

- The Eastern shed has platform 6 to 10 and generally handles trains from the South.

Note.

- Changing between trains is just a step-free walk across the station concourse.

- Both sections have their own taxi rank and full-size clock.

- The Ticket Office is in the Western train shed.

I just walked from my train to the Ticket Office, bought a Lancashire Day Ranger ticket and then walked fifty metres to my next train.

How many stations have such an easy change of trains?

Is Liverpool Lime Street Station Ready For High Speed Two?

Consider.

- I travelled North in an 11-car Class 390 train, which is 265.3 metres long and can carry 607 passengers.

- As the last pictures show, the train fitted easily into platform 10.

- High Speed Two plans to send 200 metre classic-compatible trains to Liverpool Lime Street, with each having a capacity of up to 528.

It looks to me, that these High Speed Two classic-compatible trains will fit into Liverpool Lime Street station, at any platform that currently accepts an eleven-car Class 390 train.

Looking on Real Time trains over the last few days, I’ve found eleven-car Class 390 trains using platforms 9, 10 and 6.

It seems that Network Rail’s engineers have done a superb job to turn the Grade II Listed station, into one of the best operationally.

Redundant Coal Wagons To Be Converted For Construction Traffic

The title of this post is the same as that of this article on Railway Gazette.

These three paragraphs describe the project.

WH Davis is to convert coal wagons owned by leasing company Porterbrook for use by Freightliner to transport aggregates.

’This is a fantastic opportunity to demonstrate what can be achieved by giving redundant fleets a purpose for the next 30-plus years’, said WH Davis Managing Director Andy Houghton on December 19. ‘It’s a truly sustainable option that also gives UK manufacturing a boost to enable the creation of UK jobs in the industry. I really can’t wait to see our latest box wagon design in traffic for Freightliner in 2025.’

Mark Wyborn, Head of Freight at Porterbrook, said freight volumes in the construction sector were expected to continue growing, and the deal ’highlights our commitment to investing in the long-term growth of rail freight while providing affordable, innovative and sustainable rolling stock for the UK railway’.

We need more recycling projects like these.

In the article, there is a picture of a Class 66 locomotive like this one.

Except this one, which is named after Benjamin Gimbert GC, is different in that it is running on Hydrotreated Vegetable Oil (HVO). which is a more sustainable fuel.

Unfortunately, there is only so much second-hand vegetable oil from the likes of McDonalds and Burger King and it is also a component of Sustainable Aviation Fuel (SAF).

But in the UK, we have engineers at Cummins, JCB, Ricardo and a number of other companies, research organisations and universities, who could create a conversion for the American two-stroke diesels of the Class 66 locomotive so they could run on hydrogen.

These posts detail attempts to create a zero-carbon or dual-fuel locomotive in the UK and some of my thoughts.

- Dual-Fuel Class 37 And 66 Locomotive Concepts Unveiled

- Could Class 66 Locomotives Be Converted Into Battery-Electric Locomotives?

- Freightliner Secures Government Funding For Dual-Fuel Project

- Grants To Support Low-Carbon Technology Demonstrators

- Thoughts On A Battery/Electric Replacement For A Class 66 Locomotive

- A Hydrogen-Powered Locomotive

- Our Sustainability Journey

The Bi-Mode Class 99 locomotive is coming, but we need action now.

I estimate it would probably cost up to £2million to convert a Class 66 locomotive to hydrogen.

So why not have a competition with a prize of perhaps £10million to see who, can produce the best Class 66 or Class 68 locomotive conversion by the end of 2025?

Conclusion

We need urgent action to cut pollution, noise and emissions from heavy freight locomotives and market forces and government grants don’t seem to have produced a solution, so perhaps a competition with a big prize might do it.

It could even be televised,

Iarnród Éireann Looks At Diesel Loco Replacement Options

The title of this post, is the same as that of this article on Railway Gazette.

These three paragraphs introduce the article.

The Stadler Class 99 electro-diesel locomotive for UK operator GB Railfreight was receiving close scrutiny from Iarnród Éireann at InnoTrans in Berlin, with the Irish national operator confirming to Railway Gazette International that it had discussed with the manufacturer how the type might be adapted for operation in Ireland.

Iarnród Éireann Chief Executive Jim Meade told Railway Gazette International ‘we will eventually need to replace our aging diesel fleet with dual-mode locomotives because our freight strategy will take us down that direction after we complete our electrification programme.

‘The replacement for the class 071s and 201s eventually will have to be a bi-mode electric with some form of HVO [renewable diesel fuel] traction in the long term; even the Class 201s are beyond mid-life already.

The Class 99 locomotive is a version of the Stadler Eurodual locomotive, which is described in this Stadler data sheet.

The Wikipedia entry for the Stadler Euro Dual is also informative and lists a dozen different versions of the locomotive, that have been sold to various countries and operators.

This paragraph summarises how the design can handle different gauges and electrical voltages.

The Euro Dual was designed from the onset as a highly modular platform, allowing it to be offered to customers in various different configurations, covering various gauges and voltage systems.

I doubt Stadler would have great difficulty producing an Irish gauge locomotive capable of running on whatever electrification, the Irish erect.

Will The Irish Class 99 Have Enough Power?

The power of the various diesel locomotives are as follows.

- Current Irish Class 071 – 1.68 MW

- Current Irish Class 201 – 2.4 MW

- UK Class 66 – 2.4 MW

- UK Class 99 – 1.79 MW

It would appear that the Class 99 is less powerful than the Irish Class 201 and the UK Class 66, but the Wikipedia entry for the Class 99 says this.

The chief executive of GBRf, John Smith, reports that the Class 99, despite having a less powerful diesel engine than the Class 66, will outperform the Class 66 at low speeds. The greater tractive effort means that the Class 99 on diesel power can deliver more power at the rail than the 66.

But as the Class 99 has 6.17 MW in electric mode, the solution must be to electrify the difficult sections.

I have just looked at the Felixstowe Branch Line, which will be very much Class 99 territory. I am fairly sure, that with some short lengths of electrification on the single-track sections, any performance problems with the Class 99 on the branch could be solved.

Could The Irish Class 99 Use Hydrogen As Secondary Power?

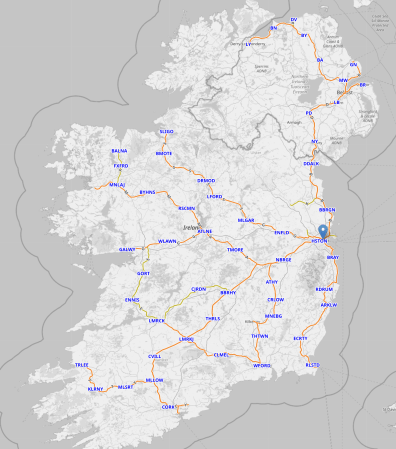

This OpenRailwayMap shows all the railways on the island of Ireland.

Note.

- All railways on the island of Ireland have an Irish gauge of 1.6 m.

- Only the DART in Dublin is electrified with 1,500 VDC overhead.

- There are 2,733 km. of track.

- New lines are still being added and old ones have been reopened in recent years.

- There will surely be pressure for the Irish to decarbonise their railways, both North and South of the Northern Irish border.

- There are no rail connections to another country, except for the link between Northern Ireland and the Republic of Ireland, which is between two similar systems.

- It is unlikely, that there will ever be a rail link between the Irish gauge railways on the island of Ireland and the standard gauge railways of Europe.

Effectively, the island of Ireland has an isolated network of tracks on which they could build a zero-carbon railway system.

- Signalling could be an off-the-shelf digital system.

- Zero-carbon traction power could be trains powered by either electricity and/or hydrogen.

- Both electricity and hydrogen would need substantial amounts of new rolling stock.

- Electricity would require electrification at €1,000,000 per single track kilometer, which could be around €5.5 billion for the electrification alone.

- Electrification would also need many bridges, stations and tunnels to be modified or rebuilt.

- Hydrogen would need a refuelling infrastructure and could go anywhere that diesel can.

- Hydrogen locomotives and trains, would be one-to-one replacements for diesel locomotives and trains.

It would appear that because of their geographic isolation, hydrogen could be an ideal zero-carbon fuel for the railways of Ireland.

In Do Cummins And Stadler Have a Cunning Plan?, I speculated that the electro-diesel Class 99 locomotive could be converted into an electro-hydrogen Class 99 locomotive, as Cummins are building diesel engines that can be converted into hydrogen ones.

Ireland with its unusual network could change to a zero-carbon railway in the following way.

- Purchase a fleet of diesel locomotives and trains that can run on Hydrotreated Vegetable Oil (HVO) and be convertible to hydrogen.

- A version of the Class 99 with or without the electrical gubbins would satisfy the locomotive replacement.

- A version of the tri-mode Stadler FLIRT like a Class 745 train, would satisfy the train replacement.

- All new trains and locomotives would replace the current stock and run on HVO.

- The hydrogen infrastructure would be built.

- The new trains and locomotives would be gradually converted to run on green hydrogen.

Within a few years, the island of Ireland would have a zero-carbon railway.

Advantages Of A Fully-Hydrogen Railway

These are a few advantages.

- One fuel for all trains.

- All trains and locomotives would be one manufacturer.

- No expensive electrification.

- Hydrogen trains and locomotives have a long range.

- No infrastructure modification for gauge clearance.

- Ireland has plenty of onshore and offshore wind for hydrogen.

- Standard fuelling systems are being developed.

- There would be no disruption as the trains changed to HVO and little disruption as they changed to hydrogen.

I believe that there would be a large increase in train usage both from locals and visitors, which can only be good for the Irish economy.

Managing The Project

This could be one of those rare projects that flows well.

- The changeover to hydrogen could involve very little rail infrastructure work.

- The hydrogen filling stations could be more-or-less independent of the rail infrastructure.

- Trains and locomotives could go into service, when they are accepted and the staff have been trained.

- Trains and locomotives would only be converted to hydrogen, as routes are made hydrogen-capable.

- There should be no gauging problems with the new trains and locomotives.

- There is only one train manufacturer.

Hopefully, it will all be delivered on time and on budget.

Electrification Between Newbury And East Somerset Junction

In the August 2023 Edition of Modern Railways, there is an article, which is entitled GWR Seeks Opportunities To Grow.

This is the sub-heading.

Managing Director Mark Hopwood tells Philip Sherratt there is plenty of potential to increase rail’s economic contribution.

This is two paragraphs.

The desire to provide electrification to support aggregates traffic from the Mendip quarries could also benefit GWR , says Mr. Hopwood. ‘Having an electric loco would massively help with pathing heavy freight trains through the Thames Valley. If you could electrify from Newbury to East Somerset Junction, a big chunk of the Berks and Hants route would be wired.

Then you can ask how much further you could get on battery power on an IET without running out of juice.’

I have some thoughts.

Where Is East Somerset Junction?

This OpenRailwayMap shows East Somerset junction.

Note.

- The East Somerset junction is marked with the blue arrow.

- East Somerset junction is 5.2 miles North of Bruton station and 5.4 miles South of Frome station on the Reading and Taunton Line.

As the map shows there is a branch to Merehead Rail Sidings, which is shown in yellow.

This Google Map shows Merehead Rail Sidings.

Note.

- It looks like there is a massive quarry to the North of the A361 road, which curves across the map.

- It is labelled Torr Works – Aggregate Industries.

- Torr Works has a Wikipedia entry.

- The rail sidings are South of the A361.

- Zooming in on the map, shows that the railway between East Somerset junction and Merehead is single-track and only a few miles long.

Distances from East Somerset junction are as follows.

- Dorchester junction – 41.2 miles

- Newbury – 53.4 miles

- Taunton – 37.2 miles

- Weymouth – 47.8 miles

Note that it is electrified with 750 VDC third-rail between Weymouth and Dorchester junction.

Range of Battery-Electric Trains

Consider.

- A Bombardier engineer told me eight years ago, that the battery-electric Class 379 train had a range of sixty miles.

- Stadler’s FLIRT Akku has a Guinness world record of 139 miles on one battery charge. See this page on the Stadler web site.

- Even Stadler’s Class 777 trains for Merseyrail have a range of 84 miles on battery power. See New Merseyrail Train Runs 135 km On Battery.

It does appear that five-car battery-electric trains will have ranges in excess of a hundred miles.

I believe that because Hitachi’s battery makers have a good record, they will probably be very ambitious and will want that Guinness record, that Hitachi’s Class 802 trains will have a battery range not far short of the 139 miles of the Stadler FLIRT Akku.

I will be very surprised if Hitachi’s battery-electric version of a Class 802 train, doesn’t have range of at least 125 miles.

But say if they could do say 140 miles, the battery-electric Class 802 train could cover every long-distance route in the UK, which would attract orders for trains to run on the following routes.

- Cardiff and Swansea

- Crewe and Holyhead

- Edinburgh and Aberdeen

- Edinburgh and Inverness

- Crewe and Holyhead

- London Waterloo and Exeter St. Davids

A substantial reward to the battery makers, would probably not be out of order.

Aggregate Trains From The Mendips

Consider.

- Mining and quarrying companies are under pressure from governments, shareholders and environmentalists to reduce their carbon footprints.

- Many are replacing diesel-powered mining excavators and trucks, with electric or hydrogen versions.

- In addition, those companies delivering building products to the construction industry are under pressure to provide low-carbon products.

- Using rail with electric traction to deliver products to market would cut carbon emissions and might even help sales.

These Mendip quarries appear to be connected to the Reading and Taunton Line.

- Torr Works – Connects 5.4 miles to the South of Frome.

- Whatley Quarry – Connects close to Frome.

There may be others.

But these rail-connected quarries, connect at or North of East Somerset junction, to where Mark Hopwood is proposing electrification.

Zero-carbon rail traction could even be possible, by electrifying the short single-track branch lines. or by using hydrogen-electric hybrid locomotives.

GWR’s London And South-West Services

These services use the Reading and Taunton Line to join the Bristol and Exeter Line at Taunton, before going on to Exeter, Plymouth and other destinations in the South-West of England.

These are distances from East Somerset Junction.

- Exeter – 67 miles

- Paignton 95.2 miles

- Penzance – 198.5 miles

- Plymouth – 119.0 miles

- Taunton – 37.2 miles

Note.

- Exeter, Paignton, Penzance and Plymouth stations would need short lengths of electrification to charge terminating trains or top-up passing trains.

- In Thoughts About Electrification Through Devon And Cornwall, I showed that the average stop time at Plymouth station was eight minutes, which could be enough for the rail equivalent of a Formula One splash and dash.

- A 125 mile battery range, not only enables London and Penzance, but also Cardiff and Swansea, and Edinburgh and Aberdeen, when the extra electrification is completed.

Could my estimate of a 125 mile battery range, be Hitachi’s objective for their battery-electric trains?

The Ultimate Battery-Electric Class 802 Train

Hitachi have been totally silent on how the fitting of batteries to Class 802 trains is going.

But Mark Hopwood is more forthcoming in the GWR Seeks Opportunities To Grow article. where this is said.

Meanwhile, GWR had announced plans with Eversholt Rail to trial the replacement of a diesel generator unit with batteries on a Class 802 IET. However, Mr. Hopwood says this would not be useful for GWR and so the trial is not proceeding; instead, a TransPennine Express Class 802 will be the subject of a battery trial.

It sounds to me that another solution is being developed to get trains to run on electric power between London and the South-West.

- I think we can rule out full electrification on the grounds of cost, disruption, time and the Nimbys and objectors will have a field day.

- Newbury and Penzance is a distance of 251.9 miles, which would surely need a lot of batteries.

Mark Hopwood’s idea to electrify the 53.4 miles between Newbury And East Somerset junction, is starting to look like a good compromise.

GWR’s Bristol/Gloucester And Weymouth Services

These stopping trains are run by diesel trains and take the following route between Bristol Temple Meads and Weymouth stations.

- Keynsham

- Oldfield Park

- Bath Spa

- Freshford

- Avoncliff

- Bradford-on-Avon

- Trowbridge

- Westbury

- Frome

- East Somerset junction

- Bruton

- Castle Cary

- Yeovil Pen Mill

- Thornford

- Yetminster

- Chetnole

- Maiden Newton

- Dorchester West

- Dorchester junction

- Upwey

Note.

- I would assume that there is enough electrification at Bristol Temple Meads and towards Gloucester to charge the trains.

- Trains would leave Bristol Temple Meads with a full battery.

- The eighteen stops mean that an electric train with regenerative braking will be more efficient.

- Bristol Temple Meads and Westbury is not electrified.

- Westbury and East Somerset junction will be electrified with 25 KVAC overhead electrification under Mark Hopwood’s proposal.

- Trains take sixteen minutes between Westbury and East Somerset junction.

- East Somerset junction and Dorchester junction is not electrified.

- Dorchester junction and Weymouth is electrified with 750 VDC third-rail electrification.

- Trains take ten minutes between Dorchester junction and Weymouth.

Distances of the various legs are as follows.

- Bristol Temple Meads and Westbury – 28.3 miles – Not Electrified

- Westbury and East Somerset junction – 11.4 miles – Electrified

- East Somerset junction and Dorchester junction – 41.4 miles – Not Electrified

- Dorchester junction and Weymouth – 6.6 miles – Electrified

The two sections without electrification, should be well within range of a dual-voltage battery-electric train, that has been designed for the route.

GWR’s Cardiff Central And Portsmouth Harbour Service

These stopping trains are run by diesel trains and take the following route between Bristol Temple Meads and Portsmouth Harbour stations.

- Keynsham

- Oldfield Park

- Bath Spa

- Freshford

- Avoncliff

- Bradford-on-Avon

- Trowbridge

- Westbury

- Warminster

- Salisbury

- Romsey

- Redbridge

- Southampton Central

- Fareham

- Cosham

- Fratton

- Portsmouth & Southsea

Note.

- I would assume that there is enough electrification at Bristol Temple Meads and towards Cardiff Central to charge the trains.

- Trains would leave Bristol Temple Meads with a full battery.

- The seventeen stops mean that an electric train with regenerative braking will be more efficient.

- Bristol Temple Meads and Westbury is not electrified.

- Westbury station will be electrified with 25 KVAC overhead electrification under Mark Hopwood’s proposal.

- Trains would leave Westbury with a full battery.

- Westbury and Redbridge is not electrified.

- Redbridge and Portsmouth Harbour is electrified with 750 VDC third-rail electrification.

Distances of the various legs are as follows.

- Bristol Temple Meads and Westbury – 28.3 miles – Not Electrified

- Westbury and Redbridge – 46.4 miles – Not Electrified

- Redbridge and Portsmouth Harbour – 28.5 miles – Electrified

The two sections without electrification, should be well within range of a dual-voltage battery-electric train, that has been designed for the route.

GWR’s Bristol Temple Meads And Salisbury Services

These stopping trains are run by diesel trains and take the following route between Bristol Temple Meads And Salisbury stations.

- Keynsham

- Oldfield Park

- Bath Spa

- Freshford

- Avoncliff

- Bradford-on-Avon

- Trowbridge

- Dilton Marsh

- Warminster

Note.

- I would assume that there is enough electrification at Bristol Temple Meads to charge the trains.

- Trains would leave Bristol Temple Meads with a full battery.

- An electric train with regenerative braking will be more efficient.

- Bristol Temple Meads and Westbury is not electrified.

- Westbury station will be electrified with 25 KVAC overhead electrification under Mark Hopwood’s proposal.

- Trains would leave Westbury with a full battery.

- Westbury and Salisbury is not electrified.

Distances of the various legs are as follows.

- Bristol Temple Meads and Westbury – 28.3 miles – Not Electrified

- Westbury and Salisbury – 24.4 miles – Not Electrified

The two sections without electrification, should be well within range of a battery-electric train, that has been designed for the route.

GWR’s Swindon And Westbury Services

These stopping trains are run by diesel trains and take the following route between Swindon and Westbury stations.

- Chippenham

- Melksham

- Trowbridge

Note.

- This is the Transwilts service.

- I would assume that there is enough electrification at Swindon to charge the trains.

- Trains would leave Swindon with a full battery.

- An electric train with regenerative braking will be more efficient.

- Chippenham and Westbury is not electrified.

- Westbury station will be electrified with 25 KVAC overhead electrification under Mark Hopwood’s proposal.

- Trains would leave Westbury with a full battery.

Distances of the various legs are as follows.

- Swindon and Chippenham – 16.9 miles – Electrified

- Chippenham and Westbury – 15.8 miles – Not Electrified

The section without electrification, should be well within range of a battery-electric train, that has been designed for the route.

What Can Be Done If The Electrification Is Not Long Enough?

Some of these routes battery-electric routes may need more electrification to work efficiently.

Despite some routes having both 25 KVAC overhead and 750 VDC third-rail electrification, any extension of the electrification would be overhead, as new third-rail electrification is effectively banned.

Conclusion

It looks like Mark Hopgood proposal is an excellent idea to enable the decarbonisation of GWR services in Wiltshire and Somerset.

- Express services would be run by battery-electric Class 802 trains.

- Local services would be run by battery-electric trains with perhaps three cars.

Some of the local trains would need to be dual-voltage to use both forms of electrification.